Professional Documents

Culture Documents

Operating Manual - Enertronic T UPS 8 KVA

Operating Manual - Enertronic T UPS 8 KVA

Uploaded by

hasan 310 ratings0% found this document useful (0 votes)

25 views78 pagesOriginal Title

Operating Manual_Enertronic T UPS 8 KVA

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views78 pagesOperating Manual - Enertronic T UPS 8 KVA

Operating Manual - Enertronic T UPS 8 KVA

Uploaded by

hasan 31Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 78

UPS

Operating and Maintenance Manual

‘ex March 2009

ode 5040260300

‘The orglnal of this document is drawa upin the talan language

ce

operating and Maintonanco Manual

code 5040260300 Rev, March 2009

Index of Contents

1, FOREWORD

WW

12

13

14

15

16

7

18

2, TECHNOLOGICAL DESCRIPTION ..

21

22

23

24

25

254

252

253

254

3, SAFETY PROVISIONS rs

3A

32

33

34

Bad

342

35

350

36

3.6.1

37

38

39

3.91

392

Purpose of the manual.

Were and howto keep the manual.

Manual update.oo-—

Collaboration with the user.

Manufacturer anenom 7

Responsibilities of the manufacturer

and guarantee.

Copyright,

UPS technology

Features.

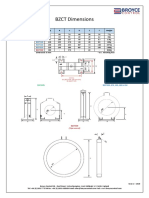

Models... Z

Technical specifications.

Communication devices...

5232 serial pOrts.nu

Relay interfacenennn

Logic level interface .

Communications sto...

General notes..

SYMBOLS. ne nnnn

Reference standards. 7

Definitions of operator’ and

‘specialized technician’.

7 32

Qualification required to the operator... 3-2

Qualification required to the

specialized technician... 32

Individual protective gear 33

Gear 0 WERT eno inst 33

Indications of danger in the work place ..3-4

tnications onboard the equipment. BA

Residual risks oom a4

General warnings. 35

Emergency interventions. 36

First ald interventions... 36

36

/e-prevention measures.

‘Operating and Maintenance Menual

ode 5040260300 Re. Merch 2008,

9, MAINTENANCE. a ot

BT IRODUCION nen 4

9.2 Preventive maintenance... ot

9.3 Perlodical checks. se 92

93,1 Preparing the UPS for maintenance.

Forced bypass mode.. 92

9.4 Adding oF replacing a power module

for battery BOX on 93

9.4.1 Power Module wm 93

9.4.2 Battery boxes... 4

10. DISMANTLING...

10.1 Disposing of the batteries...

10.2 Dismantling the UPS

103 Disposing of the electronic components... 10-1

11, TABLES,

12, NOTES

UNPACKING rn

41 Visualingpection.

41.4 Checking the equipment and

accessories supplied...

42 Unpacking snnnennn

43 Checking the contents of the pack

44 Storing

BAL UPS cue

442 — Batteries.

45 Handling,

AB Positioning enum

47 Last operations... rd

5, INSTALLATION.

5.1 Safety rules and regulat ;

5.2 Electrical connections... vee ST

5.2.1 Safety recommendations m2

5.22 Preliminary operations 5-2

5.2.3 Connecting the loads.snmuenn 52

5.24 Emergency Power Off (Remote E.P.0) mum 5-3

5.2.5 Installing the UPS BATTERY,

5.26 Protections nan

B27 Bathing vesrononen

5.2.8 Connecting the power supply...

529 ing

53. Wiring diagrams enn nrnnn

5.3.1 Factory set configuratior

‘THREE-PHASE input,

THREE-PHASE OUtpUt ooo wn 59

53.2 THREE-PHASE input, SINGLE PHASE

‘output connection...

533. SINGLE-PHASE input, SINGLE PHASE

‘output connection,

5.4 SINGLE-PHASE input, THREE-PHASE

‘output connection.

5.3.5 SINGLE-PHASE input connection,

no. 3 separate OULPUtS nn

6, CONFIGURATION AND START-UP.

G1 Input configuration ..

6.2 Output configuration.

6.3 Checks prior to switching on

64 Starting procedure.

7. CONTROL PANEL sinssseunnneennnn

7.1 ‘Service Mode’ function.

7.2 Main menu and submenus.

7.2.1 UPSstatus

7.22 UPSsettings.

723 Power Modules.

7.24 Events

725 Tools..

7.26 Turning the single output phases on

and off ..

7.2.7 Shutting down the UPS

8, DIAGNOSTICS

81 Luminous and acoustic SIGNALS nomen 87

82 Messages.

Operating end Maintononce Manul

‘de 5090260360 Rev. March 2002

Operating and Maintonance Manvat

code 5040260300 Rv. March 209,

ee

1. Foreword

1.1 OVERVIEW

Congratulations for having bought a UPS product.

‘Thanks to UPS unit your crtical equipment will be protected by a constant and

reliable supply of power for years to come.

‘The Manufacturers based in italy and specializes n designing and producing UPS

units, The UPS system Is unique, modular and the last generation of three-phase

medium power UPS units.

Highly reliable, low running costs and excellent electrical performance are but a

fewofthegreat features ofthis innovative UPS. Moreover, the criterlaandmethods

the Manufacturer uses for its design and production comply with the strictest

quality standards,

‘The productis in fact, produced atan IS014001 certified factory in full compliance

with the eco-design laws.

‘The UPS system is made in compliance with the existing European Community

directives and with the technical standards thatinclude their requirements.as.cer-

tified by the Declaration of Conformity issued by the Manufacturer and enclosed

with this manual.

‘This publication, simply defined ‘manual’ herein, contains all the information for

the installation, use and maintenance of the equipment specified in the Declara-

tion of Conformity.

This equipment will be referred to simply as ‘equipment’ or even ‘machine’ in this manual and is

manufactured by the Manufacturer whose address can be found further on in this chapter.

‘The contents of this manual are intended for an operator who has already been instructed on the

precautions to be taken in relation to the presence of electricity.

The persons to whom this publication is addressed, normally defined users, are all those people who,

for their field of expertise, have the need and/or obligation to provide instructions or work directly

‘on the equipment.

These people can be the following:

= managers;

heads of operating areas;

= department heads;

~ operators directly concerned with transporting, storing, installing, using and servicing machines

from the moment they are put on the market up to the day they are scrapped;

direct private users.

“The original text of this publication, written in the Italian language, is the only reference for solving

any disputes concerning the interpretation of translations into Community languages.

‘This publication is to be considered an integral part of the equipment supplied and, as such, must be

kept for future reference up until the equipment is definitively dismantled and scrapped.

code 5040260300 fe. March 2009

Foreword

1-41

Operating and Maintonance Manual

1.8 COPYRIGHT

‘The information in this manual must not be disclosed to third parties. Any duplication, total or partial,

‘not authorised in writing by the Manufacturer, obtained by photostatting, duplicating or any other

‘method, even electronically, violates the copyright conditions and can be persecuted by law.

Forenond

1-4 ‘Code 5640260300 Rev. March 2009

Operating and Maintenance Menual

2. Technological description

2.1 UPSTECHNOLOGY

Congratulations on your purchase of a UPS product from the Manufacturer.

‘Thanks to the UPS your critical equipment will be protected by a constant and rellable supply of power

for years to come.

‘The Manufacturer has developed a project that is both innovative and unique, creating the UPS with a

power range of 8, 10, 16, 20, 30, 45 and 60 kVA capable of adapting itself at any time to the changing

requirements of protected loads: greater power, longer autonomy, redundancy. The basic concepts of,

the UPS projectare infact, modularity, expandabilty and redundancy which, besides offering maximum

reliability, ae also the guarantee of a considerable economic saving.

UPS is a modular uninterrupted power supply unit with individually programmable basic modules so

you can have the input/output configuration you want. in this way itis possible to control three- and

single-phase voltage in input and output to have, as preferred the classical three/three, three/single,

single/three and single/single lines but it is not limited to just this: you can also have single- and

three-phase lines in output simultaneously or two or more single-phase lines also of different powers,

(on request)

{And then, for each configuration it is possible to obtain re-

0.99 - High Yield — High Reliability - Easy

to install and service.

2.2 FEATURES

Redundant modular architecture

Redundant modular architecture is the best way to protect a

company's critical points.

Advantages:

‘There is just one control of the devices powered

= Modular Expandability

Module redundancy

Easy to service

Low running cost

= Compact size

‘ode 5010260200 Rev, March 2008

‘Technologie

Description

24

inotogica

Description

2-2

‘Operating ond Maintenance Menuat

ield

“The UPS units place particular attention on the energy taken from the mains and that supplied to the

user points. High Yield (93%), PFC in Input >0.99, THDI 3%.

‘Advantages:

~ Increasing the yleld means reducing the part of power absorbed by the UPS but not supplied at the

load and transmitted to the environment in the form of heat.

~ Less heat dispersed in the environment means reducing the use of aerating or conditioning systems

on the installation premises.

= PFC in Input means no rephasing costs and consequently no increased rates.

= Noneed to oversize a generator (if used) upstieam from the UPS.

Expandability

The majority of UPS units on the market is neither modular nor expandable and therefore i

sizing of the system Is necessary to ensure future expansions (which might not even happen).

‘Advantages:

~ Themodular and expandable UPS systemsallow optimisation ofthe investments made in UPS units,

adapting them to actual requirements without preventing future expansions and avoiding an un-

necessary waste of energy.

~ System yield is increased thanks to correct sizing.

Reliability

To have a redundancy level with traditional UPS units itis necessary to put at least

oubling the power bought, the space taken up and the electricity consumed.

Instead this UPS's modular architecture allows redundant configurations inside Just ane single cabi-

net,

‘Advantages:

~ AUPS with a modular cedundant architecture can be configured as an N#X system redundant in

power; even in the case ofa failing module the equipment carries on working and there is no stop.

in work,

~ Clear indications and a large display speed up troubleshooting,

~ The madular architecture makes short work of repairing a failure by simply replacing the module in

question without interrupting service,

~ high resolution percentage of failures at the frst assistance intervention.

in paral, thus

Power module

‘The basic module, available in three power sizes, 2,700 VA, 3,400 VA and 5,000 VA, is basicaly made

Up of the following functional blocks: command and control logic (microprocessor controlled), rect

fier/PFCr, inverter, Booster, battery charger, automatic bypass.

‘The power unit is the Plug & Play type to facilitate power expansion and all maintenance works. Each

‘module is paralleled with other identical ones until the UPS power is reached.

The power modules are separate from each other and can work even if one malfunctions. A LED on

the front of the module, witha traffic-light code, quickly shows the operating state of the electronic

unit.

Battery box

The battery modules are designed for easy insertion in the cabinet with no work needed to connect

them; they are easy to handle thanks to thelr light weight, likewise any maintenance or replacing.

Aboxholds 5 12V, 7.2 Ahor9 Ah batteries connected in series and, thanks to the Plug & Piay connection

can be easily pulled out and put inside the cabinet. In order to guarantee maximum safety, especially

during maintenance, the voltage of each box is adequately disconnected into two 24 and 36V branches

and restored only when the box is placed right inside its housing.

‘This conforms to the CEIEN 60950 standard on electrical safety which establishes that adequate safe-

guards must be used and particular attention where there are dangerous voltages higher than 50 Vee

with the possibility of direct contact.

code 5040260300 Ree. March 2009

Operating and Mointensnce Manuel

‘Autonomy can be increased further still by adding other battery ‘boxes’ in multiples of four, exploiting

the space inside the UPS and the space in the additional ‘modular cabinets:

Digital display and displaying alarms

UpSis controlled by a microprocessor and has a backlit alphanumerical liquid crystal display (LCD) with

20 characters on 4 lines bull into the front of the UPS where there also a highly luminous operating

Status indicator which, by means ofa trafficlight code, indicates the operating status and any alarm

conditions.

Four simple push buttons near the

eters, analyse the state of each single power module, select the languagein whi

and execute a set of functional tests.

play allow the user to: see operating data, set operating param-

hto seethe messages

2.3 MODELS

JC

Ax ISK 7.8m

22 xB x SAN}

ee

ee

ca

[(_

BRIS 7,280)

‘Bax(sx San)

4x15x7.20n)

‘ox fex Sam

UPS 8/10

«code 5040260300 Rev. March 2008

‘Technological

‘Deseription

2-3.

reg.» 5)

CUVEE XS)

(nersoits

CoCo

Coico

fat

OD;

UPS 16/20

=

‘elelebhal.

SS)

UPS 30

‘Operating and Maintenance Monual

ees |S |,

Technological

Degetipion

255

‘ode 5040260300 fev. March 2009 d

Technological

Description

WiCH

=

Conc

icy

I I

ic

ic

iC)

[oo]

UPS BATTERY

de 5040260300 er. March 2009

(CI

Operating ord Matntonance Manuat

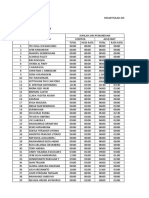

2.4 TECHNICAL SPECIFICATIONS

‘UPS: ‘UPS UPS ‘UPS ‘UPS: UPS ups |

| a _| to | se | 20 | ao | as | ‘00

Rated power | BRWA_| TORVA] Te RVR | ZOWA | BORVA | ASRVA | CORA

Active power [sa nw skw i2exw] TORW|-24kW [96 RW | 4 kW

Technology ‘On ing ddl conversion = NEC 62040-3- VFI 111-5

Sing? Single = Single 7H

are Tay Sio- That wart

(canbocortigure by usr)

Moduler with 2700 VA 400 VAT SO00VA powar mouwes

ooo housed in ashgle cabinet

pee ee Expendable, Redundant N+X

____(excop for bP 30KVA ondUPs GOKVA)

UPS | UPS]_UPs Ws] urs] ups

va _8 10 16 30 45 60

[Maximum current z

tivee-mnaso- | 149A] 185A| 206A | 97a | 5554 | 0320 | 1110

Threo-phose)

Maxim curent

reo pnase- 49a | iesa| 26a] ara] - | - | -

Single-phase) a

Maxima curent

Ginge-pese- | aaa} sssa| ossal ana) - | -

Three-phase) oe

Moxa curant

|(Single-phase- 44.48 | 555A | BBA | 111A a - -

Single-phase)

BOW 16% BOK [400 V HIG 20% | ADO V FIN =20%

Imput voltage (Neutral line is essential) (Neutral jine is essential)

[TD Taputeurent a

Powe arent Sods

Input frequency Poe BOFz/ 60 Hz

UPS” | UPS Ups | UPS | UPS | UPS | UPS

Oureue a 40 1G 20 30 45 60.

Weaximan carent |

(Tvoeprase- | 11.50} 1440] 23.10. 20.00 | 49.40.0652 | 06.95 A

yr

(Tveeprase- |sa70afasasaloosralessen| - | - | -

Single-phase) cae

Maxima currant

fsingepnase- | 11.59a] 149A] 2at0a]2econ) - | - |.

‘Tvee-phaee) Baee|

Maxim curent

(Singephase- |3478A| 4a4aalovsralecoea| - | - | -

Single-phase)

iit aia 250V E 1% (Singh Phase} FOOW 7% (THT Phasey

[Output voltage 400 V 41% (Tri Phase)

Stas loan of a

pulpal vllage:

fOulputTrequeng So RETOO Fz sypeivonzed

Wave shape | Sinusoidal

Mains afionay

(AGIAG on line) bitadbesd _

Mains eicioney

(ACIAC eco modo) | —__ adidas

oleated oveioad TZ or 100 aoe 150M par BOSSE

Toctnoages

eepion

2-8 code 54026000 Res Moh 09

‘Operating and Maintenance Manual

Ups | “UPS

_ BATTERIES i nt

‘Types of batieries: leadbattedes |

‘Autonomy

ateosatine od : See tab. 9 (Long autonomies)

“Toleraied overload 125% per 100 sec - 150% per 30 seo a

ups | Ups | ups | ups | UPS | UPS | UPS

accessories | UP [Ebtne ti fein tea ee [east tos

a ‘Automatic (static and électromechanical)

Bypa ‘Manual (for maintenance)

Signal ond sims | "#08 aphanarora! deplay wih 4 Ines, mlteslord status neato,

Communieatce: ‘Two RS 232 ports, 1 relay Interface, 1 contact port

ports

Electronic against overloads, short-circuits and excessive battery

sischarging. Functions blocks if autonomy ends. Powering surge limiter

Protections E.P.O, contact (total shutdown in an emergency)

INOUT mains peepee

connection Terminal board

I

‘Net weight UPS

hithout batteries) 110 Kg 130 Kg 154g | 1859 | 212K9

Dimensions UPS

MEE HED (414% 1345 x 628) (414 x 1880 x 628)

270OVA Power 5 7 ; 7 7 :

‘modules installed i

‘3400VA Power 7 3 i 7 7 z

modules installed

'5000VA Power 7 = 5 2

modules installed i: =

2T00VA-3400VA-

‘S000VA Power Kg

modules Net weight | —_

7.2Ah - 9Ah Battery

‘drawing Net Weight 14 Kg

ENVIRONMENTAL | UPS | UPS | UPS | UPS ] UPS | UPS | UPS

CONDITIONS, 8 10 16 20, 30 45 80

Operating ne naet

temperature | eee

Relative humidity 20% 10-80% non-condensing

Noise level at im 42.10 46 dBA

Grado of 1P20 (IEC529)

protection

UPS Ups | UPS | UPS | UPS

_ STANDARDS 7 ae 7 i ni

Noms EN 50001-2, EN 620463

Techactogical

Deseripion

2-9

‘ode 5040260300 Re. Moreh 2008

Description

2-10

Operating and Maintonance Manual

2.5 COMMUNICATION DEVICES

The uninterrupted power supplies of the UPS family have 2 RS 232 serial ports, 1 relay interface and 1

output on a 9-pole male tray-shaped connector, logic level SELV. insulated,

2.5.1 RS232 serial ports

The first of the two RS232 serial ports used on the uninterrupted power supply unit and called ‘main-

tenance interface’ is located at the top behind the front door. It is dedicated exclusively to diagnostic

functions and updating machine firmware.

‘The second, called ‘user interface, is at the top at the back of the UPS. Thanks to this port that, with

either a computer or specific network card, itis possible to access UPS operating data and to control

the unattended turning off of the operating system,

2.5.2 Relay interface

‘The default setting of the relay interface contacts is Normally Open (NO) but can be configured as

Normally Closed (NC) via the UPS display.

‘The technical specifications of the relay interface contacts are the following:

# lay 2 5A

+ Vyqr® 250VAC- 30VDC

The indications available with this interface are the following:

Pia Tundtion

2 Running on bate

4 ‘Autonomy Reserve

=6 Generic alm

5 ‘Overload

For contact numbering:

TBE logiciel

stlport one Dey Contactinterface

5678

it]

S$ B- 10-16-20 -30

o@Jesiaa00

UPS 45 - 60

[oe

‘xe 5040260300 ev, March 2009,

COporating and Maintenance Menual

2.5.3 Logic level interface

UPS 8-10- 16-20-30

Logic level interface is available on the male D89 connector; itis used to connect the UPS to a remote

system for monitoring its operating status. The following indications are available with it:

+ Mains/battery run;

+ UPS failure;

+ Overload;

+ Autonomy reserve

‘The functions of the interface pins a

+ Pin 1: Input ON/OFF (Maximum voltage +15Y, equivalent to the ON/OFF’ key on the panel)

+ Pin 5:GND (common);

+ Pin 6: UPS failure output (Open Collector ~ active low}

+ Pin 7: UPS on autonomy reserve output (Open Collector active lows

+ Pin 8: GND (common);

+ Pin 9: UPS on battery output (Open Collector - active low).

UPS 45-60

‘The interface at logic levels is available on connector DBI.

Itallows the UPS to be connected to a remote system s0 as to monitor its operating status and pro-

vides the following signals:

+ Mains/battery operation;

+ UPS fault:

+ Overload;

+ Autonomy reserve.

‘The functions of the interface pins are:

+ Pin 1:GND (common);

in 2: Mains / Battery (active high};

+ Pin 3: Autonomy reserve (active high);

+ Pin 4: 85232 Voltage;

+ Pin 5: ON/OFF input (Vmax = +15V, equivalent to the “ON/OFF* key on the panel}:

+ Pin 12: Mains / Battery (active low);

+ Pin 14: Autonomy reserve (active low);

+ Pin 15:Alacm,

ode 5090260300 fe. March 2009,

rchnological

‘Description

2-11

Operating and Maintenance Manual

2.5.4 Communication slot

In the rear part of UPS an SNMP Slot is available for SNMP Adapter (Optional)

Tacheciogical

Pescriation

212

cde 5040260300 Re. March 2009

‘Oporating and Maintenance Menval

3. Safety Provisions

3.1 GENERAL NOTES

A

WARNING

Before doing any operation on the equipment, it is necessary to read through the whole manual

‘carefully, paying attentlon to this chapter In particular,

‘The equipment has been built for the application specified in the declaration of conformity enclosed

with this manual

For no reason whatsoever itis allowed to use it for purposes other than those for which it has been

designed, nor in ways different to those explained in the manual.

“The various interventions must be carried out following the criteria and chronology described in this

manual.

3.2 SYMBOLS

In this manual some operations are highlighted by graphical symbols that call the attention of the

reader to the dangerousness of the operations. The graphics are as follows:

A

WARNING

“This means the possibility of an event happening that could lead to serious injury or great

‘damage to the equipment ifadequate precautions arenot taken.

A

ATTENTION

‘This means the possibility of an event happening that could lead to

slight Injury or material damage if adequate precautions are not taken.

INDICATION

This means important information thot must be read paying maximum attention.

3.3. REFERENCE STANDARDS

EN 62040-1-2

PART 1: general provisions and safety recommendations for the UPS

EN 50091-2 EN62040-2

PART 2: EMC provisions

EN 50272-2: Safety provisions for accumulator batteries and their installation

code 5040260800 Ren March 2009

Safely Provisions

3-1

Say Provisions

3-2

Operating and Malntonance Manual

3.4 DEFINITIONS OF ‘OPERATOR’ AND’SPECIALIZED TECHNICIAN’

The professional figure that is going to access the equipment for normal use is defined by the term

‘operator.

With this definition we mean personnel who know how to use and service the equipment and have

‘the following requirements:

1 specific training that authorises them to work according to the safety standards in relation to the

dangers that the presence of electricity can bring about.

/e Devices and on the basic first aid interventions.

2. tralning on how to use the Individual Protes

When the company personin charge of safety chooses the operator whois to use the equipment who

‘must be suitable for work in accordance with the existing laws — he must consider the physical aspect

(no impairment), the psychological aspect (mental equilibrium, sense of responsibility) and personal

education, training, experience and knowledge of the standards, prescriptions and provisions for the

prevention of accidents.

Based on the skill and capacity found, he shall also see to the operator's training in order to give him

full knowledge of the equipment and of the parts itis made of.

To conclude, the operator must be made aware of the contents of this manual.

3.4.1 Qualification required to the operator

“The operator must follow the Instructions given to ensure maximum safety for himself and for the oth-

ers. In particular he must comply with all the requirements contained in this manual throughout

all the operating phases.

‘Typical activities envisaged:

~ using the equipment when itis working normally and resetting subsequent to a stop;

~ taking the necessary measures to maintain performance quality;

= cleaning the equipment

= collaborating with personnel who aretosee to extraordinary m

cian),

wtenance work('specialized techni-

3.4.2. Qualification required to the specialized technician

The professional person who has to look after installation, starting and extraordinary maintenance is,

defined by the term ‘specialized technician’

With such a definition we mean people with knowledge of the procedures for installing, assembling,

repairing and servicing the equipment and who have specific technical qualification.

Besides the requirements listed for a generic operator, the specialized technician must have had

‘echnical training or specific training for the procedures needed to use and service the equipment in

complete safety.

Broadly speaking, the specialized technician will be a person selected among the professional people

in the department and who has proven experience and capacities and specific technical expertise in

relation to the type of work to be done.

code 5040260300 Re. March 2009

Operating and Maintenance Manual

A

WARNING

‘The person in charge of safety is responsible for the protection against and prevention of company

risks In accordance with the European Directive 89/391 EEC (safety at the work place), In ITALY itis

part of the Law Decree dated 12/11/1994. The person in charge of safety must ensure thatall people

working on themachine havereceived all the relevant instructions of this manual, included start-up

and commissioning, and with particular reference to the contents of this chapter,

3.5. INDIVIDUAL PROTECTIVE GEAR

WARNING

‘There Is a high risk of electrical shock with the equipment as woll as a considerable short circuit

current. When using and servicing the equipment itis absolutely forbidden to work without the

protective gear mentioned in this paragraph.

The personnel who are going to work and/or transit near the equipment must not wear clothes with

baggy sleeves or laces, belts, bracelets or other metal items that could be a hazard source.

3.5.1 Gear to wear

‘The following indications summarise the protective gear to wear.

inforced toe

‘Accident and spark proof footwear with rubber sole and

Use: always

Ce

Waterproof rubber gloves

Use: always,

Protective glasses

Use: always

@o

Safely Provisions

3-3

«oe 5040260300 Rev March 2008

Safety Provisions

3-4

‘Operating and Maintenance Manual

3.6 INDICATIONS OF DANGER IN THE WORK PLACE

The following signs must be placed in all points of access to the premises where the equipment is

installed,

Electric current

Itindicates the presence of live parts.

Emergency interventions

Donot use water to extinguish fie but only the extinguishers designed specifically 4

for putting fires out on electronic equipment.

No smoking

This indication explains that itis forbidden to smoke in the area where the sign is

affixed.

3.6.1 Indications on board the equipment

The explanatory plates on the equipment can vary according to the country of destination and to the

relative applicable construction laws.

Strictly comply with what is required. It Is strictly forbidden to remove these plates or to work in a way

different from what is indicated on them.

Allthe data on the plates must always be readable and cleaned periodically,

Ifa plate is ruined and/or is no longer legible, even only in part, ask for a new one from the Manufac-

turer who is bound to supply a substitute,

WARNING

‘The plates must be neither removed nor covered: it Is forbidden to affix others on the equipment

without the prior written authorisation from the Manufacturer.

3.7 RESIDUAL RISKS

‘Reesidual'tisks are risks that were impossible to eliminate at the design phase and, as such, are poten-

tially present on the equipment.

‘These risks are found with a specific analysis as prescribed by the standards of the sector,

‘The documentation relative to the analysis is included in the Technical File of the machine filed by the

Manufacturer.

In the case of the UPS there are no residual risks provided that all the indications and provisions in this

‘manval are scrupulously complied with.

«code 5040260300 ey, March 2009,

‘Oporating and Maintonanco Menual

A

WARNING

The risk can be drastically reduced by wearing the Individual Protec-

tive Gear listed In thls chapter, considered indispensable. Always work with due

cauition when near the dangerous ereas Indicated by the signs on board the equipment.

3.8 GENERALWARNINGS

AN

ATTENTION.

‘The equipment generates, uses and can radiate energy and radio frequencies

not installed and used in agreement with the indications given in this manual, Itcan interfere with

radio communications.

= The equipment must be kept and used in accordance with the instructions given herein and as

suggested from time to time,

= The department manager must instruct the operating and maintenance personnel on how to use

and service the equipment in complete safety.

= Only specialized and specifically Instructed personnel must be allowed to access the equipment for

‘maintenance work.

All the time such maintenance work is being done, ‘Work underway’ signs must be affixed in the

department that can be seen from all access points.

~ Connection of the equipment (and of any accessory devices) must include standard earthing to

discharge short circuit current and electrostatic voltages. Mains voltage must correspond to the

value on the ID plate. Use of current adapters is not allowed. When connecting pay attention to

polarities.

= Any work on the equipment must be done only after it has been disconnected from the supply

mains via the switch which must be padlocked.

~ When the equipment is received, or prior to switching on each time, DO NOT switch the UPS on if

the batteries are leaking,

~ Tools used for maintenance (pliers, screwdrivers, etc.) must be the electrically insulated type.

Itis strictly forbidden to deposit combustible materials near the equipment. It must always be kept

locked and access allowed only to specifically trained personnel.

Do not deactivate the safety devices or delude the indications, alarms end warnings, whether they

are communicated automatically of by means of plates on the installation.

Do not turn the machine on without the fixed protections in place (panels, etc).

‘oe 5040260300 Re. March 2008

Safely Provisions

3-5

Salaty Provisions

3-6

Operating and Maintenance Menual

~ In the case of breakages, deformation or malfunctions of the equipment or parts of It, repair or

replace immediately, avoiding ‘emergency’ repairs.

~ Itis not allowed. for any reason, to modify, manipulate or in any way alter the structure of the

equipment, the devices mounted on it, operating sequence, etc, without having fst consulted the

Manufacturer.

~ the fuses have to be changed, always and only use ones of the same type.

~ Changing the batteries is a job for a specialized technician. Bear in mind that the electrolyte can

cause irreparable injury to skin, mucous membranes, and eyes and is toxic iFinhaled or swallowed,

Always work with the most suitable Individual Protective Gear, Do not forget that the batteries must

be disposed of according to the laves existing in the country where the equipment is installed as

they are toxic waste. Under no circumstances can a battery be burnt as it would cause an explo-

siont

~ All maintenance work, routine and extraordinary, must be recorded in a register, noting the date,

time, type of job, name of the operator and all useful information. If necessary use the pages added

at the end of the Maintenance’ chapter.

~ Do not use olls or chemicals to clean with as they can corrode or damage parts of the equipment,

~ Both the equipment and the work place must be kept perfectly clean,

~ When maintenance i finished check carefully that no tools and/or materials have been leftnear the

equipment before turning the electricity back on.

3.9 EMERGENCY INTERVENTIONS.

The following information is of a general nature. For specific interventions please consult the laws

existing in the country where the equipment is installed.

3.9.1 First aid interventions

If any first aid intervention is required, comply with company rules and traditional procedures.

3.9.2 Fire-prevention measures

~ Donot use water to extinguish fire but only the extinguishers designed specifically for putting fires,

‘out on electronic equipment.

code 5010260300 Rex March 2009

ee

4. Unpacking

4.1 VISUAL INSPECTION

When the UPSisdelivered, examine the packaging and product j

carefully to see if any damage was done during transport. In

particular check the Integrity of the indicator on the external

‘Shock Watch’ label, ]

(2

le or ascertained damage is found report it Im-

Ifetther pos

mediately to:

~ the cartier;

= the Manufacturer Technical Assistance Centre.

‘Make sure that the unit received corresponds to the material

specified on the delivery document.

‘The UPS packaging protects the equipment againstmechanical

and environmental damages.

For greater protection it Is also wrapped in a transparent

film,

4.1.1 Checking the equipment and accessories supplied

“The equipment and relative accessories supplied (as agreed with the manufacturer) must be in perfect

condition.

Before itis shipped the equipment is checked carefully; however, itis always advisable to check itis

complete and in order when receiving it.

‘Make sure that:

= The shipping data (consignee's address, number of packs, order number, etc) are the same as those

written on the accompanying documents;

= The technicaltegal documentation that comes with the equipment includes the user manual for

the specific type of UPS to install together with the CE Declaration of Conformity.

In the case of defects and/or material missing, send a report immediately to the Manufacturer

and wait for 1ns before commissioning the equipment.

4.2 UNPACKING

‘Yo remove the packing material observes the ‘ARROW’ on the outside box.

‘To remove the UPS from the packaging follow these steps:

1 cut the wrapping and open the plastic safety straps:

Unpacking

4-1

«ode 5040260300 Rev March 2009

Unpacking

4-2

Operating and Mointenance Manual

‘open the top of the cardboard box;

remove the top protection

remove the four corner protections;

remove the packaging container, pulling it

upwards;

removethepalletand front/rear bracketfrom

the UPS, loosening the 4 securing screws;

7 inspect the UPS to see if it has been dam-

aged in any way. Notify the carrier and

supplierimmediatelyifanyapparentdamage

is found.

Keep the packaging material in case the UPS

has to be shipped in the future.

‘The packaging materials are 100% recyclable;

if you want to dispose of them please comply

with the existing laws,

4.3 CHECKING THE CONTENTS OF THE PACK.

Below is a list of the materials supplied. The list is general. Please refer to the packing lst for shipment

details.

UPS INVERTER

= No.1 UPS unit;

+ No. 1 bag of accessories with a set of screws for installing the unit correctly;

+ No.1 front closing panel;

~ No.2 base strips for side closing;

= Operating and maintenance manual

= International guarantee.

UPS BATTERY

~ No, TUPS BATTERY cabinet;

= Operating and maintenance manual

+ No. 1 multicore cable for connecting to the UPS inverter;

~ No. 1 bag containing fuses and keys for the front door.

UPS BATTERY/2

= No.1 UPS BATTERY/2 cabinet;

+ Operating and maintenance manual

+ No. 2 multicore cables for connecting to the UPS inverter;

+ No. 1 bag containing fuses and keys for the front door.

‘Check that the UPS technical data on the plate on the sticker affixed on the inside panel of the door, in

side the hatch of the UPS, correspond to the material bought, described on the delivery document.

4.4 STORING

4.4.1 UPS

{f the UPS is going to be stored prior to installation, regardless of whether or not its still packed, it

‘must be on dry, clean and fresh premises where the ambient temperature Is between O°C and +50°C

(62-12%) and with humidity below 0% (not condensing)

code 5040260300 Rev. March 2009

Operating and Maintenance Manual |

4.4.2 Batteries

‘The standard batteries of the UPS are sealed lead-acid, they are maintenance-free and installed inter-

rally.

Lead is a dangerous substance for the environment

is not recycled by specialized companies.

If the batteries are not charged they cannot be kept for more than 6 months at 20°C (68°F) oF more

than 3 months at 30°C (86°F] or more than 2 months at 35°C (95°F).

ATTENTION: sealed batteries must never be stored if they are partly or totally flat

‘To charge the batteries before and after storing simply connect the input power supply to the UPS,

plug in the mains fuses (FL1, F L2 and FL3) and those of the battery (F B+ and F B-) and the bridge in

the neutral switch and then close the switches,

When the unit detects the input voltage it automatically proposes starting a battery charging cycle.

After about 1 minute charging starts automatically an the time left to finish charging is shown on the

display. The charging cycle can be stopped at any time by pressing the‘ESC’ key.

If the UPS is delivered without batteries, the Manufacturer is not liable for any damage or bad opera:

tion caused to it by an incorrect wiring of the batteries.

4.5 HANDLING

A

WARNING

Handle with great care lifting itonly to the extent necessary, keep it well balanced and avold swing-

ing which could be dangerous.

If it weighs less than 30 kg (check on the transport document) the equipment can be moved around

by hand as it has two wheels,

Do not forget that the equipment must always be handled by trained personnel, equipped with the

Individual Protective Gear as specified in Chapter 3.

Ifthe equipment needs to be lifted, use a forklift truck or transpallet of a suitable capacity, inserting

the forks in the wooden base, making sure they come through on the opposite side by at least twenty

centimetres.

4.6 POSITIONING

‘The UPS must be placed observing the following conditions:

= humidity and temperature must be withia the prescribed limits;

- the fire protection regulations must be observed;

~ wiring must be of easy execution;

the front and rear must be accessible for assistance or routine maintenance;

> the flow of cooling air must be guaranteed;

the air conditioned system must be adequately sized

+ there must be no corrosive/explosive gases;

Ecode 5040260300 Rex March 2008

Unpacking

43

Unpacking

4-4

Operating and Molntenance Manual

= the premises must be free from vibrations;

+ the clearance at the back and sides must guarantee adequate circulation of the cooling ait.

x

Y

io

‘Minimumn clearances recommended forthe UPS

X=100mm//Y=200 men

‘Minimum clearances recommended forthe UPS + UPS BATTERY

2100 m1m/¥=200 mm

|

|

£

Bear in mind that the average life of the batteries is strongly influenced by the environmental operat-

ing temperature.

Place the unit on premises where the temperature ranges between +18°C (64.4°F) and 423°C (73.4°F)

‘hich will guarantee a very long battery life.

Before commencing installation, make sure there is enough lighting on the equipment so that each

single detail can be seen easily.

Use artifical lighting if natural lighting is not enough for the aforementioned requirements

I maintenance work has to be done on parts that are insufficiently illuminated, itis compulsory to

Use portable lighting, being careful not to create shadows that will prevent or reduce visibility on the

point you ere working on or on the surrounding areas.

4.7 LAST OPERATIONS

‘Once positioned correctly fit the two side basestrips

and the front one supplied in the accessory kit.

code 5010260300 March 2009

operating and Mointonance Monual

5. Installation

AN

(WARNING

‘The Instructions in this chapter are not addressed to a normal operator but to a specialized techni-

cian, authorised to work only if he uses the Individual Protective Gear mentioned in Chapter 3.

5.1 SAFETY RULES AND REGULATIONS

Before starting installation please read and apply the following:

1 Itisnecessary to ensure that the distribution panel, to which the UPS is going to be connected, has

a proper connection to the earth circuit and adequate protection, as required by law.

2 The mains supply panel or disconnecting device, must be installed near the equipment and easy to

access.

WARNING

‘The uninterrupted power supply units of the UPS family DO NOT have the Back Feed Protection

circuit. For this reason:

1. only the fixed type of the UPS units must be installed with a thermal circuit breaker upstream.

Connection of the unit to the mains using a traditional plug is not allowed,

2.A warning label must be affixed on all mains supply isolating switches installed far away from the.

UPS area to remind assistance personnel that the circut is connected to a UPS. The label must give

the following message (or the equivalent):

ISOLATE THE UPS UNIT BEFORE WORKING ON THIS CIRCUIT!

+ Since the dispersion currents to earth of all the loads are summed together In the earth wire of the UPS,

{for safety reasons and in accordance with the EN 620400 1 1 standard, you must make certain that the

um of these currents does not exceed 2.7 mA.

5.2 ELECTRICAL CONNECTIONS

The electrical connection of the UPS to the switchboard is part of theinstallation and is usually done by

the user and not by the UPS manufacturer; therefore the following indications are purely an example

and the actual electrical connections must be done in accordance with local standards.

‘Once the UPS has been removed from the packaging and positioned in its final place of installation,

the authorised technician can start its installation

«ode 5040260300 Rev Motch 2008

Instataion

5-2

‘Operating and Maintenance Manu!

5.2.1 Safety recommendations

A

WARNING

19 please read and apply the following with attention, It is strictly forbidden to proceed

with installation if one or more of the following conditions have not been checked.

1. Do not proceed with installation i there is water oF moisture.

2. Remember that opening or removing the panels from the UPS you

gerous voltages.

3. Check there is no mains voltage on the equipment.

4. Check that the loads are off and disconnected from the UPS;

5. Check that the UPSis off and not lve.

exposure to high and dan-

Allthe electrical connection operations are done working on the distribution box.

‘he fuse carriers, output switch and manual bypass switch are on the outside of the box while inside

‘you will find the terminal block on which to do the connectic

5.2.2 Preliminary operations

Before connecting the UPS make sure that:

1 mains voltage (volt V in input) and frequency correspond to the values on the UPS rating plate;

earthing complies with the 1EC standards (International Electronic Commission) of local regula-

tions;

3 the electrical systom is equipped with all the necessary diferential protections and thermal circuit

breakers upstream from the UPS input.

5.2.3 Connecting the loads

Before actually starting to connect the loads make sure the rated power of the UPS (OUTPUT POWER)

Indicated on its rating plate is equivalent to or greater than the total sum of the load powers,

INDICATION

The loads wiring diagram isn the DIAGRAMS chapter.

‘The characteristics of the output cables must conform to the sections of the cables indicated in table

5 of the TABLES chapter,

A separate switchboard must be supplied for the load. It is @ good idea to use isolating switches or

thermal circuit breakers conforming to the IEC standards to protect the lines leading from the elect

cal panel.

Use adhesive labels or some similar way to indicate the following values on the system's general

panel:

~ maximum rated power of the total load;

~ maximum rated power of the load at power intakes.

ode 5040260300 Re harh 2009,

‘Operating and Maintenance Menus

if an ordinary switchboard Is used (outlets for mains voltage and for the UPS), make certain that

there is an indication of the voltage applied on each outlet ( Mains’ or'UPS').

5.2.4 Emergency Power Off (Remote E.P.O,)

In accordance with the standards, the UPS is fitted with an emergency device that uses a normally

closed contact (already installed on the UPS) that can be opened to activate the emergency machine

power off. The E.RO. terminals are on the right of the terminal block inside the distribution box.

‘To connect the emergency power off device please follow these instructions:

= use a cable with double insulation;

= connect the cables as shown in the following figure.

ae

a2

Emeagency Power Off Switch (NC=Normally Closed)

E.P.O.

5.2.5 Installing the UPS BATTERY

It is possible to connect external battery units to increase UPS autonomy.

If the configuration uses more than one battery It is necessary to position all the UPS BATTERY units

‘on the same side of the UPS and connect them in cascade with each other using the multicore cables

supplied.

‘There are two different external battery cabinets for the UPS BATTERY units:

= a modular model consisting of a cabinet with an internal structure that uses battery boxes for up

toa maximum of 80 12V 7.2Ah or 12V 98h batteries (16 boxes).

~ a moduiar model consisting of a cabinet with an internal structure that uses battery boxes for up

to2 maximum of 100 12V 7.2Ah or 12V 9Ah batteries (20 boxes).

~ compact, non modular, economical model that uses a shelf architecture instead and on which the

batteries are placed. Itcan house 60 of 120 12V 7.2Ah or 12V 9Ah batteries.

.clure instead and on which the

= acompact, non modular, economical model that uses a shelf arc

batteries are placed. It can house 20 12V 94h batteries.

AUPS BATTERY can be connected to several UPS units.

«ode 5040260300 Re Match 2009

Inslaaton

5-3

Instataion

5-4

Operating and Molntenance Menuet

AN

WARNING

‘The following instructions are of a prescriptive nature and itis imperative they be complied with.

‘Opening or removing the panels from the UPS or UPS BATTERY you risk exposure to high and

dangerous voltages! To guarantee protection of personnel during Installation of the UPS BATTERY

‘make sure that the connections are done under the following conditions:

1. there must be no mains voltage

2, the loads are off and disconnected;

3. the UPS is off with no voltage and all fuse carrier isolating switches on the UPS and UPS BATTERY

are open.

‘To ensure that the UPS has stopped completely if you want to add a UPS BATTERY in an exi

lation, follow the steps illustrated in the MAINTENANCE chapter,

ing instal-

The connection of a UPS BATTERY to the UPS must be done according to the following diagram and

the steps listed below:

UPS BATTERY UPS BATTERY ups:

1. make sure that all the battery fuse carrier isolating switches are open;

2. connect the UPS and the additional battery cabinet using the earth cable (yellow-green);

3. use the wiring supplied with the UPS BATTERY to connect the positive and negative terminals of

the UPS to those of the UPS BATTERY,

‘ode 5040260300 Re, March 2009

Operating and Maintenance Manual

My

1

ft

I

ft

ae.

i)

isi

I

PE Ae]

eI BEE __- AAD

UPS 45 - 60

‘The connection of a UPS BATTERY to the UPS 45 - 60 must be done accoring to the diagram above

and the steps listed below:

1, make sure that all the battery fuse cartier isolating switches are open;

2.im each UPS BATTERY remove the lower front panel;

3. in each UPS BATTERY remove the terminal block loosening the 2 securing screws;

‘ee 5040260500 Rev Morch 2009,

{astalaton

5-5

5-6

Operating and Maintenance Manual

4. connect the UPS and the additional battery cabinet using the earth cable (yellow-green;

5. use the witings supplied with the UPS BATTERY to connect the positive and negative

terminals of the UPS to those of the UPS BATTERY,

A

WARNING

‘The connection of a UPS BATTERY to the UPS 45 must be done using

BOTH wirings supplied with the UPS BATTERY

The connection of a UPS BATTERY to the UPS 60 must be done using

BOTH witings supplied with the UPS BATTERY

6. in each UPS BATTERY insert the terminal block securing it with the 2 screws provided:

7. in each UPS BATTERY secure the lower front panel.

«ode 5040260300 fev. March 2009

Operating and Maintenance Manual

5.2.6 Protections

To ensure correct operation ofthe UPS and its accessories the electrical system must be adequately

protected. Automatic differential switches and thermal circuit breakers are typically used, connected

Eetween the mains supply and the UPS with the purpose of providing additional protection in the

event of overloads or short circuits.

INDICATION

Table 4, tn the TABLES chapter gives Information about the thermal clcut breakers.

5.2.7 Earthing

Connect the earth wire leading from the low voltage switchboard pane! to the EARTH terminal on the

UPS terminal block.

INDICATION

The iting diagrams are given in the DIAGRAMS chapter.

5.2.8 Connecting the power supply

For safety reasons, connection ofthe power supply must be the last thing to be done.

Before connecting the power supply cables with input make sure that the maintenance by-pass S1

is open in the OFF position and arrange fuses and jumpers on the terminal block according to the

required input-output configuration.

INDICATION

Tables 1 to 5, in the TABLES chapter, gives Information about sizing cables, fuses, cicult breakers and diferen:

tas,

‘The default configuration for the UPS units distributed by the Manufacturer is a THREE-PHASE

INPUT and a THREE-PHASE OUTPUT.

r

ray

!

{I

19 this type of distribution, the fuses and jumpers are already correctly sized and.

code 5040250300 Rew Merch 2009

5-7

Installation

5-8

ing and Malntonance Manual

For different configurations please consult the following chapter and wiring diagrams in the

DIAGRAMS chapter.

Connect the power cable leading from the low voltage switchboard to the UPS terminals as lustrated

in the previous figure (or in the wiring diagram for the type of connection used), taking care to observe

the cyclic direction of the phases (R,§,T).

WARNING

Theneutral canductor cable in input must ALWAYS be connected!

UPS could be seriously damaged when powered by the mains.

Ifthe neutral Isnot connected the

5.2.9 Wiring

‘The UPS has holes in the base for putting cables through if they are coming from underneath.

ferent diam-

It also has a pre-punched metal plate at the back arranged for inserting fairleads of

eters,

The falrleads are supplied in the accessories kit.

The plate is fixed to the UPS with four screws.

5.3 WIRING DIAGRAMS

The electrical configuration can be set up either on the operator panel or on the terminal block of the

distribution box, located inside at the bottom of the front door.

To access the distribution terminal block you have to loosen the box locking screws and pull

AN

WARNING

Af the factory set configuration is changed (see paragraph 5.2.8) the new configuration must be set

correctly via the instrument panel as described in paragraph 6.4.

out

code 5040260200 ev. March 2009,

operating end Maintenance Manual

5.3.1. Factory set configuration: THREE-PHASE input, THREE-PHASE output

“The UPS is dispatched with the connections as per the following diagram. To useit with this configura

tion no Interventions are required. We do however suggest that you check beforehand that the wi

in input, output and the connection of the modular terminals is correct.

@RSBS[ an ea h

ul MESS | oor: Z )

i mss | seco 4 C)

i ~ |

DOT GTO G OG

pelea ie

ODO D1D)

EPP === |=] a | Ta

mas

_—

—

ee SEs ‘NOuT

ef 1

i

Ff mmps[

ms) le

wm | ©

rerncoe [ee ® |

vas le 8 SI [=

anne fe | [=

on TS FOI [-

nner fe Of l=

Orso eg [-

UPS 8- 10-16-20

«oe 5040260300 ev. March 2009

Installation

5-9

Operating and Mointenance Menual

# ES ma [STNG

s eo |e — .

Le] vo (ssn BE

* wu (smog

iy a

cm

ion | SS

SJ

OP Doge

oa

DID DO O!O!l®

wuiosn

tsavo7eu) snaino

anos. SS

8 OC) 4 | sans aauvo« [sg

1 | 3enaaruva-

ses Liea nino

arava wwasRax

oT

oe (SSN

UPS 30

Instataton

5-10 ade 5040260300 Rev. March 2009

{nsallation

5-11

Sa ee

of He} | HHI 3)

Lv 9T| ST vfele T

‘Oo OOK) aoan 7

: | = : Tm ! \ 2

: olo OOOO

‘Operating and Maintanance Manual

8

‘

i

i

Operating and Maintenance Manus!

5.3.2 THREE-PHASE Input, SINGLE-PHASE output connection

For this type of connection, besides the wiring shown in the following figure, the software has to be

configured via the instrument panel as illustrated in paragraph 6.4 STARTING PROCEDURE.

| BSL on Jes

ice “pve

SB OL un

ell ¢

UPS 8 - 10-16-20

AN

ATTENTION

If the UPS is used with a single-phase output (available on all models of the UPS family except for

‘the UPS 30 model) you will have to plug inall the’Back Panel’ cards in the connector supplied in the

accessory kit. the'Back Panel'cardsaralocated inside the machine behind the power modules. There

is only one“Sack Panel’ card in the UPS 8 and 10 models while in the UPS 16 and 20 models there

are two, To access the ‘Back Panel’ cards and insert the connector, simply extract 3 power modules

that are on the same shelf and refer to the following figure. The connector must be inserted in the

Position indicated with EC 15 on the card serigraphy.

To extract the power modules please consult the MAINTENANCE chapter.

u Uf oe

Installation

5-12 ode 5040260800 fev. arch 2009

‘Operating and Maintenance Menval

ee

ee

FS;

Lee

“i

i

®

5} ex war

@ /

®

® }

cams

OMSSEES

SL

Installation

5-13

ede 5040260300 Rev. Meh 2009

(Operating and Maintonance Manual

5.3.3 SINGLE-PHASE input, SINGLE-PHASE output connection

For this type of connection, besides the wiring shawn in the following figure, the software has to be

configured via the instrument panel as illustrated in paragraph 6.4 STARTING PROCEDURE.

|B Smee

fos]es]ex]refor] «

oes

1] unt |S

Rio

Ormlomm gl

@ a

UPS 8-10-16-20

ATTENTION

I the UPS is used with a single-phase output (available on all models of the UPS family except for

the UPS 30 model) you will have to plug in al the’Back Panel’ cards in the connector supplied in the

accessory kit.

Follow the Instructions given in the previous paragraph.

Instatation

5-14 ede s040%40300 Ret March 2009

operating and Maintenance Manual

5.3.4 SINGLE-PHASE input, THREE-PHASE output connection

sor this type of connection, besides the wiring shown in the following igure, the software has to be

configured via the instrument panel a illustrated in paragraph 6.4 STARTING PROCEDURE,

@mas[ = jes [B

= 1 Olle

t mms|om eC) | R

raat

=

j mes SSE

ef mes! oe 62

i mo SF

mes[ eH SE

mes| fe a

i co e xe a

"i me a)

om (8 7

poem fe ae]

ison fy) [=]

aE

Ss a

aa

€

anon

@anss(e" B=

a

UPS 8- 10-16-20

WARNING

in the UPS models 8, 10, 16 and 20, In the case of a single-phase input and three-phase outPut

sDatiguration, the manual by-pass 51 MUST NOT be activated for any reason whatseavar To ini ond

Shetclative switch must be locked in the’OFF? position. For greater safety its possible to deactivate

Urey pacs completely by cutting the brown cable that connects therelativey-pass witch S140 "he

rae eaerapUt fusecarser isolating switch isolating it.To the contrary the cable connecting terminal

B tothe phase fuse carrer Isolating switch MUST remain connected.

code 5040260300 fe. Merch 2009

Instaation

5-15

Inctalaton

5-16

‘Operating and Maintenance Monual

5.3.5 SINGLE-PHASE input connection, no. 3 separate outputs

For this type of connection, besides the wiring shown In the following figure, the software has to be

configured via the instrument panel as illustrated In paragraph 6.4 STARTING PROCEDURE.

»| BS at Jac

7] [RSL ens

2) (Op Sf siren

Jee

ete

&

TIE

=e] ]sin] =|) <6

8 | ea

a

[2] ee

UPS 8-10-16-20

AN

WARNING

In the UPS models 8, 10, 16 and 20, In the case of a single-phase input and three-phase output

‘configuration, the manual by-pass S1 MUST NOT be activated for any reason whatsoever. To this end

the relative switch must be locked in the OFF’ position. For greater safety Its possible to deactivate

theby-pacs completely by cutting the brown eablethat connects therelative by-passswitchS1 tothe

MAING INPUT fuse carrier Isolating switch, isolatingit.To the contrary, the cable connecting terminal

18 to the phase fuse carrier isolating switch MUST remain connected.

code 5040280300 Rex. Morch 2009,

Operating ond Maintonance Monual

Take (rom the packet of acettoros one cote connector and cu In dart get the regu

length. .

Secure the cross-connector to modular terminal with all the provided screws

«ode 5040260300 Rew. March 2009

Inctaliation

5-17

5-18

Screw all cross connectors

Insert the plastic cover

Operating and Mointonance Menus!

‘de sooo ner. er 2009

cs

Operating and Maintenance Manu!

6. Configuration and Start-up

AN

WARNING

‘The instructions glveninthis chapterare not foranordinary operatorbutforaspecialized, authorised

technician only i hes using the Individual Protective Gear specified in chapter 3,

As illustrated in the previous chapter the default configuration for the UPS units entalls a THREE-PHASE

INPUT and a THREE-PHASE OUTPUT.

If this type of connection is used, the equipment requires no additional configuration as it has already

been set in the factory.

‘On the other hand however, ifthe connection is changed please refer to the following instructions.

6.1 INPUT CONFIGURATION

UPS automatically recognises the voltage, frequency and number of phases in input even ifthe electrical

connection on the terminal block is changed, So once the input wiring to the terminal block has been

modified accordingly, no further configuration via the display is necessary.

6.2 OUTPUT CONFIGURATION

‘The UPS does not automatically recognise the electrical configuration on the output terminal block.

‘Therefore, itis ALWAYS necessary to select the load type applied via the display.

“The default configuration for the UPS units is THREE 120" phases, 400 VAC. For powers of 6 to 20 KVA

‘the unit can be configured to obtain just one single-phase output (230 VAC).

If the unit is configured with a three-phase output, itis possible to select management of the three

phases as follows:

- THREE singl outputs: this setting is necessary if three separate single-phase lines were

created at the UPS output, In this case, the UPS manages the three outputs separately one from the

other. For example, if an excessive load is applied to one of the three output lines, the bypass will

intervene only on the overloaded line while power is guaranteed on the other two by the UPS.

= THREE 120° phases: this is the default setting and itis normally used if three-phase loads have been

appliedin output from the UPS (eg. three-phase electrical motors) or f three-phase and single-phase

Toads are being powered by the UPS. In thiscase the UPS manages the three output phases, protecting

the three-phase load, For example, ifan excessive load is applied to one of the three output lines, the

automatic bypass switches all three output ines.

nin

To select the system output configuration correctly on the display follow the instructions

paragraph 6.4

code 5040260300 Rev. Morch 2009,

Contiguraton and

Start,

6-1

—————————————

‘Operating and Maintenance Manus!

{

6.3 CHECKS PRIOR TO SWITCHING ON

Check the following before powering the equipment:

1. Make sure the fuse carrier isolating switches for powering the UPS in the distribution box (F L1, F

Land F L3) are open;

2. Ensure that the fuse carrier isolating switches of the UPS batteries (F B++ and F B-) and those of the

UPS BATTERY (if used) are open;

3, Ensure that the input and output wiring is correct; check correct cycling of the phases in input;

4. Check that the mains input parameters (power voltage and frequency) are compatible with those

specified on the UPS data plate.

5, Check that the maintenance by-pass switch S1 and the UPS output switch S2 are both in the OFF

position.

ema ouru

Bn | ety

SHARE | “users

UPS 45 - 60

Startup

6-2 ‘code 5040260300 Re. March 2009

Oporoting and Maintenance Mania!

6.4 STARTING PROCEDURE

1. Insert the fuses for the UPS power supply in the fuse cartier isolating switches located at the bot-

tam of the UPS on the distribution box (F Li, F L2 and F L3);

2. check for the presence of the ‘alse fuse’ in the Isolating switch relative to the neutral;

3. insert the battery fuses in the relative isolating switches (F B+ and F B-) and, if applicable, those in

the UPS BATTERY cabinets [if they exist).

WARNING

‘Once the door has been closed and the key taken out, before switching the unit on the

correct output configuration must be selected (Single-pha:

separate phases). To do this, proceed as follows.

s/Three-phase 120°/Three

4, With the unit off, press the ENTER key on the operator panel to gain access to the Service Mode,

See the next chapter for more information about the SERVICE MODE and panel operation

5, Follow this path: Config. UPS g Output g Inverter

Select Single-phase / Two-phase /Three-phase 120° / Two separate phases / Three separate

phases depending on the connection,

Use the arrow keys to move the selection on the display, the Enter key to confirm, the ESC key to can:

A

WARNING

Wrong connections or output configuration settings can cause injury to people or damage to

things!

«ode 5040260300 Rev March 2008

Startup

6-3

ee

Operating and Malatenance Manual

Close the battery isolating switches (Including those of any additional UPS BATTERY) and then the

‘mains isolating switches;

6. Power the UPS via the dedicated switch.

A

ATTENTION

when the unit detects the input voltage it automatically proposes starting a battery che

Press the’ESC’ key to proceed to switching the UPS on.

7. Press the ENTER button to switch the UPS on;

8, Walt until the status indicator on the display turns green;

9. Check that the output voltage and frequency values set cor-

respond to the applied load requirements. If they do not, enter

the necessary values (see next chapter);

10. Close the output switch $2.0n the UPS.

At this stage the load is powered and protected by the UPS.

AN

WARNING

1, when Installing, you thinkitis necessary

tocheckthat thebattery-run UPSis working

properly, turnthemains powervoltagectfby

‘means of theswitch upstream fromthe UPS

and NOT by means ofthe input fuse carrier

isolating switches inside the UPS distribu-

ton box. Only In this way will there be no

voltage on the terminal block!

ifthe UPS has internalbatterlesitwillinstead

benecessary toopenatleastoneboxforeach

set (one set consists of 4 boxes). This cuts

the power voltage off to the terminal block

generated by the various sets of batteries.

‘This must be done forall sets.

Eachboxiefixed with twoserews which must

be removed beforehand.

Before programming theunit, make sure that

all the modules (inverter and/or battery boxes) are closed and fixed with the screws,

Close the door and take the keys out.

Contiguration and

Startup

6-4 code 5040250300 Rew. March 2009

Operating and Maintenance Manual

7. Control panel

The control panel at the front ofthe unit, has a 4-line, 20-character LCD display, a backlit multicolour

status indicator and a 5-key keypad

Fi

Hn ar 0

ou.

oi ma (8)

The keys on the front panel are used to gain access to the UPS menus.

ESCAPE

Exit funclon withour modifying

Goes from alower toa higher menu evel

Exit the main men ond elu to displaying status

Silencing the acousteInalcator

up ARROW

Selects the previous funciton

eases a value inside a function

ects anew item inside function (eg, from DISABLED to ENABLED)

Scrolls the menus that conta moe than 4 lines

own arrow

Selects the next function

Reduces a value inside a function

Selects anew tem inside a function (e.g from ENABLED to DISABLED)

‘Scrolls the menus that contaln more than 4 lines

eter

Contms a value

Aecesses 2 menu tier

‘Goes rom zhigher toa lower men level

onyorr

‘lows starting and stopping the UPS. Keep pressed to shut down,

code 5040260300 Rev. March 2009

Control panel

7-1

Seeerereeerenner renner eee eceer eer eeaee ere REREPREEGPEREECoEe EASTER SPPPECSPEEECSE

COporaliag and Malntenance Manual

7. ‘SERVICE MODE’ FUNCTION

Even when itis off the UPS allows you to make all the settings and programming described below; by

pressing the ENTER’ key the UPS enters the ‘Service Mode’ and from here it is possible to access the

DISPLAY menu.

‘To exit this mode press the ON/OFF’ key otherwise the UPS exits the function autom:

itself off after 1 min. if it has not received any manual or serial commands.

ly and turns

7.2. MAIN MENU AND SUBMENUS

[At the end of the start-up procedure the main frame appears on the display. Remember that when

starting the voltage in output from the machine is present only when the UPS STARTUP bar reaches

the end and the main frame appears

‘The following image is an example of the main frame.

UPS

IN 230V / 230V / 230V

OUT 230V / SW 19%

Batt BERET 24h

‘The following data are shown on the display under normal operating conditions:

= UPS operating status;

+ Input voltages;

> Set voltage in output/active power absorbed by the load and percentage of the total load applied

= Bar showing residual battery capacity and actual minutes of operation in the case of a power failure

from the mains,

INDICATION

Press the ARROW keys on the main frame to gain access to other Information pages. In particular:

~ Load percentage on the phases in output.

= Output voltage on the phases, power in KVA in relation to rated power and relative percentage,

~ Output voltage, current and active power

~ Line voltage between the phases (in output).

~ Input voltage, current and active power.

= Line voltage between the phases (in input)

= Batteries: voltage, load current (negative value with load ongoing, positive value when the batteries

are powering the machine), capacity, residual load, battery charger phases (charging, voltage limiter,

‘maintenance, stand-by).

INDICATION

Press the ENTER key on the main frame to gain access to the maln menu which contains the follewing options:

= UPS STATUS: itallows checking of the machine's functional status in real time;

= UPS SETTINGS: itallows configuration of all the UPS functions; |

~ POWER MODULES: it allows analysing of the status of each single power module In reat |

time; ]

Control panel

7-2 code 5040260300 ev. March 2009

Operating and Maintenance Menval

+ EVENTS:

log;

= TOOLS:

The following table summarises them all,

itallows the visual display and/or deletion of stored events in the UPS

It allows a series of functional tests to be run on the UPS.

By selecting one ofthe above listed Items again with ‘ENTER; you gain access to the relative submenu.

UPSSTATUS ps SETTINGS POWER EVENTS Toots,

moouLes

UPS info ‘Options ut status Visual ispay ‘arenes

Ps Config, output Diagnoses) Delete Signaiog Test

Measurements lapat PM sw Update”) cD Display Test

lune Bypass

Historia Data fatteries

Operator Panel

Clock setting

L Contact inter

()Aveilable inthe Service Mode’ only

7.2.1 UPS status

‘The machine has a menu structure with relative tree submenus, the functions of which are explained

in the following paragraphs. An arrow facing down or up appears on the right of the display when

there are other items to see, Use the arrow keys to see these items.

UPS nfo [urs Medel Eauipmnent medal :

Maeva Maximum supplable apparent power IRVAL

Mew Maximum supplable active power IRN

iver mare version Inside the machine

Paisw ve rare version of the power mods

si [Machine sedainumber

[UPS config. [OUT

Nore oF KBs nw

ied (1 KB= 4 batery boxed

ax. cap Capacity ofthe batteries tle Ah

Yio tate pare Nurnber of batteries nseries nore KB

ouiparx Power Fetivs ponar supplied by the UPS on phase XW) 7

AopPow. | Apparent power supplied in oviput fom the UPSon phaseXWA) |

ems Eective votage supplied in output Wor the UPS on phase XIVRMSI

Linkedin [fective tine voltage betwoon the phses in output fiom the UPS V RSI |

rns xecve rent supple in oiput from the UPS on phase XTA RMSL

FeskiVel [Peskccutrent supplied n outputfrom the UPS on phase X(AD

Frequency [Frequency ofthe sinrold vokage in output rom phase XIHA)

Peak Factor [ Peakactr on phase X -

Power Factor” [ Power factor oftheload conneciedto the UPS.on phase X

MoxW Maxim active power supiable by the UPS on phase XW]

Power aximm active power supplable by the UPS on phase K expressed as

percentage

Naa Maximum apparent power suppliabe by the UPS on phase XW

[Appar Power | Maximum apparent poner aupploble by the UPS on phase, expressed

lasapercentage

cede 5040260300 Re. March 2009

"Note: press’ENTER’ to change the X value and consequently vary the phase of which you are reading the data

Control pane!

7-3

Control panel

7-4

‘Operating and Maintenance Monual

[Measurements [input Power Power absedbed bythe UPSby the mans on phase (W)

Appa: Power | Apparent power absobed ty the UPS by the mains on phase IVAL

fins ctive voiageininputto the UPS on phase XIV RWS)

funkedvinas | efecveiine volage between the phases in input othe UPSIVENS)

BypassVis | Efetiveveltageininputto the UPS on phase X forthe bypass line

VRS)

us fective cuventabsorbedbiy the UPS by the alns on phase TA

AMS)

Peakvalue [Peak curant absoibed bythe UPS by the mains on phase XA

Frequency [Frequency ofthe voltage snasoidin input the UPS on phase Ka)

oak Factor | Peat factor applied by the UPS othe mains on phase X

Power Factor [Powe actor applied by the UPS to the mang on phage X

Note: press ENTER to change the X value and consequently vary the phase of which youre reading the data

(Measurements [Baticres Waiage Woe measured oie ends ofthe bates Mi

Fcuent current supplied by thebartertes (negate ifthe Bates are bag

chaigee Ad

Fesdval Capac. | Sotary charged status expressed as a percentage 0-1CO%)

[cagStatus [Working status af the battery charger

Tot avtonory [Total autonomy the UPS would have with batteries charged 109%

Res autonomy | Restal autonomy ofthe UPS

End ofaut [Battery dveshold vohage for end of avtonony

No.ran downs _ | Total number oftimes the batteries have been competed run down

Use otal number of hous the UPS has ben running on bawery

cal Day and Une theft calbaton was made.

No. Calibrations [Total numberof aliations made

[iteavureiments | Misc. iteral Temp. [Temperature inside he UPS PC)

HV.fuspes. | Vollage onthe DCBUS positve

HV.Busnec, | Voltage onthe DCBUS negative |V)

‘aes ‘Ns Lon. Se chore

HistovcalData [UPS operation Total ane the UPSas been working

wa atery Total ime te UPSthas boen running on batery

Battery chorger Op. Total ime debater charger as been working

Hot undonns Total number of ines the bateris have been cornplely an down

Boose. Total umber of Booster interventions

eypessint Fetal numberof Eypassinterventions

ae calbr. Total number of batery Cabratons

Barer ch.cyles otal numba: ofbatery charger eles

Battegiyces ota number ofbatery equalsaton cides

Operating and Maintenance Msnust

7.2.2 UPS settings

‘Opttons ~ [Siar with Batiery [enabled i atlows the UPS to be stared when here a power alure