Professional Documents

Culture Documents

1-2. NE4040-40 - 200311 - LHK - Ver 1.0

Uploaded by

Kenz ZhouOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1-2. NE4040-40 - 200311 - LHK - Ver 1.0

Uploaded by

Kenz ZhouCopyright:

Available Formats

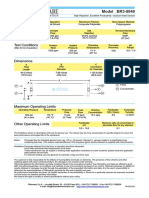

NE4040-40

High productivity NF element

SPECIFICATIONS:

General Permeate flow rate: 2,500 GPD (9.5 m3/day)

Features Divalent ion rejection (MgSO4) : 99.0%

Effective membrane area: 85 ft2 (7.9 m2)

1. The stated product performance is based on data taken after 30 minutes of operation at the following

test conditions:

• 2,000 mg/L MgSO4 solution at 75 psig (0.5 MPa) applied pressure

• 15% recovery

• 77 oF (25 oC)

• pH 6.5–7.0

2. Minimum MgSO4 rejection is 98.0%

3. NaCl rejection is 20-40% (Test conditions are equivalent with MgSO4)

4. Permeate flow rate for each element may vary +30 / -15%.

5. Elements are supplied as dry-type. Dry elements are sealed in a poly bag and individually boxed.

Membrane type: Thin-Film Composite

Membrane material: Polyamide (PA)

Element configuration: Spiral-Wound, FRP Wrapping

Dimensions Part Number

Model Name A B C D/E Inter-

Brine Seal

connector

40.0 inch 3.9 inch 0.75 inch 1.05 inch

NE4040-40 SWA01050 SWA01046

(1,016 mm) (99 mm) (19 mm) (26.7 mm)

1. Each membrane element supplied with one brine seal, one interconnector (coupler) and four o-rings.

All NE4040 elements fit nominal 4.0 inch (101.6 mm) I.D. pressure vessels.

The information provided in this document is solely for informative purposes. It is the user’s responsibility to ensure

the appropriate usage of this product. Toray Advanced Materials Korea Inc. assumes no obligation, liability or damages

incurred for the misuse of the product or for the information provided in this document. This document does not

express or implies any warranty as to the merchantability or fitness of the product.

Toray Advanced Materials Korea Inc.

For more information on our products, company and regional contacts, please visit our website at www.csmfilter.com.

Product Specification Sheet / Model NE4040-40

Page 1 of 2 Rev.1.0 March 2020

NE4040-40

High productivity NF element

APPLICATION DATA:

Operating Limits · Max. Pressure Drop / Element 15 psi (0.1 MPa)

· Max. Pressure Drop / 240” Vessel 60 psi (0.41 Mpa)

· Max. Operating Pressure 600 psi (4.14 MPa)

· Max. Feed Flow Rate 18 gpm (4.09 m3/hr)

· Min. Concentrate Flow Rate 4 gpm (0.91 m3/hr)

· Max. Operating Temperature 113 oF (45 oC)

· Operating pH Range 3.0–10.0

· CIP pH Range 2.0–11.0

· Max. Turbidity 1.0 NTU

· Max. SDI (15 min) 5.0

· Max. Chlorine Concentration < 0.1 mg/L

Design Guidelines for Various · Wastewater Conventional (SDI < 5) 8–12 gfd

Water Sources · Wastewater Pretreated by UF/MF (SDI < 3) 10–14 gfd

· Seawater, Open Intake (SDI < 5) 7–10 gfd

· Seawater, Beach Well (SDI < 3) 8–12 gfd

· Surface Water (SDI < 5) 12–16 gfd

· Surface Water (SDI < 3) 13–17 gfd

· Well water (SDI < 3) 13–17 gfd

· RO permeate (SDI < 1) 21–30 gfd

Saturation Limits · Langlier Saturation Index (LSI) <+1.5

(Using Antiscalants)† · Stiff and Davis Saturation Index (SDSI) <+0.5

· CaSO4 230% saturation

· SrSO4 800% saturation

· BaSO4 6,000% saturation

· SiO2 100% saturation

†

The above saturation limits are typically accepted by proprietary antiscalant

manufacturers. It is the user’s responsibility to ensure proper chemical(s) and

concentration are dosed ahead of the membrane system to prevent scale

formation anywhere within the membrane system. Membrane elements fouled

or damaged due to scale formation are not covered by the limited warranty.

GENERAL HANDLING PROCEDURES

Elements contained in the boxes must be kept dry at Keep elements moist at all times after initial wetting.

room temperature (7–32°C; 40–95°F) and should not be

Avoid excessive pressure and flow spikes.

stored in direct sunlight.

Only use chemicals compatible with the membrane

Permeate from the first hour of operation should be

elements and components. Use of such chemicals may

discarded to flush out the preservative solution. void the element limited warranty.

Used elements should be immersed in a preservative

Permeate pressure must always be equal or less than the

solution during storage, shipping and system shutdowns feed/concentrate pressure. Damage caused by permeate

to prevent biological growth and freezing. The standard back pressure voids the element limited warranty.

storage solution contains 1% by weight sodium bisulfite or

sodium metabisulfite (food grade). For short term storage

(i.e. one week or less) 1% by weight sodium metabisulfite

solution is adequate for preventing biological growth.

Toray Advanced Materials Korea Inc.

For more information on our products, company and regional contacts, please visit our website at www.csmfilter.com.

Product Specification Sheet / Model NE4040-40

Page 2 of 2 Rev.1.0 March 2020

You might also like

- Biomedical Electron Microscopy: Illustrated Methods and InterpretationsFrom EverandBiomedical Electron Microscopy: Illustrated Methods and InterpretationsNo ratings yet

- 5-2. NE4040-ARM50 - 200311 - LHK - Ver 1.0Document2 pages5-2. NE4040-ARM50 - 200311 - LHK - Ver 1.0Msach RoysNo ratings yet

- 1-1. NE8040-40 - 200311 - LHK - Ver 1.0Document2 pages1-1. NE8040-40 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 2-2. NE4040-70 - 200311 - LHK - Ver 1.0Document2 pages2-2. NE4040-70 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 4-2. NE4040-HRM - 200311 - LHK - Ver 1.0Document2 pages4-2. NE4040-HRM - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 3-1. NE8040-90 - 200311 - LHK - Ver 1.0Document2 pages3-1. NE8040-90 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 4-1. NE8040-HRM - 200311 - LHK - Ver 1.0Document2 pages4-1. NE8040-HRM - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0Document2 pages5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0Msach RoysNo ratings yet

- 2-1. NE8040-70 - 200311 - LHK - Ver 1.0Document2 pages2-1. NE8040-70 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Ne4040 SRMDocument2 pagesNe4040 SRMMsach RoysNo ratings yet

- High productivity RO element for brackish waterDocument2 pagesHigh productivity RO element for brackish waterWilly ChandraNo ratings yet

- Re8040-Ce - 190312 - PMKDocument2 pagesRe8040-Ce - 190312 - PMKMsach RoysNo ratings yet

- Re8040-Br400 - 190312 - PMKDocument2 pagesRe8040-Br400 - 190312 - PMKMsach RoysNo ratings yet

- RE16040-BE - 200907 - HSHDocument2 pagesRE16040-BE - 200907 - HSHMsach RoysNo ratings yet

- CSM Re8040 SHN LDocument2 pagesCSM Re8040 SHN LSundari RaviNo ratings yet

- Correos Electrónicos CSM-RE2521-BLN-LDocument2 pagesCorreos Electrónicos CSM-RE2521-BLN-LNahum Cesar Hernandez SorianoNo ratings yet

- Nano SW MaxDocument1 pageNano SW Maxfelipe RezendeNo ratings yet

- OltremareDocument1 pageOltremareAfraz ShaikhNo ratings yet

- Sea2 4040 PDFDocument1 pageSea2 4040 PDFMd. Suruz ZamanNo ratings yet

- Signet 2536 Rotor-X Paddlewheel Flow SensorsDocument6 pagesSignet 2536 Rotor-X Paddlewheel Flow SensorsMETHOR SERVICE GROUPNo ratings yet

- Datasheet LG SW 400 SR G2 ENGDocument1 pageDatasheet LG SW 400 SR G2 ENGMohamed MotaweaNo ratings yet

- 550series - HydraustarDocument8 pages550series - HydraustarvijaykumarnNo ratings yet

- Membrana RO Industrial 4x40 y 8x40Document2 pagesMembrana RO Industrial 4x40 y 8x40luisNo ratings yet

- LG SW 440 SRDocument1 pageLG SW 440 SRkylealamangoNo ratings yet

- Membrane Element SWC - 2540: PerformanceDocument1 pageMembrane Element SWC - 2540: PerformanceAshish GulrandheNo ratings yet

- Membrane Element Cpa2: Application DataDocument1 pageMembrane Element Cpa2: Application DataMilton Jiménez NaveaNo ratings yet

- Esna1 LF2 LD 4040Document1 pageEsna1 LF2 LD 4040Soledad OrtegaNo ratings yet

- Datasheet LG BW 400 R Dura ENGDocument1 pageDatasheet LG BW 400 R Dura ENGSaul RosalesNo ratings yet

- Data Sheet: LG SW 4040 RDocument1 pageData Sheet: LG SW 4040 RAcquetech AcquetechNo ratings yet

- Model 500-600 Series II (FM-1280 Rev.A)Document6 pagesModel 500-600 Series II (FM-1280 Rev.A)Carlos Miguel LópezNo ratings yet

- Electrodes For Hollow Perforated ElectrodesDocument14 pagesElectrodes For Hollow Perforated ElectrodesPraful N KNo ratings yet

- System ManualDocument14 pagesSystem ManualCareers SSPNo ratings yet

- Membrane LG CW 4040 SFDocument1 pageMembrane LG CW 4040 SFPT Deltapuro IndonesiaNo ratings yet

- Datos Tecnicos FlujometroDocument4 pagesDatos Tecnicos FlujometroJuverCupeNo ratings yet

- Hydranautics SWC5 LD LDocument1 pageHydranautics SWC5 LD LAlexis Jara VidalNo ratings yet

- RTP 299 X 90078 SSC 63023Document2 pagesRTP 299 X 90078 SSC 63023kls.thorodinsonNo ratings yet

- Microdyn BWRO-1Document2 pagesMicrodyn BWRO-1Rogerio SilvaNo ratings yet

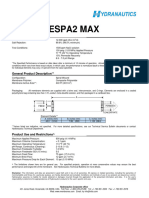

- ESPA2-MAXDocument1 pageESPA2-MAXoussama bvbNo ratings yet

- Мембрана TM810 SpecDocument2 pagesМембрана TM810 SpecAlexanderNo ratings yet

- ESPA2-LD-4040 membrane specificationsDocument1 pageESPA2-LD-4040 membrane specificationsJesus SelasorNo ratings yet

- SE20Document5 pagesSE20seyedmajidgNo ratings yet

- Mini Gaskleen High-Flow Filter Assemblies: DescriptionDocument2 pagesMini Gaskleen High-Flow Filter Assemblies: Description3DP HelloNo ratings yet

- NE4040-40 v2.3 (23) 1Document2 pagesNE4040-40 v2.3 (23) 1Andri Sanjaya SembiringNo ratings yet

- Lfc3-Ld: Specified PerformanceDocument1 pageLfc3-Ld: Specified PerformanceLuqmanNo ratings yet

- Membrane Element Cpa5-Ld: (Low Fouling Technology) PerformanceDocument1 pageMembrane Element Cpa5-Ld: (Low Fouling Technology) PerformanceAbid HaroonNo ratings yet

- Cpa5 LDDocument1 pageCpa5 LDHolliver Michael Estredo Ch.No ratings yet

- Cpa5 LD PDFDocument1 pageCpa5 LD PDFNarin InverterNo ratings yet

- CPA5-LD Membrane Element Performance SpecsDocument1 pageCPA5-LD Membrane Element Performance SpecsBassemNo ratings yet

- Hydranautics SWC5-LD (PW)Document1 pageHydranautics SWC5-LD (PW)mahdi rasoulianNo ratings yet

- Megfhven Ultipor GF-HVDocument3 pagesMegfhven Ultipor GF-HVarisNo ratings yet

- Toray TML20D LDocument2 pagesToray TML20D LEber saidNo ratings yet

- VONTRON LP21-4040T RO Element IntroductionDocument2 pagesVONTRON LP21-4040T RO Element Introductionsukiraj RasalingamNo ratings yet

- Procedure & Tool: InstallationDocument30 pagesProcedure & Tool: InstallationMuhd NazirulNo ratings yet

- LG SW 440 GRDocument1 pageLG SW 440 GRkylealamangoNo ratings yet

- GSX-431 GSX-431: 4.0 X 2.5mm SM Crystal For 4.0 X 2.5mm SM Crystal For Bluetooth / Wireless Bluetooth / WirelessDocument6 pagesGSX-431 GSX-431: 4.0 X 2.5mm SM Crystal For 4.0 X 2.5mm SM Crystal For Bluetooth / Wireless Bluetooth / WirelessMikeDonovanNo ratings yet

- MetaCeram-25040.. Castollin EutecticDocument2 pagesMetaCeram-25040.. Castollin EutecticAndrés MolinaNo ratings yet

- Signet 515 Rotor-X Paddlewheel Flow Sensors: FeaturesDocument6 pagesSignet 515 Rotor-X Paddlewheel Flow Sensors: FeaturesJonhatan SilvaNo ratings yet

- Membrane LG BW 400RDocument1 pageMembrane LG BW 400RPT Deltapuro IndonesiaNo ratings yet

- SanRO HS PDFDocument1 pageSanRO HS PDFjohn_paisNo ratings yet

- BW RO Membranes Desalinate Brackish WaterDocument2 pagesBW RO Membranes Desalinate Brackish Waterpkgoyal1983No ratings yet

- MembraneSpecSheet 60umDocument1 pageMembraneSpecSheet 60umKenz ZhouNo ratings yet

- MembraneSpecSheet 60umDocument1 pageMembraneSpecSheet 60umKenz ZhouNo ratings yet

- AQ OptiVenn Sept21Document8 pagesAQ OptiVenn Sept21Sergio ZamoranoNo ratings yet

- Daftar Harga - Rucika (RHC) Special FittingDocument1 pageDaftar Harga - Rucika (RHC) Special FittingKenz ZhouNo ratings yet

- 201410MLC PSC Reports PDFDocument11 pages201410MLC PSC Reports PDFAbd ZouhierNo ratings yet

- YPV6 Mobile Air Conditioner ManualDocument18 pagesYPV6 Mobile Air Conditioner ManualTecnicas Metalicas100% (1)

- Climate-Friendly Agribusiness Irrigation Canal ProjectDocument112 pagesClimate-Friendly Agribusiness Irrigation Canal ProjectMendrakevNo ratings yet

- 07 Chapter2Document11 pages07 Chapter2hareesh13hNo ratings yet

- Comparison of Run-Off Computed by Strange's Table and Dry Damp Wet' MethodDocument5 pagesComparison of Run-Off Computed by Strange's Table and Dry Damp Wet' MethodIJSTENo ratings yet

- Abc DG 2014 PDFDocument114 pagesAbc DG 2014 PDFSutrisnoNo ratings yet

- Forester SyllabusDocument7 pagesForester Syllabusgizmo 2k23No ratings yet

- Kodak Automixer II Plus - User ManualDocument36 pagesKodak Automixer II Plus - User ManualNikolay PenevNo ratings yet

- Adulteration in Food Items BDocument18 pagesAdulteration in Food Items BBen DavidNo ratings yet

- Water Resources and Irrigation Engineering - Lecture Notes, Study Material and Important Questions, AnswersDocument9 pagesWater Resources and Irrigation Engineering - Lecture Notes, Study Material and Important Questions, AnswersM.V. TVNo ratings yet

- Biogenic AAPG PDFDocument21 pagesBiogenic AAPG PDFYusron YazidNo ratings yet

- F1a 1Document107 pagesF1a 1潘步成Poon Po ShingNo ratings yet

- Lake Volume CalculationsDocument2 pagesLake Volume CalculationsHtay Win OoNo ratings yet

- DLL - English 4 - Q3 - W9Document5 pagesDLL - English 4 - Q3 - W9Nick P. DimatulacNo ratings yet

- Design of Gas Absorber For The Exhaust Gases of Ammonia PlantDocument11 pagesDesign of Gas Absorber For The Exhaust Gases of Ammonia PlantVan LimNo ratings yet

- Monitor Colour Sensor App NotesDocument2 pagesMonitor Colour Sensor App NotesanhchangluoiNo ratings yet

- Hypothesis About Electron Quantum Tunneling During Sonochemical Splitting of Water MoleculeDocument12 pagesHypothesis About Electron Quantum Tunneling During Sonochemical Splitting of Water MoleculeMichel AertsNo ratings yet

- 624 2009 Ethiopia Building ProclamationDocument17 pages624 2009 Ethiopia Building ProclamationWondemeneh AsratNo ratings yet

- Group 1 CocaCola BDGDocument6 pagesGroup 1 CocaCola BDGKristine JarinaNo ratings yet

- Clean Water Is Essential For LifeDocument2 pagesClean Water Is Essential For LifePaulina MartinNo ratings yet

- Water Treatment PlantDocument100 pagesWater Treatment PlantDr. Akepati Sivarami Reddy96% (23)

- Performance Evaluation of Dimoro IrrigationDocument9 pagesPerformance Evaluation of Dimoro IrrigationAgung R RamadhaniNo ratings yet

- Assessment of Rainwater Harvesting Potential of NSTU CampusDocument5 pagesAssessment of Rainwater Harvesting Potential of NSTU CampusFahim SiddikiNo ratings yet

- Heliocol Informacion Tecnica PiscinasDocument2 pagesHeliocol Informacion Tecnica PiscinasCesar Cuasapaz GoyesNo ratings yet

- Imaginarium - Class 9 - Month 2 PDFDocument61 pagesImaginarium - Class 9 - Month 2 PDFdattatray deshmukhNo ratings yet

- Pannox 140 GHS-SDSDocument5 pagesPannox 140 GHS-SDSBERKAT RAJA SEMESTANo ratings yet

- Urban Wetlands in The Core of Africa Protection A-Groen Kennisnet 371571Document107 pagesUrban Wetlands in The Core of Africa Protection A-Groen Kennisnet 371571Racolta RaulNo ratings yet

- Esdm 231Document30 pagesEsdm 231Priyanka Mestri100% (1)

- Presentation SC RusikulyaDocument5 pagesPresentation SC RusikulyaGayadhar SahuNo ratings yet