Professional Documents

Culture Documents

Oem Kit - PG - HR109-21

Uploaded by

aceel fitchOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oem Kit - PG - HR109-21

Uploaded by

aceel fitchCopyright:

Available Formats

Post Glover Resistors

High Resistance Grounding OEM Kit

Line to ground faults are the cause of 98% of all plant electrical Why You Should Use HRG

failures. With increased attention industry-wide to lowering the

potentially deadly effects of arcing faults, tackling the problem at Protect Equipment Limit ground fault current to less than 10 A,

reducing damage and stress to equipment

its source remains the surest method of increasing your network’s and power system components

reliability. Downtime costs in both productivity and profits, and

Reduce Down Time Process equipment can continue to operate in the

Post Glover’s PulserPlus.Net™ keeps plants running 24/7/365. event of a line to ground fault, increasing profitability

Post Glover’s PulserPlus.Net™ is available in an OEM kit suitable

Increase Safety Virtually eliminates flash hazard possibility

for mounting in low or medium voltage switchgear cubicles or in the event of a potential arcing fault

standard MCC’s. Its ease of installation, top-level factory support

Fast Fault Location Pulsing circuit and optional ammeter allow for

and overall superiority make this the easy choice when the customer easier fault location, saving time and frustrations

requires a pulsing system for complete ground protection.

Features of the PulserPlus.Net™

Post Glover’s fourth generation PulserPlus.Net™ is the premier digital high resistance pulsing grounding system

on the market today. It has been engineered and tested to be easy to install and provide the most compre-

hensive feature set available. From tapped resistors wired to a terminal block to easy to use software, the most

advanced HRG system available is designed for seamless integration into your system protection scheme.

Why You Should Choose Post Glover

PulserPlus.Net™ Competitors’ offerings

Front panel

Data Logging Up to 200 alarms and events can be logged in memory

with a time/date stamp to catalog system issues to assist in Not available

determining the cause of faults or trend developing faults.

Reduced Nuisance The neutral current and voltage is filtered for 60 Hz to ensure

Alarms harmonic content is not included in the measurement, elim- Optional

inating nuisance alarms created by excessive harmonics.

Easily Accessed Engineered flexibility allows the user to accurately customize protec-

Alarm Settings tion for their electrical network including alarm levels, time delays, Difficult to adjust

and enabling or disabling features. Access is controlled by password.

Loss of Ground Continuous neutral path and resistor monitoring

Back panel

Protection protects users from undetected resistor failures Optional

that can compromise safety.

Automated Charging Guarantees you can select the proper fault level by

Current Measurement measuring the system charging current after installation or

Not available

and Adjustable upgrades. Tapped resistor allows to you to easily tune your

Resistor Taps protection on-site without ordering a new system.

Ethernet Real time neutral monitoring and the ability to

Communications integrate into a complete network supervision Optional

package gives you total control of your system.

Open Frame resistor

1369 Cox Avenue • Erlanger, KY 41018 • USA • Phone: 800-537-6144 / 859-283-0778 • www.postglover.com

PGR Document #HR109-21

High Resistance Grounding OEM Kit

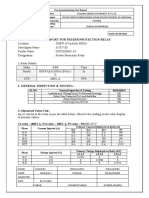

The OEM kit, designed for use at 600 volts and below, consists

of three parts: a Front Control Plate, the Internal Control Plate

and an Enclosed Resistor suitable for remote mounting.

The Front Control Plate is designed to be installed over a

cut-out of dimensions 16” high by 12” wide. This is compatible

with most OEM switchgear manufacturers. A rectangular shaft

couples the disconnect switch handle on the Front Control

Plate to the switch block on the Internal Control Plate when

the cubicle door is closed. The distance between the plates

is set at installation, and the shaft can be cut to length. The

distance between the two plates is typically around 10”.

Cabling between the display interface module and the control-

ler is factory supplied. All customer connections are made on

the supplied terminal strip. The controller is pre-wired to the

strip, simplifying installation and limiting potential mistakes. Item Front Panel Layout

Switchgear Door Cut-

1

out Cover Plate

2 PulserPlus.Net Controller

Disconnect Switch

3

Operating Handle

4 Alarm Horn

5,6,7 Pilot Lights

The grounding resistor itself is shipped loose and suitable for

mounting in existing cabinets or on top of the switchgear cab-

inet. The standard resistor offering is Open Frame, but NEMA 1

and NEMA 3R options are available. Enclosed options are mill

galvanized steel with an ANSI-61 gray powder-coated finish

but other colors or stainless steel are available upon request.

Item Back Panel Layout

Approximate Resistor Dimensions

1 Pulser Backplate

Open Frame: 17.5”W x 12”L x 12”H

2 Panel Ground Plate

3 Power Supply, 24 VDC

NEMA 1: 29”W x 18”L x 29”H

4,5 Fuseblocks NEMA 3R: 29”W x 18”L x 29”H

6 Pulser Electronics Module

7 Disconnect Switch

Save time and money using Post Glover’s pre-engineered, easy

to install OEM kit. As the industry’s leading experts in high

8 Terminal Block

resistance grounding, we are constantly pushing the technology

9 Relay

and product forward. Trust Post Glover to deliver faultlessly.

1369 Cox Avenue • Erlanger, KY 41018 • USA

™

Phone: 800-537-6144 / 859-283-0778 • Fax: 859-283-2978

www.postglover.com

Serving the Electrical Industry Since 1892 © 2021 Post Glover Resistors, Inc. • PGR Document #HR109-21

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Conduit Sealing Instructions For Equipment in Hazardous LocationsDocument2 pagesConduit Sealing Instructions For Equipment in Hazardous Locationsaceel fitchNo ratings yet

- FilenameDocument2 pagesFilenameaceel fitchNo ratings yet

- FilenameDocument2 pagesFilenameaceel fitchNo ratings yet

- FilenameDocument2 pagesFilenameaceel fitchNo ratings yet

- Presen Rewr W WDocument34 pagesPresen Rewr W Waceel fitchNo ratings yet

- RisetDocument7 pagesRisetaceel fitchNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Nte 201-300Document11 pagesNte 201-300api-242591736No ratings yet

- SK 1045 yDocument2 pagesSK 1045 ysahabateman100% (1)

- Aux Power SupplyDocument2 pagesAux Power Supplyphyo7799No ratings yet

- Building A Combiner BoxDocument5 pagesBuilding A Combiner BoxELECTROSTATIC SPRAYERS GREECENo ratings yet

- Transmisor de Presión PXTKDocument4 pagesTransmisor de Presión PXTKNicolii RamonNo ratings yet

- SMC SMPDocument2 pagesSMC SMPEmir RodríguezNo ratings yet

- Rift Valley Technical Trainig Institute Attachment ReportDocument19 pagesRift Valley Technical Trainig Institute Attachment Reportchuck254100% (2)

- Path of The LevinboltDocument2 pagesPath of The LevinboltMiha DuhNo ratings yet

- Datasheet Trilogy Systems With Smartpack2Document4 pagesDatasheet Trilogy Systems With Smartpack2JoseGarciaNo ratings yet

- S18 Series Sensors (AC Voltage) DatasheetDocument1 pageS18 Series Sensors (AC Voltage) DatasheetPaulomario RemuzgoNo ratings yet

- Catalog 06 07Document161 pagesCatalog 06 07Radovan JaicNo ratings yet

- CLP Delta TP4Document9 pagesCLP Delta TP4Ricardo ChumaNo ratings yet

- TIG & MIG Welding ProcessDocument2 pagesTIG & MIG Welding ProcessRIYA SHARMANo ratings yet

- Cazalla White 2700K 08 06 20Document2 pagesCazalla White 2700K 08 06 20Arul SankaranNo ratings yet

- Power Inverter 3kw SchematicsDocument5 pagesPower Inverter 3kw SchematicsLODELBARRIO RD0% (1)

- NEC Article 440Document3 pagesNEC Article 440Brandon ChoateNo ratings yet

- Unops JMPC 00085788 Itb Elec Works LoadschedDocument97 pagesUnops JMPC 00085788 Itb Elec Works LoadschedAlerick VelascoNo ratings yet

- User Manual For TDC3000 (V1.3.3)Document27 pagesUser Manual For TDC3000 (V1.3.3)Said WahdanNo ratings yet

- Electrical ServicesDocument62 pagesElectrical ServicesAshmita AryalNo ratings yet

- AMW Services SDN BHD Presentation - 9. January 2012-NewDocument26 pagesAMW Services SDN BHD Presentation - 9. January 2012-Newhizbi7No ratings yet

- Standby GeneratorDocument11 pagesStandby Generatortecmak AngolaNo ratings yet

- Dyna Edm Motor Drive: SettingsDocument2 pagesDyna Edm Motor Drive: SettingsDilhara WickramaarachchiNo ratings yet

- Catalogo Prisma G PlusDocument256 pagesCatalogo Prisma G PlusnfmaykoxNo ratings yet

- Test Report For Feeder Protection RelayDocument3 pagesTest Report For Feeder Protection RelayHari haranNo ratings yet

- 21R - 7SA610 V4 - 3 Var Var - PRN - 15 - 45 - 06Document7 pages21R - 7SA610 V4 - 3 Var Var - PRN - 15 - 45 - 06Kuenley TiNy OndeNo ratings yet

- AC Power Supply SkantiDocument24 pagesAC Power Supply SkantiJadi Purwono100% (2)

- ED3M-EC User ManualDocument165 pagesED3M-EC User ManualНикола МојсиловићNo ratings yet

- SSC JeDocument16 pagesSSC JeM IMTHIYAZ BASHANo ratings yet

- Renegade: Owner's ManualDocument20 pagesRenegade: Owner's Manualsangreh6190100% (1)

- HTTP 320volt - Com en SPDT Relay and DPDT RelayDocument7 pagesHTTP 320volt - Com en SPDT Relay and DPDT Relayluis.sinatoNo ratings yet