Professional Documents

Culture Documents

Practical ME 5

Practical ME 5

Uploaded by

KR Bhatta0 ratings0% found this document useful (0 votes)

4 views1 pageThis document outlines the curriculum for a practical examination for a senior assistant position in the Technical Service Department. It is divided into three sections worth a total of 30 marks. Section A covers workshop practices like turning, boring, threading, and welding exercises. Section B covers vehicle maintenance tasks such as servicing brakes, spark plugs, and diagnosing electrical systems. Section C covers air conditioning system maintenance, including identifying components, changing refrigerants, and repairing split units.

Original Description:

ME practical file

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the curriculum for a practical examination for a senior assistant position in the Technical Service Department. It is divided into three sections worth a total of 30 marks. Section A covers workshop practices like turning, boring, threading, and welding exercises. Section B covers vehicle maintenance tasks such as servicing brakes, spark plugs, and diagnosing electrical systems. Section C covers air conditioning system maintenance, including identifying components, changing refrigerants, and repairing split units.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pagePractical ME 5

Practical ME 5

Uploaded by

KR BhattaThis document outlines the curriculum for a practical examination for a senior assistant position in the Technical Service Department. It is divided into three sections worth a total of 30 marks. Section A covers workshop practices like turning, boring, threading, and welding exercises. Section B covers vehicle maintenance tasks such as servicing brakes, spark plugs, and diagnosing electrical systems. Section C covers air conditioning system maintenance, including identifying components, changing refrigerants, and repairing split units.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

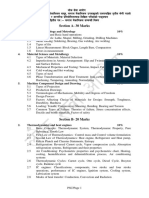

g]kfn gful/s p•og k|flws/0f

k|ljlws ;]jf, d]sflgsn OlGhlgol/Ë ;d"x, kfFrf}+ tx, jl/i7 ;xfos kbsf] k|of]ufTds k/LIffsf] kf7\oqmd

k"0ff{Í M #) pQL0ff{Í M !%

A. Workshop Practices (10 Marks)

1. Identification and use of hand tools and special tools

2. Identification of main components and parts of machine

3. Identification of major specifications of machine

4. Identification and use of safety tools and devices

5. Use of workshop manuals

6. Lathe exercise: Turning, Boring, Internal/External thread cutting, Eccentric turning

7. Shop fitting exercise: Cutting, Fitting, Drilling, Tapping, Male and Female Joints

8. Milling exercise; Horizontal milling with cylindrical and Side/Face cutters

9. Welding exercise; Single vee, Butt-weld, Fillet weld, Brazing, Soldering

B. Vehicle Maintenance (10 Marks)

1. Identification of major components of vehicle

2. Use of maintenance manual and spare parts manual

3. Change of oil, fuel and air filter

4. Top-up and Change of lubricants

5. Changing of hydraulic/pneumatic pipe, hose and grease nipples system

6. Servicing of cooling, fuel, clutch and brake system

7. Cleaning, Changing, Gap setting of spark plugs

8. Identification of electrical components of vehicle

9. Changing of bearings, disassembly/assembly of electric motor/water pump

10. Servicing of starter motor

11. Diagnosis and fault finding related to fuses, charging, ignition and electrical system

C. Air Conditioning System Maintenance (10 Marks)

1. Identification of major components

2. Identification of spare parts

3. Servicing of air conditioning system

4. Identification and changing of refrigerants

5. Dismantling, Assembling, Repair and Maintenance of split air-conditioning unit

You might also like

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- Generator Caterpillar SR4B ADJUSTINGDocument76 pagesGenerator Caterpillar SR4B ADJUSTINGonyx_luciano82% (17)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Derbi Terra Workshop ManualDocument118 pagesDerbi Terra Workshop Manualfarroyoxl100% (3)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- KATO HD2310-3 Excavator Workshop Manual PDFDocument232 pagesKATO HD2310-3 Excavator Workshop Manual PDFBaciu Nicolae93% (15)

- 3516 Genset Overhauling ProposalDocument2 pages3516 Genset Overhauling Proposaldirkcat100% (2)

- Automotive Air Conditioning and Climate Control SystemsFrom EverandAutomotive Air Conditioning and Climate Control SystemsRating: 4 out of 5 stars4/5 (6)

- g1 Test GuideDocument12 pagesg1 Test GuideOctavio Maciel100% (1)

- DRF 400-450 Workshop ManDocument1,040 pagesDRF 400-450 Workshop ManMohamedSalah100% (5)

- Epson Stylus Pro 9900 Service ManualDocument519 pagesEpson Stylus Pro 9900 Service Manualhpatel_714706100% (2)

- Hanix H09D Service and PartsDocument207 pagesHanix H09D Service and PartsBaciu Nicolae100% (1)

- New Me-5Document3 pagesNew Me-5kapun kumar nayakNo ratings yet

- 14senire-Mechanics Curriculim - 0Document5 pages14senire-Mechanics Curriculim - 0RanjanNo ratings yet

- Campro TEST FORMDocument2 pagesCampro TEST FORMMohd. Za'im Bin SaidiNo ratings yet

- Automotive Shs-DipDocument4 pagesAutomotive Shs-DipAl M. GamzNo ratings yet

- I C Engine LabDocument3 pagesI C Engine LabDevNo ratings yet

- Nepal Electricity AssociationDocument2 pagesNepal Electricity Associationmanojkhadka23No ratings yet

- ME ELFAE Vehicle Preventive Maintenance and Repair ServicesDocument2 pagesME ELFAE Vehicle Preventive Maintenance and Repair ServicesAdam MirandaNo ratings yet

- Nepal Army Mechanical Engineer SyllabusDocument6 pagesNepal Army Mechanical Engineer SyllabusYuvaraj Khanal100% (2)

- Service Manual: For Serial Number: 65-3707Document11 pagesService Manual: For Serial Number: 65-3707FRANK PRUDENCIO OBREGON100% (1)

- Syllabus - Driver Cum Auto MechanicDocument13 pagesSyllabus - Driver Cum Auto MechanicMichael Alba100% (1)

- Me 9Document3 pagesMe 9atpradhumnaNo ratings yet

- Syllabus Motor Mechanic 243-22Document2 pagesSyllabus Motor Mechanic 243-22Titto K OusephNo ratings yet

- Document 2 3Document8 pagesDocument 2 3siddhartha2862No ratings yet

- Gujarat Technological University: % WeightageDocument4 pagesGujarat Technological University: % WeightageEr Samkit ShahNo ratings yet

- AD45B Underground Articulated Truck - Service SheetDocument7 pagesAD45B Underground Articulated Truck - Service SheetaleciolyraNo ratings yet

- AutomobileDocument67 pagesAutomobileAlexanderMarkovikNo ratings yet

- Manual Bevelling and Deburring System B15 Air: Operating Instructions For The DeviceDocument20 pagesManual Bevelling and Deburring System B15 Air: Operating Instructions For The DevicebulentNo ratings yet

- Primera Entrega TR1 Ingles TecnicoDocument8 pagesPrimera Entrega TR1 Ingles TecnicoYolvi YsagaNo ratings yet

- Course Content Form: AUT 100 Small Engine Troubleshoot and RepairDocument2 pagesCourse Content Form: AUT 100 Small Engine Troubleshoot and RepairMyriam ValanNo ratings yet

- Ind Mech Mill Lev3Document12 pagesInd Mech Mill Lev3DiyaNegiNo ratings yet

- Automobile Systems - 9057Document5 pagesAutomobile Systems - 9057Khushbu JoshiNo ratings yet

- Me 7Document3 pagesMe 7vijayNo ratings yet

- ASE MaintenanceLtRepair Study Guide 2024Document12 pagesASE MaintenanceLtRepair Study Guide 2024Matthew MccaaNo ratings yet

- M015710 - 04E 4 Turbos MtuDocument211 pagesM015710 - 04E 4 Turbos MtuRaul BxinNo ratings yet

- Forceclima 9050Document100 pagesForceclima 9050David LagunaNo ratings yet

- AL Tumba - Complete ManualDocument298 pagesAL Tumba - Complete ManualMikhail Tibes SoaresNo ratings yet

- Aut 116-05 8wk Revised 1-11 FinalDocument13 pagesAut 116-05 8wk Revised 1-11 FinalJsy LangNo ratings yet

- A. Stages and Procedure of Examination System: Multiple Choice QuestionsDocument3 pagesA. Stages and Procedure of Examination System: Multiple Choice QuestionssantoshNo ratings yet

- Cforce 1000 2018Document365 pagesCforce 1000 2018Aigars Mulis100% (1)

- Ael I ManualDocument29 pagesAel I ManualNivedita kNo ratings yet

- Experiment 10Document4 pagesExperiment 10garysingh187westNo ratings yet

- V2 ManualDocument143 pagesV2 Manualjuanmanuelpenaruiz3No ratings yet

- Om Manual For 4 12tca 6 12tca 70Document103 pagesOm Manual For 4 12tca 6 12tca 70Santiago Del Rio OliveiraNo ratings yet

- Lok Sewa Aayog - RA PA 3rd - Mechanical 2nd Paper Syllabus PDFDocument4 pagesLok Sewa Aayog - RA PA 3rd - Mechanical 2nd Paper Syllabus PDFविशाल पुडासैनीNo ratings yet

- August QuestionsDocument8 pagesAugust Questionsbaba maachoNo ratings yet

- Kertas Kerja: Kod Dan Nama ProgramDocument11 pagesKertas Kerja: Kod Dan Nama ProgramLeeNo ratings yet

- Pump LHD Maintenance ManualDocument33 pagesPump LHD Maintenance ManualBracilides Mamani ArizaNo ratings yet

- ASE MaintenanceLtRepair Study Guide 2022Document12 pagesASE MaintenanceLtRepair Study Guide 2022meNo ratings yet

- Automobile Engineering (EG704ME) : Course OutlinesDocument4 pagesAutomobile Engineering (EG704ME) : Course OutlinesDipendra SenNo ratings yet

- 12V Mtu 4000Document248 pages12V Mtu 4000Mig Vazq100% (5)

- AE314 Aero Engine Maintenance L T P CDocument2 pagesAE314 Aero Engine Maintenance L T P CMadhan KumarNo ratings yet

- Course Title: Automobile Servicing & Maintenance Course Code: 6052 Course Category: A Periods/Week: 6 Periods/Semester: 75 Credits: 6Document5 pagesCourse Title: Automobile Servicing & Maintenance Course Code: 6052 Course Category: A Periods/Week: 6 Periods/Semester: 75 Credits: 6VaisakVenugopalNo ratings yet

- Cat Engine Fundamentals Lab Manual: Student's Name(s)Document32 pagesCat Engine Fundamentals Lab Manual: Student's Name(s)masabaraoiNo ratings yet

- Electrical MotorDocument35 pagesElectrical MotorTshering Peljor100% (4)

- Operating Instructions Diesel Engine MTUDocument204 pagesOperating Instructions Diesel Engine MTUBradley Lodder100% (3)