Professional Documents

Culture Documents

Ansi B36.19

Uploaded by

BimaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ansi B36.19

Uploaded by

BimaCopyright:

Available Formats

A AN M E R I C A NN A T I O N ASL T A N D .

A R D

Stainless Steel Pipe

ANSIIASME B36.19M-1985

(REVISION OF ANSI 836.19-1 976)

SPONSORED A N D P U B L I S H E D B Y

T H EA M E R I C A NS O C I E T Y O F M E C H A N I C A LE N G I N E E R S

UnitedEngineeringCenter 3 4 5 East 47thStreet - N e w York, N. Y. 1 001 7

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Date of Issuance: Novembe! 29, 1985

This Standard will be revised when the Society approves the issuance of a new edition.

There will be no addenda or written interpretations of the requirements of this Standard

issued to this Edition.

This code or standard was developed under procedures accredited as meeting the criteria for

American National Standards. The Consensus Committee that approved the code or standard was

balanced t o assure that individuals from competentand concerned interests have had an opportunity

t o participate. The proposed code or standard was made available for public review and comment

which providesanopportunityforadditionalpublicinputfromindustry, academia, regulatory

agencies, and the public-at-large.

ASME does not "approve," "rate," or "endorse" any item, construction, proprietary device, or

activity.

ASME does not take any position with respect to the validity of any patent rights asserted in

connection with any items mentioned in thisdocument, and does not undertake t o insure anyone

utilizing a standard against liability

for infringement of anyapplicable Letters Patent, nor assume any

such liability. Users of a code or standard are expressly advised that determination of the validity of

any such patent rights, and the risk of infringement of such rights,is entirely theiro w n responsibility.

Participation by federal agency representativek)or person(s) affiliated with industry is not t o be

interpreted as government or industry endorsementof this code orstandard.

ASME accepts responsibility for only those interpretations issued in accordance with governing

ASMEproceduresandpolicies whichprecludetheissuanceofinterpretations by individual

volunteers.

No part of this document maybe reproduced in anyform,

in an electronic retrieval-systemor otherwise,

without theprior written permission of the publisher.

Copyright 0 1985 by

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

All Rights Reserved

Printed in U.S.A.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

FOREWORD

(This Foreword is not part of ANWASME B36-19M-1985.)

This Standard for corrosion resistant piping, designated categorically as stainless, is

based on thesame principles.that formed the backgroundfor thedevelopment of ANSI/

ASME B36.10M, Welded and Seamless Wrought Steel Pipe, and reference is made to this

source of information.

The wall thicknesses shown forSchedules 4% and 80s are identical with those of Sched-

ules 40and-80in ANWASME B36.10M except in the 12 in. size in Schedule 40s and the 10

in. and 12 in. sizes in Schedule 80s. The thickness for these threesizes corresponds to wall

thicknesses of Standardwall and Extra-Strong wall.

The more recent development of the highly alloyed stainless steels has brought about a

minor conflict with convention. With thesenewer materials, theneed forstandards is just as

great and thepresent types of threads are justas satisfactory, but thebasic cost of the metal

is much higher and theart of fusion welding has developed concurrently. The character of

stainless steel permits the design of thin-wall piping systems without fear of early failure due

to corrosion, and the use of fusion welding to joinsuch piping has eliminated the necessity

of threading it. Forthese reasons, the wall thickness dimensions shown under Schedule 10s

have been developed, based on the conventional formula,but thenmodified to correspond

to thenearest Birmingham Wire Gage (B.W.G.) number.

Following publication of the 1949 edition theredeveloped a demand for a still lighter wall

pipe. A Schedule5 s was determined cooperatively by representatives of chemical compan-

ies, processing industries, and manufacturersof welding fittings. This was endorsed by the

ASA Chemical Industry Correlating Committee and the Manufacturers Standardization

Society of the Valve and Fittings Industry. The new schedule was included in the revised

standard which was approved by ASA (now ANSI) on April 7, 1952.

In 1956 it was recommended that thewall thickness of 12 in. 5s be lessened, and anew re-

:.ision of the standardwas issued shortly afterits approval by ASA (now ANSI) on Febru-

ary 17, 1957. In this fourthedition, dimensions were expanded beyond 12 in. pipe size by

incxion of,and reference to, ASTM Specification A 3”. This revision was approved by

ASA (now ANSI) on October 29, 1965.

The B36 Standards Committee membership was asked in March 1970 for recommenda-

tions as to what action should be taken on ANSI B36,19-1965 since,according to ANSI pro-

cedures, this standard was due forrevision or reaffirmation. The B36 Standar - Committee

recommended reaffirmation. This actionWas approved by the Secretariat and by the Amer-

ican National Standards Institute on May 26, 1971.

In 1975the B36 Standards Committee undertook review a of the standard,considering its

acceptability and usefulness. The results were favorable; some editorial refinements and

updating were proposed alongwith the incorporationof factors forconversion to SI (met-

ric) units. T h C revision was approved by the Standards Committee, the Secretariat, and sub-

sequently the American National Standards Institute on October 4, 1976.

This standardwas revised in 1984 to include SI metric dimensions. The outside diameter

and wall thicknesses were converted to millimeters by multiplying the inch dimensions by

25.4. Outside diameters larger than 16 in. were rounded to thenearest 1 mm, and outside

iii

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

diameters 16 in. and smaller were rounded to the nearest 0.1 mm. Wall thicknesses were

rounded to the nearest 0.01 mm. These converted and rounded SImetric dimensions were

added in Table 2A. A formulato calculate the SImetric plain end mass, kg/m, using SI met-

ric diameters and thicknesses, was added to Section 5 . The SI metric plain end mass was cal-

culated for each size and thickness, and added in Table 3A.

These changes in the standardwere approved by the Standards Committee, the Sponsor,

andthe American NationalStandardsInstitute,andit was designated an American

National Standard on October7, 1985.

iv

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ASME STANDARDS COMMITTEEB36

Standardization of Wrought Steel Pipe

(The following is the roster of the Committee at the time

approval

of of this Standard.)

OFFICERS

F. G. Doar, Chairman

W. R. Daisak, Secretary

COMMITTEE PERSONNEL

AMERICAN BUREAU OF SHIPPING

J. Tiratto, American Bureau of Shipping, New York, New York

AMERICAN GAS ASSOCIATION, INC.

R; Jackson, Northwest Central Pipeline Corp., Oklahoma City, Oklahoma

L. T. Ingels, Alternate, American Gas Association, Inc., Arlington, Virginia

AMERICAN IRON AND STEEL INSTITUTE

R. P. Stripay, United States Steel Corp., Pittsburgh, Pennsylvania

ELECTRIC LIGHT AND POWER GROUP

F. G. Doar, Southern Company Services Inc., Birmingham, Alabama

J.-P. Markey, Alternate, Edison Electric Institute, Washington, D.C.

MANUFACTURERS STANDARDIZATION SOCIETY OF THE VALVE AND FITTINGS

INDUSTRY

R. A. Schmidt, Ladish Co., Cudahy, Wisconsin

MECHANICAL CONTRACTORS ASSOCIATION OF AMERICA

J. H. Zink, Heat & Power Corp., Baltimore, Maryland

OIL COMPANIES MATERIALS ASSOCIATION

J. W. Strawson, Liaison, Engineer Equipment & Material Users Association,

London, England

PIPE FABRICATION INSTITUTE

J. S. Cole, ITT Grinnell Industrial Piping Inc., Kernersville, North Carolina

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

CONTENT!,

Foreword ................................................................ iii

StandardsCommittee Roster ..... .......................................... v

1 Scope ............................................................... 1

2 Size ................................................................ 1

3 Materials ........................................................... 1

4 Permissible Variations ................................................ 1

5 Weights ............................................ ................ 1

PipeThreads .........................................................

-

6 2

7 Wall Thickness Selection ............................................. 2

Tables

1 Specifications for Pipe With ASTM Designations and Titles of Standard

Specifications ...................................................... 2

.2 Dimensions of Welded and Seamless Stainless Steel Pipe - Customary

units ............................................................ 3

2A Dimensions of Welded and Seamless Stainless Steel Pipe - SI Units. ....... 4

3 Nominal Weights of Steel Pipe,PlainEnds - Customary Units ............ -5

3A Nominal Weights of Steel Pipe,PlainEnds - SI Units ................... 6

Vii

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ANSVASME B36.19M-1985

AN AMERICAN NATIONAL STANDARD

AN AMERICAN NATIONAL STANDARD

STAINLESS STEEL PIPE

1 SCOPE 3 MATERIALS

This Standard covers the standardization of dimen- The dimensional standards for pipe described here

sions of welded and seamless wrought stainless steel are for productscovered in theASTM specifications

pipe. listed in Table 1.

The word pipe is usedas distinguished from tube to

apply to tubular products of dimensions commonly

used for pipeline and piping systems, Pipe dimensions 4 PERMISSIBLE VARIATIONS

of sizes 12and smaller have outside diameters numeri-

cally larger than the corresponding size. In contrast, Variations in dimensions differ depending upon the

the outside diameters of tubes are numerically identi- method of manufacture employed in making the pipe

cal to the size number for all sizes. to the various specifications listed in Table1. Permis-

The wall thicknesses for sizes 14through 22 inclu- sible variations for dimensions are indicated in each

sive ofSchedule lOS, for size 12 of Schedule 40S, and specification.

for sizes 10 and 12of Schedule 80s are not the same as

those of ANWASME B36.10M. The suffix “S” in

the ScheduleNumber is used to differentiate B36.19M 5 WEIGHTS

pipe from B36.10M pipe. ANWASME B36.10M in-

cludes other pipe thicknesses whichare also commer- The nominal weights’ of steel pipe are calculated

cially available with stainless steel material. values and are tabulatedin Table 3. The nominal plain

end weight, lb/ft, is calculated using the following

formula:

WPe = 10.68(0 - t)f

where

2 SIZE

wPe = nominal plain end weight rounded to the

The size ofall pipe in Tables 2 through3A isidenti- nearest 0.01 lb/ft

fied by the nominal pipe size. D = outside diameter to the nearest 0.001 in. (The

The manufacture of pipe in theinch nominal sizes symbolD is to be used for O.D. only in math-

of !h-12 inclusive is based on a standardized outside ematical equations or formulas.)

diameter (O.D.). This O.D. was originally selected so f = specified wallthickness rounded to the near-

that pipe with a standard O.D. and having a wall est 0.001 in.

thickness which wastypical of the period would have The nominal plain end mass, kg/m, is calculated-

an inside diameter (I.D.) approximately equal to the using the following formula:

nominal size. Although there is no such relation be-

tween the existing standard thicknesses - O.D. and WPe = 0.02466(0 - t)t

nominal size - these nominal sizes and standard

O.D.’s continue in use as “standard.”

-Themanufacture of pipe in nominal sizes of 14 and

‘The different gradesof stainless steel have differentspecific densi-

larger proceeds on thebasis of an O.D. corresponding ties and hence may weigh more orless than thevalues listed in this

to the nominal size. table would indicate [see Table 3, General Note (c)].

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

I

ANSI/ASME 836.1 9M-1985

AN AMERICAN NATIONAL STANDARD STAINLESS STEEL PIPE

TABLE 1 SPECIFICATIONS FORPIPE WITH ASTM DESIGNATIONS AND

TITLES OF STANDARD SPECIFICATIONS

ASTM

Designation Title

A 312 Specification for Seamless

and

Welded Austenitic Stainless

Steel

Pipe

A 358 Specification for Electric-Fusion-WeldedAustenitic Chromium-Nickel Alloy

Steel Pipe for High-Temperature Service

A 376 Specification for Seamless Austenitic Steel Pipe for High-Temperature

Central-Station Service

A 409 Specification for Welded

Large

Diameter Austenitic Steel Pipe for Corro-

sive or High-Temperature Service

where Schedules 5s and 10s wall thicknesses do notpermit

W = nominal plain end mass rounded to the near- threading in accordancewith ANWASME B1.20.1.

est 0.01 kg/m

D = outside diameter to the nearest 0.1 mm for

outsidediameterswhichare 16 in. and

smaller 'and 1 .O mm for outside diameters

7 WALL THICKNESS SELECTION

larger than 16 in. (Thesymbol D is to be used

for O.D. only in mathematical equations or When the selection of wall thickness depends pri-

formulas.) marily upon capacity to resist.interna1 pressure under

t = specified wall thickness rounded to thenear- givenconditions, the designer shall computethe exact

est 0.01 mm value ofwall thickness suitable for conditions for

NOTE: 1 in, = 25.4 mm; 1 lb/ft = 1.4895 kg/m.

which the pipeis required as prescribed in detailin the

ASME Boiler and Pressure Vessel Code, ANSI/

ASME B3 1 Codefor Pressure Piping,or othersimilar

codes, whichever governs the construction. A thick-

6 PIPETHREADS

ness willthen beselected from theschedules of nomi-

Unless otherwise specified, the threads of threaded nal thickness contained in Tables 2 and 2A to suit the

pipe shall conform to ANSI/ASME B1.20.1, Pipe value computed to fulfill the conditionsfor which the

Threads, General Purpose (Inch). pipe is desired.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

I

ANSllASME B36.19M-1985

STAINLESS STEEL PIPE AN AMERICAN NATIONAL STANDARD

TABLE 2 DIMENSIONS OF WELDED AND SEAMLESS STAINLESS STEEL

PIPE - CUSTOMARY UNITS

Inch

Nominal Wall Thickness, in.

Nominal Outside

Pipe Diameter, Schedule Schedule Schedule

Schedule

Size in. 5s (1) 10s (1) 40s 805

'18 0.405 ... 0.049 0.068 0.095

'I4 0.540 ... 0.065 0.088 0.119

310 0.675 ... 0.065 0.091 0.126

'I2 0.840 0.065 0.083 0.109 0.147

3/4 1.050 0.065 0.083 0.1 13 0.1 54

1 1.31 5 0.065 0.109 0.133 0.1 79

1'14 1.660 0.065 0.109 0.140 0.1 91

1'I2 1.goo 0.065 0.109 0.145 0.200

2 2.375 0.065 0.109 0.1 54 0.218

2'12 2.875 0.083 0.120 0.203 0.276

3 3.500 0.083 0.1 20 0.216 0.300

3'12 4.000 0.083 0.120 0.226 0.318

4 4.500 0,083 0.1 20 0.237 0.337

5 5.563 0.109 0.1 34 0.258 0.375

6 6.625 0.109 0.134 0.280 0.432

8 8.625 0.109 0.148 0.322 0,500

10 10.750 0.134 0.165 0.365 0.500 (21

12 12.750 0.1 56 0.180 0.375 (2) 0.500 (2)

14 14.000 0.156 0.188 (2) ... ...

16 16.000 0.165 0.188 (2)

18 18.000 0.165 0.188 (2) ... ...

20 20.000 0.188 0.21 8 (2) ...

...

. . I

22 22.000 0.188 0.218 (2)

... ...

. I .

24 24.000 0.218 0.250

30 30.000 0.250 0.312 ... ...

GENERAL NOTES:

(a) 1 in. = 25.4 mm

(b) For tolerances, see Section 4.

NOTES:

(1) Schedules 5s and 10s wall thicknesses do not permit threading in accordance with ANSI/

ASME B1.20.1.

(2) These-dimensionsdo not conform to ANSllASME B36.10M.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ANSllASME 836.1 9M-1985

AN AMERICAN NATIONAL STANDARD STAINLESS STEEL PIPE

TABLE 2 A DIMENSIONS OF WELDED AND SEAMLESS STAINLESS,STEEL

PIPE - SI UNITS

Inch

Nominal Wall Thickness, mm

Nominal Outside

Pipe Diameter, Schedule Schedule Schedule

Schedule

Size mm (1 5s 1 10s (1) 40s 805

118 10.3 ... 1.24 1.73 2:41

13.7 ,.. 1.65 2.24 3.02

318 17.1 . .. 1.65 2.31 3.20

'I2 21.3 1.65 2.1 1 2.77 3.73

314 26.7 1.65 2.1 1 2.87 3.91

1 33.4 1.65 2.77 3.38 4.55

I' I 4 42.2 1.65 2.77 3.56 4.85

1'12 48.3 1.65 2.77 3.68 5.08

2 60.3 1.65 2.77 3.91 5.54

2'I2 73.0 2.1 1 3.05 5.1 6 7.01

3 88.9 2.1 1 3.05 5.49 7.62

3 101.6 2.1 1 3.05 5.74 8.08

4 1 14.3 2.1 1 3.05 6.02 8.56

5 141.3 2.77 3.40 6.55 9.53

6 168.3 2.77 3.40 7.1 1 10.97

8 219.1 2.77 3.76 8.18 12.70

10 273.1 3.40 4.19 9.27 12.70 (2)

12 323.9 3.96 4.57 9.53 (2) 12.70 (2)

14 355.6 3.96 4.78 (2) ... ...

16 406.4 4.19 4.78 (2) ... ...

18 457 4.19 4.78 (2) ... ,..

20 508 4.78 5.54 (2) ... ...

22 559 4.78 5.54 (2) ... ...

24 610 5.54 6.35 ... *..

30 762 6.35 7.92 ... ...

GENERAL NOTES:

(a) 25.4 mrn = 1 in.

(b) For tolerances, see Section 4.

NOTES:

(1 Schedules 5s and 1OS wall thicknesses do not permit threading in accordance with ANSI/

ASME B1.20.1.

(2) These dimensions do not conform t o ANSllASME B36.10M.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ANSVASME B36.19M-1985

STAINLESS STEEL PIPE AN AMERICAN NATIONAL STANDARD

TABLE 3 NOMINAL WEIGHTS OF STEELPIPE, PLAIN ENDS -

CUSTOMARY UNITS

Inch

Weight of Steel Pipe, Plain Ends, lblft

Nominal

Pipe Schedule Schedule Schedule Schedule

Size 5s 1os 405 805

118 ... 0.19 0.24 0.31

’14 ... 0.33 0.42 0.54

3t8 0.42 0.57 0.74

112 0.54 0.67 0.85 1.09

% 0.69 0.86 1. I 3 1.47

1 0.87 1.40 1.68 2.17-

1’14 1.1 1 1.81 2.27 3.00

1‘I2 1.28 2.09 2.72 3.63

2 1.61 2.64 3.65 5.02

2’12 2.48 3.53 5.79 7.66

3 3.03 4.33 7.58 10.25

3% 3.48 4.97 9.1 1 12.51

4 3.92 5.61 10.79 14.98

5 6.36 7.77 14.62 20.78

6 7.60 9.29 18.97 28.57

8 9.93 13.40 28.55 43.39

10 15.19 18.65 40.48 54.74

12 20.98 24.1 7 49.56 65.42

14 23.07 27.73 ... ...

16 27.90 31.75 ... ...

18 3 1.43 35.76 ... ...

20 39.78 46.06 ... ...

22 43.80 50.71

24 55.37 63.41 ... ..

30 79.43 98.93 ... ..

GENERAL NOTES:

(a) 1 Ib/ft = 1.4895 kglm

(b) Weights are given in poundsper linear foot and are for carbon steel pipe with plain ends.

(c) The different grades of stainless steel permit considerable variations in weight. The ferritic

stainless steels may be about 5% less, and the austeniticstainl.ess steels about 2% greater

than the values shown in thistable, which are based on weights for carbonsteel.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

r

ANSIIASME 636.19 ~ -985

I

AN AMERICAN NATIONAL STANDARD STAINLESS STEEL PIPE

TABLE 3A NOMINAL WEIGHTS OF STEEL'PIPE, PLAIN ENDS -

SI UNITS

Inch

Weight of Steel Pipe, Plain Ends, kglm

Nominal

Pipe Schedule Schedule Schedule Schedule

Size 5s 1os 40s 80s

... 0.28 0.37 0.47

... 0.49 0.63 0.80

0.63 0!84 1.10

0.80 1 .oo 1.27 1.62

1.03 1.28 1.69 2.20

1.30 2.09 2.50 3.24

1.65 2.70 3.39 4.47

1.91 3.1 1 4.05 5.41

2.40 3.93 5.44 7.48

3.69 5.26 8.63 11.41

4.51 6.45 11.29 15.27

5.18 7.40 13.57 I 8.63

5.84. 8-36 16.07 22.32

9.47 1 1,57 21.77 30.97

11.32 I 3.84 28.26 42.56

42.55 819.96 14.79 64.64

60.310 27.78 22.63 1 96.01

73.88 36.00 31.25 12 I 32.08

14 34.36 41 -30. ... ...

47.29 41.56 16 .... ...

53.26

18 46.81 ... ...

59.25 20 . . 68.61

. ...

75.53 65.24 22 ...

*.. ...

I . .

24 82-47 94.45

30147.36 118.31 ... ...

GENERAL NOTES:

(a) 1.4895 kglm = 1 Ib/ft

(b) Weights are given in kilograms per meter and are for carbon steel pipe with plain ends.

(c) The different grades of stainless steel permit considerable variations in weight. The ferritic

stainless steels may be.about 5% less, and the austenitic stainless steels about 2% greater

than the values shown in this table, whichare based on weights for carbon steel.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

AMERICAN NATIONALSTANDARDS FOR PRODUCT SIZES

Preferred Thicknesses for Uncoated Thin Flat Metals (Under

.0.250 In.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B32.1-1952(RI 983)

Preferred Diameters for Round Wire- 0.500 Inches and

Under. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B32.2-1969(RI 979)

Preferred Metric Sizes for Flat Metal Products. . . . . . . . . . . . . . . . . B32.3M-1984

Preferred Metric Sizes for Round, Square, Rectangle and

Hexagon Metal Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B32.4M-1980

Preferred Metric Sizes for Tubular Metal Products Other

Than Pipe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B32.5-1977(R1983)

Preferred Metric Equivalents of InchSizes for Tubular Metal

Products Other Than Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B32.6M-1984

Welded and Seamless Wrought Steel Pipe.. . . . . . . . . . . . . . . . . . . B36.1 OM-I 9 8 5

Stainless Steel Pipe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B36.19M-1985

The ASME Publications Catalog shows a complete list of all Standards published

by the Society.

The catalog and binders for holding these Standards are available uponrequest.

MOO013

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

You might also like

- Ultrasonic Welding of Lithium-Ion Batteries: Enter asset subtitleFrom EverandUltrasonic Welding of Lithium-Ion Batteries: Enter asset subtitleNo ratings yet

- B36.19M 1985 Stainless Steel Pipe PDFDocument13 pagesB36.19M 1985 Stainless Steel Pipe PDFMadidj_2014No ratings yet

- Pressure Vessels Field Manual: Common Operating Problems and Practical SolutionsFrom EverandPressure Vessels Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (12)

- Asme B36 - 19M PDFDocument13 pagesAsme B36 - 19M PDFEme Eme LorcaNo ratings yet

- Friction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysFrom EverandFriction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysNo ratings yet

- b16 10Document39 pagesb16 10Gustavo FamaNo ratings yet

- Asme B36.10M 2000Document20 pagesAsme B36.10M 2000waheedulhassan56No ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Asme B36.10M PDFDocument31 pagesAsme B36.10M PDFSubhash KumarNo ratings yet

- Bioceramics: Materials and Applications V: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004From EverandBioceramics: Materials and Applications V: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004Veeraraghavan SundarNo ratings yet

- ANSI B16 5 Bridas y AccesoriosDocument157 pagesANSI B16 5 Bridas y AccesoriosDaniel FloresNo ratings yet

- ISA Handbook of Measurement, Equations and Tables, Second EditionFrom EverandISA Handbook of Measurement, Equations and Tables, Second EditionRating: 5 out of 5 stars5/5 (2)

- Asme B16.10-1992 PDFDocument39 pagesAsme B16.10-1992 PDFRuben Dario Mamani ArellanoNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- b16 34Document121 pagesb16 34Gustavo Fama100% (2)

- Advances in Photonic Materials and Devices: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004From EverandAdvances in Photonic Materials and Devices: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004Suhas BhandarkarNo ratings yet

- B 36.10mDocument31 pagesB 36.10mmisaelzaNo ratings yet

- Developments in Solid Oxide Fuel Cells and Lithium Ion Batteries: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004From EverandDevelopments in Solid Oxide Fuel Cells and Lithium Ion Batteries: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004Arumugam ManthiramNo ratings yet

- Asme b16.3 (1998) Malleable Iron Threaded FittingsDocument30 pagesAsme b16.3 (1998) Malleable Iron Threaded FittingsMarcos RosenbergNo ratings yet

- Surfaces, Interfaces and Science of Ceramic Joining: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004From EverandSurfaces, Interfaces and Science of Ceramic Joining: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004K. Scott WeilNo ratings yet

- Asme-B16 3 PDFDocument30 pagesAsme-B16 3 PDFmatiasjoseruiz80% (5)

- Synthesis, Properties, and Crystal Chemistry of Perovskite-Based Materials: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004From EverandSynthesis, Properties, and Crystal Chemistry of Perovskite-Based Materials: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004Winnie Wong-NgNo ratings yet

- ASME B16.11 Fittings Socket PDFDocument26 pagesASME B16.11 Fittings Socket PDFYorman TorresNo ratings yet

- Ceramic Nanomaterials and Nanotechnology III: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004From EverandCeramic Nanomaterials and Nanotechnology III: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004Song Wei LuNo ratings yet

- Licensed by Information Handling Services Licensed by Information Handling ServicesDocument20 pagesLicensed by Information Handling Services Licensed by Information Handling ServicesAnonymous AA30q4100% (1)

- Nuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresFrom EverandNuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresRating: 5 out of 5 stars5/5 (1)

- Asme B16.15-1985 PDFDocument37 pagesAsme B16.15-1985 PDFRuben Dario Mamani ArellanoNo ratings yet

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Asme B36.10M-2004Document26 pagesAsme B36.10M-2004Yen Piankin Wee Valencia100% (2)

- Asme Ansi 16.11 Accesorios PDFDocument27 pagesAsme Ansi 16.11 Accesorios PDFMiguel Urzagaste CruzNo ratings yet

- Welded and Seamless PipesDocument36 pagesWelded and Seamless Pipesssen8No ratings yet

- b16 25Document22 pagesb16 25Gustavo FamaNo ratings yet

- Asme B16.11Document27 pagesAsme B16.11Nelson Alejandro Fernández NúñezNo ratings yet

- Asme B36.19MDocument13 pagesAsme B36.19Mdongpc1No ratings yet

- ASME B1.16 - B1.16M - 1984 (Reaffirmed 2006) PDFDocument184 pagesASME B1.16 - B1.16M - 1984 (Reaffirmed 2006) PDFKristin Jones100% (1)

- Specification For In-Line Centrifugal Pumps For Chemical ProcessDocument29 pagesSpecification For In-Line Centrifugal Pumps For Chemical ProcessIlka RaffaelliNo ratings yet

- Ansi B31.8 PDFDocument185 pagesAnsi B31.8 PDFAndres Antonio Moreno Castro100% (1)

- Asme B1.21M-1997 (2018)Document68 pagesAsme B1.21M-1997 (2018)Md. Firozur RahmanNo ratings yet

- Asme b18.2.26 (1996) - Fasteners For Use in Structural AppllcatlonsDocument23 pagesAsme b18.2.26 (1996) - Fasteners For Use in Structural Appllcatlonsgusla7No ratings yet

- b16 47Document65 pagesb16 47Gustavo FamaNo ratings yet

- Asme B31.9Document86 pagesAsme B31.9mrivera100% (5)

- Licensed by Information Handling Services Licensed by Information Handling ServicesDocument147 pagesLicensed by Information Handling Services Licensed by Information Handling Servicesrogel_ganaNo ratings yet

- Asme B16.21Document21 pagesAsme B16.21Anant RubadeNo ratings yet

- B01 16M PDFDocument174 pagesB01 16M PDFziedNo ratings yet

- b18 10Document13 pagesb18 10Gustavo FamaNo ratings yet

- Asme B16.3Document30 pagesAsme B16.3JamesNo ratings yet

- Asme B18.8.200M-2000 (2010)Document44 pagesAsme B18.8.200M-2000 (2010)vijay pawar100% (1)

- Asme b16 9 2003 PDFDocument48 pagesAsme b16 9 2003 PDFNicole Williams100% (2)

- Stainless Steel Pipe: ASME B36.19M-2004Document14 pagesStainless Steel Pipe: ASME B36.19M-2004shakeelahmadjsr100% (1)

- Final NAAMM Pipe RailingDocument50 pagesFinal NAAMM Pipe RailingricosanojuanNo ratings yet

- Asme b1.2-1983 (r2017) - en Norma de Rines y PlgaDocument197 pagesAsme b1.2-1983 (r2017) - en Norma de Rines y PlgaSICAAM QUERETARONo ratings yet

- Asme b16.25 Buttwelding EndsDocument22 pagesAsme b16.25 Buttwelding Endsgst ajahNo ratings yet

- Asme B16.20Document47 pagesAsme B16.20tofikur08100% (2)

- ASME B16.10 Face To Face and End To End Dimension of ValvesDocument39 pagesASME B16.10 Face To Face and End To End Dimension of ValvesOlieev100% (1)

- Asme B29.1M 1993 (R1999)Document59 pagesAsme B29.1M 1993 (R1999)J Ferreyra Libano100% (4)

- b16 21 PDFDocument21 pagesb16 21 PDFavinash_k007No ratings yet

- Asme B16.11Document27 pagesAsme B16.11hanan147100% (1)

- ASME B36.19M Stainless Steel PipesDocument14 pagesASME B36.19M Stainless Steel Pipesdssscarface50% (2)

- ASME B36 10M-2015 Welded and Seamless Wrought Steel PipeDocument30 pagesASME B36 10M-2015 Welded and Seamless Wrought Steel PipeDaniel Diaz PrietoNo ratings yet

- Pump Data Sheet and Checklist: GENERAL DESCRIPTION OF APPLICATION (Type of Process, Fluid, Etc.)Document1 pagePump Data Sheet and Checklist: GENERAL DESCRIPTION OF APPLICATION (Type of Process, Fluid, Etc.)BimaNo ratings yet

- Saddle AnalysisDocument17 pagesSaddle AnalysisAntonio Perez ZornozaNo ratings yet

- Horizontal Saddle Supported Storage Vessels: A Parametric Study of Plastic Collapse LoadsDocument27 pagesHorizontal Saddle Supported Storage Vessels: A Parametric Study of Plastic Collapse LoadsBimaNo ratings yet

- Pump Data Sheet and Checklist: GENERAL DESCRIPTION OF APPLICATION (Type of Process, Fluid, Etc.)Document1 pagePump Data Sheet and Checklist: GENERAL DESCRIPTION OF APPLICATION (Type of Process, Fluid, Etc.)BimaNo ratings yet

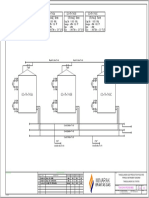

- TGA-02-K10-PID-002-MBG TGA OIL STATION-Model PDFDocument1 pageTGA-02-K10-PID-002-MBG TGA OIL STATION-Model PDFBimaNo ratings yet

- Scanned With CamscannerDocument8 pagesScanned With CamscannerBimaNo ratings yet

- CH4 2 Welding Joint PreparationDocument46 pagesCH4 2 Welding Joint PreparationMatija BušićNo ratings yet

- ASME SpreaderBar CalcsDocument5 pagesASME SpreaderBar Calcsganesh100% (1)

- Radioactive Half LifeDocument5 pagesRadioactive Half LifeVietNo ratings yet

- AJPMenu Bar MCQDocument8 pagesAJPMenu Bar MCQAkNo ratings yet

- Switchword PairsDocument6 pagesSwitchword PairsLaleKulahli100% (7)

- Ground Penetrating Radar For Locating Buried Utilities: Operation ManualDocument75 pagesGround Penetrating Radar For Locating Buried Utilities: Operation ManualArmando BiringkanaeNo ratings yet

- Palm Kernel Reinforced Composites for Brake Pad ApplicationsDocument18 pagesPalm Kernel Reinforced Composites for Brake Pad ApplicationsSachin SukumaranNo ratings yet

- Splices: S100 S100 S101 S101 S101 S102Document3 pagesSplices: S100 S100 S101 S101 S101 S102Albert BriceñoNo ratings yet

- Structural Knowledge LEEERRR PDFDocument22 pagesStructural Knowledge LEEERRR PDFMaría Paula BaqueroNo ratings yet

- MC61ADocument5 pagesMC61AAlison Foster100% (1)

- The Biology of Vascular Epiphytes Zotz 2016 PDFDocument292 pagesThe Biology of Vascular Epiphytes Zotz 2016 PDFEvaldo Pape100% (1)

- Resume Dianne Ostrander 4-27-06-09Document2 pagesResume Dianne Ostrander 4-27-06-09api-12400587No ratings yet

- A Survey of English and American Literature Module 1 3Document80 pagesA Survey of English and American Literature Module 1 3Jathalia VillaNo ratings yet

- Solar/Wind/Diesel Hybrid Energy System With Battery Storage For Rural ElectrificationDocument15 pagesSolar/Wind/Diesel Hybrid Energy System With Battery Storage For Rural ElectrificationWelde AynaleNo ratings yet

- Global Detection - Electronic and Electromechanical Sensors Catalogue 2006.10 PDFDocument800 pagesGlobal Detection - Electronic and Electromechanical Sensors Catalogue 2006.10 PDFSarah RichardNo ratings yet

- Section 6 - Diagnostic ProceduresDocument13 pagesSection 6 - Diagnostic Proceduresanon_152488453100% (1)

- Solid State Device Analysis ApproximationsDocument34 pagesSolid State Device Analysis Approximationsmrd9991No ratings yet

- Aquilion ONE GENESIS Edition Transforming CTDocument40 pagesAquilion ONE GENESIS Edition Transforming CTSemeeeJuniorNo ratings yet

- ESL Students' Experiences of Online Peer Feedback: Martin Guardado, Ling ShiDocument19 pagesESL Students' Experiences of Online Peer Feedback: Martin Guardado, Ling ShiJun PrinceNo ratings yet

- 3 Huang2015Document10 pages3 Huang2015kikoNo ratings yet

- Rogers Lacaze Case InfoDocument1 pageRogers Lacaze Case InfomakeawishNo ratings yet

- Standard Top Up Vouchers: Prices:: Internet Blocked Internet BlockedDocument15 pagesStandard Top Up Vouchers: Prices:: Internet Blocked Internet BlockedJeet SinghNo ratings yet

- Basavarajeshwari Group of Institutions: Self Balancing UnicycleDocument15 pagesBasavarajeshwari Group of Institutions: Self Balancing UnicycleJeerigi DeepikaNo ratings yet

- 2-Stress-Test Your Strategy The 7 Questions To AskDocument9 pages2-Stress-Test Your Strategy The 7 Questions To AskMalaika KhanNo ratings yet

- Me f215 Mel Lab ManualDocument105 pagesMe f215 Mel Lab ManualpankazspamNo ratings yet

- Arnold Jacobs: His Global Influence: Midwest Clinic, Thursday, December 17 12:00-1:00pmDocument17 pagesArnold Jacobs: His Global Influence: Midwest Clinic, Thursday, December 17 12:00-1:00pmAlex MoralesNo ratings yet

- Valvula Contrabalance CBV1 10 S O A 30Document21 pagesValvula Contrabalance CBV1 10 S O A 30Judith Daza SilvaNo ratings yet

- Teaching English Poetry at Secondary LevelDocument15 pagesTeaching English Poetry at Secondary LevelEngr Saud shahNo ratings yet

- Compare and Contrast History EssayDocument9 pagesCompare and Contrast History EssayGiselle PosadaNo ratings yet

- Y10 ICT End of TermDocument7 pagesY10 ICT End of TermIvy Atuhairwe BisoborwaNo ratings yet

- Haven, Quantum Social ScienceDocument306 pagesHaven, Quantum Social ScienceMichael H. HejaziNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Design Is The Problem: The Future of Design Must Be SustainableFrom EverandDesign Is The Problem: The Future of Design Must Be SustainableRating: 1.5 out of 5 stars1.5/5 (2)

- Iconic Advantage: Don’t Chase the New, Innovate the OldFrom EverandIconic Advantage: Don’t Chase the New, Innovate the OldRating: 4 out of 5 stars4/5 (1)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorFrom EverandThe Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorRating: 4 out of 5 stars4/5 (7)

- Top-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsFrom EverandTop-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsNo ratings yet

- Designing for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionFrom EverandDesigning for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionNo ratings yet