Professional Documents

Culture Documents

Asu e

Uploaded by

asdf0 ratings0% found this document useful (0 votes)

11 views2 pagesOriginal Title

ASU-E

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views2 pagesAsu e

Uploaded by

asdfCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

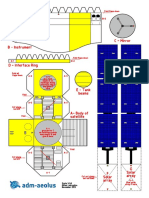

The Stardial

Shepherds,hunters and members of other trades who regularly performed

their work at night time have always been able to read the time according to

the position of the stars. Towards the end of the Middle Ages resourceful

astronomers and makers of instruments invented the stardial, also called

Nocturnal or Nocturlabium and first mentioned in 1295, for serving the igno-

rant town dweller or the impatient soldier being on night-watch. This sophis-

ticated instrument makes us of the fact that the constellation Big Dipper

orbits the Pole Star once in 23 hours and 56 minutes as if it were the pointer

of a huge clock. Due to the difference of 4 minutes compared with an entire

day the stardial is set to the current date prior to reading. Then it displays

with amazing accuracy the true local time. How this happens you will read at

the end of these assembly instructions.

The old instrument-makers liked to combine the stardials with a second in-

strument attached at the rear side, for example a sundial or, as it is the case

here, with an astrolabe.

The mariner’s astrolabe was usually made from heavy brass so it would not

sway in the wind so easily and could take simple measurings of the eleva-

tion angle of sun and stars. From this again important conclusions could be

made about the present position on the sea. In the 17th century this was a

widespread instrument, it was for example part of the standard equipment of

all ships of the Dutch East India Company.

Nevertheless only a few of these stardials and astrolabes have survived and

they consequently are among the precious treasures of large museums.

Instructions for assembly

Before starting work please read every sec- [B2] as at step 1 and clear the hole in the centre. Step 12: Glue the handle reinforcement [E1] with

tion completely. The assembly is not difficult, Step 4: Remove the white counter pieces from its rear side on the rear side of the astrolabe disk

because all parts are pre-cut / die-cut for exact the thick cardboard plate, glue the hour disk [B1] [F1] so, that the edges and the hole of the handle

fitting. (to punch: rather used for holes only.) and the axle [B2] exactly flush to their counter- reinforcements are exactly flush with the edges

You need a sharp knife for the assembly, in order parts and write the piece part number on the axle and the hole of the astrolabe suspension.

to remove the punched parts neatly from the card- [B2]. Step 13: Remove the alidade [G1] and the axle

board, possibly some fine emery paper and a good Step 5: Glue the indented hour disk [B1] onto the [G2] from the cardboard and remove the remain-

all-purpose glue. An all-purpose glue containing date disk [A1]. Please observe that the indenta- ing cardboard from both pre-cut rectangles of the

solvent is better suitable than a so-called solvent- tions are placed exactly onto the indentations of alidade as well as from the small hole in the axle.

free glue on water base, because it does not make the white glueing area and that the holes are Glue the alidade [G1] and the axle [G2] onto their

the carton wavy. placed in the centre of both parts above each other. counterparts of thick cardboard and write the

Each part is marked with a piece part number Ehen correctly aligned the edge of the 18h inden- piece-part numbers on their rear sides.

([A1], [A2], [B1], [B2] etc.) as well as its name (in tation points to 5th of June. Step 14: Remove the two feet of the sighting de-

German language). The letter of the piece part Step 6: Remove the punched cardboard part from vice [H1] and [H2] from the cardboard, then re-

number is the same within a subassembly. Always the reading window of the star pointer [C1]as well move the cardboard from the pre-cut rectangles

only remove the parts from the cardboard which as the axle [C2] in its centre and open its small and glue both parts on their counterparts of thick

you require at that moment or otherwise write hole . Glue the star pointer [C1] and the axle [C2] cardboard.

down the number of the part on the rear side. to their counterparts of thick cardboard. Write the Step 15: Glue the feet of the sighting device [H1]

To each of the parts with a piece part number of piece-part numbers on their rear sides. and [H2] onto both ends of the alidade in such a

thin printed cardboard belongs a corresponding Step 7: Glue the reinforcement of the star pointer manner that the cut out rectangles and the curved

part with identical contour of thick non-printed [C3] to the rear side of the star pointer. The coun- edges at the left top are exactly flush with the rec-

cardboard. These parts are identified as “coun- terpart of thick cardboard is not required. When tangle and the curved edge of the alidade.

terparts” in the assembly instructions. A few parts glueing the parts onto each other the edges at the Step 16: Remove the two halves of sighting de-

of thick cardboard are not required, they had how- end and at the sides of the pointer must be flush. vice [J1] and [J2] from the cardboard and clear

ever to be included in the cutting process for tech- Step 8: Remove the covering disk [D1] from the the small hole. Remove one of the two counter-

nical reasons. cardboard plate and the small cardboard piece parts from the thick cardboard and glue the halves

Content of this kit: from the hole in its centre. Glue it on its counter- of the sighting device onto both its sides. Pay at-

2 die-cut cardboards, 0,4 mm thick, printed. part of thick cardboard and write the piece-part tention that the steps in the lower edge are placed

2 die-cut cardboards, 1 mm thick, non-printed number on its rear side. exactly on top of each other. The other counter-

Step 9: Remove the handle-reinforcement [E1] part is not required.

from the cardboard and clear the hole for the sus- Step 17: Remove the reinforcements of the sight-

The parts for the stardial pension. Glue the handle-reinforcement onto its ing device [J3] and [J4] from the cardboard and

counterpart of white cardboard and write the piece- glue them onto their counterparts of thick card-

Step 1: Remove the date disk [A1] from the printed part number on the rear side. board. Then glue one of the two reinforcements

cardboard plate and remove the axle [A2] from Step 10: Remove the handle [E2] from the card- of the sighting device onto each side of the sight-

the centre. The small round little disk in the cen- board. Clear the hole for the suspension and the ing device [J1/J2]. Please observe that the steps

tre of the axle is removed so that a hole isopened. window for reading the date and glue the handle in the lower edges of the three parts are placed

Step 2: Remove the white counterpart to the date on its counterpart of thick cardboard. Write the exactly on top of each other.

disk from the thick cardboard plate, remove here piece-part number on its rear side. Step 18: Proceed with the two other halves of the

also the axle from the centre and clearthe hole in sighting device [J5] and [J6] as in step 16. Here,

the centre. Now glue the date disk [A1] as well as The parts for the too, the other counterpart is not required.

Step 19: Proceed with the two reinforcements of

the axle [A2] on their white counterparts. Pay at-

tention to the fact that the edges at the outside mariner’s astrolabe the sighting device [J7] and [J8] as in step 17 and

and at the holes are flush. Then write down the glue them onto both sides of the sighting device

piece part numbers [A1] and [A2] at the rear sides Step 11: Remove the astrolabe disk [F1] and the [J5/J6].

of both parts. axle [F2] from their sheet, clear the hole in the Step 20: Remove the covering disk [L3] from the

Step 3: Remove the hour disk [B1] carefully from axle and glue both parts on their counterparts of cardboard and clear the hole in the centre. Glue

the cardboard making sure the indentations (teeth) thickcardboard. Write the piece-part numbers on ist onto its counterpart of thick cardboard and write

at the edge are not be damaged. Remove the axle the rear sides. the piece-part number on the rear side.

The assembly of Five simple steps for reading the time

the stardial and astrolabe from the stars at night

Step 21: Glue all axles made so far [A2], [B2], 1. Turn the date disk until today’s date is shown in the reading window of the handle above the arrow

[C2], [F2] and [G2] on top of each other to form mark.

one cylindrical axle block. Then remove axle [K2], 2. Look for the constellation of the Big Dipper and from there for the Pole Star. You find it when you

situated in the interior of the sliding disk [K1], of extend the distance of the both rear stars of the Dipper box (= the two bright stars in the figure on the

thin cardboard and glue it also to the block. The star pointer) 5½ times in direction of the box opening (on the star dial this corresponds to the direction

counterpart of thick carton is not required. Please towards the axle).

pay attention that the outer edges and the holes 3. Hold the stardial with half-bent arm handle pointing vertically downwards and take aim at the Polar

of all disks are situated exactly on top of each Star through the hole in the axle.

other. Check whether the axle block can be in- 4. Turn the star pointer until its straight edge is parallel to both rear stars of the Dipper box. The Big

serted and turned in the star pointer, the date disk, Dipper on the stardial stands now like the one in the sky.

the astrolabe disk and the alidade ; carefully grind 5. Read the true local time in the reading window of the stardial. You can however also make out the

off projecting edges by means of fine emery pa- time by touching the long and short teeth on the hour disk, just as with all ancient stardials, whose

per. The axle block has now exactly the height of owners only rarely had a light source available during night time. The somewhat longer teeth represent

all parts which shall rotate around it. the full hours, the shorter ones the half hours, indicatiing the time which stands in the direction of the

Step 22: Glue the axle block onto the unprinted axle underneath the tooth. Consequently the valid indentation is always the one whose time appears

side of the covering disk [D1] and here also make at that moment in the reading window of the star pointer, and the latter always releases with its outer

sure the holes in the centre are situated exactly edge the matching tooth at that moment. For easier orientation the teeth for 18, 24 and 6 o’clock are

on top of each other. shaped somewhat differently than the ones of the other full hours by their larger length and width.

Step 23: Place the axle block with the covering Therefore you can also start with the 18 o’clock tooth and then count the teeth of the hours that have

disk down onto your working surface and push all passed since 18 o’clock.

parts prepared so far onto the axle block in this Remark: The stardial does not indicate the civil time which we know as Central European Time or

sequence without using glue: Summer Time, but the true local time determined by the course of the sun. According to this solar time

a) Star pointer [C1]: printed side down, glued-on it is 12 o’clock noon when the sun is standing exactly in the south, respectively midnight when it has

pointer reinforcement up. reached its lowest point under the horizon. This occurs earlier in places further east and later in places

b) Sliding disk [K1]: only the thin cardboard disk, further west, alsoeven if the citizens in these locations live according to the same uniform zone time.

printed side down. – The thick counterpart is not For example in Warsaw (Poland) the sun is one hour and 16 minutes earlier in the south than in Barce-

required. lona (Spain) although both cities belong to the Central European Time zone. The instructions for the

c) Date disk [A1]: glued-on hour disk down, white Astro-Media kit The digital sundial provide a detailed description of the differences between true local

side up. time and zone time as well as instructions how to calculate it.

d) Astrolabe disk [F1]: glued-on handle reinforce-

ment down, astrolabe disk up.

e) Alidade [G1]: white side down, glued-on feet of Four simple steps for measuring the elevation of the

sighting device up.

Step 24: When all parts are placed tightly on top

sun and stars by means of the mariner’s astrolabe

of each other, the end of the axle block has to be

flush with the surface of the alidade. Check 1. In order to measure elevation angles the astrolabe has to be suspended at a cord pulled through the

whether all parts can be rotated around the joint hole in the handle. For this you have to first balance the asymmetrically shaped star pointer by adjust-

axle independently from each other. A slight re- ing its reading edge to the small golden marking which is situated at the lower left on the astrolabe

sistance is eased off by frequent use. If neces- scale between 66° and 67°. This is howway you can check whether the astrolabe is really vertically

sary, the axle or the axle hole of one part has to suspended: Simply Hold a simple plumb line, composed of a thread and a small weight, in front of the

be carefully refinished by means of emery paper. suspended astrolabe. The thread has to run via both the 90° markings and the centre of the axle.

Step 25: Glue the covering disk [L3] onto the axle 2. To measure the angle between a horizontal line and the tip of a mountain orand a building or also a

block where it projects from the alidade. Carefully star, hold the astrolabe by the cord at eye heightlevel and shift the alidade until you can see the point

pay attention that no glue enters between the cov- you are aiming at through both holes of the sighting device at the same time.

ering disk and the axle and between the axle and 3. To measure the elevation of the sun, let the astrolabe hang lower and shift the alidade until a sun

the alidade. beam simultaneously falls through both holes, for example onto the palm of your hand . Important:

Step 26: Turn over the astrolabe, so that the Never aim directly into the sun; this can cause permanent damage to your eyes!

stardial comes to be at the top. Glue the handle 4. Read the angle at the ends of the alidade on the scale.

[E2] onto the white glueing area of the handle re- Here are some examples about what can be followed from the elevation angle:

inforcement in such a manner that the curved

edges and the hole for the suspension come to

be situated on top of each other. Hereby the han-

dle also projects above the date disk and the set

date appears in its reading window. 1. When I know the distance to the tip of a build-

Step 27: Turn over the stardial again so that the ing and the angle between the horizontal line and

astrolabe comes to be on top. Glue one of the and the line connecting the stardial and the tip of

sighting devices reinforced at both sides to each the building, I can mathematically or graphically

end of the alidade in such a manner that the bev- determine the height of the building.

elled pegs at the lower side are glued into the cut-

out rectangles of the alidade. The hole in the sight- 2. When I know the elevation of the Pole Star, I also know my geographical latitude width, because both

ing devices then are situated exactly above the are (almost) the same. This measurement was of great importance for the sailor in the past.

reading edge of the alidade. 3. When the sun is at its highest elevation, it is true noon. With this measurement it was not only

The stardial and the mariner’s astrolabe are possible to readjust the hourglasses onboard in the past, but to determine the geographic latitude as by

now completed. Congratulations to this high means of the Pole Star: All you had to do was to look up to a tablethe angle between the sun and the

quality cardboard instrument! celestial equator at this day and it was very simple to determine the geographical latitude from this.

These measurements were perfected by means of the Hadley sextant invented some hundred years

later.

A more detailed description of how to navigate with the determination of the elevation of sun at noon

can be found in the instructions for the Astromedia* kit “The Sextant”.

You might also like

- A Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsFrom EverandA Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsNo ratings yet

- Classic Wooden Toys: Step-by-Step Instructions for 20 Built to Last ProjectsFrom EverandClassic Wooden Toys: Step-by-Step Instructions for 20 Built to Last ProjectsRating: 1 out of 5 stars1/5 (1)

- Bob's Card Models: Short 330-200 (Scale 1:72)Document11 pagesBob's Card Models: Short 330-200 (Scale 1:72)Luiz Fernando MibachNo ratings yet

- Bob's Card Models: Short 330-200 (Scale 1:72)Document11 pagesBob's Card Models: Short 330-200 (Scale 1:72)Kerry YipNo ratings yet

- Bob's Card Models: Douglas DC-6B 1:72Document18 pagesBob's Card Models: Douglas DC-6B 1:72Luiz Fernando MibachNo ratings yet

- Bob's Card Models: Fairchild C-119G 'Flying Boxcar" (1:72)Document16 pagesBob's Card Models: Fairchild C-119G 'Flying Boxcar" (1:72)Luiz Fernando MibachNo ratings yet

- TOTAL TrackerDocument11 pagesTOTAL TrackerLuiz Fernando MibachNo ratings yet

- TOTAL TrackerDocument11 pagesTOTAL TrackerLuiz Fernando MibachNo ratings yet

- Bob's Card Model: Conair C S 2F (Tracker) Water-Bomber (1:72)Document11 pagesBob's Card Model: Conair C S 2F (Tracker) Water-Bomber (1:72)Luiz Fernando MibachNo ratings yet

- Total Dash8Document14 pagesTotal Dash8Luiz Fernando MibachNo ratings yet

- C 54 DouglasDocument13 pagesC 54 DouglasLuiz Fernando MibachNo ratings yet

- Instructions For Optional Detailed Interior Parts of The Tintin Moon RocketDocument8 pagesInstructions For Optional Detailed Interior Parts of The Tintin Moon RocketBevNo ratings yet

- C119 BoxcarNewDocument16 pagesC119 BoxcarNewLuiz Fernando Mibach100% (1)

- ShasOKais Conversion DoWDocument13 pagesShasOKais Conversion DoWCurtis PetersNo ratings yet

- Instructions For Building A Kepler Paper Model: Other MaterialsDocument12 pagesInstructions For Building A Kepler Paper Model: Other MaterialsAyman NairatNo ratings yet

- Bob's Card Models: Junkers Ju 52 ("Tante Ju" - "Iron Annie") 1:72Document9 pagesBob's Card Models: Junkers Ju 52 ("Tante Ju" - "Iron Annie") 1:72Luiz Fernando MibachNo ratings yet

- Total UsntrackerDocument11 pagesTotal UsntrackerLuiz Fernando MibachNo ratings yet

- Bob's Card Models: and (Resources)Document19 pagesBob's Card Models: and (Resources)Luiz Fernando MibachNo ratings yet

- Vulcan Paper Model KitDocument16 pagesVulcan Paper Model KitRubín AbelNo ratings yet

- Bob's Card Models: Mitsubishi A5M4 1:30Document11 pagesBob's Card Models: Mitsubishi A5M4 1:30Prabhudatta Bhuyan100% (1)

- Miss Hyperion HydroDocument5 pagesMiss Hyperion HydroJoel LaguárdiaNo ratings yet

- ALMA 12m Antenna: Let's Build A Paper Model ofDocument5 pagesALMA 12m Antenna: Let's Build A Paper Model ofAlvaro Jose Cano MejiaNo ratings yet

- Bob's Card Models: Gippsland Airvan GA8Document11 pagesBob's Card Models: Gippsland Airvan GA8srgseg0% (1)

- Bob's Card Models: Martin Mars Water Bomber (1:72)Document21 pagesBob's Card Models: Martin Mars Water Bomber (1:72)Luiz Fernando MibachNo ratings yet

- Stardust 1/26 Scale Model Assembly Instructions: A. You'Ll Need The FollowingDocument10 pagesStardust 1/26 Scale Model Assembly Instructions: A. You'Ll Need The FollowingIsaacPerellóMartíNo ratings yet

- Vacuum Tube Amplifier: Otona No KagakuDocument24 pagesVacuum Tube Amplifier: Otona No Kagakusuper_lativoNo ratings yet

- Cardboard Jedi StarfighterDocument112 pagesCardboard Jedi StarfighterZeal EducationNo ratings yet

- 28-51 BODTrak Firmware Replacement ProcedureDocument5 pages28-51 BODTrak Firmware Replacement ProcedureproentecsasNo ratings yet

- Bob's Card Models: Gippsland Airvan GA8 1:36Document12 pagesBob's Card Models: Gippsland Airvan GA8 1:36Luiz Fernando MibachNo ratings yet

- Guitarra Electrica Instrucciones PDFDocument10 pagesGuitarra Electrica Instrucciones PDFEmmanuel VargasNo ratings yet

- R2 D2 Papercraft Star Wars Star Tours Printable 0213Document5 pagesR2 D2 Papercraft Star Wars Star Tours Printable 0213Claudia GómezNo ratings yet

- Assembly Instructions For V-2 Rocket: HistoryDocument4 pagesAssembly Instructions For V-2 Rocket: HistoryEmerson URNo ratings yet

- Om1 Papercraft M eDocument11 pagesOm1 Papercraft M ejdude104No ratings yet

- Airwolf Instructions PDFDocument6 pagesAirwolf Instructions PDFoeoensuryaNo ratings yet

- Dsc11 Assembly FullDocument15 pagesDsc11 Assembly FullMichael LesterNo ratings yet

- 4 PCB Design: Transfer To Ultiboard 14.0. Save The Ultiboard File in The Same Location As The SchematicDocument5 pages4 PCB Design: Transfer To Ultiboard 14.0. Save The Ultiboard File in The Same Location As The SchematicAhmad RazaNo ratings yet

- Bob's Card Models: Avro 696 Shackleton MR MK 2 - 1:72Document16 pagesBob's Card Models: Avro 696 Shackleton MR MK 2 - 1:72Luiz Fernando Mibach100% (1)

- Frame: Paper Aquarium: Moorish IdolDocument2 pagesFrame: Paper Aquarium: Moorish IdolZainulikhwanNo ratings yet

- "Discovery" XD-1: Assembly InstructionsDocument7 pages"Discovery" XD-1: Assembly InstructionsTaide Ding100% (1)

- Chrom@ II Disassembly: Required Tools Disassembly Instructions Reassembly InstructionsDocument20 pagesChrom@ II Disassembly: Required Tools Disassembly Instructions Reassembly Instructionsg321m46No ratings yet

- The Microscope PDFDocument3 pagesThe Microscope PDFDrew StoutNo ratings yet

- Nikon Ni-U Service ManualDocument30 pagesNikon Ni-U Service ManualAndrew Holmes100% (1)

- Cambridge International AS & A Level: PHYSICS 9702/31Document12 pagesCambridge International AS & A Level: PHYSICS 9702/31sangdeepNo ratings yet

- TB61 - Dta-150-ModDocument9 pagesTB61 - Dta-150-ModJorge MartinelliNo ratings yet

- Mars Express Model KitDocument15 pagesMars Express Model Kitsuthirak100% (1)

- Designed by Greg K. Poehlein © 2005 Greg K. Poehlein: Parts ListDocument3 pagesDesigned by Greg K. Poehlein © 2005 Greg K. Poehlein: Parts ListStevenNo ratings yet

- Build Your Own Aeolus ModelDocument2 pagesBuild Your Own Aeolus ModelDevesh JoshiNo ratings yet

- Blaine - Moto G6 - QL1688 Disassemblyprocess GuideDocument17 pagesBlaine - Moto G6 - QL1688 Disassemblyprocess GuideDiego Fernando OspinaNo ratings yet

- Disassembly ProcedureDocument30 pagesDisassembly Procedurebluefenix11No ratings yet

- Unpacking and Installation Procedure For The Main Body and OptionsDocument11 pagesUnpacking and Installation Procedure For The Main Body and OptionsNistor SilviuNo ratings yet

- x220.x230 FHD Mod Rev5 v0.2Document19 pagesx220.x230 FHD Mod Rev5 v0.2Rafael Enrique Garcia CastañoNo ratings yet

- R2 D2 Papercraft Star Wars Star Tours Printable 0213Document5 pagesR2 D2 Papercraft Star Wars Star Tours Printable 0213edavi1100% (2)

- Star Wars R2D2 PDFDocument5 pagesStar Wars R2D2 PDFGustavo PonneNo ratings yet

- HP 1160-1320 KitDocument8 pagesHP 1160-1320 KitwagnervielmondNo ratings yet

- Versa AX Disassembly: Required Tools Disassembly Instructions Reassembly InstructionsDocument18 pagesVersa AX Disassembly: Required Tools Disassembly Instructions Reassembly Instructionsg321m46No ratings yet

- (Â ) (Paper Model) (Aircraft) (Modelart - Scale 1.32) - GER - Dornier DO17.P - v.GERDocument37 pages(Â ) (Paper Model) (Aircraft) (Modelart - Scale 1.32) - GER - Dornier DO17.P - v.GERpaulagrant91% (11)

- The Pochade and Wet Panel Carrier Do It Yourself PlanFrom EverandThe Pochade and Wet Panel Carrier Do It Yourself PlanRating: 4 out of 5 stars4/5 (1)

- One - Touch Fittings: Series: WP2Document12 pagesOne - Touch Fittings: Series: WP2PrashantNo ratings yet

- 5 - Oral Mucosa and Salivary Glands (Mahmoud Bakr)Document115 pages5 - Oral Mucosa and Salivary Glands (Mahmoud Bakr)MobarobberNo ratings yet

- Brief List of Temples in Haridwar Is Given BelowDocument8 pagesBrief List of Temples in Haridwar Is Given BelowPritesh BamaniaNo ratings yet

- Pump Shotgun: Instruction ManualDocument5 pagesPump Shotgun: Instruction ManualJustinNo ratings yet

- The Redesigning of Junction: Tatya Tope Square BhopalDocument15 pagesThe Redesigning of Junction: Tatya Tope Square BhopalAr Raj YamgarNo ratings yet

- Curvature CorrectionDocument7 pagesCurvature CorrectionE J SNo ratings yet

- Handbook (P)Document224 pagesHandbook (P)Joe80% (5)

- Silo Dryers: Mepu - Farmer S First Choice Mepu To Suit Every UserDocument2 pagesSilo Dryers: Mepu - Farmer S First Choice Mepu To Suit Every UserTahir Güçlü100% (1)

- X Glo LED Strip Lighting For Tunnelling BrochureDocument6 pagesX Glo LED Strip Lighting For Tunnelling BrochureJOSE HUAMANINo ratings yet

- NID DATPrelimsTestPaper2018 BDesDocument24 pagesNID DATPrelimsTestPaper2018 BDesManaswini ReddyNo ratings yet

- Guide To Storage Tanks and EquipmentDocument15 pagesGuide To Storage Tanks and EquipmentbadelitamariusNo ratings yet

- Homoeopathy and MigraineDocument4 pagesHomoeopathy and MigraineEditor IJTSRDNo ratings yet

- Chapter 4: Palm Oil and Oleochemical Industries.: Presented By: Lovelyna Eva Nur Aniqah Siti MaryamDocument15 pagesChapter 4: Palm Oil and Oleochemical Industries.: Presented By: Lovelyna Eva Nur Aniqah Siti MaryamdaabgchiNo ratings yet

- Manual Bomba HLXDocument16 pagesManual Bomba HLXVictor Manuel Hernandez GomezNo ratings yet

- Acoustic Phonetics PDFDocument82 pagesAcoustic Phonetics PDFAnonymous mOSDA2100% (2)

- 6RA80 Quick Commissioning Without TachoDocument7 pages6RA80 Quick Commissioning Without TachoBaldev SinghNo ratings yet

- Grand Vitara 2005Document35 pagesGrand Vitara 2005PattyaaNo ratings yet

- Barium Chloride 2h2o LRG MsdsDocument3 pagesBarium Chloride 2h2o LRG MsdsAnas GiselNo ratings yet

- The Coffee Shop Easy Reading - 152542Document1 pageThe Coffee Shop Easy Reading - 152542Fc MakmurNo ratings yet

- DA-42 Performance Calculator v2.3.1Document23 pagesDA-42 Performance Calculator v2.3.1DodgeHemi1No ratings yet

- The Fat CatsDocument7 pagesThe Fat CatsMarilo Jimenez AlgabaNo ratings yet

- Circle Theorems, Class 10Document7 pagesCircle Theorems, Class 10Susan MathewNo ratings yet

- Motion of A Simple Pendulum in A FluidDocument16 pagesMotion of A Simple Pendulum in A FluidGokul JeevaNo ratings yet

- Indian Standard: Application Guide For Voltage TransformersDocument16 pagesIndian Standard: Application Guide For Voltage TransformersGnanavel GNo ratings yet

- Pastor O. I. Kirk, SR D.D LIFE Celebration BookDocument63 pagesPastor O. I. Kirk, SR D.D LIFE Celebration Booklindakirk1100% (1)

- Black Mamba Vs Mongoose Vs King Cobra Vs Komodo Vs PhythonDocument44 pagesBlack Mamba Vs Mongoose Vs King Cobra Vs Komodo Vs PhythonmarcNo ratings yet

- 08 A330 Ata 35Document32 pages08 A330 Ata 35Owen100% (1)

- Pottery Making May06 Poi0506dDocument52 pagesPottery Making May06 Poi0506dMadeleineNo ratings yet

- Bar Tending TerminologyDocument3 pagesBar Tending TerminologySiska WangNo ratings yet

- Mold Maintenance StepDocument0 pagesMold Maintenance StepMonica JoynerNo ratings yet