Professional Documents

Culture Documents

Energy Absorption in Composite Stiffener

Uploaded by

GamelopOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Energy Absorption in Composite Stiffener

Uploaded by

GamelopCopyright:

Available Formats

Composites 26 (1995) 291 301

B UTTE

E I N

RWQR

E M A

TH

N N 9 1995 Elsevier Science Limited

Printed in Great Britain. All rights reserved

0010-4361/95/$10.00

Energy absorption in composite stiffeners

A.O. Bolukbasi

McDonnell Douglas Helicopter Systems, Mesa, AZ 85205-9797, USA

and D.H. Laananen*

Department of Mechanical and Aerospace Engineering, Arizona State University,

Tempe, AZ 85287-6106, USA

(Received 15 February 1994; revised 11 August 1994)

The energy absorption behaviour of composite stiffeners subjected to axial compression has been inves-

tigated. A semi-empirical analysis methodology has been developed for prediction of the energy absorp-

tion capability of composite stiffeners based on crush tests of flat plate specimens and an understanding

of the fundamentals of the energy absorption process. Flat plate, angle and channel specimens were fab-

ricated from T650-35/F584 graphite/epoxy plain-weave fabric using five different lay-ups that consisted

of varying percentages of 450 and 0~ plies. The specimens were crush tested under axial compression, and

measured levels of sustained crushing stress were compared with model predictions.

(Keywords: composite stiffeners; energy absorption; crush initiators)

INTRODUCTION In spite of the considerable work done on the energy

The overall objective of designing an aircraft for crash absorption of composite materials, reliable analytical

protection is to minimize the number of injuries and methods are not yet available to predict the energy

absorption capability of practical composite aircraft

fatalities in survivable crash impacts. The crashworthy

fuselage structures. The current practice is to conduct

design of aircraft involves a systems approach with the

expensive and time-consuming design support tests at the

fuselage structure, landing gear and seats working

together to absorb the aircraft kinetic energy and slow element and sub-assembly level prior to fabrication of

the occupants to rest without injurious loading. An the fuselage structure. Therefore, additional research is

important part of this energy absorption system is the needed to study the energy absorption behaviour of prac-

structure below the fuselage floor, which may absorb tical composite structural elements and to develop analy-

up to 80% of the aircraft's kinetic energy. sis tools to support the design of composite fuselage

Application of composite materials to aircraft fuse- structures in a timely and cost-effective manner.

lage structures offers potentially significant weight and The objective of this research effort has been to study

cost reductions relative to metallic structures. However, the energy absorption behaviour of composite stiffeners,

because composite materials are typically brittle and do specifically angle and channel sections, in order to develop

not exhibit either plasticity or high elongation prior to a design technique for such components. Selection of the

failure, special design approaches are required to provide stiffeners over other structural elements such as sine-wave

energy absorption capability comparable to that of metal beams or tubes was based on widespread use of such

structures. elements in semi-monocoque fuselage structures.

The energy absorption characteristics of various com- The following section describes experiments that were

posite structural elements have been experimentally conducted with flat plate specimens of graphite/epoxy

studied by several researchers. Circular tube specimens composite that were crushed by uniaxial in-plane load-

have been the most extensively studied structural ing. Axial crush tests of angle and channel stiffeners

elements I s, but experiments have also been conducted fabricated with the same material and lay-ups are then

with square tubes 9J~ flat plates 11 and sine-wave described. Finally, a semi-empirical analysis method,

beams 12'13. The results obtained with the tube specimens which uses the flat plate crush test data, is described and

have indicated that the energy absorbed depends on such applied to the angle and channel stiffeners.

design parameters as the material system, lay-up and

cross-section geometry. The tests have also demonstrated EXPERIMENTS

that when controlled stable crushing is produced through

selection of appropriate design parameters, the compos- Test specimens

ite tubes can yield a higher specific crushing efficiency The crust test specimens were flat plates, angle stiff-

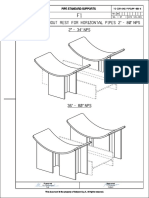

than aIuminium tubes. eners and channel stiffeners, the geometries of which are

illustrated in Figure 1. Three different lay-ups were used

* T o w h o m c o r r e s p o n d e n c e s h o u l d be a d d r e s s e d for most of the specimens: [45]~0, [452/0/452]~ and

COMPOSITES Volume 26 Number 4 1995 291

Energy absorption in stiffeners: A.O. Botukbasi and D.H. Laananen

Machined

..% graphite/epoxy plain-weave fabric, the mechanical prop-

chamfer erties of which, based on material supplier data, are listed

crush

initiator

in Table 2. The cured ply thickness was -0.203 mm.

The stiffener specimens were fabricated using a male

19 19

tool, and all specimens were cured in an autoclave under

690 kPa pressure.

A crush initiator in the form of a 2.5 mm long chamfer

was machined at one end of all crush test specimens. The

150

unchamfered end of each angle and channel crush test

specimen was potted in a 25 mm deep aluminium ring

using an epoxy-based potting compound. The flat plate

I

O0

specimens were not potted but were tested in a special

test fixture that provided lateral support along the

unloaded edges.

The dimensions of the flat plate crush test specimens

were selected to fit an existing test fixture. The dimensions

J'----.... of the angle and channel stiffener crush specimens were

selected based on elastic stability analyses to ensure that

Flat plate Angle stiffener Channel stiffener these specimens, except the specimens with the [45]5

Dimensions in rnm All radii = 3 mm

lay-up, would not undergo local or global buckling during

Figure 1 Crush test specimens testing. The specimens with the [45]5 lay-up were designed

to experience limited local buckling to investigate its effect

on the energy absorption capability of the stiffeners.

[45JOJ45]~. These lay-ups, which are typical of those

As indicated in Table 1, a total of nine flat plates, five

used with fabric prepregs, were selected to contain 0-40%

angle stiffener and five channel stiffener specimens of five

0~ plies in order to evaluate their effect on the energy

different lay-ups were fabricated and tested.

absorbing capability of the laminates. Results of previ-

ous studies have indicated that stable crushing can be

Flat plate crush tests

achieved in tubes consisting entirely of bias plies, and

that the addition of some axial pries can increase the Flat plate specimens were selected for most of the

specific crush stress for graphite/epoxy laminates2. crush experiments because they are less expensive and

However, as the percentage of 0 ~ plies is increased, at easier to fabricate than other types of test specimens such

some point the failure mode may change to a less effi- as stiffeners, tubes and sine-wave beams. A simple

cient mode. The 0 e plies tend to split longitudinally coupon configuration is also desirable for practical eval-

without crushing, and the tendency towards delamina- uation of material and laminate energy absorption capa-

tion increases, with a resulting drop in specific energy bility. A problem with the fiat plate specimen is, however,

absorption capability. Hull 6 reported on the axial crush- the possibility of global buckling of the plate rather than

ing of tubes fabricated from glass cloth with various the desired failure mode of sustained crushing. The buck-

warp to weft ratios that produced a range of ratios of ling problem was eliminated by selection of the plate

hoop to axial plies. Results indicated that beyond a hoop dimensions based on elastic stability analysis and by

to axial ratio of 1:1 the initial crash load increased, but using a special text fixture that provided lateral support

the sustained crush stress was reduced. to the specimen during the test.

In addition to the 10-ply lay-ups, two channel and The flat plate specimens were loaded using a special

two angle specimens were also fabricated using [45]7 and text fixture14, which is shown in Figure 2. The fixture

[45]5 lay-ups to evaluate the effect, on the energy absorp- consisted of eight steel rods and upper and lower platens.

tion capability of the stiffener, of different width to thick- The four 25 mm diameter steel rods at the corners of the

ness aspect ratios for the stiffener web and flanges. fixture served to guide the movable upper platen. The

Lay-ups for all specimens are listed in Table 1. fixture provided lateral support to the specimen through

All specimens were fabricated using T650-35/F584 four 13 mm diameter inner steel rods located at the centre

of the platens. The inner support rods were positioned

in pairs located 38 mm apart, so that the effective

Table 1 Test specimens supported plate width was 38 mm. Each pair had a

Specimen Specimen Quantity Lay-up

number type Table 2 Material properties for T650-35/F584 graphite/epoxy plain-

weave fabric

F1 Flat plate 3 [45]~

F2 Flat plate 3 [452/0/45z]s Material property Value

F3 Flat p]ate 3 [452/02/45]~

A1 Angle 1 [45]10 Longitudinal Young's modulus, El (GPa) 70.3

A2 Angle 1 [45J0/452]s Transverse Young's modulus, E2 (GPa) 70.3

A3 Angle 1 [45j02/45]s Out-of-plane Young's modulus, E3 (GPa) 8.27

A4 Angle 1 [45]7 Poisson's ratio, v12 0.028

A5 Angle 1 [45]5 In-plane shear modulus, G~2 (GPa) 5.65

C1 Channel 1 [45]10 Longitudinal tensile strength, S, (MPa) 855

C2 Channel 1 [452/0/452]s Transverse tensile strength, S2t (MPa) 855

C3 Channel 1 [452/02/45]s Longitudinal compressive strength, $1~ (MPa) 848

C4 Channel 1 [45]7 Transverse compressive strength, $2c (MPa) 848

C5 Channel 1 [45]5 In-plane shear strength, SI2 (MPa) 152

292 COMPOSITES Volume 26 Number 4 1995

Energy absorption in stiffeners: A.O. Bolukbasi and D.H. Laananen

Figure 3 Channel stiffener crush test

Figure 2 Flat plate crush test fixture

Flat plate crush tests

separation of 2 mm, the specimen thickness, so that the The flat plate specimens, which are shown in Figure

specimens could slide into the fixture from the side. 4, crushed between the lateral support rods of the text

The load was applied to the specimens and fixture fixture in what has been called by Hull 6 a 'splaying'

through a 25 mm diameter steel ball which rested in a mode and by Farley and Jones 8 a 'lamina bending'

seat that was machined in the upper platen of the fixture. mode. Each specimen tore against the lateral support

The displacement-controlled crosshead rate of the testing rods and exhibited a central crack, which split the plate

machine was 1.3 mm min 1. The load and crosshead into a Y-shaped cross-section with multiple lamina

displacement were digitally recorded during the test. The bundles in each leg. The crushing force was reacted

flat plate specimens were crushed for ~38 mm. through bending and compression of the lamina

bundles.

Angle and channel stiffener crush tests The load versus crosshead displacement response for

The angle and channel stiffeners were placed between specimen F2-1, which is typical of the flat plate speci-

the platens of the test machine with the stiffeners free men data, is shown in Figure 5. The response curves for

standing on the potted ring, as shown for one of the the flat plate specimens show an initial peak force asso-

channel stiffeners in Figure 3. The lower surface of each ciated with initiation of the fracture process followed by

potted ring was precision machined to ensure that the sustained crushing of the specimen. For crashworthiness

stiffener was vertically aligned between the platens. A applications, it is desirable that the initial peak load

smooth steel plate was also placed between the upper should not significantly exceed the average load during

end of the specimens containing the failure initiator and steady crushing. The initial peak, maximum and average

the movable platen of the test machine. crushing loads for all flat plate specimens tested are listed

As in the case of the flat plate specimens, the stiffener in Table 3, where the initial peak load is seen to be less

specimens were crushed using a displacement-controlled than the maximum crushing load for all specimens and

crosshead rate of 1.3 mm rain i. The angle and channel is comparable to the average crushing load. This indi-

stiffener crush test specimens were crushed for ~38 and cates that the machined chamfer at one end of the

64 ram, respectively. specimens was a very effective crush initiator. The exper-

imental data were also repeatable for specimens with

identical lay-ups with the exception of specimen F1-2,

EXPERIMENTAL RESULTS

which experienced a premature delamination.

The test results for the flat plate, angle and channel stiff- A good indicator of the crushing performance is

ener crush tests consist of force and deflection values, the specific sustained crushing stress (SSCS), which is

which were analysed to identify loads for initiation of a measure of the energy absorption capability of the

crushing as well as the loads associated with the sustained material:

crushing process for each of the specimens. In addition,

photomicrographs of the specimens were prepared to

obtain data on the delaminations and material failures SSCS = r (1)

associated with the crushing process. P

COMPOSITES Volume 26 Number 4 1995 293

Energy absorption in stiffeners: A.O. Bolukbasi and D.H. Laananen

in which p is the material density and o-~:is the sustained

crushing stress given by

o'~ = ~

P~V (2)

A

where Pa,~is the average crushing load and A is the cross-

sectional area. Experimental data in Table 3 indicate that

the SSCS of the laminates tested increased with increas-

ing percentage of 0~ plies in the laminate.

To study the crush regions in more detail, the crushed

flat plate specimens were sliced using a diamond saw,

and photomicrographs of the plate segment edge surfaces

were made. Typical photomicrographs of edge surfaces

at the centre of the plate and near one of the lateral

supports are shown in Figure 6. The photomicrographs

indicate that the principal crack occurred at or close to

the centre of the cross-section. The depth of this central

crack was about twice the thickness of the plate and

tended to be longer in the middle of the plate span away

from the lateral supports. The photomicrographs also

show interlaminar cracks in the legs of the Y-shaped

cross-section, present between all plies. The depths of the

interlaminar cracks were less than that of the central

crack and extended slightly beyond the lamina surface

in contact with the crush surface.

Stiffener crush tests

Examples of crushed angle and channel stiffener spec-

imens are shown in Figures 7 and 8, respectively. Except

for specimens A5 and C5, the stiffener specimens exhib-

Figure 4 Crushed flat plate specimens: (a) side view of all specimens; ited a crushing behaviour similar to the flat plate speci-

(b) top view of specimen F2-1 mens. They tore at the corners, and each segment of the

cross-section exhibited a central crack, which split the

segment into a Y-shaped cross-section with multiple

lamina bundles on each leg.

Specimens A5 and C5 were [45]5 laminates. Due to

the greater width to thickness ratio of the flanges, these

specimens experienced limited local buckling, and their

crushing behaviour was very different from that of the

other stiffeners. The A5 and C5 specimens tore at the

corners and did not exhibit a central crack. The crush-

ing force was reacted through bending and compression

of the torn flanges as a whole. As the crushing force

increased, the flanges started to tear at the corners, and

interlaminar cracks formed within the flanges. After the

flanges were torn at the corners, the crush load decreased

Figure 5 Crush test results for specimen F2-1 slightly and the flange lamina bundles slid laterally on

Table 3 Summary of flat plate crush test results

Initial Average Maximum Sustained Specific sustained

peak load load load crush stress crush stress

Specimen (kN) (kN) (kN) (MPa) (kJ kg 1)

FI-1 15.3 14.9 19.8 144 91,1

F1-2 16.4 10.5 16.5 102 64.6

Ft-3 16.4 14.3 22.2 138 87.3

F2-1 15.1 15.4 20.9 150 94.9

F2-2 16.1 15.1 20.9 147 93.0

F2-3 15.1 15.4 20,7 149 94.3

F3-1 13.8 16.0 20,5 155 98.1

F3-2 15.3 15.4 20.4 149 94.3

F3-3 15.5 15.8 20.3 153 96.8

294 COMPOSITES Volume 26 Number 4 1995

Energy absorption in stiffeners: A.O. Bolukbasi and D.H. Laananen

Figure7 Crushedanglestiffenerspecimens:(a) specimenA2; (b) spec-

imen A5

test fixture and the stiffener specimens. The flat plate

specimens were supported at both edges, where they tore

as they crushed. The stiffener specimens, however, had

flanges with free edges and tore only on the corners. The

S S C S tor both the angle and channel stiffener specimens

shows an increase with increasing percentage of 0 ~ plies.

The S S C S values for specimens A5 and C5 are much

Figure 6 Photomicrographsof flat plate specimenF2-1: (a) centre of

plate; (b) near lateral support less than those of the other stiffener specimens. This indi-

cates that energy absorbed with flange bending as a

the crush surface. As the stiffeners were crushed further, whole without the formation of a central crack is less

the crush loads once again increased, and the flanges tore efficient than energy absorption in the presence of a

further, repeating the crushing process. central crack. The formation and growth of the central

The load versus crosshead displacement for the stiff- crack significantly contributes to the crushing force and,

ener specimens A2 and C2, which are typical for their consequently, to the energy absorbed during the crush-

stiffener types, are shown in Figures 9 and 10. As noted ing process.

previously for the flat plate specimens, the response To study the crush regions in more detail, the crushed

curves show an initial peak force associated with initia- stiffener specimens were sliced using a diamond saw, and

tion of the crushing process, followed by sustained crush- photomicrographs of the edge surfaces were made. The

ing of the specimen. The initial peak, maximum and photomicrographs of all the stiffener specimens except

average crushing loads, and S S C S for all angle and specimens A5 and C5 showed failures similar to those of

channel specimens tested are listed in Tables 4 and 5, the flat plates. Photomicrographs of specimens A1 and

respectively. The experimental data in Tables 4 and 5 C3, which are typical of these stiffeners, are shown in

show that the initial peak load was less than the Figures I1 and 12. The photomicrographs indicate that

maximum crush load and is comparable to the average the central crack occurred at or close to the middle of

crushing load, indicating that the crush initiator was the cross-section. For the channel stiffener specimens,

effective. The only exception was specimen A l, where the depth of the central crack was about twice the thick-

the initiation load was about 5% higher than the ness of the stiffener and tended to be longer at the free

maximum crushing load. edge of the flange and at the centre of the web than near

The S S C S values for all specimens except A5 and C5 the corners of the stiffener where the web and flanges

(the [4515 lay-ups) are comparable but somewhat less intersected.

than those for the flat plate specimens. This is due to The photomicrographs also show inter/intralaminar

differences in boundary conditions between the flat plate cracks in the legs of the Y-shaped cross-section. The

COMPOSITES Volume 26 Number 4 1995 295

Energy absorption in stiffeners: A.O. Bolukbasi and D.H. Laananen

30

25

z

2O

/,

10

0

0 10 20 30 40 50 60 70

Displacement (mm)

Figure 10 Crush test result for channel stiffener specimen C2

interlaminar cracks were present between all plies. The

depths of the interlaminar cracks were less than that of

the central crack and extended slightly beyond the

lamina surface in contact with the crush surface.

Photomicrographs of specimens A5 and C5 are shown

in Figures 13 and 14. These photomicrographs indicate

that, as the flange was torn at the stiffener corner and

then was bent, interlaminar cracks were formed in the

flange between all plies, as observed in other stiffener

specimens. The section of the flange undergoing bending

and cracking was about three times the thickness of the

specimen.

ANALYSIS

A semi-empirical analysis methodology, which has been

developed for use in design of energy-absorbing com-

posite structures, is based on observations of the energy

absorption process during the experimental studies, on

phenomenological failure criteria and on fiat plate crush

Figure 8 Crushed channel stiffener specimens: (a) specimen C1; test data. The concept behind this analysis method is to

(b) specimen C5 be able to predict the energy absorption capability of

composite structural elements such as stiffeners based on

crush tests of fiat plate specimens. The fiat plate speci-

mens are relatively easy to fabricate and test using a

specialized text fixture. Therefore, the fiat plate speci-

mens potentially can be used to reduce or eliminate costly

fabrication and testing of actual structural elements.

The energy absorption capability of composite struc-

tures is strongly dependent on the crushing mode 8.

Therefore, a fundamental requirement of the semi-

empirical analysis is that the crushing behaviour of the

structural elements being analysed should be identical

to that of the fiat plate specimens tested.

The experimental studies that were described in the

previous section have indicated that most of the angle

and channel stiffeners crushed in a lamina bending crush-

ing mode much like the fiat plate specimens. The only

Figure 9 Crush test results for angle stiffener specimen A2 exceptions were the angle and channel stiffeners of [45]5

Table 4 Summary of angle stiffener crush test results

Initial Average Maximum Sustained Specific sustained

peak load load load crush stress crush stress

Specimen (kN) (kY) (kN) (MPa) (kJ kg-~)

A1 8.90 6.23 8.90 84.9 53.7

A2 8.10 7.43 9.92 101.4 64.2

A3 8.63 7.74 10.90 105.6 66.8

A4 4.80 3.91 5.20 83.7 53.0

A5 2.31 1.19 3.87 50.7 32.1

296 COMPOSITES Volume 26 Number 4 1995

Energy absorption in stiffeners: A.O. Bolukbasi and D.H. Laananen

Table 5 Summary of channel stiffcncr crush test results

Initial Average Maximum Sustained Specific sustained

peak load load load crush stress crush stress

Specimen (kN) (kN) (kN) (MPa) (kJ kg ~)

C1 20,(1 18,5 24.2 lt)7 67.7

C2 22.7 22,1 27.4 128 81.0

C3 18.7 22.8 27,8 132 83.5

C4 14.9 10.6 14,9 96.9 61.3

C5 7.83 5.56 8.14 63.0 39.9

Figure 12 Photomicrographs of channel stiflkner specimen C3

lqgure 11 I'hotomicrographs of angle stiffener specimen A l: (a) near (flange): (a) near free edge; (b) near corner

free edge; (b) near corner

plates 15and applied to postbuckling and crippling behav-

iour of composite stiffeners 16'17.

lay-up, which experienced local buckling and demon- To utilize the empirical crippling curves, the stiffener

strated much lower SSCS values than other specimens. cross-section is divided into a number of rectangular

Therefore, to ensure that the stiffeners crush in the same plate segments of width b and thickness t with either one-

mode as the fiat plate specimens, it is necessary to edge free or no-edge free boundary conditions.

develop a composite design criterion that will avoid local Definitions of element dimensions and the distinctions

buckling of the stiffener cross-section. between one-edge and no-edge free elements for angle

The design Of metal stiffeners is performed using a and channel stiffeners are illustrated in Figure 16.

crippling analysis, which predicts compression failure Materials properties used are the elastic modulus E

due to the stress distribution associated with local buck- and the compressive yield strength ~roy. The parameter

ling. This type of analysis tbr isotropic materials has r is the crippling compressive stress. If all the parame-

traditionally been carried out using empirically derived ters except crcc arc known, then the curves shown in

design curves of the form shown in Figure 15. A similar Figure 15 can be used to calculate a crippling stress value

approach has been developed for crippling of composite for each element of a cross-section. The total cross-

COMPOSITES Volume 26 Number 4 1995 297

Energy absorption in stiffeners: A.O. Bolukbasi and D.H. Laananen

Figure 14 Photomicrographs of channel stiffener specimen C5: (a)

flange near free edge; (b) web near corner

Figure 13 Photomicrographs of angle stiffener specimen AS: (a) near analogous to ~rcyfor metal stiffeners. Therefore, to avoid

free edge; (b) near corner

local buckling effects which may change the crushing

mode, it is necessary to select the stiffener element dimen-

section crippling strength can then be found by a sions so that the crippling stress lies on the horizontal

weighted average of the contributions of the individual part of the empirical curve. Beyond this analogy,

elements as follows: however, the empirically derived crippling curves for

isotropic materials are not directly applicable for lami-

n nated composite materials for several reasons.

Z (cr~c)iAiE; The traditional crippling curve has taken advantage

a,~ = i=1 (3) of the fact that, for an isotropic material, the stiffness

Y. AiEI can be represented in terms of a single elastic modulus.

i=1 This simplicity is not possible for laminated composite

materials. For isotropic materials, there is also a direct

where o'cc is the critical compressive stress for the total proportionality relationship between bending and exten-

cross-section, and A~ and Ei are the cross-sectional area sional stiffness given by the expression

and elastic modulus associated with each individual no-

edge or one-edge free element, for which the crippling

stress is (o-=)i.

The empirical crippling curves shown in Figure 15

indicate that, for relatively thick sections which lie on

~

T

the horizontal line to the left of the empirical crippling ~ _ _ N o Edge Free

0.8

curve, the cross-section will experience no local buckling Gc~ 0.6

and the element will fail due to a reduction in material Gcy 0.4

stiffness after yielding. For thinner cross-sections, which

lie on the sloped line to the right of the empirical crip- 0,2

pling curve, the section will experience local buckling

prior to reaching the yield strength under compressive 0.1

0.1 1 b O~r 10

load. TVT

It is possible to draw an analogy between metal and

composite stiffeners. The sustained crushing stress o'so

which was defined in equation (2) can be considered Figure 15 Empirical crippling curves for isotropic materials

298 COMPOSITES Volume 26 Number 4 1995

Energy absorption in stiffeners: A.O. Bolukbasi and D.H. Laananen

One end of the angle and channel specimens was potted

,,~jb "

t and the other end was restrained by friction on the

crosshead; the end conditions were assumed to be those

of a column with one end fixed and the other end pinned.

b The effective length was then -0.7L (ref. 18), and c was

set to a value of 2.04.

Given that equation (5) is applicable, consider a no-

edge free stiffener cross-section for which crushing occurs

at a load equal to or less than the load for which local

L elastic buckling of the cross-section as a whole occurs.

One-Edge Free Element No-Edge Free Eleroeot

This case can be represented mathematically as

Figure 16 Definition of one-edge and no-edge frec elements

acr 2> 1 (7)

G~frp.

El 3

D - (4) fp,

12(1 vz ) where o-~ is the sustained crushing stress of the flat plate

specimen of identical material and lay-up, and ~re~is the

critical buckling stress for the one-edge free stiffener

where D is the isotropic bending stiffness; E is the elastic element.

modulus; t is the thickness; and v is Poisson's ratio. The Substituting for ~r~ from equation (5) into equation

relationship between the bending and extensional stiff- (7), the design criterion to ensure that the no-edge free

nesses for a composite laminate is not as straightforward, stiffener element crushes in the same mode as the flat

and the bending stiffness is defined by a 3 • 3 flexural plate specimen, without local buckling of the cross

stiffness matrix D. section as a whole, can be written as

The approach taken in formulating the semi-empiri-

cal analysis model is, therefore, to develop expressions

for local buckling of the elements of the stiffener cross-

section with one-edge free and no-edge frcc boundary bZt \IDI1022+(D]2 +2D66) (8)

conditions using the coefficients of the D matrix.

One-edge free element

No-edge fi'ee element

Stability analysis of the one-edge free element is

A no-edge free element with a length of at least twice

similar to that for the no-edge free element, except that

the width b may be modelled as a rectangular plate

one of the edges parallel to the loading direction is free

simply supported on all four edges 18. An example of such

rather than simply supported 18, Examples of one-edge

an element is the web of the channel stiffeners tested.

free elements are the flanges of the angle and channel

The critical buckling stress for a simply supported

orthotropic plate can then be calculated by 19 stiffeners tested. The critical buckling stress for a rectan-

gular, orthotropic plate with one free, unloaded edge is

Gcr

2rc2[-'D 11/9, -2 +(/912+2/966)

] (5)

given by 2~

12D66 tc2Dll

a~ - - - + - - (9)

where o-0~is the critical buckling stress; b is the width of b2t L'2t

the element; and Dll, D12, D22 and D06 are coefficients of

the laminate flexural stiffness. This equation is strictly

true only for specially orthotropic laminates. However, where L' is the effective length given by equation (6).

any balanced symmetric angle-ply laminate considered Therefore, the design criterion that the one-edge free

for structural applications will be approximately ortho- stiffener element should crush in the same mode as the

tropic, so that equation (5) will be applicable. flat plate specimen, without local buckling of the cross-

The critical buckling stress given by equation (5) also section as a whole, can be written as

does not take into account the stiffener length, other than

assuming that the length is at least twice the width of the a~r~

p _ 12/966 4 - Jv2Du

-- (10)

individual stiffener elements, but not long enough for the

b2t L'2t

stiffener to fail in global column buckling. In general, a

segment with a slenderness ratio (L'/p) less than 20 will

not be subject to column buckling, and all of the stiff- When the stiffener is designed to meet both these

ener specimens were designed to have a slenderness ratio criteria for the one-edge and no-edge free elements, the

below this limit. The effective length L' in the slender- experimental data indicate that the crushing modes of

ness ratio is defined as the stiffeners will be identical to those for the flat plates.

However, the experimental data also indicate that the

L ' = L/,,,;cc (6) ~r~, values for one-edge free elements are less than those

for the flat plate specimens. The no-edge free elements

such as the webs of the channel specimen, on the other

where L is the actual length and c is the fixity coefficient, hand, have o-~ very close to that of the flat plate speci-

which takes into account the end support conditions. mens. Therefore, taking into account the free edge effect,

COMPOSITES Volume 26 Number 4 1995 299

Energy absorption in stiffeners: A.O. Bolukbasi and D.H. Laananen

the sustained crushing stress O'~cfor a stiffener designed specimens except those with the [45]5 lay-up, which

to comply with the local buckling criteria of equations buckled locally.

(8) and (10) is given by the following empirical relation- The energy absorption capability of the stiffeners that

ship: have crushed in the same mode as the fiat plate speci-

mens can be calculated using equation (11), provided

nweb nflange that the coefficients o~and/3 have been determined. Using

A web + ~ Y~ A flange

O~ ~ --i the values of a -- 0.978 and /3 -- 0.680 determined by

O-sc = O-sfP i:l i=1 (11) multiple linear regression of experimental data 22 and

A equation (11), the ~sc for the angle and channel stiffen-

where A web and A/flange a r e the areas for the stiffener web ers were calculated and are shown in Table 7.

and flange elements; nweb and nflange indicate the To evaluate the accuracy of the semi-empirical

numbers of each element in the cross-section; A is the method to predict the energy absorption capability of

total stiffener cross-sectional area; and a and/3 are exper- the stiffeners using equation (11), a statistical error

imentally determined constants. analysis of the data presented in Table 7 was performed.

The average spread of the experimentally measured

sustained crushing stress from that predicted by the

ANALYSIS RESULTS multiple linear regression analysis of the semi-empirical

An analysis of the energy absorption capability of the method is 2.52 MPa, which represents less than 3% vari-

angle and channel stiffeners was performed using the ation between test and analysis data. A coefficient of

semi-empirical analysis method described above. The determination of 0.988 indicates that 98.8% of the orig-

critical buckling stresses for the web and flange elements inal uncertainty in the data has been explained by the

of the stiffeners tested were calculated using equations semi-empirical model using a multiple linear regression

(5) and (9). These critical stresses and the measured Crsc analysis. These results support the conclusion that the

of the corresponding fiat plate specimens with the same semi-empirical analysis method provides an accurate

lay-up are compared in Table 6. The flanges of the angle means of predicting the energy absorption capability of

composite stiffeners.

and channel stiffeners have different critical buckling

stresses due to the fact that the angle and channel stiff-

ener lengths were different, 100 and 150 mm, respec- CONCLUSIONS

tively. The angle and channel stiffeners fabricated using T650-

The data in Table 6 indicate that, for all stiffener 35/F584 plain-weave graphite/epoxy fabric material with

elements except those with the [45]5 lay-up, the criti-

cal buckling stress O'er is greater than the fiat plate Table 7 Sustained crushing stress for angle and channel stiffeners

fp

sustained crushing stress o-s~. Therefore, the semi-

empirical analysis predicts that these stiffener specimens Sustained crushing stress, cr~c(MPa)

will crush in the same crushing mode as the fiat plate Specimen no. Test Analysis

specimens. On the other hand, for the stiffener elements

with the [45]5 lay-up, Crcris less than O'SfPC, and the analy- A1 84.9 87.2

sis predicts that they will suffer local buckling of the A2 101 101

entire cross-section and will not crush in the same mode A3 106 104

C1 107 110

as the flat plate specimens. These predictions are consis- C2 128 127

tent with the experimental observations where all the C3 132 131

specimens crushed in the same mode as the flat plate

Table 6 Critical buckling stress for stiffener web and flange elements

Element critical Flat plate sustained

Stiffener buckling stress, o'er crushing stress, o~

element Lay-up (MPa) (MPa)

Web [45]10 370 128

Flange (angle) [45h0 438 128

Flange (channel) [45]10 406 128

Web [45d0/452]s 348 148

Flange (angle) [452/0/452]s 395 148

Flange (channel) [452/0/452]s 360 148

Web [452/0J45]s 339 152

Flange (angle) [45d0d45]s 379 152

Flange (channel) [45d0d45]s 360 152

Web [45]7 182 128

Flange (angle) [45]7 215 128

Flange (channel) [45]7 199 128

Web [45]5 92.7 128

Flange (angle) [45]5 110 128

Flange (channel) [45]5 102 128

300 COMPOSITES Volume 26 Number 4 1995

Energy absorption in stiffeners: A.O. Bolukbasi and D.H. Laananen

[45110, [45]7, [452/0/452]s and [45J02/45]s lay-ups all State University, in whose laboratory the fiat plate crush

crushed in a lamina bending mode similar to the flat plate tests were conducted.

specimens of the same lay-ups. The stiffeners with the

[45]5 lay-up and fabricated using the same material REFERENCES

crushed in a local buckling mode and demonstrated an

SSCS much lower than the other stiffeners. The SSCS 1 Thornton, P.H.J. Compos. Mater. 1979, 13, 247

2 Farley, G.L.J. Compos. Mater. 1983, 17, 267

values of the flat angle and channel specimens tested 3 Hull, D. in 'Structural Crashworthiness' (Eds N. Jones and T.

showed an increase with increasing number of 0 ~ plies Wierzbicki), Butterworths, London, 1983, pp. 118-135

in the laminate. However, the SSCS values for all stiff- 4 Kindervater, C. in 'Proc. National Specialists Meeting on

eners were lower than those of the flat plate specimens Composite Structures', American Helicopter Society,

Alexandria, VA, 1983

with identical lay-ups. 5 Schmueser, D.W. and Wickliffe, L.E.J. Eng. Mater. Technol.

The failure initiator, in the form of a 2.5 mm long 1987, 109, 72

chamfer machined at one of all crush specimens, was 6 Hull, D. Compos. Sci. Technol. 1991, 40, 377

very effective. The initial peak crush loads for most 7 Sigalas, I., Kumosa, M. and Hull, D. Compos. Sci. Technol.

1991, 40, 265

specimens were at or below the maximum crush loads 8 Farley, G.L. and Jones, R.M.J. Compos. Mater. 1992, 26, 59

recorded during the sustained crushing phase of the 9 Thornton, P.H. and Edwards, P.J.J. Compos. Mater. 1982, 16,

specimens. 521

Using the criterion that the sustained crushing stress 10 Czaplicki, M.J., Robertson, R.E. and Thornton, P.H. Compos.

~rsc for the web and flange elements of the stiffener be Sei. Technol. 1991, 40, 31

11 Jackson, K., Morton, J., Lavoie, J.A. and Boitnott, R. J. Am.

less than a critical buckling stress ~rcr,the semi-empirical Helicopter Soc. 1994, 39, 17

model successfully predicted that all stiffeners except the 12 Kindervater, C.M. in 'Proc 30th National SAMPE Symposium,

stiffeners with [45]5 would crush in a lamina bending SAMPE, Covina, CA, 1985, pp. 1191-1201

mode similar to the flat plate specimens. These predic- 13 Hanagud, S., Craig, J.I., Sriram, P. and Zhou, W. Z Compos.

Mater. 1989, 23, 448

tions were consistent with the experimental observations. 14 Lavoie, J.A. and Morton, J. NASA Contractor Report 4526,

The semi-empirical analysis method was also used to National Aeronautics and Space Administration, Washington,

predict the energy absorption capability of the stiffeners DC, 1993

based on data from flat plate crush tests of identical lay- 15 Spier, E.E. and Klouman, F.L. in 'Composite Materials: Testing

and Design (Fourth Conference), A S T M STP 617, American

ups and multiple regression analysis. The multiple regres- Society for Testing and Materials, Philadelphia, PA, 1977, pp.

sion analysis successfully accounted for the free edge 255-271

effects associated with stiffeners, and the predicted 16 Renieri, M.P. and Garrett, R.A. Report MDC A7091,

energy absorption capability was within 3% of the stiff- McDonnell Aircraft Company, St Louis, MO, 1981

17 Reddy, A.D. and Rehfield, L.W. AIAA Paper No. 85~9672, 26th

ener crush test results. The flat plate specimens are rela- AIAA/ASME/SAE SDM Conference, American Institute of

tively easy to fabricate and test using a special test fixture. Aeronautics and Astronautics, Washington, DC, 1985

Therefore, the semi-empirical analysis method along 18 Timoshenko, S. 'Theory of Elastic Stability', McGraw-Hill

with flat plate crush test data can potentially be used to Book Company, Inc., New York, 1961

19 Whitney, J.M. 'Structural Analysis of Laminated Anisotropic

eliminate or reduce costly fabrication and crush testing Plates,' Technomic Publishing Company, Inc., Lancaster, PA,

of actual composite structural elements. 1987

20 Fogarty, J.H.J. Compos. Mater. 1992, 26, 991

21 US Air Force Flight Dynamics Laboratory, 'DOD/NASA

Advanced Composites Design Guide', DTIC Accession No. AD

ACKNOWLEDGEMENT B8080182L, Wright-Patterson AFB, OH, 1983

22 Chapra, S.C. and Canale, R.P. 'Numerical Methods for

The authors wish to acknowledge the assistance of Engineers', McGraw-Hill Book Company, Inc., New York,

Professor J. Morton of Virginia Polytechnic Institute and 1988

COMPOSITES Volume 26 Number 4 1995 301

You might also like

- Crushing Performances of Winding Square Kenaf Fiber Reinforced CompositesDocument5 pagesCrushing Performances of Winding Square Kenaf Fiber Reinforced CompositesGarett MasterNo ratings yet

- International Journal of Advanced and Applied Sciences: Numerical Modeling of Defective Hybrid Composite PlatesDocument7 pagesInternational Journal of Advanced and Applied Sciences: Numerical Modeling of Defective Hybrid Composite Platesbachour58No ratings yet

- AMME - Volume 18 - Issue 18th International Conference On Applied Mechanics and Mechanical Engineering. - Pages 1-15Document15 pagesAMME - Volume 18 - Issue 18th International Conference On Applied Mechanics and Mechanical Engineering. - Pages 1-15Valentina DiamanteNo ratings yet

- Oshkovr 2012Document6 pagesOshkovr 2012Sait Ozan YılmazNo ratings yet

- Vehicle Crash Can FEA Model Simulation and Validation With Experiment DataDocument8 pagesVehicle Crash Can FEA Model Simulation and Validation With Experiment DataNguyenNo ratings yet

- Acara MultiobjectivecrashworthinessoptimizationDocument12 pagesAcara MultiobjectivecrashworthinessoptimizationELDHO JACOB JOYNo ratings yet

- Composites Part B: Zhi Sun, Shanshan Shi, Xu Guo, Xiaozhi Hu, Haoran ChenDocument8 pagesComposites Part B: Zhi Sun, Shanshan Shi, Xu Guo, Xiaozhi Hu, Haoran ChenPaulo UtargNo ratings yet

- 2019-Containment of Soft Wall Casing Wrapped With Kevlar FabricDocument13 pages2019-Containment of Soft Wall Casing Wrapped With Kevlar FabriclaokanNo ratings yet

- Finite Element Modeling of The Crushing Behavior of TH - 2014 - Composites PartDocument9 pagesFinite Element Modeling of The Crushing Behavior of TH - 2014 - Composites Partsaif ullahNo ratings yet

- Composite Structures: A. Launay, V. Keryvin, J.-C. Grandidier, P.-Y. Mechin, R. BalzeDocument9 pagesComposite Structures: A. Launay, V. Keryvin, J.-C. Grandidier, P.-Y. Mechin, R. BalzePierre-Yves Harlé-MechinNo ratings yet

- Thin-Walled Structures: D. Quinn, A. Murphy, W. Mcewan, F. LemaitreDocument12 pagesThin-Walled Structures: D. Quinn, A. Murphy, W. Mcewan, F. LemaitreOraib AljaafrehNo ratings yet

- Energy - Absorbing Characteristics of The Compositr Contoured - CoreDocument9 pagesEnergy - Absorbing Characteristics of The Compositr Contoured - CoreSourav Roy0% (1)

- Preliminary Design of Tubular Composite Structures Using Netting Theory and Composite Degradation FactorsDocument5 pagesPreliminary Design of Tubular Composite Structures Using Netting Theory and Composite Degradation FactorsDILEEP AJAYAGHOSHNo ratings yet

- Vibration and Damping of Composite Sandwich Box Column With Viscoelastic/electrorheological Uid Core and Performance ComparisonDocument15 pagesVibration and Damping of Composite Sandwich Box Column With Viscoelastic/electrorheological Uid Core and Performance ComparisonMaya GlamourstickesNo ratings yet

- Mohamed Et Al. 2015 - Manufacturing and Characterization of Polyurethane Based SandwichDocument11 pagesMohamed Et Al. 2015 - Manufacturing and Characterization of Polyurethane Based SandwichALEXA FRYNo ratings yet

- FEM of UHPC Beams Under Pure TorsionDocument5 pagesFEM of UHPC Beams Under Pure TorsionHHTNo ratings yet

- Composites: Part A: Alain Prenleloup, Thomas Gmür, John Botsis, Konstantin O. Papailiou, Kurt ObristDocument9 pagesComposites: Part A: Alain Prenleloup, Thomas Gmür, John Botsis, Konstantin O. Papailiou, Kurt ObristAdam PrasetyaNo ratings yet

- Viscoelastic Energy Dissipation of Deployable Composite StructuresDocument10 pagesViscoelastic Energy Dissipation of Deployable Composite StructureslucasNo ratings yet

- Jurnal FiberglassDocument10 pagesJurnal FiberglassChristian Jovie YudhanantaNo ratings yet

- Composite Structures: Broderick H. Coburn, Zhangming Wu, Paul M. WeaverDocument12 pagesComposite Structures: Broderick H. Coburn, Zhangming Wu, Paul M. Weaveriname11No ratings yet

- A Review of The Recent Trends On Core Structures and Impact Response of Sandwich PanelsDocument43 pagesA Review of The Recent Trends On Core Structures and Impact Response of Sandwich Panelssameterkan5864No ratings yet

- Effect of Adhesive in Sandwich Panels Subjected To Low-Velocity ImpactDocument11 pagesEffect of Adhesive in Sandwich Panels Subjected To Low-Velocity Impactimad derbalaNo ratings yet

- Experimental Studies On The Impact Characteristics of Seamless Fibremetal Laminate (FML) TubesDocument5 pagesExperimental Studies On The Impact Characteristics of Seamless Fibremetal Laminate (FML) TubesNurlia HanimNo ratings yet

- An Axial Crushing Characteristics of Hybrid Kenaf/Glass Fabric Wrapped Aluminium Capped Tubes Under Static LoadingDocument6 pagesAn Axial Crushing Characteristics of Hybrid Kenaf/Glass Fabric Wrapped Aluminium Capped Tubes Under Static LoadingTJPRC PublicationsNo ratings yet

- Pantelakis 2013Document10 pagesPantelakis 2013kvs ptpNo ratings yet

- Osterberg CellDocument47 pagesOsterberg CelltehNo ratings yet

- Modling Slit Tape Buckling During Automated Prepreg ManufacturingDocument9 pagesModling Slit Tape Buckling During Automated Prepreg Manufacturingpopmart21No ratings yet

- Mechanical Behavior of Polypropylene-Based Honeycomb-Core Composite Sandwich StructuresDocument11 pagesMechanical Behavior of Polypropylene-Based Honeycomb-Core Composite Sandwich Structuresburak köseerNo ratings yet

- Energy Absorption Characteristics of A TDocument10 pagesEnergy Absorption Characteristics of A TsantoshbillurNo ratings yet

- Design and Analysis of Wind Turbine Blade UsingDocument5 pagesDesign and Analysis of Wind Turbine Blade Usingமகேஸ்வரி மாடசாமிNo ratings yet

- $% Bài Quan Trọng%Energy Absorption and in-plane Crushing Behavior of Aluminium ReinforcedDocument6 pages$% Bài Quan Trọng%Energy Absorption and in-plane Crushing Behavior of Aluminium ReinforcedNhanNo ratings yet

- Experimental Investigation of The Crashworthiness Performance of Laminated Composites Using Plastic-Fiber Wind Shield and Carbon FiberDocument10 pagesExperimental Investigation of The Crashworthiness Performance of Laminated Composites Using Plastic-Fiber Wind Shield and Carbon FiberAbhijeet SableNo ratings yet

- 2017-Containment Tests and Analysis of Soft Wall Casing Fabricated by Wrapping Kevlar Fabric Around Thin Metal RingDocument10 pages2017-Containment Tests and Analysis of Soft Wall Casing Fabricated by Wrapping Kevlar Fabric Around Thin Metal RinglaokanNo ratings yet

- The Effect of Hydrostatic Pressure On The Mechanical Properties of Glass Fibre/epoxy Unidirectional CompositesDocument11 pagesThe Effect of Hydrostatic Pressure On The Mechanical Properties of Glass Fibre/epoxy Unidirectional CompositesMartín KunuschNo ratings yet

- A Simplified Model To Simulate Crash Behavior of HoneycombDocument5 pagesA Simplified Model To Simulate Crash Behavior of Honeycombkevinrick49No ratings yet

- Composite Structures: Matias Garcia-Avila, Marc Portanova, Afsaneh RabieiDocument10 pagesComposite Structures: Matias Garcia-Avila, Marc Portanova, Afsaneh RabieiBhaskar RamagiriNo ratings yet

- Thananjayan Sivaprakasam ThesisDocument418 pagesThananjayan Sivaprakasam Thesisellerc8No ratings yet

- Static and Fatigue Analysis of Auxetic Re-Entrant Sandwich Panels by Three Points Bending TestDocument17 pagesStatic and Fatigue Analysis of Auxetic Re-Entrant Sandwich Panels by Three Points Bending Testsameterkan5864No ratings yet

- Beam Col Joints Using FRP Jee 2001Document18 pagesBeam Col Joints Using FRP Jee 2001Fernando TorresNo ratings yet

- An Experimental Investigation of The Properties of Cross-Ply Laminate Used For Manufacturing of Small Aircraft ComponentsDocument7 pagesAn Experimental Investigation of The Properties of Cross-Ply Laminate Used For Manufacturing of Small Aircraft ComponentsInidian CitizenNo ratings yet

- Ultimate Strength of Completely Overlapped Joint For Fixed Offshore Wind Turbine Jacket SubstructuresDocument15 pagesUltimate Strength of Completely Overlapped Joint For Fixed Offshore Wind Turbine Jacket SubstructuresDr R Panneer SelvamNo ratings yet

- Ex PressureDocument11 pagesEx PressureAhmad HadyNo ratings yet

- Ben Ammar 2014Document12 pagesBen Ammar 2014Anand NagarajanNo ratings yet

- Composite StructuresDocument11 pagesComposite StructuresJulianaSatizabalNo ratings yet

- Effectof Plies Stacking Sequenceand Tube GeometryonDocument9 pagesEffectof Plies Stacking Sequenceand Tube GeometryonNew SainNo ratings yet

- Effects of Stress Ratio On Fatigue Life of Carbon-Carbon Composites-1995, Theoretical and Applied Fracture MechanicsDocument11 pagesEffects of Stress Ratio On Fatigue Life of Carbon-Carbon Composites-1995, Theoretical and Applied Fracture MechanicsaeromatNo ratings yet

- Materials and Design: Masoud Haghi Kashani, Hamid Shahsavari Alavijeh, Hossein Akbarshahi, Mahmoud ShakeriDocument9 pagesMaterials and Design: Masoud Haghi Kashani, Hamid Shahsavari Alavijeh, Hossein Akbarshahi, Mahmoud ShakeriHamid ShahsavariNo ratings yet

- Use of Split-Disk Tests For The Process Parameters-Kaynak2005Document8 pagesUse of Split-Disk Tests For The Process Parameters-Kaynak2005houcinejNo ratings yet

- Cracking in Autoclaved Aerated Concrete: Experimental Investigation and XFEM ModelingDocument12 pagesCracking in Autoclaved Aerated Concrete: Experimental Investigation and XFEM ModelingAmar BayatNo ratings yet

- Mechanical Behavior Characterization of Aluminium Based Honey Comb Structure by Optimized Modeling and Numerical SimulationsDocument8 pagesMechanical Behavior Characterization of Aluminium Based Honey Comb Structure by Optimized Modeling and Numerical SimulationsDanial KhanNo ratings yet

- International Journal of Impact Engineering: A. Baroutaji, M.D. Gilchrist, D. Smyth, A.G. OlabiDocument15 pagesInternational Journal of Impact Engineering: A. Baroutaji, M.D. Gilchrist, D. Smyth, A.G. OlabiNhanNo ratings yet

- Quasi-Static Indentation Tests On Aluminium Foam Sandwich PanelsDocument8 pagesQuasi-Static Indentation Tests On Aluminium Foam Sandwich PanelsamarNo ratings yet

- 1 s2.0 S0264127517307347 MainDocument15 pages1 s2.0 S0264127517307347 Mainali aliNo ratings yet

- 2021 - D.Chatterjee - Composite Thin Skewed Hypar ShellsDocument13 pages2021 - D.Chatterjee - Composite Thin Skewed Hypar ShellsArpita SaxenaNo ratings yet

- 1 s2.0 S1359836816310939 MainDocument8 pages1 s2.0 S1359836816310939 MainRavindu ChavindaNo ratings yet

- Mechanical Characterization of Sheet Moulding Composites For The Automotive IndustryDocument6 pagesMechanical Characterization of Sheet Moulding Composites For The Automotive IndustryCaio OliveiraNo ratings yet

- High-Strain-Rate Compressive Behavior of A Rigid Polyurethane Foam With Various DensitiesDocument9 pagesHigh-Strain-Rate Compressive Behavior of A Rigid Polyurethane Foam With Various DensitiesATISH KUMAR DASNo ratings yet

- Analysis of Crashworthiness and Optimization of Bi-Tubular Thin-Walled StructuresDocument7 pagesAnalysis of Crashworthiness and Optimization of Bi-Tubular Thin-Walled StructuresInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Comparative Study of Energy Absorption Characteristics of Foam-Filled and Multi-Cell Square Columns (2007)Document14 pagesA Comparative Study of Energy Absorption Characteristics of Foam-Filled and Multi-Cell Square Columns (2007)naveed6069No ratings yet

- Effect of Dents in PipelinesDocument9 pagesEffect of Dents in PipelinesAnonymous avGU1iNo ratings yet

- Steel Making IntroductionDocument17 pagesSteel Making IntroductionHari sadu100% (2)

- Nonlinear Finite Element Anlaysis of Elastomers PDFDocument52 pagesNonlinear Finite Element Anlaysis of Elastomers PDFRaju63No ratings yet

- Expertip Tips For Reducing Forming Fabric Drive LoadDocument5 pagesExpertip Tips For Reducing Forming Fabric Drive LoadnotengofffNo ratings yet

- CF CM HE 4206a enDocument60 pagesCF CM HE 4206a enNius Pahala NainggolanNo ratings yet

- OGA - Chemical Series - EPDM Rubber Market Outlook 2019-2025Document22 pagesOGA - Chemical Series - EPDM Rubber Market Outlook 2019-2025ambarish ramNo ratings yet

- Wind Turbine Installation-ManualDocument23 pagesWind Turbine Installation-Manualויליאם סן מרמיגיוסNo ratings yet

- ENA - 12 - 24 TS For Ducts - Buried Electric CablesDocument17 pagesENA - 12 - 24 TS For Ducts - Buried Electric CablessdvijayNo ratings yet

- Api and British Standard Trim DesignationsDocument1 pageApi and British Standard Trim DesignationsPOTDARNo ratings yet

- Soportes de TuberíasDocument8 pagesSoportes de Tuberíasaecf_13No ratings yet

- Chemistry Heating-Cooling MathDocument14 pagesChemistry Heating-Cooling MathM Carlson0% (1)

- Double Containment EDocument43 pagesDouble Containment EDavid FonsecaNo ratings yet

- Storage and Blending Bed Technology.: PolysiusDocument7 pagesStorage and Blending Bed Technology.: PolysiusNguyen Ngoc AnhNo ratings yet

- Strip Tensile Properties of Reinforced Geomembranes: Standard Test Method ForDocument2 pagesStrip Tensile Properties of Reinforced Geomembranes: Standard Test Method ForLupita RamirezNo ratings yet

- TM550FN ManualDocument24 pagesTM550FN ManualJuan Carlos MoralesNo ratings yet

- PPPDocument5 pagesPPPscbd83No ratings yet

- Example Schedules of Rates/Bills of QuantitiesDocument63 pagesExample Schedules of Rates/Bills of QuantitiesKiss BalazsNo ratings yet

- Efficiency of A Simple Internal Combustion Engine Lab ReportDocument10 pagesEfficiency of A Simple Internal Combustion Engine Lab ReportGabriel ZaniNo ratings yet

- Fosc-230j 2014V1 0Document3 pagesFosc-230j 2014V1 0Francisco LaraNo ratings yet

- 592-A2GA DesbloqueadoDocument27 pages592-A2GA DesbloqueadoVicktor GranadosNo ratings yet

- Chehab Industrial and Medical Gases S.A.L: Beirut, Lebanon Saifi, Nahib Houbika St. Chehab BLDGDocument15 pagesChehab Industrial and Medical Gases S.A.L: Beirut, Lebanon Saifi, Nahib Houbika St. Chehab BLDGinstrumed_globalNo ratings yet

- Physical Property AnalyzersDocument211 pagesPhysical Property AnalyzersabbutalibbNo ratings yet

- PT Petrolab Services: Test DetailDocument2 pagesPT Petrolab Services: Test DetailDaniel Fr SinagaNo ratings yet

- Axial Stop Without Rest For Horizontal Pipes 2" - 80" NPS: Pipe Standard SupportsDocument4 pagesAxial Stop Without Rest For Horizontal Pipes 2" - 80" NPS: Pipe Standard SupportsMainuddin AliNo ratings yet

- Mk2 Fuse Boards and Fuses Updated 26 Feb 14Document3 pagesMk2 Fuse Boards and Fuses Updated 26 Feb 14csp_675491No ratings yet

- Applications: Eni Spa Refining&Marketing Viale Giorgio Ribotta, 51 - 00144 Roma +39 06 5988.1 Date 25/01/2019 Code 1035 1Document2 pagesApplications: Eni Spa Refining&Marketing Viale Giorgio Ribotta, 51 - 00144 Roma +39 06 5988.1 Date 25/01/2019 Code 1035 1haripuscasNo ratings yet

- slide valve orifice chamber (좋은 자료)Document54 pagesslide valve orifice chamber (좋은 자료)jmgwoo100% (2)

- ABB 2600 Series-SealsDocument40 pagesABB 2600 Series-SealsDarkhan Serikbayev100% (1)