Professional Documents

Culture Documents

CARBOLITE Controladores

Uploaded by

Erwin Putro Setyo BudiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CARBOLITE Controladores

Uploaded by

Erwin Putro Setyo BudiCopyright:

Available Formats

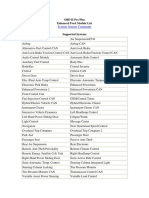

Product Configurations

88 Temperature Control Options

301 Standard controller

The 301 PID controller has a large display mounted behind The 301 provides END-TIME

a smooth wipe-clean membrane and offers a single ramp to precise PID (Proportional

Integral Derivative) control

set point. It includes a 99 hour process timer which can be

TEMP

meaning that ramp rates

programmed for a timed delay at the start of the process or and set points are very RAMP DWELL

used as a countdown timer. closely followed.

TIME

Options

301 Over-temperature control

This option offers a variable set point

to protect either the chamber or the

load. Selection of this option provides an

additional independent thermocouple

and protection circuit which is fully integrated into the

301 controller. Whilst all Carbolite products are designed

to fail safe in the event of a controller malfunction, over-

temperature protection is strongly recommended for

unattended operation or where valuable loads are to be

processed.

Programmable controllers

DWELL x1

TEMP

3216P1 & 3216P5 x5

RAMP

These controllers offer programmable control using up to TIME

8 segment pairs, each segment comprising a ramp followed SEGMENT PAIRS up to 8

by a dwell; the dwell may be set to zero time.

The 3216P5 can also store and retrieve up to 5 separate

programs.

3508P1, 3508P10 & 3508P25 x1

DWELL

These controllers offer programmable control in which x 10

TEMP

20 segments may be set as ramp, step or dwell and may

also be configured to control relays or logic outputs. RAMP x 25

The 3508 series provide a comprehensive information TIME

display. If precise temperature control is required over a SEGMENT up to 20

(Ramp, Step or Dwell)

wide range of temperatures, the 3508 series allows the use

of multiple PID terms (gain scheduling). This feature is

not enabled as standard, but can be activated on request.

The 3508P10 and 3508P25 can also store and retrieve

10 and 25 programs respectively.

Options

Over-temperature control

This has a variable set point to protect either the furnace, oven or the load. If the

main controller is from the 3216 or 3508 series this is provided by the addition of an

independent 2132 controller. Whilst all Carbolite products are designed to fail safe in the

event of a controller malfunction, over-temperature protection is strongly recommended

for unattended operation or where valuable loads are to be processed.

Leading Heat Technology | www.carbolite.com

Product Configurations

Temperature Control Options 89

Eurotherm nanodac™

Recorder & PID controller

In this configuration the nanodac™ combines precision PID

temperature control, with a fully functional data logger. The

full colour display can be changed to display text in English,

French, German, Italian or Spanish.

Data is continuously logged into either CSV (comma

separated variable) or securely to UHH (Eurotherm Hydra

History) files. Data can be archived onto a USB flash drive

or via Ethernet to a networked server. Up to 4 channels can

be recorded, with up to 14 virtual channels that can be set

to record trends, alarms, communications or mathematical

functions such as totals or averages.

Logged files can be opened and displayed on a PC, in chart

form, using Eurotherm Review Lite software.

Programm status Program edit

Recorder & PID programmable

controller

This controller offers programmable control in which

25 segments may be set as a ramp, step or dwell and

may also be configured to control relay or logic outputs.

It stores and retrieves 100 programs.

Additional programs can be saved to, and retrieved from,

a networker server via a USB flash drive or Ethernet. The

action of up to 3 relays, or logic outputs, can be linked to a

program segment; this can be used to switch on external

devices such as gas solenoid valves and audible alarms

Note that some configurations may require additional

components.

+ 100 Programm Segment Program time

progress progress remaining

DWELL x 100

TEMP

In this configuration the nanodac™ can hold up to 100

programs

RAMP

TIME

SEGMENT up to 25

(Ramp, Step or Dwell)

RS232, RS485 and Ethernet communications

• RS232 allows a single controller to communicate with a single computer

• RS485 allows multiple controllers to communicate with a single computer

• Both require, but do not include, suitable PC based software (eg iTools) and connection cables

• 301 controller – RS232 is only available when ordered with over-temperature option

(RS485 is not available with the 301 controller)

• 3216 and 3508 series controllers both have the option to add RS232 or RS485 communications

• Ethernet communication is supplied as standard with the nanodac™ controller and is optional in the 3508 series

www.carbolite.com | Leading Heat Technology

You might also like

- Rinnai RCE229hDocument22 pagesRinnai RCE229hvictor.imagemarketing0% (1)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Lithium-Ion Stationary Battery Capacity Sizing Formula For The Establishment of Industrial DesignDocument7 pagesLithium-Ion Stationary Battery Capacity Sizing Formula For The Establishment of Industrial Design장중구100% (1)

- Huawei Active Antennas Design Guideline v05 VF-ESDocument35 pagesHuawei Active Antennas Design Guideline v05 VF-ESestebanarca100% (2)

- Ibwave V 6.5.3Document38 pagesIbwave V 6.5.3Idoga Meshach Ameh100% (1)

- TC515Document2 pagesTC515RICHARDNo ratings yet

- XR30C - XR30D: Digital Controller With Off Cycle DefrostDocument4 pagesXR30C - XR30D: Digital Controller With Off Cycle DefrostJennifer Eszter SárközyNo ratings yet

- XR20C - XR20D: Installing and Operating InstructionsDocument4 pagesXR20C - XR20D: Installing and Operating InstructionsJennifer Eszter SárközyNo ratings yet

- Xr70cx RTC GB DixellDocument4 pagesXr70cx RTC GB DixellTeknik1 sultengNo ratings yet

- XR20C - XR20D: Digital Controller With Off Cycle DefrostDocument4 pagesXR20C - XR20D: Digital Controller With Off Cycle DefrostJennifer Eszter SárközyNo ratings yet

- Ducted Split Systems: Technical DataDocument20 pagesDucted Split Systems: Technical DataFilipNo ratings yet

- ToptronicDocument4 pagesToptronicGianina BiancaNo ratings yet

- Dixell XR60CDocument4 pagesDixell XR60CCarlos0% (1)

- Dixell xw260lDocument4 pagesDixell xw260lMiftakhul KhoirNo ratings yet

- Honeywell t3 Spec SheetDocument11 pagesHoneywell t3 Spec SheetCkgnnvNo ratings yet

- 30GT CB PDFDocument4 pages30GT CB PDFSaad PathanNo ratings yet

- Heat Pumps: Compact Reliable EfficientDocument4 pagesHeat Pumps: Compact Reliable EfficientarminsarajevoNo ratings yet

- LAUDA Proline AtsDocument20 pagesLAUDA Proline AtsAndrei BănceuNo ratings yet

- XR70C - XR70D - XR72C: Installing and Operating InstructionsDocument4 pagesXR70C - XR70D - XR72C: Installing and Operating InstructionsJennifer Eszter SárközyNo ratings yet

- XR60C - XR60D: Digital Controller With Defrost and Fans ManagementDocument4 pagesXR60C - XR60D: Digital Controller With Defrost and Fans ManagementHaiam BordaNo ratings yet

- XR70C - XR70D - XR72C: Digital Controller With Defrost and Fans ManagementDocument4 pagesXR70C - XR70D - XR72C: Digital Controller With Defrost and Fans ManagementJennifer Eszter SárközyNo ratings yet

- UntitledDocument8 pagesUntitledCretu Stefan-DanielNo ratings yet

- XR30C - XR30D: Installing and Operating InstructionsDocument4 pagesXR30C - XR30D: Installing and Operating InstructionsJennifer Eszter SárközyNo ratings yet

- Dixell XH240K - GBDocument4 pagesDixell XH240K - GBionut ciobanuNo ratings yet

- 4 Stage ThermostatDocument16 pages4 Stage ThermostatKrishnan GovindarajNo ratings yet

- Honeywell Thermostat T7350Document40 pagesHoneywell Thermostat T7350carlos.castillo.ing.1No ratings yet

- XH260L-V GB r1.0 29.02.2007Document4 pagesXH260L-V GB r1.0 29.02.2007Jennifer Eszter SárközyNo ratings yet

- Visionpro™ 8000 Touchscreen Programmable Thermostat: FeaturesDocument40 pagesVisionpro™ 8000 Touchscreen Programmable Thermostat: Featurespctyson100% (1)

- EWPC 974: Freezer ControlDocument3 pagesEWPC 974: Freezer ControlFlávio MatosNo ratings yet

- XR20C - XR20D: Digital Controller With Off Cycle DefrostDocument4 pagesXR20C - XR20D: Digital Controller With Off Cycle DefrostJennifer Eszter SárközyNo ratings yet

- TERMOSTATODocument40 pagesTERMOSTATOISMAEL ENRIQUE VALENCIA JURADONo ratings yet

- Regulator PID KS 40 - KS 40-1 DatasheetDocument8 pagesRegulator PID KS 40 - KS 40-1 DatasheetAco mijoskiNo ratings yet

- Mk8Controller 24 03 2017Document12 pagesMk8Controller 24 03 2017iskandarNo ratings yet

- t4r Gi sp1h32318057 005uk07r0816Document10 pagest4r Gi sp1h32318057 005uk07r0816FrodoNo ratings yet

- Vemer Climate ControlDocument38 pagesVemer Climate ControlHydrolectric Ltd.No ratings yet

- RB8ES202Document2 pagesRB8ES202Taufan JustvandsNo ratings yet

- XH240L-V GB r1.0 12.01.2004Document4 pagesXH240L-V GB r1.0 12.01.2004Jennifer Eszter SárközyNo ratings yet

- XR70C-D XR72C GB r1.0 18.11.2015Document4 pagesXR70C-D XR72C GB r1.0 18.11.2015Jennifer Eszter SárközyNo ratings yet

- Hướng dẫn sử dụng bộ điều khiển nhiệt độ Dixell-XR72CXDocument4 pagesHướng dẫn sử dụng bộ điều khiển nhiệt độ Dixell-XR72CXVĩnhNo ratings yet

- Installing and Operating Instructions: DixellDocument4 pagesInstalling and Operating Instructions: Dixellmartinfood100% (1)

- NRB 0282-0754 HDocument8 pagesNRB 0282-0754 HZvonimir PerasovićNo ratings yet

- Vaporizer Control: The Dry-Type Vaporizer FAS 2000i Has Been SpecificallyDocument1 pageVaporizer Control: The Dry-Type Vaporizer FAS 2000i Has Been SpecificallyLpg Power SupplyNo ratings yet

- Euro Therm 2416Document13 pagesEuro Therm 2416restor3dNo ratings yet

- M52 Controller - Simplicity by DesignDocument6 pagesM52 Controller - Simplicity by Designluis pardo solano100% (1)

- Motan 960 PDFDocument11 pagesMotan 960 PDFDgfdghfghFfdhgfhjgNo ratings yet

- T775 Series 2000 Electronic Stand-Alone Controllers: DescriptionDocument4 pagesT775 Series 2000 Electronic Stand-Alone Controllers: DescriptionJose NavarroNo ratings yet

- 30Gx - Nee: Global ChillerDocument12 pages30Gx - Nee: Global ChillermanoNo ratings yet

- 06 Oil Injected Screw GAR 11-37-2Document2 pages06 Oil Injected Screw GAR 11-37-2RUN GONo ratings yet

- Adap - KoolDocument12 pagesAdap - Kooldp3006No ratings yet

- 81130I Gefran-Controllers and Programmers EN 08 20Document24 pages81130I Gefran-Controllers and Programmers EN 08 20cxvxcNo ratings yet

- Cgwn/Ccun Indoor Liquid Chillers: The Compact Aquastream SolutionDocument8 pagesCgwn/Ccun Indoor Liquid Chillers: The Compact Aquastream SolutionDianaNo ratings yet

- Reference Guide For The DDC ControllerDocument32 pagesReference Guide For The DDC ControllerIsmael PerezNo ratings yet

- DDC Controls Package Manual: VHC-36, - 42 and - 50Document24 pagesDDC Controls Package Manual: VHC-36, - 42 and - 50Emanuel MaracajáNo ratings yet

- XR10C - XR10D: Digital Controller With Cooling or Heating ActionDocument4 pagesXR10C - XR10D: Digital Controller With Cooling or Heating ActionJennifer Eszter SárközyNo ratings yet

- Big Dutchman Stallklima Poultry Climate Control Viper enDocument6 pagesBig Dutchman Stallklima Poultry Climate Control Viper enjhsee72No ratings yet

- 30Gx - Nee: Air-Cooled Screw Compressor Liquid Chillers, High Outdoor Temperature VersionDocument12 pages30Gx - Nee: Air-Cooled Screw Compressor Liquid Chillers, High Outdoor Temperature VersionmanoNo ratings yet

- Doc-0083126 L2 ENDocument20 pagesDoc-0083126 L2 ENalseusrahNo ratings yet

- VRF SLB010 en - 100714Document40 pagesVRF SLB010 en - 100714Anabel Hernández DíazNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Thiết Bị Merlin Gerin: Domae MCB, RCCBDocument14 pagesThiết Bị Merlin Gerin: Domae MCB, RCCBNgoc Nguyen KimNo ratings yet

- Logic GateDocument12 pagesLogic Gateapi-254068557No ratings yet

- Chapter 4 Laplace TransformDocument54 pagesChapter 4 Laplace Transformkhaled jNo ratings yet

- CMW LTE UE UserManual V3-5-30 en 22Document940 pagesCMW LTE UE UserManual V3-5-30 en 22monel_24671100% (3)

- Unisonic Technologies Co., LTD: Eight High Voltage, High Current Darlington ArraysDocument5 pagesUnisonic Technologies Co., LTD: Eight High Voltage, High Current Darlington ArraysTojo BasheerNo ratings yet

- Swimming Pool Lighting DesignDocument2 pagesSwimming Pool Lighting DesignquletjavierNo ratings yet

- Schmitt TriggerDocument4 pagesSchmitt TriggerSaurabh ChakravartyNo ratings yet

- HVAC BrochureDocument18 pagesHVAC BrochureCarlos Benavides AlvarezNo ratings yet

- DM7416 Hex Inverting Buffers With High Voltage Open-Collector OutputsDocument3 pagesDM7416 Hex Inverting Buffers With High Voltage Open-Collector OutputsnooorNo ratings yet

- 01-04 ChassisDocument433 pages01-04 ChassisThị Thanh Thảo TrầnNo ratings yet

- Analysis and Design of Small Signal Low Frequency BJT AmplifiersDocument18 pagesAnalysis and Design of Small Signal Low Frequency BJT Amplifiersvenkiscribd444No ratings yet

- Auto Trans Diagnosis - Aw03-72Le Article TextDocument15 pagesAuto Trans Diagnosis - Aw03-72Le Article TextCarlos Andres Campos TorresNo ratings yet

- Low Power & Area Efficient Layout Analysis of Cmos EncoderDocument5 pagesLow Power & Area Efficient Layout Analysis of Cmos EncoderSamiksha GautamNo ratings yet

- Siemens-7SJ62-dir OcDocument4 pagesSiemens-7SJ62-dir OcAbo Abdullah MohamedNo ratings yet

- Wireless World 1990 01Document92 pagesWireless World 1990 01Milton Nast0% (1)

- Gate Triggering Ckts Resistance TriggeringDocument6 pagesGate Triggering Ckts Resistance TriggeringAkhilrajscribdNo ratings yet

- OBD II Pro PlusFordDocument50 pagesOBD II Pro PlusFordkamaleon doradoNo ratings yet

- VIP396 ManualDocument8 pagesVIP396 ManualWONG HOW YANNo ratings yet

- 6SLA130L - 817738nDocument1 page6SLA130L - 817738nPaul DingelstadNo ratings yet

- Sumitomo Type 39Document2 pagesSumitomo Type 39Hans IgelerNo ratings yet

- Chapter 22 - Principles of Electronic Communication Systems - FrenzelDocument110 pagesChapter 22 - Principles of Electronic Communication Systems - FrenzelDrex GarciaNo ratings yet

- COntoh Jurnal ProsidingDocument9 pagesCOntoh Jurnal Prosidingfebrian nandaNo ratings yet

- Servo MotorDocument21 pagesServo Motorthreephasefault100% (1)

- ReleaseNotes IndraDrive MPB20VRS ENDocument224 pagesReleaseNotes IndraDrive MPB20VRS ENLinh Pham0% (1)

- V 0130 GB Modulation Techniques - ModulatorsDocument266 pagesV 0130 GB Modulation Techniques - Modulatorsحسين حيدر آلوس عباسNo ratings yet

- Eead422 TransformerDocument183 pagesEead422 TransformerRenzJohnAmpostaNo ratings yet

- Antennas: Constantine A. BalanisDocument45 pagesAntennas: Constantine A. BalanisAzeem BhattiNo ratings yet