Professional Documents

Culture Documents

Maquina Healdo Suave

Uploaded by

Arq.Alfonso CamachoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maquina Healdo Suave

Uploaded by

Arq.Alfonso CamachoCopyright:

Available Formats

Item No.

___________________________________________

794

Soft Serve Freezer

Twin Twist

Features

Offer all the popular soft serve variations from low or non-fat ice creams to

custards, yogurt and sorbet. Serve two separate soft serve flavors, or an equal

combination of both in a twist.

Freezing Cylinder

Two, 3.4 quart (3.2 liter).

Mix Hopper

Two, 14 quart (13.2 liter). Separate hopper refrigeration (SHR) maintains mix

below 41ºF (5ºC) during Auto and Standby modes.

Indicator Lights

Mix Low light alerts operator to add mix. Audible alarm may be enabled to

sound when mix is low.

Electronic Controls

SoftechTM is our exclusive microprocessor based master control that regulates

refrigeration by measuring product viscosity to maintain consistent quality.

Standby

During long no-use periods, the standby feature maintains safe product

temperatures in the mix hopper and freezing cylinder.

Optional Drain Assembly

An optional factory installed drain assembly, with funnel, is avaliable to simplify

the cleaning process. A drain line, connected under the drip tray connects to a

1” FPT coupling in the base pan to drain rinse water to a floor drain.

Two Locking Casters

Front casters have a locking feature for operators to lock to maintain

equipment in place. The locking casters can be released to move the equipment

for cleaning.

Freezer Door

A specially designed thermo-plastic door allows quick ejection of product.

Push forward on the ergonomic draw handle to dispense. Self-closing draw

handles are standard.

Door Interlock System

Protects the operator from injury as the beater will not operate without the

dispensing door in place.

750 N. Blackhawk Blvd. Rockton, Illinois 61072

800-255-0626

Phone 815-624-8333 Fax 815-624-8000 ISO 9001:2008

www.taylor-company.com

Registered Firm

info@taylor-company.com

Weights lbs. kgs. Specifications

Net 640 290.3 Electrical

Crated 699 317.1 Two dedicated electrical connections are required. See the Electrical chart

cu. ft. cu. m. for the proper electrical requirements. Manufactured to be permanently

Volume 48.9 1.38 connected. Consult your local Taylor distributor for cord & receptacle

specifications as local codes allow.

Dimensions in. mm.

Width 20-7/16 519 Beater Motor

Two, 1.5 HP.

Depth 33-3/16 844

Height 59-7/8 1521 Refrigeration System

Two, 9,500 BTU/hr. R404A.

Floor Clearance 4-1/2 114

Separate Hopper Refrigeration (SHR), One, 400 BTU/hr. R134a.

*Mounted on standard casters (BTUs may vary depending on compressor used.)

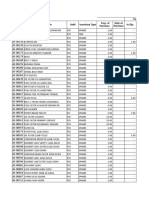

Electrical Maximum Minimum Poles (P)

Fuse Size Circuit Ampacity Wires (W) Air Cooled

Left Right Left Right Minimum 3” (76 mm) around all sides. Install the deflector provided to

prevent recirculation of warm air. Minimum air clearances must be met to

208-230/60/1 Air 35 35 27 23 2P 3W

assure adequate air flow for optimum performance.

208-230/60/1 Water 25 25 21 18 2P 3W

208-230/60/3 Air 15 15 13 12 3P 4W Water Cooled

Water inlet and drain connections under side of base 1/2” FPT.

208-230/60/3 Water 15 15 13 12 3P 4W

220-240/50/1 Air 25 20 19 17 2P 3W

380-415/50/3N~ Air 9 8 8 6 4P 5W

Options

• Cone Dispenser

• Drain with Funnel

• Draw handles to meet Americans with Disabilities Act requirements

This unit may be manufactured in other electrical characteristics and may have additional regulatory • Draw Valve Lock Kit

agency approvals. Consult the local Taylor Distributor for other electrical characteristics and agency • Faucet

approvals based on specific electrical and country requirements.

(For exact electrical information and approval marks, always refer to the data label of the unit.)

• Sneeze Guard

• Syrup Rail Kit (side mount)

Continuing research results in steady improvements; therefore,

these specifications are subject to change without notice.

Bidding Specs

Electrical: Volt Hz ph

Neutral: nYes nNo Cooling: nAir nWater nNA

Options:

Authorized Taylor Distributor

750 N. Blackhawk Blvd.

Rockton, Illinois 61072

www.taylor-company.com

044658-ADV 6/16

You might also like

- Understanding and Servicing Alarm SystemsFrom EverandUnderstanding and Servicing Alarm SystemsRating: 1 out of 5 stars1/5 (1)

- Taylor+C713+落地型雙口味霜淇淋機 型錄Document2 pagesTaylor+C713+落地型雙口味霜淇淋機 型錄Yimin TsengNo ratings yet

- S C723Document2 pagesS C723C.H. WEENo ratings yet

- Soft Serve Freezer: Twin TwistDocument2 pagesSoft Serve Freezer: Twin TwistAndres MoralesNo ratings yet

- Soft Serve Freezer: FeaturesDocument2 pagesSoft Serve Freezer: FeaturesPablo CastilloNo ratings yet

- Soft Serve Freezer: Twin TwistDocument2 pagesSoft Serve Freezer: Twin TwistMisael RodríguezNo ratings yet

- S C708Document2 pagesS C708Eric Ongkowijoyo100% (1)

- 20120227-1b29e sC716Document2 pages20120227-1b29e sC716Pablo CastilloNo ratings yet

- Soft Serve Freezer: Twist, Pump, Heat TreatmentDocument2 pagesSoft Serve Freezer: Twist, Pump, Heat TreatmentAndres MoralesNo ratings yet

- Maq. Helados Taylor sC707 PDFDocument2 pagesMaq. Helados Taylor sC707 PDFxray123zzzNo ratings yet

- Soft Serve Freezer: Single FlavorDocument2 pagesSoft Serve Freezer: Single FlavorAndres MoralesNo ratings yet

- Taylor 336Document2 pagesTaylor 336Andres MoralesNo ratings yet

- c723 Specification SheetDocument2 pagesc723 Specification SheetDominik Cornelio Cardona VelezNo ratings yet

- Taylor C713 SoftServeFreezer SpecSheet 1Document1 pageTaylor C713 SoftServeFreezer SpecSheet 1mededsmithNo ratings yet

- Softy Ice Cream Machine Prices Call: 91-9899332022Document2 pagesSofty Ice Cream Machine Prices Call: 91-9899332022Brand PNo ratings yet

- Frozen Carbonated Beverage Freezer: Four Flavor FeaturesDocument2 pagesFrozen Carbonated Beverage Freezer: Four Flavor FeaturesAndrewNo ratings yet

- Oceanpower OP138CS DatasheetDocument2 pagesOceanpower OP138CS DatasheetKléber DavidNo ratings yet

- Ultra High Output and Maximum Flexibility: Standard RangeDocument2 pagesUltra High Output and Maximum Flexibility: Standard RangeAlfonso GasqueNo ratings yet

- Stoelting E131-38Document2 pagesStoelting E131-38dstout74No ratings yet

- Jura Giga 5Document2 pagesJura Giga 5ינון שיNo ratings yet

- LB 200 G Tronic Operation ManualDocument14 pagesLB 200 G Tronic Operation Manualscott2cooper-1No ratings yet

- La Rotonda: Horizontal Display CabinetDocument2 pagesLa Rotonda: Horizontal Display CabinetGrim Cat GNo ratings yet

- Aire Acondicionado INROWDocument9 pagesAire Acondicionado INROWSander SanchezNo ratings yet

- Owner'S Manual: Stellar Air Conditioning Unit Split-System Cooling With Environmentally Friendly R-410ADocument4 pagesOwner'S Manual: Stellar Air Conditioning Unit Split-System Cooling With Environmentally Friendly R-410Aramon5356No ratings yet

- Frost Only CoolDocument4 pagesFrost Only CoolHaitham Elhefni0% (1)

- Resubmition (3) GTDDDocument10 pagesResubmition (3) GTDDjsebastian7.saNo ratings yet

- Refrigerator Service Manual GuideDocument45 pagesRefrigerator Service Manual GuideNelson AraujoNo ratings yet

- DZF 6050Document13 pagesDZF 6050Kevin José SánchezNo ratings yet

- Mirage Drop in Warmer SpecsheetDocument2 pagesMirage Drop in Warmer SpecsheetAna Maria Berrio ReyesNo ratings yet

- Koppel Ceiling SuspendedDocument2 pagesKoppel Ceiling SuspendedLeomark RespondeNo ratings yet

- ScienceTemp-40 9.b SpecificationDocument1 pageScienceTemp-40 9.b Specificationbocah tileNo ratings yet

- Condensing Dryer Service Manual: MODEL: TD-C7004 SeriesDocument44 pagesCondensing Dryer Service Manual: MODEL: TD-C7004 Seriesalexjcc10No ratings yet

- Brochure GMP Ironers Eline gb-3Document4 pagesBrochure GMP Ironers Eline gb-3reparatii24suceavaNo ratings yet

- Washing Machine: Service ManualDocument46 pagesWashing Machine: Service ManualJacky NplNo ratings yet

- Ult Freezer MDF U33vDocument2 pagesUlt Freezer MDF U33vAprilia KrisnawatiNo ratings yet

- Washing Machine Service ManualDocument36 pagesWashing Machine Service ManualOdissei KritharidisNo ratings yet

- C834 MCD: Electric Clamshell GrillDocument2 pagesC834 MCD: Electric Clamshell GrillВолодимир БроNo ratings yet

- LR Trittico Startronic Premium 2022 EngDocument4 pagesLR Trittico Startronic Premium 2022 Engnunesoliveira.fabioNo ratings yet

- Manual Screw Chiller Water Cooled PDFDocument76 pagesManual Screw Chiller Water Cooled PDFAbhinav Sai100% (1)

- SS4D-2 - Information SheetDocument2 pagesSS4D-2 - Information SheetFrancis BoeyNo ratings yet

- MODEL T46/T46A: Maximise Your ProfitsDocument2 pagesMODEL T46/T46A: Maximise Your Profitsscripterbdi100% (1)

- NRB Model Data SheetDocument4 pagesNRB Model Data Sheet조주현No ratings yet

- Washing Machine Service ManualDocument44 pagesWashing Machine Service ManualLuisAlhodaSilvaNo ratings yet

- Autoclave EVO PDFDocument1 pageAutoclave EVO PDFfpanciNo ratings yet

- FM3700 Product CatalogueDocument2 pagesFM3700 Product CataloguelocoNo ratings yet

- Ecotron: A Starter Model With RefinementDocument2 pagesEcotron: A Starter Model With RefinementkulathuiyerNo ratings yet

- 4032 Sterilizer Steam GetingeDocument12 pages4032 Sterilizer Steam GetingeBlack Angels100% (1)

- 2 - ClassiCool Inverter Sales Catalogue - EnglishDocument5 pages2 - ClassiCool Inverter Sales Catalogue - EnglishxianzaiegNo ratings yet

- S3378-1217Document12 pagesS3378-1217eliot martinezNo ratings yet

- 7899 - Technical - Trane - ECGAN 700Document6 pages7899 - Technical - Trane - ECGAN 700BLUBLUNo ratings yet

- F1496TDP3 SVC Manual 04.11Document44 pagesF1496TDP3 SVC Manual 04.11Gabriel BeguiriztainNo ratings yet

- LDF 8874 STDocument68 pagesLDF 8874 STEric SimardNo ratings yet

- 50VT-16PD-CPDocument40 pages50VT-16PD-CPJesmar VonNo ratings yet

- LDT9965 Dis WasherDocument70 pagesLDT9965 Dis WasherJosé Airton TirakowskiNo ratings yet

- Packaged Air Conditioners with Cooling Range 4.1 to 52.3 TRDocument38 pagesPackaged Air Conditioners with Cooling Range 4.1 to 52.3 TRAhmed Ebrahim67% (3)

- Instruction Manual: Explanatory BookletDocument37 pagesInstruction Manual: Explanatory BookletMuhammad RezzaNo ratings yet

- Serological Water Bath (PLT 109)Document2 pagesSerological Water Bath (PLT 109)dashrathlodhi412No ratings yet

- Ficha Técnica Nevera ICNh-IM51130Document2 pagesFicha Técnica Nevera ICNh-IM51130marilyncmdNo ratings yet

- LM Scheda Tecnica GS3 ENG Upd - Oct HighDocument2 pagesLM Scheda Tecnica GS3 ENG Upd - Oct HighGermaine RamosNo ratings yet

- Offshore - Introduction LayoutDocument135 pagesOffshore - Introduction Layoutsantosh_ms_kumar2827No ratings yet

- Holophane HMS Lowering System Brochure 1971Document4 pagesHolophane HMS Lowering System Brochure 1971Alan MastersNo ratings yet

- % Impedance 75 KVA Etc EatonDocument14 pages% Impedance 75 KVA Etc EatonNOELGREGORIONo ratings yet

- Anaesthetic Gas Scavenging SystemDocument3 pagesAnaesthetic Gas Scavenging SystemAH MDNo ratings yet

- Dimension-C521 Service Manual En-UsDocument50 pagesDimension-C521 Service Manual En-Ussupermango007No ratings yet

- 275HDV High Voltage DetectorDocument5 pages275HDV High Voltage DetectorByron PanchiNo ratings yet

- Ema Hydraulic 1Document8 pagesEma Hydraulic 1Nikola AngjelkovskiNo ratings yet

- Manual de Servicio - Magicolor1680-1690MF Delcop 3009Document380 pagesManual de Servicio - Magicolor1680-1690MF Delcop 3009oneil moleroNo ratings yet

- Civic & North-Min - 06.22.23Document6 pagesCivic & North-Min - 06.22.23Francis DedumoNo ratings yet

- SIKA Electronic Thermometers PDFDocument7 pagesSIKA Electronic Thermometers PDFMohamed ElsemanNo ratings yet

- Challeger Testeo y AjusteDocument304 pagesChalleger Testeo y AjusteCarlos Irabedra100% (1)

- 342Document1 page342crazymax90No ratings yet

- TP20 Touch Trigger Probe SystemDocument2 pagesTP20 Touch Trigger Probe SystemKaya Eralp AsanNo ratings yet

- Assignment 5 Spring2024Document7 pagesAssignment 5 Spring2024fu MozaNo ratings yet

- Liugong CLG908C Excavator Parts ManualDocument438 pagesLiugong CLG908C Excavator Parts ManualCristobal Henriquez83% (6)

- Sterilamp Uv System Operation ManualDocument9 pagesSterilamp Uv System Operation ManualsigitNo ratings yet

- IHT Installation Manual Ignition System EDocument16 pagesIHT Installation Manual Ignition System EraiNo ratings yet

- Calibration Tools ListDocument5 pagesCalibration Tools ListdianNo ratings yet

- Code Error On Canon Printer MP287Document2 pagesCode Error On Canon Printer MP287Er SallyNo ratings yet

- Air Conditioning Systems in BuildingsDocument38 pagesAir Conditioning Systems in BuildingsFarhan Danish100% (1)

- 6 - Dos & Donts Inside A Computer LabDocument17 pages6 - Dos & Donts Inside A Computer LabCrisanta a dumlaoNo ratings yet

- Boilermaker Practice ExamDocument8 pagesBoilermaker Practice ExamSastoe DubeNo ratings yet

- Distribution TransformarsDocument6 pagesDistribution TransformarsBanupriya Balasubramanian100% (1)

- Free InternetDocument1 pageFree InternetNyasha Chihungwa100% (2)

- Ile All 2Document429 pagesIle All 2Eyob HaylemariamNo ratings yet

- Brosur Teknindo Mining PartsDocument2 pagesBrosur Teknindo Mining PartsRudi Anto SianturiNo ratings yet

- 5-1 Gauge BlockDocument20 pages5-1 Gauge BlockJulius HendraNo ratings yet

- ManualB 63323enDocument559 pagesManualB 63323eningector64No ratings yet

- SCX-4600/4623 Series Parts CatalogDocument60 pagesSCX-4600/4623 Series Parts Catalogpab39xNo ratings yet

- TransducersDocument2 pagesTransducersvinayan k pNo ratings yet