Professional Documents

Culture Documents

Pitfalls & Risks - in - Engaging - Geotechnical - Consultants

Uploaded by

Shahin FalahatiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pitfalls & Risks - in - Engaging - Geotechnical - Consultants

Uploaded by

Shahin FalahatiCopyright:

Available Formats

FOUNDATIONS ON SHALE AND SANDSTONE - Pelts, Douglas, Radway, Thorne & McMahon

Design Loadings for Foundations on Shale and Sandstone in the

Sydney Region

P.J.N. Pells, D.J. Douglas, F.l.E. Aust., B. Rodway, M.l.E. Aust., C. Thorne, F.l.E. Aust., and

B.K. McMahon, M.l.E. Aust.*

SUMMARY This paper considers the design of vertically loaded, isolated foundations located on or socketed

into the sandstones and shales of the Sydney Basin. Inclined loading and loading near the edge of an

excavation are not considered. A classification scheme for the shales and sandstones is proposed coupled

with suggested allowable values for end bearing pressure and socket shear stress. These recommended

pressures and shear stresses are based on limiting displacements to 1% of the socket or footing diameter.

1 INTRODUCTION which applies throughout New South Wales with the

exception of a few remote areas. Commonwealth and

In May 1976 a sub-committee of the Sydney State Government Departments are not bound by the

Geomechanics group was formed to review the situ- rules but the policy of these Departments is to

ation regarding the design of foundations on the endeavour to conform to them unless there ;are

Sydney shales and sandstones. It was decided to special reasons which justify departures./

limit the investigation to the bearing capacity and

deformations of vertically loaded, isolated found- Specific criticisms of the Ordinance incluJ~:

ations that are located on, or socketed into.level

strata; interaction effects and the problems (a) It does not acknowledge the dependerice;of

associated with founding near the edge of an exist- foundation behaviour on footing width ·

ing or proposed excavation were thus specifically

excluded. This work was prompted by various crit- (b) The descriptive terms for the different rock

icisms of the existing New South Wales Ordinance types (e.g. soft shale, weathered rock,

(Ordinance 70) that have been made from time to medium sandstone) are not defined

time, and by the existence of numerous cases where

substantially higher stresses than those tabled in (c) All "defects" in a rock mass are treated

the Ordinance have been successfully carried, both alike, there being no concept of a graded

by the Sydney rocks and also by similar or poorer significance to differentiate between say

quality rocks elsewhere. a strong shale layer in sandstone and a soft

clay seam

This paper gives the results of the investigation

and traces the sequence_ of study as follows: (d) No consideration is given to socket shear.

(i) Existing legal requirements and design However, it is clear that for structures whose

methods foundation costs do not merit special design

(ii) Theoretical studies and laboratory data consideration, the Ordinance, in essentially its

related to the bearing capacity of rock present form, provides a convenient and conservative

(iii) Field tests on individual foundations on approach, particularly where its provisions are

rock. applied with reasonableness and judgement. Hence

this paper is directed primarily to situations in

Based on these studies the paper culminates with which significant financial savings can be made by

guidelines for those designers, who, in accordance increasing the foundation stresses above those

with the "let-out" clause in the existing given in the Ordinance 70 table. Ordinance 70 has,

Ordinance, wish to design for higher foundation since 1974, made provision for the acceptance of

pressures, where these can be justified following higher foundation stresses through clause 32.3(i).

an appropriate site investigation.

2 EXISTING LEGAL REQUIREMENTS AND DESIGN 2.2 Existing Design Methods

ME1HODS

A questionnaire circulated to engineering firms and

2.1 Ordinance Regulations organisations produced the following generalised

picture of the existing design of foundations on

The legal document relevant to foundation loadings Sydney shales and sandstones.

is Ordinance No.70 - Building, a Local Government

ordinance which came into force in July 1974 and Practically all foundation desig~ers recognize

Ordinance 70 as the operative guideline and approx-

* Mr.Pells is a Lecturer in Civil Engg, University of imately 80% "usually" adopt the allowable bearing

Sydney; Mr.Douglas is Managing Director of Ground pressures listed in the Ordinance. Some 30% of

Test Pty.Ltd. Sydney; Mr.Radway is Chief Engineer those surveyed never use design values in excess of

with Dept. of Construction, Sydney; Mr.Thorne is a the Ordinance table even when obviously strong rock

partner in Coffey &Partners, Sydney and Dr. is available but about 15% "frequently" use higher

McMahon is a partner of McMahon, Burgess and values; foundations on uniform Ashfield shale, for

Yeates, Sydney. (Paper S1015, submitted 12 May example, have been designed on the basis of 2000

1978). and 3000 kilopascals on a number of occasions and

Australian Geomechanics Journal, 1978 31

FOUNDATIONS ON SHALE' AND SANDSTONE~ Pelts, Douglas, Radway, Thorne & McMahon

5000 kilopascals in one instance despite the One other theoretical aspect that needs consider-

Ordinance limit of 960 kPa. ation is the use of elastic theory to evaluate the

load distribution in rock sockets and also to pre-

Most designers take into account load carried in dict settlement. Figure 1 gives curves from

shear on the sides of bored piers but few consider elastic theory (Pells and Turner, 1978b) that

that such potenrial support should be depended upon enable the determination of the proportion of load

when designing pad foundations. Of those using that reaches the base of a socket. Alternatively

"socket design", most regard the socket support as these curves can be used to determine when a part-

additional to end bearing capacity rather than in icular socket design implies possible slip down the

place of it. socket side with a redistribution of load into end

bearing. Figure 2 gives curves for the elastic

A wide range of socket design stresses is used but settlement of a rock socketed pile assuming the rock

there is considerable inconsistency from designer to be homogeneous, isotropic and infinitely deep.

to designer and the values are infrequently sub- The use of these elastic solutions is illustrated

stantiated; they range from SO kPa up to 1400 kPa. in the worked example at the end of this paper.

Values are usually selected on the basis of rock

type and quality but are sometimes expressed as a 4 FIELD DATA

percentage of the allowable end bearing pressure.

For example one designer uses 400 kPa for shale and Theoretical methods are of relevance to certain

700 kPa for sandstone while another uses 25% - 35% field situations but in general data on the effects

of the allowable end bearing pressure in the case of jointing and layering on displacement can only

of shale and 35% - 65% of the end bearing pressure be obtained from field tests conducted on prototype

for sandstone. The Council of the City of Sydney foundations. These field tests also provide the

has approved socket stresses as high as 25% of the

stress taken in end bearing; Some full-scale pile

load tests have also been used to determine design

shear stresses. 60

50

3 1HEORETICAL AND MODEL STUDIES

...

0

40

The review of theoretical and model studies related lL

to load bearing on rock is given elsewhere by Pells

and Turner (1978a) and only the main conclusions

"': 0

30 K = Epfle

.0

lL Erock

are given here. These are:

20

(i) the ultimate bearing capacity of intact

sandstone and good quality shale, for surface 10

loading, is between 6 and 10 times the uni-

axial strength.

0

0 2 3 4 5 7 8

(ii) the ultimate bearing capacity increases L/a

significantly with embedment in the rock. Figure 1 Elastic load distribution in a

Rock Socket

(iii) tight, closely spaced, continuous joints are

unlikely to reduce the bearing capacity to

less than 50% of the value for intact rock.

(iv) the load-penetration curve for bearing on

intact sandstone or shale exhibits a large

"plastic" component and displacements in

excess of 10% of the footing diameter are

required to develop ultimate bearing capacity. 2·0

(v) In model tests the shape of the load-pene-

tration curve, up to a penetration of at

least 8% of the footing diameter, is indep- (

endent of embedment. This is contrary to

elastic theory and is probably due to local- 0·8

ised failure occurring very early. 0·7

0·6

(vi) At working load there may be some fracturing

Ip 0·5

in the rock mass beneath a foundation. This

is considered quite acceptable and is compar- 0·4

able with the localised yield zones that

exist in slopes with factors of safety less 0·3

than about 1. 7 and beneath foundations on

plastic clay.

These conclusions indicate that although the bear-

ing capacity of sandstone or shale may be signif-

icantly greater than the uniaxial strength of the

rock substance, the allowable loadings for most

foundations may best be determined from consider-

ation of allowable structural displacements. It L/a

is suggested that typically a settlement of 1% of Figure 2 Elastic settlement influence

the footing diameter would be acceptable. factors for a rock socket

32 Australian Geomechanics journal, 1978

FOUNDATIONS ON SHALE AND SANDSTONE - Pelis, Douglas, Radway, Thome & McMahon

only significant source of data regarding the dev- Figure 3 shows the average shear stress versus

elopment of shear resistance on the sides of rock displacement curves obtained in the various socket

sockets. shear tests summarised in Table II. It is import-

ant to note that none of the tests have shown

Some 30 field tests have been examined even though brittle behaviour and the peak shear resistance is

a few of these relate to rock quite different from sustained even up to large displacements.

that found in the Sydney basin. The tests have

been divided into two groups, namely those related Again these test data have been used in developing

primarily to end bearing (summarised in Table I) the design tables and are referred to again later.

and those related to socket shear (summarised in

Table II). Where tests conducted on complete 5 DESIGN RECOMMENDATIONS

sockets were such that virtually all the load was

taken in end bearing the tests are included in 5.1 Design Philosophy

Table I and vice-versa in Table II. Some tests of

this nature could not be used as the load was even- The basic philosophy that has been adopted here is

ly distributed between shear and end bearing. that the allowable loadings of rock foundations are

limited by an allowable settlement of 1% of the

Very few of the end bearing tests have been taken footing width or diameter and not by applying some

to failure. However, it is clear that the field load factor to the peak side shear or end bearing

tests support the laboratory model tests in that capacity. Of course, by choosing a suitable load

large displacements (greater than 10% of the foot- factor one can effectively limit displacements but

ing diameter) were required to develop maximum when the maximum bearing capacity is very difficult

bearing capacity. In addition embedment does not to determine this latter approach is less satisfact-

affect the shape of the normalised load-displace- ory. Typically one would require a load factor on

ment curves until the displacements become very end bearing in excess of 4.0.

large (Williams, 1977).

Design tables have thus been prepared with suggested

Making the assumption that allowable displacements parameters for footings, piles and piers supported

are typically 1% or 2% of the footing diameter then on rock in the Sydney area. A value of 1 MPa for

it is possible, from the field tests summarised in the unconfined strength of the material is taken as

Table I, to abstract the bearing pressures at these the boundary between soil and rock. Foundations on

two percentage displacement values. These values materials with a lower strength than 1 MPa are best

have been used to develop the design tables in the dealt with using Soil Mechanics principles.

final section of this paper and are discussed in

more detail at that stage.

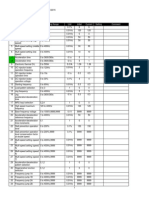

TABLE I

TESTS OF END BEARING ON ROCK

Uniaxial Loaded Depth of

.

No. Material Fracturing Loading below Location Reference

Strength Diameter Surface

MPa

""

l Weathered Highly Highly fractured 760 9 Melbourne Ervin (1976)

~dstone Variable frequent c 1ay (Aust.)

seams

> 2MPa 40 - 120 fract/m

2 Shale No intact Fra!JDented 915 6.3 United Kingdt11 Thorburn (1966)

core

3 Argill ite 18 Fractured 300 Surface Brisbane

(Weathered) (Aust.) Bunnan and

3a Argillite No intact Fragmented 450 Surface Gladstone H._tt (1975)

(Highly Weathered) core (Aust.)

4 Sandstone and 4 - 10 RQO 1060 8 Coventry (U. K.) Cole and Stroud

Siltstone • 301 (1976)

5 Mica schist and 15 - 20 RQO 1000 Surface Jo 1 8urg Pells (1975)

gneiss (weathered) (gneiss) 0 - 251 (Sth. Africa)

6 Shale 21 - 51 Fractured ( spac- 450 6.5 WestMead Thorne ( 1976)

(fresh) x = 34 in9 20 - 100 .. ) (Aust.)

7 Clays tone 1 Est. RQO 670 6 Port Elizabeth Wilson (1976)

> 75% (Sth. Africa)

8 Shale 30 RQO 400 4 Redfern Ground Test (1976)

(fresh) 901 (Aust.)

9 Tuff and 1 - 15 Very widely 500 Surface Napoli (ltaly) Pellegrino (1974)

talcarenites Mean 4 spaced fracture$

10 Hawkes bury 20 - 33 Intact 25 - 150 Surface Sydney Uni.

sandstone (fresh) Pells and Turner

25 Surface Sydney Uni.

(1978)

11 Ashfield 8 Intact

Shale (freMI) Nonnal to (Laboratory)

Bedding

12 Shaley slate Badly sheared, 500 Surface Newfoundland Vogan (1977)

some open

fractures

13 Sandstone and O.B RQO 500 14 Auckland Moss (1971)

Siltstones > 90S (N.Z.)

14 Clay Shale 1.4 Est. RQO 750 7 - 8 Montopolis Aurora and

> 75% (U.S.A.) Reese (1977)

14a Clay Shale 0.6 Est. RQD 890 7 Dallas (U.S.A.)

> 75S

15 Muds tone 0.6 Fractured Various Embedment Melbourne Willia111s (1977)

Ratio l/D D-16 (Aust.)

Australian Geomechanics journal, 1978 33

FOUNDATIONS ON SHALE AND SANDSTONE - Fells, Douglas, Radway, Thorne & McMahon

TABLE II

IN SITU TESTS OF SOCKET SHEAR

No. Material Un1axial Socket Socket Depth below

Strength Fracturing Location Reference

Diameter Length rock surface

MPa m

"" ~

I Sandstone 30 Intact 267 .58 & .97 Surface Sydney (Aust.) MacKenzie

(1969)

2 Clay Shale 0.6 - 1.4 Not known 740 to 1.35 to 1.52 O to 0.5 Dallas & Montopolis Aurora & Reese

960 (U.S.A.) (1977)

3 Shale (fresh) 30 RQO = 90% 400 1.0 2.9 Redfern Ground Test

Horiz. bedding (Aust.) (1976)

4 Muds tone Highly Highly fractured 1092 1.52 Melbourne Ervin (1976)

Variable frequent c 1ay (Aust.)

> 2MPa seams

5 Andesite 10 Fractured and 457 .56 0 canada

sheared, soft

chlorite on Rosenberg and

surfaces Journeaux

(1976)

6 Shale 21 Spacing 75-150 n111 203 .91 0 Canada

Horiz. bedding

7 Shale/Slate No core Highly fractured 2743 .64 to 1.39 0 Come-by-Chance

obtainable near vertical (Canada) Vogan (1977a,

uncemented 1977b)

fractures

Also

8 Sandstone with 12-24 for Hori zonta 1ly 245 • 64 to .97 O to .5 Lennox Isl . Gibson and

Claystone layers best rock bedded (Canada) Devenny (1973)

(coreable)

9 Shale 48 - 100 Slightly fract- 480 2.1 0 Ottawa ( canada) Seychuk (1970)

ured, calcite Vogan (1977b)

stringers

10 Shaley siltstone Moderately fract- 711 3.35 1.83 Perth (Aust.) Soilmech

and clay shale ured with hi 9h ly (1972)

fractured zones

II Shale 21 - 51 Fractured (spac- 450 and 0,7 and 1.3 0 Westmead - Coffey &

(mean 34) ing 20 - 100 nm) 900 Sydney (Aust.) Partners (1975)

12 Shale No core Fragmented • 914 3.35 0 U.K. Thorburn (1966)

obtainable

13 Sandstone and Highly fractured 508 2.59 0 California Moore (1964)

Shale (U.S.A.)

14 Shale Approx. Massive but with 609 6.0 2 Nova Scotia Matich and

I MPa weathered zones (Canada) Kozicki (1967)

be only slightly fractured and have not more than 3%

defects for the zone in question. If lower than

minimum strength or greater defects are observed,

6 then the rock would be graded at a lower level.

5.2.2 Unconfined compression strength

Noter: ! Numbers refer to rows

in Table II

It is important to ensure that the measured value

relates to the soaked or saturated condition. In

sandstones, saturation is readily achieved by soak-

,, ing prior to testing. Shales may be subject to

significant weathering or breakdown when soaked in

free water and the only really successful procedure

is to test core samples shortly after extraction

with in-situ moisture content being maintained by

appropriate sealing.

9

It is not envisaged that testing of core sample

should be an essential prerequisite in all cases:

Figure 3 Field tests on shear sockets the field guide or the use of point load tests will

often, in the hands of experienced engineers, be

5.2 Design Tables completely adequate for reliable classification and

selection of design values.

The values are given in Tables III and IV and indic-

ate significantly increased design values by com- 5.2.3 Fracturing

parison with Ordinance 70 values, in conditions

where reliable site data indicate this to be app- The concept of degree of fracturing has been used as

ropriate. an index for rock quality, and the terms which

relate to diamond drill cores and the spacing of

The design tables should be read in conjunction natural fractures have the following definitions.

with the following comments and explanations.

Fragmented the core is comprised primarily of

5.2.1 Class nwnber lengths less than 20 mm and mostly

of widths less than the core diameter.

As shown in Tables III and IV a numerical classif-

ication system has been adopted to provide ease of Highly fractured core lengths are generally less

reference, e.g. Class I sandstone, Class III shale. than 20 - 40 mm, with occasional

Thus, for example, a Class II sandstone should have fragments.

a minimum unconfined compression strength of 12 MPa,

34 Australian Geomechanics Journal, 1978

FOUNDATIONS ON SHALE AND SANDSTONE - Pelis, Douglas, Radway, Thome & McMahon

TABLE III

DESIGN VALUES FOR FOUNDATIONS ON SHALE

General Description Unconfined End Efield Typical Suggested Mfnilfllll1

Allowable Shaft

Class

& Field Guide

Compression

Strength

q •

u

MP a

.

Fracturing

.

Defects

.

Bearing

Pressure

.

Adhesion Eco re Efield

MPa

Investigation or

Proving Techniques

I Strong shale - core > !6 Slightly to 2% Max. 8 MPa 0.05 f'c 0.9 > 2000 Comprehensive site invest-

sections can only be fractured igation sufficient to define

slightly scratched seams & 1ayers of rock -

with steel knife. cored boreholes on a mininun

I 0 metre grid spac f ng OR

cored ho 1es at not 1ess than

5~ of footings. Jackhanmer

holes and spoon testing at

the remainder.

II Medium to strong 7 - 16 Fractured 4% 3.5 MPa OR 350 kPa OR 0.7 700 - Site investigation to

shale - core sections 0.5 qu 0.05 qu 2000 include at least 4 cored

can be scored with boreho 1es with jackhanmer

steel knife. Max. 6 MPa Max. 800 hole• and spoon testing or

kPa cores in at least sen; of

footings.

III Medium strong shale - 2 - 7 Fractured to 8% l MPa OR 150 kPa OR 0.5 200 -

core sections can be highly fractured 0.5 qu 0.05 qu 1200

deeply scored with a

steel knife. Max. 3.5 Max. 350

MPa kPa Engineers site

inspection to

IV Weak shale - core Not nonnally Highly fractured 25% 1.0 MPa 150 t kPa 0.4 100 - include at least

sections can be heav- measurable or fragmented 500 2 cored boreho 1es

ily scored or cut

with steel knife -

alternatively inter-

bedded medium strong

and very weak shale.

v Mainly shaley clay -

hard clay with thin

Not nonnally

measurable

Highly fractured

or fragmented

- 0.7 MPa 50 - t

100 kPa

- 50 -

300

Engineer's site inspection.

zones of weak sha 1es.

* See text for definitions and explanations

t Values may have to be reduced because of smear

TABLE IV

DESIGN VALUES FOR FOUNDATIONS ON SANDSTONE

Saturated End Typical Suggested Minimtn

Class General Description Unconfined Allowable Shaft Efield Investigation or

Fracturing Bearing

& Field Guide Compression

Strength

qu

MPa

. .

Defects

.

Pressure

.

Adhesion Ecore Efield

MP a

Prov 1ng Techniques

I Strong sandstone, > 24 Slightly fractur- 1.5% Max. 12 MPa 0.05 f' c 0.9 > 2000

core sections of 50 inn ed or unbroken

dia. cannot be broken Comprehensive s 1te

by hand and can be investfgatfon sufficient

only slightly scratch- to define seams & layers

ed with a steel knife. of rock - cored boreholes

at not greater than 10

metre grid spacing, OR

II Medium to strong 12 - 24 Slightly 3% 6 MPa OR 600 kPa OR o. 7 900 cored holes at not less

sandstone - core fractured 0.5 qu the lesser -3000 than 50% of footings with

sections can be broken Max. 10 MPa of jackhanwner holes and

by hand with diff- 0.05 f' c OR spoon testing at the

1culty and lightly 0.05 qu remainder.

scored with a steel Max. 1200

knife. kPa

Ill Medium strong sand- 7 - 12 Fractured 5% 3.5 MPa OR 350 kPa OR 0.5 350 Site investigation to

stone - core sections 0.5 qu 0.05 qu -1200 include at least 4 cored

can be broken easily Max. 6.0 boreho 1es with jackhanmer

Max. 600 holes and spoon testing, OR

by hand and readily

scored with a steel

MPa kPa cores in at least of t

knife. footings.

IV Weak sands tone - core 2 - 7 Fractured 10% 1 MPa OR 100 kPa OR 0.4 100

sections break easily 0.5 qu 0.05 qu - 700

and may be heavily Max. 3.5 Max. 350

scored or cut with MP a kPa Engineer's site

a steel knife. inspection with at

1east 2 cored

boreholes.

v Very weak sandstone - Not nonnally Highly fractured - 0.8 - 1.0 75 - 150 - 50

rock structure is measurable or fra!J11ented MP a kPa - 200

evident bl.l.t frequent

zones of sugary sand-

stone - crumbled by

hand.

* See text for definitions and explanations.

Australian Geomechanics Journal, 1978

35

FOUNDATIONS ON SHALE AND SANDSTONE - Pelfs, Douglas, Radway, Thorne & McA

Fractured core lengths are mainly 30 - 100 mm, to resist uplift or tensile load, a reduction of

with occasional shorter and longer 1/2 is suggested. This is simply to allow a greater

sections. factor of safety because there is no back up from

end bearing.

Slightly fractured core lengths are generally

300 - 1000 mm, with occasional longer 5.3.3 Modulus values

sections and occasional sections of

100 - 300 nun. Suggested elastic modulus values have been included

in the table together with a bulk modulus/core mod-

The rough correlation between these fracturing ulus value for use where core modulus values are

definitions and RQD is indicated in Figure 4. known. Information relating to modulus values is

very limited and the suggested values are accordi~g

5.2.4 Allowable defects ly pitched at a conservative level (i.e. they will

tend to over-predict deflections). They are includ-

Defects, in this context, are defined as clay seams, ed to allow an estimate of elastic settlement and

fragmented zones or highly weathered joints and the also of the ratio of pile modulus to rock modulus

tolerances suggested in the tables relate to a required in the elastic design method discussed at

defined zone of influence. For pad footings, the the end of this paper.

zone_ of influence is defined as 1.5 times the least

footing dimension. For socketed footings, the zone 5.3.4 Investigation techniques

includes the length of the socket plus a further

depth equal to the width of the footing. Suggested minimum investigation or proving techni-

ques are included, based on the principle that, as

In classifying the rock the total thickness of design bearing pressures are increased, increased

defects is computed by ·doubling the thickness of levels of site investigation and proving techniques

clay seams and adding the thickness -of the remain- are necessary.

ing defects. For example, when considering a foot-

ing of 2 metres width, twice the total thickness of 5.3.5 General

clay seams added to any highly weathered or frag-

mented zones over a depth of 3 metres below the It is emphasised that the suggested design rules are

footing should not exceed 150 nun for Class III intended as a general guide, to be interpreted with

sandstone. engineering judgement and a modicum of common sense.

Obviously, site conditions will need to be checked

5.3 Interpretation of the Design Tables at the time of construction but minor anomalies if

they occur should be considered on the basis of

Allowable values for end bearing pressure and side engineering performance rather than on strict appli-

adhesion are defined in terms of uniaxial compress- cation of the design rules. Thus, where seams or

ive strength. However, the important point is that defects are encountered unexpectedly, such factors

should a rock mass be classified in a lower class, as total foundation load, tolerable footing settle-

because of fracturing or defects, than indicated by ment, size of footing, nature of the defect and

its substance strength then the allowable pressures depth below the footing will need to be considered

and shear stresses are limited by the maximum uni- before a decision is made to change the design or to

axial strength of that class. The actual substance significantly deepen the footings so as to comply

strength is not used in such a case. exactly with the design criteria suggested.

5.3.1 End bearing pressure 5.4 Justification of Design Values

The suggested values here are a minimum for each The design values given in Tables III and IV are

class, with a potential for higher values if justified in terms of the field tests discussed

strengths are known. Thus, for Class II sandstone earlier. In the case of end bearing, Figure 4 shows

classified by the field guide, a design bearing the ratio between actual meaiured bearing pressures,

pressure of 6 MPa is suggested. Alternatively, if at displacements of 1% and 2%, and allowable values

test data are available which indicate an unconfin- from the design tables plotted against the degree of

ed compression strength of 15 MPa, a design bearing fracturing. To derive this figure all the cases

pressure of 7.5 MPa would be appropriate. However, given in Table I were classified according to the

the maximum allowable value for this class would be system proposed here and design values selected.

10 MPa even if the measured uniaxial strength was, It can be seen that in no case would the design

for example, 30 MPa. value have been greater than the measured value at

a displacement of 1%. The same process has been

5.3.2 Shaft adhesion followed for side shear. Table V shows the way the

different field cases were classified and also shows

The recommended values here relate to shaft adhes- the ratio between the measured and allowable shear

ion where load is transferred in a rock socket. It stress values at displacement ratios of 1% and 2%.

is emphasised that shaft adhesion will to some ex- It can be seen that in some cases the values pro-

tent be dependent on construction procedures, posed in the design tables are very conservative.

especially since the weaker shales will tend to

weather very quickly after excavation with conse- 5.5 Use of the Suggested End Bearing and Socket

quent reduction in shaft adhesion. Where augering Shear Values in Design

is carried out in weaker materials there is often

a skin of remoulded material left on the walls of Once the allowable values for end bearing and socket

the bore and this will need to be removed if full shear have been determined there are two approaches

adhesion values are to be relied on. A reduction that may be adopted in designing a socketed found-

may be required in the case where concreting is ation.

carried out under bentonite or where there is some

uncertainity as to the cleaning of the socket. (i) Method 1

The design values in the table relate to compress- This approach is based on mobilizing the full

ive load conditions and where a rock socket is used allowable end bearing pressure. The balance

36 Australian Geomechanics Journal, 1978

FOUNDATIONS ON SHALE AND SANDSTONE - Pelts, Douglas, Radway, Thorne & McMahon

.

.2

g

TABLE V

COMPARISON BETWEEN ALLOWABLE AND MEASURED SOCKET

SHEAR STRESS

Allowable I' Ratio Mea:sured I'

Case No.

(See Table II)

Table Used for

Classification

Class I Shear

~~~~~:e~ ts~;~: I ~~e~; l ~~~~~~ i

Stress

! MPa I <1t 6/0*

MPa 1% 2%

" I "

Sandstone 1.5 4.5 I s.4 3.1 I 3.6

I

I Numbtirs ria:fg:r to TABLE I

iI Mciasurcid bciaring prossur12 at Shale 0.1 0.27 I 0.28 2.7 2.s I

I

" • 6/o. ,.,.

~

0

o 6/ 0 • 2•1. Shale 1.5 >2.8 >2.8 >l.9 >1.9

~ 0 ., o~~-=20=---"°-:-::-~----::s~o~~-=ao=----:'.100 Shale 0.1 >. 77 >. 77 >7.7 >7.7

Rock Quality Dasignation (ROD) •1.

Sandstone Ill 0.5 1.03 1.12 2.1 2.2

Highly Slightly

Fracturr.rd Fracturad

Fractur11d

Shale II 0.3 1.43 1.76 1.8 2.2

Frogmanttid

Shale IV 0.15 >1.5 >1.5 >10.0 >10.0

Figure 4 Field data on end bearing compared Sandstone Ill 0.6 0.5 0.65 0.8 1.1

with suggested allowable values

Shale l.5 >3.0 >3.0 >2.0 >2.0

of the applied load, if any, is carried out 10 Shale IV 0.15 0.27 0.52 1.8 3.5

on the socket sides assuming full mobiliz-

ation of the allowable socket shear. No II Shale IV 1.5 1.63 2.1 I.l I.4

attempt is made to satisfy the elastic load lib Shale 1.5 >I.5 >1.5 >1.0 >1.0

distribution and it will be found that the

proportion of the applied load required to be 12 Shale IV 0.10 0.10 0.20 1.0 2.0

carried in end bearing is much greater than

the proportion that, according to elastic

13 I Sandstone IV 0.20 0.54 0.82 2.7 4.l

theory, would reach the base. This implies 14 Shale Ill 0.15 0.16 o.25 I l.l 1.7

that, if in the field the actual socket shear

available is no greater than the allowable * D Diameter of pier 6 Vertical settlement

value, slip will occur with load being redis-

tributed into end bearing until the end bear- trate the design process proposed in this paper.

ing pressure reaches the design value. Dis-

placement of the foundation would be greater The site is taken to consist of about 10 m of silty

than indicated by elastic theory but would be clay overlying fractured but relatively fresh sand-

limited to less than 1% of the socket dia- stone. The sandstone has an average Point Load

meter because this is the criterion upon Index of 1. O MPa indicating an unconfined compress-

which the allowable end bearing pressures are ive strength in excess of 20 MPa. Within the top 4

based. metres of sandstone are clay seams with a combined

thickness of 150 mm plus highly weathered layers of

In reality, with the base displacement limit- sandstone of 110 mm combined thickness.

ed to 1%, Table V shows that in the majority

of cases the mobilized socket shear will be Piers are required to carry 4 MN.

greater than the allowable design value.

Hence slip may well not occur or may be lim- 6.1 Classification

ited to the upper portion of a long socket

where the actual shear stresses are the The percentage "defects" in this case is estimated

greatest. by doubling the thickness of the clay seams before

adding the thickness of highly weathered layers.

(ii) Method 2 Initially the zone of influence is not known and so

one may simply consider the percentage of "defects"

This approach is based essentially on satis- over the upper 4 metres of sandstone. This is

fying elastic load distribution. For a given

pier diameter the length of socket is deter- (300 + 110) x 100 10% (Approx.)

mined compatible both with full mobilization 4000

of the allowable socket shear and elastic Thus in spite of the reasonably high strength of

load distribution. This approach does not the sandstone a classification into Class IV is in-

allow for the possibility of side slip and dicated according to Table IV. Hence the allowable

always results in a longer socket and a lower foundation loadings are:

mobilization of end bearing pressure than

yielded by the first method. Displacements end bearing 3.5 MPa

can be determined directly from the elastic

solutions given in Figure 2 and will be less side shear O. 35 MPa

than obtained using the first approach.

6. 2 Design of Sockets

In considering these two methods the present

authors consider that the first approach is quite Method 1

satisfactory for the majority of cases. Only where

very strict limitations are placed on allowable Adopting a pier diameter of 0. 75 metres one

settlement is it necessary to adopt the more has

conservative second method.

load taken in end bearing ic .75 J 2 x 3.5

6 WORKED EXAMPLE

The purpose of this "mythical" example is to illus- 1.55 MN.

Australian Geomechanics Journal, 1978 37

FOUNDATIONS ON SHALE AND SANDSTONE - Pelts, Douglas, Radway, Thorne & McMahon

4.0-1.55

length of socket required 100

TIX,75x. 35

2.97 metres

80

say 3.0 metres.

;. 60

This design requires that 39% of the applied

LL

....

load be taken in end bearing. However, .......

according to elastic theory for a socket of

these dimensions (assuming K = 10) only about 0 40

LL.o

10% of-the load would reach the base of the

socket. Thus if the mobilized socket shear

were really no greater than 0,35 MPa, side 20 Ep

-=10

slip would occur with load being transferred ER

to the base.

2 4 6 8 10 12 14

The displacement at the top of the socket L/a

would be less than 1% of the. diameter, i.e.

less than 7.5 mm. Figure 5 Elastic design method for a rock socket

Method 2

The first step is to calculate, for differ- 7 CONCLUSIONS

ent assumed pier diameters, the length of

socket required if all load were taken in An investigation has been conducted into theoret-

side shear. For a 1.0 metre diameter pier ical studies, model studies and field tests related

this length is to the design of isolated foundations located on

or socketed into rock. Inclined loading and load-

4 ing near an excavation have not been considered.

3.64 metres

nxl. OxO. 35

On the basis of this investigation it has been con-

i.e. L/ 7.3 cluded that design loadings greater than presently

a

allowed by N.S.W. Ordinance 70 may often be appro-

priate in the Sydney region. Allowable end bearing

With such values one can then superimpose and socket shear stresses are suggested for differ-

straight lines on the relevant elastic dist- ent classes of sandstone and shale together with

ribution curve taken from Figure 1. This is

guidelines as to appropriate site investigation

shown in Figure 5 where a value of K (ratio techniques necessary to justify these higher load-

of pile modulus to rock modulus) of 10 has ings. Two alternative design methods, for use with

been assumed. The intersection points re- the suggested allowable stresses, are discussed.

present the values of L/a, for each assumed The full design process is illustrated by means of

pile diameter, that satisfy both elastic load a worked example.

distribution and the allowable value of side

shear. The required socket lengths and end

bearing pressures can then be calculated as

shown below. 8 ACKNOWLEDGEMENTS

Pier Socket Mobilized End In compiling this paper much unpublished data on

Diameter Length Pressure rock foundation testing has been made available to

m m MP a the authors. In this regard particular thanks are

extended to Mess rs. Coffey and Partners, Ground

0. 75 4.6 0.5 Test Pty. Ltd. and the Public Transport Commission

of N.S.W.

1.0 3.3 0.5

1. 25 2.5 0.6

1.50 1.6 0.8 9 REFERENCES

It is readily seen that this design approach AURORA, R.P. and REESE, L.C. (1977). Field tests

results in a longer socket than the first of drilled shafts in clay-shales. Proc. 9th Int.

method. Conf. Soil Mech., Tokyo, 2/2, pp.371-376.

Settlements can be calculated using Figure 2. BURMAN, B.C. and HAMMETT, R. (1975). Design of

For example if the 1.25 metre diameter pier foundations in jointed rock masses. 2nd Aust. N.Z.

were adopted the "settlement of the socket Geomechanics Conf., Brisbane, July.

would be estimated as (assuming Efield = 2 GPa):

COFFEY and HOLLINGSWORTH PTY. LTD. (1975). ~West

mead hospital project: Pile load testing. Report

No.5568/3 to Ove Arup & Partners, Sydney.

p

4000 COLE, K.W. and STROUD, M.A. (1976). Rock socket

2000 x 0.625 x 0 • 21 mm piles at Coventry Point, market way, Coventry.

Geotechnique, Vol.16, No.I, pp.47-62.

ERVIN, M. (1976). Yarra River pile tests,

0.67 mm Melbourne. Unpublished Report, Country Roads

Board, Victoria, Australia.

38 Australian Geomechanics Journal, 1978

FOUNDATIONS ON SHALE AND SANDSTONE - Pells, Douglas, Radway, Thorne & McMahon

GIBSON, G.L. and DEVENNY, D.W. (1973). Concrete to 6th Regional Conf. Africa Soil Mech. and Fdn. Eng.,

bedrock bond testing by jacking from bottom of a Durban.

borehole. Canadian Geot. Jnl., 10, pp.304-306.

ROSENBERG, P. and JOURNEAUX, N.L. (1976). Friction

GROUND TEST PTY. LIMITED (1976). Pile testing, and end bearing tests on bedrock for high capacity

eastern suburbs railway - Redfern. Report to Pub. socket design. Canadian Geot. Jnl., Vol.13, No.3,

Trans. Commission, N.S.W. Australia, July. pp.324-333.

MACKENZIE, I.M. (1969). Foundation load tests on SEYQfUK, J.L. (1970). Load tests on bedrock.

Sydney sandstone. Rock Mech. Syrop. Univ. Sydney, Canadian Geot. Jnlo, Vol.7, pp.464-470.

pp .132-134.

SOILMECH PTY. LTD. (1972). City centre stage II at

MATIQf, M.A. and KOZICKI, P. (1967). Some load Perth, Western Australia. Report to Doust - Vibro-

tests on drilled cast-in-place concrete caissons. pile, Perth, Australia.

Canadian Geot. Jnl. Vol.4, pp.357-375.

THORBURN, S. (1966). Large diameter piles founded

MOORE, W.W. (1964). Foundation design. Civil on bedrock. Proc. Large Bored Piles Conf. Inst.

Engineering, ASCE, January, pp.33-35. Civil Engineers, London, pp.121-129 and pp.152-153.

MOSS, J.D. (1971). A high capacity load test for THORNE, C.P. (1976). Pile test on rock. Presented

deep bored piles. Proc. 1st Aust.-N.Z. Conf. to Inst. Engineers, Australia, Melbourne, February.

Geomechanics, Melbourne, pp.261-267. Unpublished Report, Coffey and Hollingsworth Pty.

Ltd., Sydney.

PECK, R.B. (1976). Rock foundations for struct-

ures. Rock Engineering for Foundations and Slopes. VOGAN, R.W. (1977a). Friction and end bearing

Proc. ASCE Specially Conf., Boulder. tests on bedrock for high capacity socket design.

Discussion. Canadian Geot. Jnl., Vol.14, No.I,

PELLEGRINO, A. (1974). Surface footings on soft pp.156-158.

rocks. Proc. 3rd Congress, Int. Soc. Rock Mech.,

Denver, Vol.IIB, pp.733-738. VOGAN, R.W. (1977b). Private Communication.

PELLS, P.J.N. and TURNER, R.M. (1978a). Theoret- WEBB, D.L. (1977). Discussion: Session 2 - Rocks

ical and model studies related to footings and other than chalk. Piles in weak rock. Inst. Civ.

piles on rock. Univ. of Sydney Research Report Eng., London, pp.209-211.

R314, March.

WILLIAMSC, A.F. (1977). The design of piles socket-

PELLS, P.J.N. and TURNER, R.M. (1978b). Elastic ed into rock. The Design of Piled Foundations,

solutions for the design and analysis of rock Extension Course, Australian Geomechanics Society,

socketed piles. Univ. of Sydney Research Report Melbourne, pp.51-57.

R325, July.

WILSON, L.C. (1975). Tests on bored and driven

PELLS, P.J.N. (1975). Predicted displacements of piles in cretaceous mudstone at Port Elizabeth,

the rock foundations of a major arch bridge. Proc. South Africa. Geotechnique, Vol.16, pp.5-12.

Australian Geomechanics journal, 1978 39

You might also like

- Pell 1978 - Design Loadings For Foundations On Shale and Sandstone in The Sydney Region PDFDocument9 pagesPell 1978 - Design Loadings For Foundations On Shale and Sandstone in The Sydney Region PDFJohn Van RooyenNo ratings yet

- Adhesion Factor For Rock Soketed PilesDocument16 pagesAdhesion Factor For Rock Soketed PilesZeyad Elsherbiny50% (2)

- 54 2 PellsDocument27 pages54 2 PellsAaron HongNo ratings yet

- Pile Capacity - An Overview - ScienceDirect TopicsDocument15 pagesPile Capacity - An Overview - ScienceDirect TopicssurNo ratings yet

- Case StudyDocument13 pagesCase StudyAnkitaNo ratings yet

- Techniques and Results of Offshore P Ie Load Test NG Inca Icareous So IsDocument16 pagesTechniques and Results of Offshore P Ie Load Test NG Inca Icareous So IsDavid WhiteNo ratings yet

- Foundations On Sandstone and Shale in The Sydney RegionDocument13 pagesFoundations On Sandstone and Shale in The Sydney RegionShahin FalahatiNo ratings yet

- Haberfield and Collingwood ICE Geotech Engg 159 GE3Document12 pagesHaberfield and Collingwood ICE Geotech Engg 159 GE3m888braunNo ratings yet

- 197 Evolution of Rock Anchor Practice Over Three DecadesDocument9 pages197 Evolution of Rock Anchor Practice Over Three DecadesMauricio GiambastianiNo ratings yet

- Characterisation of Sand-Steel Interface ShearingDocument6 pagesCharacterisation of Sand-Steel Interface ShearingMoharaNo ratings yet

- Performance of Suction Caissons in Sand and ClayDocument10 pagesPerformance of Suction Caissons in Sand and ClayDang Quang MinhNo ratings yet

- Doherty Et Al - 2015Document11 pagesDoherty Et Al - 2015dogen1980No ratings yet

- Science and Empiricism in Pile DesignDocument29 pagesScience and Empiricism in Pile DesignMohamed YousufNo ratings yet

- Otc 10979 MS PDFDocument8 pagesOtc 10979 MS PDFChinmaya Ranjan JenaNo ratings yet

- Auld 1979Document16 pagesAuld 1979inge ocNo ratings yet

- Az in E: Codes & StandardsDocument3 pagesAz in E: Codes & StandardsapirakqNo ratings yet

- Duffyetal 2023 OSIGAxialResponseVeryDenseSandDocument8 pagesDuffyetal 2023 OSIGAxialResponseVeryDenseSandGijsPNo ratings yet

- Piled Raft Design Process For A Tall Building in AustraliaDocument9 pagesPiled Raft Design Process For A Tall Building in AustraliaJosé ChávezNo ratings yet

- Eiccf 64072 033Document19 pagesEiccf 64072 033José Luis Rodríguez SánchezNo ratings yet

- Evaluation of Soil Models For Improved Design of oDocument19 pagesEvaluation of Soil Models For Improved Design of o盐饭团盖饭No ratings yet

- Rowe N Armitage Rock Socketed Piles PDFDocument17 pagesRowe N Armitage Rock Socketed Piles PDFJonathan Kok100% (1)

- 2000 Houlsby Byrne - Suction Caisson Foundations For Offshore Wind Turbines and Anemometer MastsDocument7 pages2000 Houlsby Byrne - Suction Caisson Foundations For Offshore Wind Turbines and Anemometer MastsMarcus Girão de MoraisNo ratings yet

- Evaluation of Soil Models For Improved Design of Offshore Wind Turbinefoundations in Dense SandDocument18 pagesEvaluation of Soil Models For Improved Design of Offshore Wind Turbinefoundations in Dense Sand盐饭团盖饭No ratings yet

- Geotechnical Design of Shallow FoundationsDocument35 pagesGeotechnical Design of Shallow FoundationsAndré OliveiraNo ratings yet

- 274 Seismic Performance Wall Foundation Join Concrete ReservoirsDocument44 pages274 Seismic Performance Wall Foundation Join Concrete Reservoirstooth5pNo ratings yet

- Designandconstructionofbored Piles Foundedonrocks-GuidelinesDocument12 pagesDesignandconstructionofbored Piles Foundedonrocks-GuidelinesChitharanjan VishnukripalNo ratings yet

- O'Brien & Bown 2010Document11 pagesO'Brien & Bown 2010Sana FatimaNo ratings yet

- IADC/SPE 74488 Advanced Slip Crushing Considerations For Deepwater DrillingDocument15 pagesIADC/SPE 74488 Advanced Slip Crushing Considerations For Deepwater DrillingJaaTa Da shaanNo ratings yet

- Irvine Etal 2015 Pile Design in Weak RockDocument7 pagesIrvine Etal 2015 Pile Design in Weak RockmikollimNo ratings yet

- Measurement and Analysis of Rock Mass Fractures and Their Applications in Civil EngineeringDocument24 pagesMeasurement and Analysis of Rock Mass Fractures and Their Applications in Civil EngineeringSlobodan Petric100% (1)

- Suction Piles: Their Position and Application TodayDocument6 pagesSuction Piles: Their Position and Application TodayfranciscoerezNo ratings yet

- OTC 12195 Combined Lateral and Vertical Loading of Caisson FoundationsDocument12 pagesOTC 12195 Combined Lateral and Vertical Loading of Caisson FoundationsHarsha TejaNo ratings yet

- Buckley Et Al 2020 Wikinger FinalDocument63 pagesBuckley Et Al 2020 Wikinger Finalingchiara85No ratings yet

- Efficiency of Pressurized Rock Traps For UnlinedDocument19 pagesEfficiency of Pressurized Rock Traps For UnlinedDiana AndradeNo ratings yet

- CGJ1987241126142 Rowe and ArmitageDocument17 pagesCGJ1987241126142 Rowe and ArmitageSandeep Kumar DangdaNo ratings yet

- Field Investigation of The Effect of Installation Method On The Shaft Resistance On Piles in ClayDocument13 pagesField Investigation of The Effect of Installation Method On The Shaft Resistance On Piles in Clayamin sharafianNo ratings yet

- ICSMGE2022 Thusyanthan Designguidancefortank FINALDocument7 pagesICSMGE2022 Thusyanthan Designguidancefortank FINALVidyaParamasivamNo ratings yet

- Specification of Concrete For Marine Environments: A Fresh ApproachDocument12 pagesSpecification of Concrete For Marine Environments: A Fresh ApproachRestie TeanoNo ratings yet

- Geology and Geotechnical Evaluation of Doha Rock FDocument19 pagesGeology and Geotechnical Evaluation of Doha Rock FSteve Ranchez CabahugNo ratings yet

- Journal of Rock Mechanics and Geotechnical Engineering: Sayed M. AhmedDocument15 pagesJournal of Rock Mechanics and Geotechnical Engineering: Sayed M. Ahmedu2014207659No ratings yet

- Fatigue Evaluation For Reinforced Concrete Box CulvertsDocument8 pagesFatigue Evaluation For Reinforced Concrete Box CulvertsProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (2)

- Dolos BreakwaterDocument15 pagesDolos BreakwaterGirang MarindaNo ratings yet

- Haber Field 2018Document14 pagesHaber Field 2018ahmedNo ratings yet

- Characteristics Values in Rock Socket Design: September 2013Document6 pagesCharacteristics Values in Rock Socket Design: September 2013Anonymous v1blzDsEWANo ratings yet

- Chatterjee - Geotechnical Design Considerations of Ground Storage Tanks in Southeast TX and LADocument6 pagesChatterjee - Geotechnical Design Considerations of Ground Storage Tanks in Southeast TX and LAFederico MontesverdesNo ratings yet

- Shaft Lining Design For A Potash Shaft in Rock Salts at DepthDocument11 pagesShaft Lining Design For A Potash Shaft in Rock Salts at DepthAleksandar SpasojevicNo ratings yet

- Numerical Modelling of Large Diameter Piles Under Lateral Loading For Offshore Wind ApplicationsDocument7 pagesNumerical Modelling of Large Diameter Piles Under Lateral Loading For Offshore Wind ApplicationsAhmed RamadanNo ratings yet

- Centridge Modeling of Embankment On Clay FoundationDocument18 pagesCentridge Modeling of Embankment On Clay Foundationmr yugiNo ratings yet

- Design and Construction Approach of Marine Rock-Socketed Piles For An Oil Jetty ProjectDocument7 pagesDesign and Construction Approach of Marine Rock-Socketed Piles For An Oil Jetty ProjectVetriselvan ArumugamNo ratings yet

- Back Analysing Rock Mass Modulus From Monito - 2017 - Journal of Rock MechanicsDocument15 pagesBack Analysing Rock Mass Modulus From Monito - 2017 - Journal of Rock MechanicsVassilis PentheroudakisNo ratings yet

- Codal Provisions For Foundation Design On Soils and Rocks: A ReviewDocument11 pagesCodal Provisions For Foundation Design On Soils and Rocks: A ReviewTarekNo ratings yet

- Session 2A JonkerDocument15 pagesSession 2A JonkerD_D_ANo ratings yet

- The 20 Ultimate 20 Pullout 20 Capacity 20 of 20 Anchors 20 in 20 Frictional 20 SoilsDocument18 pagesThe 20 Ultimate 20 Pullout 20 Capacity 20 of 20 Anchors 20 in 20 Frictional 20 SoilsDr Bali ReddyNo ratings yet

- Specification of Concrete For Marine Environments: A Fresh ApproachDocument12 pagesSpecification of Concrete For Marine Environments: A Fresh ApproachILIAS PROKONo ratings yet

- Justification For Base Resistance FormulaDocument110 pagesJustification For Base Resistance FormulaKS ChongNo ratings yet

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- Geological Carbon Storage: Subsurface Seals and Caprock IntegrityFrom EverandGeological Carbon Storage: Subsurface Seals and Caprock IntegrityStéphanie VialleNo ratings yet

- FT-4XR/FT-4XE FT-4VR/FT-4VE Technical Supplement: Vhf/Uhf Dual Band FM Transceiver VHF FM TransceiverDocument16 pagesFT-4XR/FT-4XE FT-4VR/FT-4VE Technical Supplement: Vhf/Uhf Dual Band FM Transceiver VHF FM TransceiverdenisNo ratings yet

- Day Trading With Canlestick and Moving Averages - Stephen BigalowDocument3 pagesDay Trading With Canlestick and Moving Averages - Stephen Bigalowarashiro100% (2)

- Norma Aisc 341 (Capítulo E)Document22 pagesNorma Aisc 341 (Capítulo E)ElmerNo ratings yet

- Coussot, P. and M. Meunier. Recognition, Classification, and Mechanical Description of Debris Ows. Earth Science ReviewDocument20 pagesCoussot, P. and M. Meunier. Recognition, Classification, and Mechanical Description of Debris Ows. Earth Science ReviewelizabethNo ratings yet

- Scale Tm-Xa Series PDFDocument153 pagesScale Tm-Xa Series PDFArmen ManasyanNo ratings yet

- Account Statement 2Document6 pagesAccount Statement 2Krishna rajaNo ratings yet

- FIGL BI ExtractionDocument3 pagesFIGL BI ExtractionDurgesh Singh67% (3)

- HR260 Series High Frequency Radar Level Gauge Instructions-HolykellDocument24 pagesHR260 Series High Frequency Radar Level Gauge Instructions-HolykellJanuar RamadhanNo ratings yet

- Technical Drawing, Drafting or Drawing, Is The Act andDocument11 pagesTechnical Drawing, Drafting or Drawing, Is The Act andAjhay BonghanoyNo ratings yet

- Intro To CFD Course DetailsDocument1 pageIntro To CFD Course Detailsmaheshj90No ratings yet

- A Jacobi Collocation Method For Solving Nonlinear Burgers-Type EquationsDocument13 pagesA Jacobi Collocation Method For Solving Nonlinear Burgers-Type EquationsEduardo SandovalNo ratings yet

- DJI Air 2S User ManualDocument52 pagesDJI Air 2S User ManualAlexandre Costa de LimaNo ratings yet

- Solving Equations (X On Both Sides)Document6 pagesSolving Equations (X On Both Sides)rj0898637No ratings yet

- Department of Computer Applications Syllabus For B.C.A. Under Choice Based Credit System (CBCS) For Candidates Admitted From 2019 - 2020Document39 pagesDepartment of Computer Applications Syllabus For B.C.A. Under Choice Based Credit System (CBCS) For Candidates Admitted From 2019 - 2020Saran VNo ratings yet

- T Lymphocytes and Macrophages in The Intestinal Tissues of Dogs Infected With Leishmania InfantumDocument12 pagesT Lymphocytes and Macrophages in The Intestinal Tissues of Dogs Infected With Leishmania InfantumWillNo ratings yet

- The Logstash BookDocument239 pagesThe Logstash Bookavira100% (1)

- Melsoft FR Configurator Sw3 Vf1Document8 pagesMelsoft FR Configurator Sw3 Vf1mo_be81No ratings yet

- Cummins: Fault Code: 527 PID: P154 SPN: 702 FMI: 3Document4 pagesCummins: Fault Code: 527 PID: P154 SPN: 702 FMI: 3Enrrique LaraNo ratings yet

- 002 Turbine Engine Fuel Metering Notes1Document116 pages002 Turbine Engine Fuel Metering Notes1Yasser Zubaidi100% (2)

- To Find Condition For Two Quadratic Equations To Have One Root CommonDocument1 pageTo Find Condition For Two Quadratic Equations To Have One Root CommonevilsadduckNo ratings yet

- Mental Math: Grade 9 Mathematics (10F)Document16 pagesMental Math: Grade 9 Mathematics (10F)Bien Andrei GaspeNo ratings yet

- Chemisorption 2017Document4 pagesChemisorption 2017AssyakurNo ratings yet

- Catalogue BZM enDocument40 pagesCatalogue BZM enSergio AvilaNo ratings yet

- Operating System Security: CSCI620M03/CSCI445M02/ITEC445 M02 Instructor: Qian WangDocument30 pagesOperating System Security: CSCI620M03/CSCI445M02/ITEC445 M02 Instructor: Qian Wangamit sharmaNo ratings yet

- Equipments Used in Making SuspensionsDocument26 pagesEquipments Used in Making Suspensionsmomina arshidNo ratings yet

- Process Capability Study With MinitabDocument36 pagesProcess Capability Study With MinitabVishalNaranjeNo ratings yet

- Organic ChemistryDocument11 pagesOrganic ChemistryHebah TanveerNo ratings yet

- Renewal Parts: HF Series GeneratorsDocument5 pagesRenewal Parts: HF Series GeneratorsSerg SergNo ratings yet

- Hitachi-12 Complete E CatalogDocument196 pagesHitachi-12 Complete E CatalogAcep KasepNo ratings yet