Professional Documents

Culture Documents

Steel Girder Stability During Bridge Erection AASHTO LRFD Check On L.B Ratios

Uploaded by

Henry Burgos N.Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Girder Stability During Bridge Erection AASHTO LRFD Check On L.B Ratios

Uploaded by

Henry Burgos N.Copyright:

Available Formats

TECHNICAL NOTES

Steel Girder Stability during Bridge Erection: AASHTO LRFD

Check on L / b Ratios

John S. Hastings, P.E.1; Qiuhong Zhao, P.E., M.ASCE2; and Edwin G. Burdette, P.E., F.ASCE3

Downloaded from ascelibrary.org by Purdue University Libraries on 08/29/19. Copyright ASCE. For personal use only; all rights reserved.

Abstract: The erection of steel plate girders during the construction process of a steel bridge is a complex operation, which is often left

to the contractor and/or the subcontractor to plan and execute. Rules of thumb have been developed through experience to check the

lateral torsional buckling of the steel girder during erection using the maximum L / b 共unbraced length/compressive flange width兲 ratio,

below which no lateral torsional buckling would occur. Although the L / b ratio check has proven to be useful and convenient on-site, it

is necessary to provide a more rational basis for the rules of thumb, and find the maximum L / b ratios by checking the lateral torsional

buckling failure of girders under erection according to the latest AASHTO LRFD code. A series of parametric studies were conducted on

cantilever and simply supported girders under self-weight as well as self-weight plus wind load, in order to: 共1兲 check the rules of thumb

on L / b ratios and 共2兲 determine the effects of girder flange width, flange thickness, web depth, web thickness, and yield strength on the

maximum L / b ratio and girder stability during erection. From the results, rules of thumb were modified for girders with common shapes,

and it was obvious that 共1兲 self-weight plus wind load controls the girder stability during erection in most cases and 共2兲 flange width and

web depth have the most effects on the maximum L / b ratio and girder stability during erection.

DOI: 10.1061/共ASCE兲BE.1943-5592.0000102

CE Database subject headings: Bridges, steel; Bridges, girder; Buckling; Construction.

Author keywords: Steel girder; Erection; Instability; Lateral torsional buckling.

Introduction and Background the girder stability during erection is checked by the L / b ratio

共unbraced length/compressive flange width兲. For a cantilever

When a steel girder is under erection during the construction pro- girder during erection: 共1兲 if the L / b value is less than 30, stabil-

cess of a steel bridge, it may experience instability and lateral ity is guaranteed; 共2兲 if the L / b value is between 30 and 40,

torsional buckling failure if the unbraced length is too large, stability is doubtful; and 共3兲 if the L / b value is over 40, tempo-

which in turn might cause collapse of the whole steel superstruc- rary support will be required. For a simply supported girder, the

ture, as illustrated by the collapse of the State Route 69 Bridge at L / b ratio limits are doubled. Although the rules of thumb on L / b

Clifton, Tennessee on May 16, 1995. ratios are convenient and useful on-site, there is no theoretical

In many cases, the steel girder erection was left to the contrac- background other than experiences, and a more rational basis is

tor and/or the subcontractor to plan and execute, based mainly on urgently needed.

past experiences. Rules of thumb have been used when an erector

needs to conduct a quick stability check or make a decision on

temporary removal of cross frames on-site, since precise stability Checking Stability of Cantilever Girder during

analysis might not be available at the moment. One set of such Erection

rules of thumb have been published in the Handbook for Con-

struction Engineers 共American Bridge Division 1983兲, in which The governing design code AASHTO LRFD Specifications

共AASHTO 2007兲 was adopted to check the rules of thumb on L / b

1

Civil Engineer Manager I, Tennessee Dept. of Transportation ratio. The girders in this study are longitudinally unstiffened,

共TDOT兲, Suite 1100 James K. Polk Building, Nashville, TN 37243-0349, straight, and prismatic with no braces along the span. According

E-mail: john.s.hastings@state.tn.us to AASHTO LRFD, a steel girder will not experience elastic lat-

2

Assistant Professor, Dept. of Civil and Environmental Engineering, eral torsional buckling if f bu ⱕ ⌽ f Fcr, where f bu = external normal

Univ. of Tennessee, 109A Perkins Hall, Knoxville, TN 37996-2010, stress and Fcr = elastic lateral torsional buckling stress. For a cer-

E-mail: qzhao@utk.edu tain girder under erection, f bu increases while Fcr decreases with

3

Professor, Dept. of Civil and Environmental Engineering, Univ. of the span L, therefore, a certain limit Lmax and 共L / b兲max exits,

Tennessee, 115 Perkins Hall, Knoxville, TN 37996-2010. E-mail: beyond which the girder will experience elastic lateral torsional

eburdett@utk.edu

buckling.

Note. This manuscript was submitted on June 6, 2008; approved on

January 19, 2010; published online on January 22, 2010. Discussion pe- Parametric studies were then conducted, in which 共L / b兲max

riod open until April 1, 2011; separate discussions must be submitted for ratios were obtained for a group of cantilever girders with varying

individual papers. This technical note is part of the Journal of Bridge geometric and material parameters, including flange width, flange

Engineering, Vol. 15, No. 6, November 1, 2010. ©ASCE, ISSN 1084- thickness, web depth, web thickness, and material yield strength,

0702/2010/6-759–762/$25.00. as summarized in Table 1. For each girder section, the span L was

JOURNAL OF BRIDGE ENGINEERING © ASCE / NOVEMBER/DECEMBER 2010 / 759

J. Bridge Eng., 2010, 15(6): 759-762

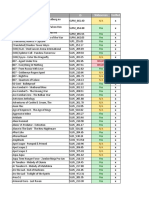

Table 1. Parameters in Analytical Studies

Flange width, b Flange thickness, t f Web depth, D Web thickness, tw Yield strength, Fy

Case 共mm兲 共mm兲 共mm兲 共mm兲 共MPa兲

Cantilever—1 305–914 25–38a 1,016–2,438 13–17b 345

Cantilever—2 914 38–102 1,219–2,438 13–17b 345

Cantilever—3 914 38 1,219–2,438 10–25b 345

Cantilever—4 914 38 1,219–2,438 10–25b 248–483

Simple—1 305–914 25–38a 1,016–2,134 13–14b 345

a

Flange thickness is constant for each given flange width.

b

Web thickness is constant for each given web depth.

Downloaded from ascelibrary.org by Purdue University Libraries on 08/29/19. Copyright ASCE. For personal use only; all rights reserved.

increased in steps, and a spreadsheet was developed to check In summary, for any specific cantilever section, the flange width

f bu ⱕ ⌽ f Fcr for each step. When the equation did not satisfy any and web depth are dominating parameters for girder stability dur-

more, the Lmax and 共L / b兲max values for this girder section were ing erection, and the flange thickness, web thickness, and material

then identified. The AASHTO Load Combination Strength IV yield strength only have negligible effects; the 共L / b兲max ratio

共1.5D兲 and Strength III 共1.25D + 1.40W兲 were considered, respec- could be directly read or interpolated from Fig. 1, beyond which

tively. Purposes of the parametric studies included: 共1兲 check the the girder will lose stability during erection.

rules of thumb on 共L / b兲max ratios for common girder shapes and Comparing the rules of thumb to the AASHTO LRFD results

共2兲 determine the effects of girder flange width, flange thickness, in Fig. 1, it is obvious that the original lower limit of 30 on the

web depth, web thickness, and yield strength on 共L / b兲max ratios L / b ratios, below which stability is guaranteed for any girder

and girder stability during erection. section, turned out to be slightly conservative, since any girder

section with an L / b ratio above 30 but below 35 would still

remain stable. But the lower limit could remain as 30, since not

AASHTO LRFD Load Combination Strength IV all possible sections were checked. On the other hand, the original

„1.5D… upper limit of 40 on the L / b ratios, above which temporary sup-

port would be needed for any girder section, turned out to be

The AASHTO Load Combination Strength IV was considered for

overly conservative, since numerous girders will remain stable

the first set of analyses, which applies to a very high dead load

with a L / b ratio above 40 but below the 共L / b兲max ratios. There-

versus live load case. For Case 1 study, the 共L / b兲max ratios are

plotted in Fig. 1, where each curve represents a group of sections fore, the rules of thumb on the lower and upper limits of L / b

with the same flange width and thickness, while the web depth ratios for cantilever should be modified to 30 and 60, based on the

and thickness vary along the curve. It is obvious that the 共L / b兲max AASHTO LRFD check under only the dead load effects.

ratio will increase with the web depth and thickness, indicating

that a lower girder section with a thinner web would generally

have more tendency for instability during erection compared to a AASHTO LRFD Load Combination Strength III

deeper girder section with a thicker web. From Case 2 to 4 stud- „1.4D + 1.25W…

ies, it turned out that the 共L / b兲max ratio would increase very

slightly with the flange thickness, while essentially not affected The AASHTO Load Combination Strength III was considered for

by the material yield strength. In addition, the 共L / b兲max ratio de- the second set of analyses, which applies to a high wind load

creased very slightly when the web depth was held constant and case. Minor-axis bending is then combined with major axis bend-

the web thickness increased from a minimum value of 150 times ing according to f bu + 共1 / 3兲f l ⱕ ⌽ f Fnc, where f l = external normal

web thickness 共AASHTO 2007兲 to a maximum value of 25 mm, stress due to wind load; f bu = external normal stress due to gravity;

mainly because the external load demand due to girder self- and Fnc = nominal flexural resistance of the compression flange.

weight would increase faster than the girder capacity in this case.

The lateral load also needs to be checked to ensure that minor-

axis failure does not occur before the onset of lateral torsional

buckling by f l ⱕ 0.6Fyc, where Fyc = yield strength of the compres-

sion flange 共AASHTO 2007兲.

The AASHTO code does not specify the magnitude of wind

pressure during erection but only for normal design, for which if

the height of the girder is less than 30 ft above ground, a design

wind pressure of 25.6 pounds per square foot 共psf兲 should be

used, corresponding to a wind velocity of 100 mi/h. However, the

design wind pressure is not suitable for a construction check,

since a contractor is not likely to erect a bridge during periods of

extremely high winds. There might be windy days during various

phases of bridge construction, but the contractor will usually have

multiple girders in place with bracing installed 共i.e., cross frames

and laterals if required兲. Unless something out of the ordinary

occurs, namely an extraordinary event, the steel girder under erec-

tion would not experience a high wind loading without any brac-

Fig. 1. Maximum L / b ratios for cantilevers under self-weight ing along the span. Therefore, the wind pressure experienced by

760 / JOURNAL OF BRIDGE ENGINEERING © ASCE / NOVEMBER/DECEMBER 2010

J. Bridge Eng., 2010, 15(6): 759-762

Downloaded from ascelibrary.org by Purdue University Libraries on 08/29/19. Copyright ASCE. For personal use only; all rights reserved.

Fig. 2. Maximum L / b ratios for cantilevers under self-weight plus Fig. 3. Maximum L / b ratios for simply supported girders under self-

wind load weight plus wind load

girder during erection should be modified for extraordinary

events.

Unfortunately, the AASHTO code does not specify the magni- nation, which turned out to be more critical in most cases. For

tude of wind pressure under extraordinary events either. ASCE Case 1 study, the 共L / b兲max ratios are plotted in Fig. 3, where each

7-05 Minimum Design Loads for Buildings and Other Structures curve represents a group of sections with the same flange width

共ASCE 2005兲 was then referred to, where the wind load factor for and thickness, while the web depth and thickness vary along the

extraordinary events is 1/8 of the wind load factor for normal curve. For any specific simply supported girder section, the

design, which means the wind pressure for extraordinary events is 共L / b兲max ratio could be directly read or interpolated from the

also 1/8 of the wind pressure for normal design. Since the wind curve, beyond which the girder will lose stability during erection.

pressure is proportional to the square of wind velocity, the wind Unlike the cantilevers, the 共L / b兲max ratio would decrease obvi-

velocity for extraordinary events could be calculated as VDZ ously when the web depth and thickness increase, especially for

= 冑共1 / 8兲 ⫻ 100 mi/ h = 35.4 mi/ h. Considering wind gusts in the girders with relatively narrow flanges, since the wind load effects

event of a sudden summer storm, the wind velocity for girder will dominate in those cases.

under erection could be further increased to 45 mi/h, resulting in Comparing the rules of thumb to the AASHTO LRFD results

a wind pressure of qz = 共45 mi/ h / 100 mi/ h兲2 ⫻ 25.6 psf in Fig. 3, it is obvious that the original lower limit of 60 on the

= 5.18 psf. L / b ratios, below which stability is guaranteed, turned out to be

The same groups of parametric studies were conducted using unsafe. All the 共L / b兲max ratios in Fig. 3 are below 60, while any

the Strength III combination. The effects of the web depth and girder section with an L / b ratio below 60 but above 共L / b兲max will

flange width on the 共L / b兲max ratio for Case 1 are shown in Fig. 2, become unstable during erection. In addition, the original upper

which generally looks similar to the Strength IV combination. limit of 80 on the 共L / b兲max ratios, above which temporary support

However, for some of the girders with narrow flanges, the would be needed, turned out to be unconservative as well, since

共L / b兲max ratio would decrease when the web depth and thickness any girder with a L / b ratio above 60 would need temporary sup-

increase, probably because the wind load would affect the girder port already. Therefore, the rules of thumb on the lower and upper

stability more in these cases. From Case 2 to 4 studies, the results limits of L / b ratios for simply supported girder should be modi-

were similar to the Strength IV combination, except that the fied to 45 and 60, based on the AASHTO LRFD check consider-

maximum L / b ratios are slightly higher. ing the combined wind load and dead load effects.

For the same girder section, the 共L / b兲max ratios under the

Strength IV combination 共1.5D兲 and under the Strength III com-

bination 共1.25D + 1.4W兲 were compared together. It turned out Conclusions

that for 73% of all shapes investigated, a lower 共L / b兲max ratio was

obtained under the Strength III combination, which means wind 1. L / b ratio is convenient and useful on-site to check girder

load plus self-weight will control the girder stability during erec- stability during lifting, shipping, erection, and temporary

tion, except for girders with very wide flanges including the lower cross frame removal. A series of graphs for the 共L / b兲max

bound curve. The difference becomes more obvious as the web ratios were created for the convenience of constructors. Note

becomes deeper and the flange becomes narrower, since the wind that the L / b ratio check cannot replace the more rigorous

load effects dominate more. Therefore, it is necessary to consider stability check if deemed needed by the structural engineers.

the combined wind load and dead load effects for most cases, 2. Based on parametric studies using AASHTO LRFD, the

when checking girder stability during erection. The rules of dominating factors for girder stability during erection are the

thumb on the lower and upper limits of L / b ratios for cantilever compression flange width and the web depth.

were then further modified to 30 and 50, based on the AASHTO 3. In most cases, especially for girders with narrow flanges or

LRFD check under the combined wind load and dead load effects. deep webs, it is more critical to consider the combined wind

load and dead load effects when checking girder stability

Checking Stability of Simply Supported Girder during erection.

during Erection 4. Based on parametric studies using AASHTO LRFD, the rules

of thumb on the lower limit of L / b ratios for cantilever were

Analyses were also conducted on simply supported girders to slightly conservative, but could remain as 30; the rules of

determine the 共L / b兲max ratios under the Strength III load combi- thumb on the upper limit of L / b ratios were overly conser-

JOURNAL OF BRIDGE ENGINEERING © ASCE / NOVEMBER/DECEMBER 2010 / 761

J. Bridge Eng., 2010, 15(6): 759-762

vative, and could be modified to 50 considering the com- Fyc ⫽ specified minimum yield strength of

bined wind load and dead load effects. compression flange;

5. Based on parametric studies using AASHTO LRFD, the rules f bu ⫽ largest value of compressive stress throughout

of thumb on the lower and upper limits of L / b ratios for the unbraced length;

simply supported girder were unsafe or unconservative, and f l ⫽ flange lateral bending stress;

should be modified to 45 and 60 considering the combined L ⫽ actual unbraced length;

wind load and dead load effects. qz ⫽ wind stagnation pressure;

VDZ ⫽ design wind velocity;

W ⫽ wind load; and

f ⫽ resistance factor for flexure.

Notation

References

The following symbols are used in this technical note:

Downloaded from ascelibrary.org by Purdue University Libraries on 08/29/19. Copyright ASCE. For personal use only; all rights reserved.

b ⫽ width of compression flange; AASHTO. 共2007兲. LRFD bridge design specifications, 4th Ed., Washing-

D ⫽ dead load due to girder self-weight; ton, D.C.

Fcr ⫽ elastic lateral torsional buckling stress; American Bridge Division. 共1983兲. Handbook for construction engineers,

Fnc ⫽ nominal flexural resistance of a compression United States Steel Corporation, Pittsburgh.

flange; ASCE. 共2005兲. Minimum design loads for buildings and other structures,

Fy ⫽ specified minimum yield strength of steel; Reston, Va.

762 / JOURNAL OF BRIDGE ENGINEERING © ASCE / NOVEMBER/DECEMBER 2010

J. Bridge Eng., 2010, 15(6): 759-762

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Cusps: Ramesh 04-Jun-1976 12:30:00 PM Krishnagiri 78:14:0 E, 12:32:0 N Tzone: 5.5 KP (Original) Ayanamsha 23:26:2Document1 pageCusps: Ramesh 04-Jun-1976 12:30:00 PM Krishnagiri 78:14:0 E, 12:32:0 N Tzone: 5.5 KP (Original) Ayanamsha 23:26:2Suresh NatarajanNo ratings yet

- Union Metal SemiconductorDocument4 pagesUnion Metal SemiconductorskinhugoNo ratings yet

- NCR Supplier PPAP Training PresentationDocument166 pagesNCR Supplier PPAP Training PresentationRajeev ChadhaNo ratings yet

- Motion in One Dimension QuestionDocument6 pagesMotion in One Dimension Questionabh_omega33% (3)

- Empowerment TechnologyDocument15 pagesEmpowerment Technologysxhan gwenNo ratings yet

- Researchpaper Should Removable Media Be Encrypted - PDF - ReportDocument15 pagesResearchpaper Should Removable Media Be Encrypted - PDF - ReportSakshi Dhananjay KambleNo ratings yet

- Silenat Berhanu SimaDocument6 pagesSilenat Berhanu SimaSilenat BerhanuNo ratings yet

- UnitPlan (P.E) Grade 6Document13 pagesUnitPlan (P.E) Grade 6Lou At CamellaNo ratings yet

- Relations Between Lean Management and Organizational StructuresDocument12 pagesRelations Between Lean Management and Organizational StructuresRENE JAVIER PACHECO SALASNo ratings yet

- Systematic Literature Review SvenskaDocument6 pagesSystematic Literature Review Svenskafihum1hadej2100% (1)

- 1991 - Defect Chemistry of BaTiO3Document20 pages1991 - Defect Chemistry of BaTiO3Beh NaatNo ratings yet

- Error Code EMR 2Document5 pagesError Code EMR 2Nafrizal SuhendrikNo ratings yet

- Cocoon 8002 PDFDocument24 pagesCocoon 8002 PDFaxisNo ratings yet

- Chapter 15 - Leukocyte Migration and Inflammation - The IS Relies Upon The Continual Circulation of Leukocytes Through The BodyDocument12 pagesChapter 15 - Leukocyte Migration and Inflammation - The IS Relies Upon The Continual Circulation of Leukocytes Through The BodyEmad ManniNo ratings yet

- PP in Ii 001Document15 pagesPP in Ii 001Dav EipNo ratings yet

- Dimensions and Methodology of Business Studies Dec 2018Document2 pagesDimensions and Methodology of Business Studies Dec 2018Nallavenaaya Unni100% (1)

- THE REFUND - Frigyes Karinthy: AuthorDocument6 pagesTHE REFUND - Frigyes Karinthy: AuthorMilind JamnekarNo ratings yet

- WideScreen Code For PS2 GamesDocument78 pagesWideScreen Code For PS2 Gamesmarcus viniciusNo ratings yet

- Algebra1 Review PuzzleDocument3 pagesAlgebra1 Review PuzzleNicholas Yates100% (1)

- Parkinson S Disease Detection Based On SDocument5 pagesParkinson S Disease Detection Based On SdaytdeenNo ratings yet

- Makaut Grade Card Collection Notice 2018-19Document1 pageMakaut Grade Card Collection Notice 2018-19Sourav PandaNo ratings yet

- Cable Systems For High and Extra-High Voltage: Development, Manufacture, Testing, Installation and Operation of Cables and Their AccessoriesDocument1 pageCable Systems For High and Extra-High Voltage: Development, Manufacture, Testing, Installation and Operation of Cables and Their AccessorieseddisonfhNo ratings yet

- Tugas English 3Document2 pagesTugas English 33751Muhammad RizqiNo ratings yet

- LogDocument67 pagesLogRudhi Al GhaisanNo ratings yet

- Malraux Anti-MemoiresDocument9 pagesMalraux Anti-MemoiresNevenaRistićNo ratings yet

- Delonghi Pinguino Water To Air Pac We125 Instruction Manual 715678Document21 pagesDelonghi Pinguino Water To Air Pac We125 Instruction Manual 715678Luis AlbertoAlmeidaSilva100% (1)

- 07 Endodontic RetreatmentDocument64 pages07 Endodontic RetreatmentGayathriNo ratings yet

- ENIRAM - Guide To Dynamic Trim Optimization 280611 PDFDocument14 pagesENIRAM - Guide To Dynamic Trim Optimization 280611 PDFPhineas MagellanNo ratings yet

- Chapter 2 Ag - EconDocument7 pagesChapter 2 Ag - EconJay Kenneth Bajar Cernal100% (1)

- Power Distribution & Utilization: Total Power Generation of Last 10 Years and Forecast of 20 YearsDocument12 pagesPower Distribution & Utilization: Total Power Generation of Last 10 Years and Forecast of 20 YearsSYED ALIYYAN IMRAN ALINo ratings yet