Professional Documents

Culture Documents

1.2436 (62-63HRc)

Uploaded by

Michel PortalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.2436 (62-63HRc)

Uploaded by

Michel PortalCopyright:

Available Formats

SIHARD 2436 Steel

Designation by Standards

Brand Name Ravne Mat. No. DIN EN AISI/SAE

SIHARD 2436 OCR12SP 1.2436 - X210CrW12 -

Chemical Composition (in weight %)

C Si Mn Cr Mo Ni V W Others

2.12 0.25 0.45 12.00 - - - 0.70 -

Description

Ledeburitic chromium steel with high durability and cutting performance; low distortion on hardening.

Applications

Cutting tools for sheet metal thicknesses up to approximately 2 mm, paper blades,stone compression moulds, section rolling-mill rolls,

deep-drawing tools.

Physical properties (average values) at ambient temperature

Modulus of elasticity [103 x N/mm2]: 210

Density [g/cm3]: 7.77

Thermal conductivity [W/m.K]: 20.0, 20.5 (at 350 oC), 24.1 (at 700oC)

Electric resistivity [Ohm mm2/m]: 0.65

Specific heat capacity[J/g.K]: 0.46

Coefficient of Linear Thermal Expansion 10-6 oC-1

20-100oC 20-200oC 20-300oC 20-400oC 20-500oC 20-600oC 20-700oC

10.8 11.8 12.4 12.5 12.8 12.9 13.0

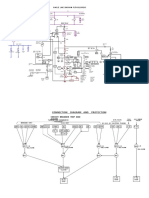

Continuous Cooling Transformation (CCT) Diagram

Time-Temperature Transformation (TTT) Diagram

Soft Annealing

Heat to 800-840oC, cool slowly in furnace. This will produce a maximum Brinell hardness of 255.

Stress Relieving

Stress relieving to remove machining stresses should be carried out by heating to 650 oC, holding for one hour at heat, followed by air

cooling. This operation is performed to reduce distortion during heat treatment.

Hardening

Harden from a temperature of 940-980oC followed by air,oil quenching or warm bath quenching 500-550 oC. Hardness after quenching

is 64 HRC.

Tempering

Tempering temperature: See the data bellow.

Tempering Temperature (oC) vs. Hardness (HRC)

100oC 200oC 300oC 400oC 500oC 600oC

63 62 60 58 56 48

Tempering Diagram

Forging

Hot forming temperature: 1050-850oC.

Machinability

The machinability rating of OCR12SP is roughly 20-25% that of free machining carbon steel 1018. Due to its abrasion resistant nature,

machining in the hardened condition should be limited to finish grinding.

Forms manufactured: Please see the Dimensional Sales Program.

Disclaimer

The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values.

Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to

make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other purposes. There is

no representation that the recipient of this literature will receive updated editions as the become available.

Unless otherwise specified, registered trademarks are property of SIJ Metal Ravne company. Copyright 2016 by SIJ Metal Ravne d.o.o.

All rights reserved. Contact our Sales Office for more information.

You might also like

- X210CR12 GradeDocument3 pagesX210CR12 GradekartsoftNo ratings yet

- OCR12VMDocument4 pagesOCR12VMcvgfgNo ratings yet

- SIHARD 2243 Steel: Designation by StandardsDocument3 pagesSIHARD 2243 Steel: Designation by StandardswalkerbhoNo ratings yet

- BRM2Document3 pagesBRM2王向荣No ratings yet

- 18crnimo7 6Document4 pages18crnimo7 6anush_swaminathanNo ratings yet

- EldaDocument28 pagesEldaEldayadi Nefty Rizky ArismawanNo ratings yet

- UTOPEX2Document4 pagesUTOPEX2emregnesNo ratings yet

- 42crmo4: Steel GradeDocument3 pages42crmo4: Steel GradeCarlos LopezNo ratings yet

- CK45 (Mat - No. 1.1191, DIN Ck45, AISI 1045)Document4 pagesCK45 (Mat - No. 1.1191, DIN Ck45, AISI 1045)hdierkeNo ratings yet

- 18CrNiMo7 6 PDFDocument2 pages18CrNiMo7 6 PDFAnuj ShahNo ratings yet

- SINOXX 4116 Steel: Designation by StandardsDocument2 pagesSINOXX 4116 Steel: Designation by StandardsSamirNo ratings yet

- Alluminium SheetsDocument7 pagesAlluminium SheetsVaibhav ShuklaNo ratings yet

- Free-Cutting Brass, UNS C36000, H02 (Cold Drawn 20%) Temper 25 MM RodDocument2 pagesFree-Cutting Brass, UNS C36000, H02 (Cold Drawn 20%) Temper 25 MM Rodkahutzed666No ratings yet

- 42crmo4: Steel GradeDocument3 pages42crmo4: Steel GradeMada TetoNo ratings yet

- Cr-Product Manual - PDFDocument28 pagesCr-Product Manual - PDFThơ Thẫn ThờNo ratings yet

- Din 1-3207Document3 pagesDin 1-3207Ornella MancinelliNo ratings yet

- 61 Si CR 7Document2 pages61 Si CR 7RaduIonNo ratings yet

- 1.4922 SteelDocument2 pages1.4922 Steeldnageshm4n244No ratings yet

- PK2SPDocument3 pagesPK2SPEmanuelValenciaHenaoNo ratings yet

- Designation by Standards: Steel Vcmo230 (Mat - No. 1.7707, Din 30crmov9, Aisi 4340)Document5 pagesDesignation by Standards: Steel Vcmo230 (Mat - No. 1.7707, Din 30crmov9, Aisi 4340)janjicbojanNo ratings yet

- Tool Steel Alloy Cr12MoVDocument5 pagesTool Steel Alloy Cr12MoVMujjo Sahb100% (1)

- 20CR4Document2 pages20CR4mercyNo ratings yet

- SINOXX 4742 Steel: o o o o oDocument2 pagesSINOXX 4742 Steel: o o o o oArielNo ratings yet

- Datasheet-Sandvik-Saf-32760-En-V2020-12-10 07 - 47 Version 1Document7 pagesDatasheet-Sandvik-Saf-32760-En-V2020-12-10 07 - 47 Version 1Weipeng LvNo ratings yet

- CK 60 PDFDocument3 pagesCK 60 PDFtaban89No ratings yet

- 100 CR 62Document4 pages100 CR 62dadNo ratings yet

- 1.6523 20nicrmo2-2 - Aisi 8620Document3 pages1.6523 20nicrmo2-2 - Aisi 8620zhenyupanNo ratings yet

- Mat - No. 1.1181, DIN Ck35, AISI 1035: Designation by StandardsDocument2 pagesMat - No. 1.1181, DIN Ck35, AISI 1035: Designation by StandardsBill MurrayNo ratings yet

- 42 CR Mo 4Document2 pages42 CR Mo 4Matthew HaleNo ratings yet

- CK45 (1.1191)Document3 pagesCK45 (1.1191)alextentwentyNo ratings yet

- 21crmov5-7: Steel GradeDocument1 page21crmov5-7: Steel GradeEdward PongracNo ratings yet

- Die Tool GradesDocument13 pagesDie Tool Gradesdarwin_huaNo ratings yet

- Aisi D2: Cold Work Tool SteelDocument7 pagesAisi D2: Cold Work Tool SteelEdilson Sarmiento AlonsoNo ratings yet

- ASTM A193 Grade B16 Boltport FastenersDocument1 pageASTM A193 Grade B16 Boltport FastenersSamkitNo ratings yet

- 42crmo6 : Steel GradeDocument2 pages42crmo6 : Steel GradeYonas Dwiananta YuwonoNo ratings yet

- SIQUAL 5736 Steel: Designation by StandardsDocument1 pageSIQUAL 5736 Steel: Designation by Standardsarjun prajapatiNo ratings yet

- Wear Resistant Steel Sheet Material DataDocument6 pagesWear Resistant Steel Sheet Material DataJuan LeonNo ratings yet

- 51 CR V4Document4 pages51 CR V4armin_kunosic9871No ratings yet

- 18nicrmo14-6: Steel GradeDocument4 pages18nicrmo14-6: Steel Gradesmith willNo ratings yet

- X20 CR Mo 13 KGDocument2 pagesX20 CR Mo 13 KGBonthala BadriNo ratings yet

- 42 CR Mo 4Document2 pages42 CR Mo 4InaamNo ratings yet

- Designation by Standards: Steel Zf7B (Din 20Mncr5, Aisi 5120)Document2 pagesDesignation by Standards: Steel Zf7B (Din 20Mncr5, Aisi 5120)Rodolfo Mayhen MartinezNo ratings yet

- Wear Resistant Steel: Material Data Sheet, Edition April 2016Document6 pagesWear Resistant Steel: Material Data Sheet, Edition April 2016Zoltán PálfyNo ratings yet

- 50MN7Document2 pages50MN7Anonymous pmp0NyDNo ratings yet

- Otel de Scule - GBDocument37 pagesOtel de Scule - GBColta VictorNo ratings yet

- Aisi A2: Cold Work Tool SteelDocument21 pagesAisi A2: Cold Work Tool SteelRahul NambiarNo ratings yet

- Rolling Technology Training Programme - AnnealingDocument52 pagesRolling Technology Training Programme - Annealingrabikm100% (1)

- 03171344yzet PDFDocument30 pages03171344yzet PDFRobin LeeNo ratings yet

- 100crmnsi6-4: Steel GradeDocument3 pages100crmnsi6-4: Steel GradeSama UmateNo ratings yet

- datasheet-saf-2205-en-v2021-10-07 13_05 version 1Document8 pagesdatasheet-saf-2205-en-v2021-10-07 13_05 version 1simone.mauriNo ratings yet

- Cold-Rolled Steel CoilsDocument28 pagesCold-Rolled Steel CoilsX800XLNo ratings yet

- S355JRDocument2 pagesS355JRThanh NguyenNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- Hardness HSS - SKD11Document5 pagesHardness HSS - SKD11Antonius PrakosaNo ratings yet

- Aco AISI 1020 PDFDocument1 pageAco AISI 1020 PDFIbsonhNo ratings yet

- Thyssenkrupp Steels For Enameling Product Information Steel enDocument6 pagesThyssenkrupp Steels For Enameling Product Information Steel enle hoangNo ratings yet

- Advances in Solid Oxide Fuel Cells and Electronic CeramicsFrom EverandAdvances in Solid Oxide Fuel Cells and Electronic CeramicsNo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Math10 Q2 Mod24 WritingtheEquationofaCircleandDeterminingtheCenterandRadiusofaCircle V3-1Document19 pagesMath10 Q2 Mod24 WritingtheEquationofaCircleandDeterminingtheCenterandRadiusofaCircle V3-1Bridget SaladagaNo ratings yet

- PRACH Optimization - V1Document11 pagesPRACH Optimization - V1Tulipe Pivoine100% (5)

- Lesson 8 Homework Practice Volume and Surface Area of Composite Figures AnswersDocument8 pagesLesson 8 Homework Practice Volume and Surface Area of Composite Figures Answerscfg1ngzn100% (1)

- Probability As A General Concept Can Be Defined As The Chance of An Event OccurDocument14 pagesProbability As A General Concept Can Be Defined As The Chance of An Event OccurMuhammad Adnan KhalidNo ratings yet

- National Parks in IndiaDocument4 pagesNational Parks in IndiaVicky PandeyNo ratings yet

- Hypothesis of The Origin of LanguageDocument6 pagesHypothesis of The Origin of LanguageJefferson KagiriNo ratings yet

- BMW Inyeccion 320i-325i Motronic M31 PDFDocument2 pagesBMW Inyeccion 320i-325i Motronic M31 PDFIvoo ooNo ratings yet

- B10 GeniE Member Plate Code CheckingDocument51 pagesB10 GeniE Member Plate Code CheckingJorge HLNo ratings yet

- U1L9 Student Guide (1) - 1Document4 pagesU1L9 Student Guide (1) - 1jonahNo ratings yet

- Module 2: Hematopoiesis I. General Principles of HematopoiesisDocument13 pagesModule 2: Hematopoiesis I. General Principles of HematopoiesisJane JapoleNo ratings yet

- Troubleshooting GuideDocument88 pagesTroubleshooting GuideFrancisco Diaz56% (9)

- Bai Tap Tieng Anh Lop 8 Unit 7 Environmental Protection Global SuccessDocument8 pagesBai Tap Tieng Anh Lop 8 Unit 7 Environmental Protection Global Successngtrmm1No ratings yet

- HTTP Sleekfreak Ath CX 81 3wdev CD3WD METALWRK GTZ075CE B65 7 HTMDocument14 pagesHTTP Sleekfreak Ath CX 81 3wdev CD3WD METALWRK GTZ075CE B65 7 HTMPavan SripadaNo ratings yet

- Jaguar Land-Rover: A Customer Centric OrganizationDocument15 pagesJaguar Land-Rover: A Customer Centric OrganizationAnmol Shukla100% (1)

- Resumen en Ingles Del Diario Ana Frank Chisaguano EmilyDocument16 pagesResumen en Ingles Del Diario Ana Frank Chisaguano EmilyChisaguano EmilyNo ratings yet

- Aberrant - Core BookDocument292 pagesAberrant - Core BookRodrigo Hky100% (7)

- I See Fire ChordsDocument4 pagesI See Fire ChordsIm In TroubleNo ratings yet

- Quality Testing of Honey StandardsDocument33 pagesQuality Testing of Honey StandardsK. N RaoNo ratings yet

- Diagram PLTA SLJDocument4 pagesDiagram PLTA SLJMEi Cuiet Luph-LuPhNo ratings yet

- Mci 2005Document3 pagesMci 2005Christos LeptokaridisNo ratings yet

- Despiece Motor Briggs 14hp 400707122102Document58 pagesDespiece Motor Briggs 14hp 400707122102leinadNo ratings yet

- Lecture Drugs in Sport - NotesDocument14 pagesLecture Drugs in Sport - NotesDavid FornitoNo ratings yet

- Pioneer Deh-X3650uiDocument65 pagesPioneer Deh-X3650uiAllnightlonificationNo ratings yet

- Band 2 eDocument58 pagesBand 2 eIonaş Claudia Ramona100% (1)

- Reflective EssayDocument5 pagesReflective Essaybwood17No ratings yet

- Copper Alloy UNS C23000: Sponsored LinksDocument2 pagesCopper Alloy UNS C23000: Sponsored LinksvinayNo ratings yet

- Analytical Reasoning Skills Part ADocument30 pagesAnalytical Reasoning Skills Part AAhmad MiftahulNo ratings yet

- ATTR State of The ArtDocument20 pagesATTR State of The ArtGenoveffa Ridalisi100% (1)

- Abandonship Drill and LSA Training With Newly Join CrewDocument3 pagesAbandonship Drill and LSA Training With Newly Join CrewSashNo ratings yet

- My Heart Sings Praises - Line UpDocument4 pagesMy Heart Sings Praises - Line UpAnthony JimenezNo ratings yet