0% found this document useful (0 votes)

4K views2 pagesVortex Breaker

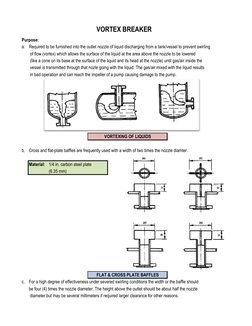

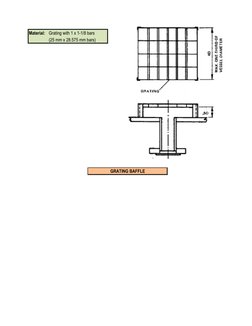

The document discusses vortex breakers, which are required to prevent swirling flow (vortex) from liquid discharging tanks through nozzles. This is to prevent the liquid surface from lowering and allowing gas/air inside the tank to enter the nozzle flow and damage pumps. Cross and flat plate baffles that are twice the nozzle diameter in width are commonly used as vortex breakers. For severe swirling, wider baffles four times the nozzle diameter work best, located half the nozzle diameter above the outlet. Grating with bars can also be used as a baffle material.

Uploaded by

naruto256Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

4K views2 pagesVortex Breaker

The document discusses vortex breakers, which are required to prevent swirling flow (vortex) from liquid discharging tanks through nozzles. This is to prevent the liquid surface from lowering and allowing gas/air inside the tank to enter the nozzle flow and damage pumps. Cross and flat plate baffles that are twice the nozzle diameter in width are commonly used as vortex breakers. For severe swirling, wider baffles four times the nozzle diameter work best, located half the nozzle diameter above the outlet. Grating with bars can also be used as a baffle material.

Uploaded by

naruto256Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd