Professional Documents

Culture Documents

ACI Hook

ACI Hook

Uploaded by

Yahia Osama0 ratings0% found this document useful (0 votes)

23 views3 pagesOriginal Title

ACI hook

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views3 pagesACI Hook

ACI Hook

Uploaded by

Yahia OsamaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

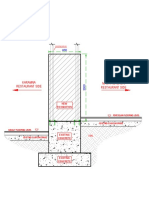

Table 25.3.1—Standard hook geometry for development of deformed bars in

tension

Type of Straight

standard Minimum inside | extension!

hook Bar size | bend diameter, mm | _ fy) mm Type of standard hook

Point at which

No. 10 through 6dy bar's developed

No. 25 ¢

No. 29 through Sy peed on

o0-degree No. 36 i 7

hook ce

No. 43 and

No. 57 ne

i Point at which

No. 10 through a fe

No. “

No. 29 through ‘ah . qa tt *

180-degree No. 36 ty Greater of ; 1 eS jot dere

hook 4dy and 65mm | Diameter —

No. 43 and |

10d; 1 rext

No. 87 1 Z bg

ah

SIA standard hook for deformed bars in tension includes the specific inside bend diameter and straight extension length. It shall

be permitted to use a longer straight extension at the end of a hook. A longer extension shall not be considered to increase the

anchorage capacity of the hook.

STRUCTURAL CONCRETE BUILDING CODE (ACI 18-11) AND COMMENTARY 2

CHAPTER 7 — DETAILS OF REINFORCEMENT

CODE

7.4 — Standard hooks

The term “standard hook” as used in this Code shall

mean one of the following:

7.1.1 — 180-degree bend plus 4dp extension, but not

less than 85 mm at free end of bar.

7.1.2 — 90-degree bend plus 12dp extension at free

‘end of bar.

7.1.8 —For stirrup and tie hooks

(a) No. 16 bar and smaller, 90-degree bend plus 6¢p

extension at free end of bar; or

(b) No. 19, No. 22, and No. 25 bar, 90-degree bend

plus 12d, extension at free end of bar: of

(c) No. 25 bar and smaller, 135-degree bend plus

6d, extension at free end of bar.

7.1.4 — Seismic hooks as defined in 22.

7.2— Minimum bend diameters

7.2.1 — Diameter of bend measured on the inside of

the bar, other than for stirrups and ties in sizes No. 10,

through No. 16, shall not be less than the values in

Table 7.2.

7.2.2 — Inside diameter of bend for stirups and ties

shall not be less than 4d for No. 16 bar and smaller.

For bars larger than No. 16, diameter of bend shall be

in accordance with Table 7.2

7.2.3 — Inside diameter of bend in welded wire

reinforcement for stirrups and ties shall not be less

than 4dp for deformed wire larger than MD40 and 2d,

for all other wires. Bends with inside diameter of less

than Bdy shall not be less than 4dp from nearest

welded intersection,

COMMENTARY

R7.1— Standard hooks

Recommended methods and standards for preparing design

drawings, typical deails, and drawings for the fabrication

and placing of reinforcing steel in reinforced concrete

structures are given in the ACI Detailing Manual, reported

by ACI Committee 315.7

Al provisions in the Code relating to bar, wire, or strand

diameter (and area) are based on the nominal dimensions of

the reinforcement as given inthe appropriate ASTM specii-

calfon. Nominal dimensions are equivalent to those of a

circular area having the same weight per meter as the

ASTM designated bar, wie, or strand sizes. Cross-sectional

area of reinforcement is based on nominal dimensions,

7.1.3 — Standard stirrup and tie hooks are limited to

No. 25 bars und smaller, and the O0-depree hook with 6,

extension is further limited to No. 16 bars and smaller, in

both cases as the result of research showing that larger bar

sizes with 90-degree hooks and 6d extensions tend to pop

‘out under high load.

R7.2— Minimum bend diameters

Standard bends in reinforcing bars are described in terms

of the inside diameter of bend because this is easier to

‘measure than the radius of bend. The primary factors

affecting the minimum bend diameter are feasibility of

bending without breakage and avoidance of crushing the

ccoerete inside the bend.

RI.22 — The minimum 4d, bend for the bar sizes

commonly used for sirups and ties is based on accepted

Industry practice in the United States. Use of a sirup bar

size not greater than No. 16 for either the 0-degree or

135-degree standard stirrup hook will permit multiple

bending on standard stirrup bending equipment.

[R7.23 — Welded wire reinforcement can be wsed for stirups

and lies. The wire af welded intersections does not have the

sume uniform ductility and bendability asin areas that were

‘not heated. These effects of the welding temperature are

usually dissipated in a distance of approximately four wire

diameters. Minimum bend diameters permitted are in most

cases the same as those required in the ASTM bend tests for

| wire material (ASTMALO64M)..

‘American Concrete Intute Copyihtod Material—www concrete org

0 [STRUCTURAL CONCRETE BUILDING CODE (ACI 3184-11) AND COMMENTARY

CODE

‘TABLE 7.2 — MINIMUM DIAMETERS OF BEND

Gara

Tie To rough Ne 2

Wa 29, Ne anda 36

Tia. 4S and No.7

Tima ae

ods

7.3 — Bending

7.3.1 — All reinforcement shall be bent cold, unless

= chemise permitted by the licensed design professional

73.2 — Reinforcement partially embedded in

concrete shall not be field bent, except as shown in the

| contract documents or permited by the licensed

design professional

7.4 — Surface conditions of reinforcement

7.A.A—At the time concrete is placed, reinforcement

shall be free from mud, cil, or other nonmetallic coatings

that decrease bond. Epoxy-coating of reinforcement in

accordance with standards referenced in 3.5.3.8 and

3.5.3.9 shall be permitted,

7.4.2 — Except for prestressing steel, steel reinforos-

ment with rust, mill scale, or a combination of both

shall be considered satisfactory, provided the minimum

dimensions (including height of deformations) and

weight of a hand-wire-brushed test specimen comply

with applicable ASTM specifications referencediin 3.5.

COMMENTARY

R7.3—Bending

73.1 — For unusual bends with inside diameters less than

ASTM bend test requirements, special fabrication may be

required

7.3.2 — Construction conditions may make it necessary 10

bend bars that have been embedded in concrete. Such field

bending should not be done without authorization of the

licensed design professional, Contract documents should

specify whether the bars will be permitted to be bent cold or

IF heating should be used. Bends should be gradual and

should be straightened as required.

‘Tests7275 have shown that A615M Grade 280 and Grade 420

reinforcing bars can be cold beat and straightened up to

90 degrees at or near the minimum diameter specified in

72. If cracking or breakage is encountered, heating 10 4

maximum temperature of $20°C may avoid this condition

forthe remainder ofthe bas. lars that fracture during bending

or straightening can be spliced outside the bend region.

Heating should be performed in a manner that will avoid

damage to the concrete. If the bend area is within approxi-

mately 150 mim of the concrete, some protective insulation

may need to be applied. Heating of the bar should be

‘controlled by temperature-indicaling crayons or other suitable

means. The heated bars should not be arficially cooled (with

Waler or forced air) until after cooling to at Least 320°C.

R74 — Surface conditions of reinforcement

‘Specific limits on rust are based on tests,” plus a review

of earlier tests and recommendations, Reference 7.4

provides guidance with regard to the effects of rust and

‘mill scale on bond characteristics of deformed reinforcing

bars. Research has shown that a normal amount of rust

Increases bond. Normal rough handling generally removes

rust that is loose enough to injure the bond between the

concrete and reinforcement.

‘American Concrete institute Copyrighted Materia concrete og

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- W2-1 Steel - SiteDocument2 pagesW2-1 Steel - SiteYahia OsamaNo ratings yet

- ProposalDocument1 pageProposalYahia OsamaNo ratings yet

- 2 Bed Rooms Villa - Plaster AreaDocument5 pages2 Bed Rooms Villa - Plaster AreaYahia OsamaNo ratings yet

- Yehia Osama Mahmoud Badawi: BriefDocument2 pagesYehia Osama Mahmoud Badawi: BriefYahia OsamaNo ratings yet

- Scanned With CamscannerDocument3 pagesScanned With CamscannerYahia OsamaNo ratings yet

- Yehia Osama Mahmoud Badawi: EducationDocument2 pagesYehia Osama Mahmoud Badawi: EducationYahia OsamaNo ratings yet

- Yehia Osama Mahmoud Badawi: EducationDocument2 pagesYehia Osama Mahmoud Badawi: EducationYahia OsamaNo ratings yet

- Management Project Group No. (1) : The Military Hospital For Armed ForcesDocument13 pagesManagement Project Group No. (1) : The Military Hospital For Armed ForcesYahia OsamaNo ratings yet