0 ratings0% found this document useful (0 votes)

277 views34 pagesChapter No 6

Uploaded by

Faiza Tabassam 546-FET/BSEE/F19Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

0 ratings0% found this document useful (0 votes)

277 views34 pagesChapter No 6

Uploaded by

Faiza Tabassam 546-FET/BSEE/F19Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

Chapter 6

HEAT CYCLES

6.1. GENERAL | ae

The function of a heat cycle (power cycle) in a steam power pI ant is to conv

a part of the total heat into work and discard the Pane a the receive, oe

heat sink. The heat is produced by burning fuel in the ra iad fumnace and it

converted into work with the help of a prime-mover steam turbine), The

condenser acts as the heat sink. Now,

‘Amount of heat converted into useful work ;

= Heat added - Heat rejected

Now thermal efficiency of the heat cycle

Output _ _Workdone

= Trput ~ Heat added

_ Hest added — Heat rejected -

Heat added

It is well-known that the highest thermal efficiency is given by Carnot cycle, as

ao

Mea = 7,

where T, and T, are the temperature range over which the working fluid operates.

Now increased temperatures cause more difficulty with the materials of the

plant components than increased pressure. Moreover irreversibility of Camot

cycle cannot be obtained in actual practice. Due to this, the Rankine cycle, which

operates between two constant pressures rather than two constant temperatures,

is universally adopted for steam power plants.

6.2. RANKINE CYCLE

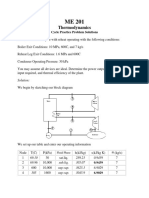

Fig. 6.1 shows the flow diagram and the total heat-entropy. I, - , diagrams for

the steam power plant working on the Rankine cycle. This cycle can be studs!

with the help of p - v ant T- @ diagrams shown in Fig. 6.2. We start with poitt

3 a Corresponds © the state when steam, after it has expanded in the turbite

is condensed in the condenser. The cond i 2 and

mer ‘ondensate is at pressure Pz

(a) io 3—4: The condensate or the feed water is raised to pressute Py

y adiabatic compression by the feed water circulating pump of fee!

pump. The temperature of feed water may increase by few degrees. It's

iiPresented by line 3 — 4 on T — @ diagram, the equivalent pump wo

cing shown by p, —3 —4 — p, on p—v diagram.

148

‘Scanned wih ComScanner

Heat Cycles // 149

Loire FHI

Generator

+ Constant

Pressure Lines

poier Condenser

',

Water circulating |

pump

Fig. 6.1. Rankine cycle.

by

saturated

Super Heated

t

cS om 7

Fig. 6.2 Rankine cycle on p-v and T-6 diagrams.

(b) Process 4—5: The feed water received sensible-heat in the boiler.

(©) Process 5—1: More heat in the form of latent heat is given to the feed

water in the boiler. The point 1 may be in wet zone, dry saturated zone

or superheated zone depending upon the heat supplied by the boiler.

Processes 4—5 and 5 — 1 take place at constant pressure.

(@ Process 1—2: It is the adiabatic expansion in the steam turbine.

(©) Process 2—3: It is the condensation process at constant temperature and

constant pressure (isothermal compression).

Now workdone = I,; — Isz

Feed pump also is given some input to the water to the boiler. Therefore, net

Work done will be.

Net work done = (Is; — Is) — Pump work

Heat supplied in boiler = Is, — lo, = [Is; — (la, + Pump work)]

io

w Toy = Io,

‘ Is — Is) Pump work

= Thy (Ranki — si = Isa)

1 (Rankine cycle) = (7. —To,)— Pump work

woetVOFk Ratio: It is defined as the ratio of the net work done and the Turbine

otk. That is,

‘Scanned wih CemScanner

| _ Wr-Wp

Work Ratio = .

Wr

king fluid, KJ/k8

Work done by the working fluid (Pump work), KI/kg

where Wy

Work done on the working

Wp

Work Ratio =

Now pump work is usually small and is neglected. Thus,

Is, — 15,

nth (Rankine cycle) = J, =Top

Js, = Total heat of steam at point 1

where

ig! =Total heat of steam at point 2

Jo, = Heat of water at point 2 ao

ork is neglected is shown in Fig. 6.3 or

‘The Rankine cycle, where pump W'

T — 6 diagram.

‘As is clear from Fig. 6.1 and equation

(62), the thermal efficiency of the Rankine

cycle can be improved by

1, Increasing the inlet pressure and

temperature conditions.

2. Increasing then condenser vacuum,

that is, lowering the exhaust pressure.

Now increasing the inlet steam pressure Hest Reade

for the given inlet steam temperature and

Fig. 6.3, Rankine cycle.

condenser pressure would result in: increase

in work (Fig. 6.4.), increase in thermal efficiency, and always an increase in the

moisture content of the steam at the turbine exhaust (Fig. 6.4).

-

Inlet Conchtion

‘Scanned wih CemScanner

Fier

Heat Cycles // 151

‘An increase in initial steam temperature would always result in: increase in

work and thermal efficiency (since heat will be added in the cycle at a higher

temperature) and decrease in moisture content of steam at turbine exhaust. So

there is no upper limit for initial steam temperature. It is limited by the materials

sed in the boiler tubes and the turbine. Most modern steam turbines are limited

toa maximum operating temperature of 535 to 595°C. The following are typical

recommended values for initial steam pressure for various rating turbines

50 MW 50 to 90 ata

50-100 MW 90 to 130 ata

100-200 MW 130 ata

200-300 MW 130 to 170 ata

300 MW and above 130 to 240 ata

Condenser Pressure: Lowering the condenser pressure results in a increase

in thermal efficiency and useful work but also an increase in moisture content

ofsteam at the turbine exhaust. Lower exhaust pressure also means larger volume

of steam towards the end of its expansion which will result in bigger |p. turbine

and condenser. However, the increased capital cost is offset by an increase in

thermal efficiency. The minimum condenser pressure is limited by the lowest

available temperature of water or air that acts as the receiver. Then the condenser

pressure will be saturated pressure corresponding to the cooling water/air

temperature. So, truly speaking, as there is no control on cooling water

temperature, we don’t have any control on condenser pressure. In our country;

the cooling water temperature usually ranges from 24°C (rivers) to 36°C (sea)

giving condenser pressures of 0.06 to 0.12 ata

It is clear from the above discussion that the only undesirable factor resulting

from increased inlet steam pressure and decreased condenser pressure is an

increase in the moisture content at the turbine exhaust. Now towards the turbine

exhaust, the steam pressure and its density are very low. This low density steam.

produces very high flow velocities in the -p part of the turbine. The water

droplets present in the steam would erode the surface of the low-pressure turbine

blades. Due to this, it is recommended that the moisture content at the turbine

exhaust should not exceed about 10%. For this, instead of expanding the steam

inonly one turbine, itis expanded in 2/3 turbines. After the steam has expanded

in the FLP. turbine, the steam is retuned to @ reheater where additional heat is

Supplied to it at constant pressure, thereby, increasing its supetheat and then it

's expanded in i-p and [-p turbines. This improvement in simple Rankine cycle

Permits the use of very high steam pressures without excessive moisture at the

turbine exhaust, Steam after partial expansion is usually reheated to initial steam

temperature at pressure 0.15 to 0.30 times the intial pressure. The reheat cycle

's discussed below.

83. REHEAT CYCLE

As discussed above there are two reasons for the use of reheat cycle. One is that

there is a limit to the degree of superheat due to metallurgical conditions, so that

itis not possible to get all superheat in one stage. And secondly, the inevitable

tHlects of higher pressures is that the saturation line is reached earlier during

Sentropic expansion and most of the turbine stages operate in the relatively

Undesirable saturated steam region. Due to the impact of particles of suspended

‘Scanned wih CamScanner

152 // Power Plant Engineering

i jon. The safe maximum lim

will be blade erosion. =

water on turbine pete shouldbe ofthe order of 12 er cent. Therigg

moisture in the crssarily practised in high pressure pl aa s. The ra eating’

reheating is neces structing the turbine so that all of the st — may be extraceg

a dnt, resuperheated in the reheat boiler and then readmited

ae oie the turbine for further expansion. Or superbe sexy

peeaten ae a high pressure turbine and its exhaust reheated and they

expal :

expanded in the low pressure turbine.

‘Super Heater 5

te LY

No me Ly ; Qe

Turbine

. Alternater:

lao | |

Re-heater| __

[Gondenser

Circulating Pump,

Feed Water

(a)

(e)

Fig. 6.5, Reheat cycle,

Fig. 6.5 (a) and (b) show the flow diagram and I, — @ diagram of the cydle.

The advantages of the Reheat cycle are:

1. The moisture in the exhaust steam is greatly reduced and due to this the

erosion of the turbine blades is reduced tremendously.

The thermal efficiency of the turbine is increased by 4 per cent to 5 pet

cent if the reheat temperature is equal to the initial throttle temperature.

Condenser size is reduced by 7 per cent to 8 per cent.

The size of the boiler is reduced because the steam flow is reduced by

about 15 per cent to 18 per cent.

The size of the low pressure turbine is reduced due to reduction in specific

volume by about 7 per cent to 8 per cent.

xR

ae

a

‘Scanned wih ComScanner

Heat Cycles // 183

6. Station heat rate is improved due to reduction in feed pump power by

about 15 per cent to 18 per cent.

Limitations of reheat cycle are that the cost of extra pipes and controls makes

this cycle more expensive than the non-reheat cycle. For economical plant, the

base load capacity should be 50 MW.

The efficiency of the cycle can be calculated as under:

Let Is, = total heat of steam at 1

Is, = total heat of steam at 2

Is, = total heat of steam at 3

Is, = total heat of steam at 4

lo, = total heat of water at 4

48;

T ——r

Throttie & Reheat Temp = 426°C

Condenser Pressure = 12 7 mm of Hg

a 137.3 bar

aah 68.65

4er 24.3 bar

Ideal Reheat Cycle Efficiency % —=

8 &

ui —a5 ga 0808 10

Ratio of Reheat o Throttle Pressure—=

Fig. 6.6. Variation of reheat cycle efficiency with reheat pressure

Then heat supplied in the boiler = Is, ~ Io,

and heat added in the reheater at constant pressure = Is ~ Is,

Total heat supplied = (Is, - Iu,) + (Is3 ~ 153)

Neglecting friction, the workdone = total heat drop

= 12 + 34 = (Is, ~ Isp) + (Is ~ Is,)

Workdone __(Isj~Isp)+( Is ~ Iss)

Heat supplied — (Is, - 104) + (Is3 - Is7)

If there is no reheating, the expansion line would bé line 15 in which case

efficiency would be

Efficiency =

the

Efficiency = Ss

Is, — 105

total heat of steam at 5

Tug = total heat of water at 5

Where Is

and

‘Scanned wih CemScanner

q

154 // Power Plant Engineering

There is an optimum reheat pressure for a given I pressure a,

n

temperature (Fig. 6.6).

For majority of the modern steam power P

(0.2 to 0.25) x initial steam pressure:

id

Jants, optimum reheat press,

Ure,

6.3.1. Methods of Reheating

‘The various methods of rehe:

Fig. 6.5 (a) illustrates the my

4, Gas Reheating: The flow he methog

gas Preainey In this method, the exhaust steam of the high pres,

imbine can be very easily reheate

the disadvantages are that long an

which means extra cost: LATB® presst

Moreover, provision for the expansion

is to be made.

2, Live steam Reh

67.

|

|

|

|

a |

MF gg the intial throttle temperature pt |

d large pipe connections are needa} |

re drops also occur in the Piping |

‘and contraction of the pipe fet |

|

|

m of this method shown in f

eating: The flow diagra

i,

LS

[Condenser

Exhaust

Circulating Pump

Fig. 6.7. Live steam reheating.

‘This method is very simple in operation and has got the following advantages

over the gas reheating:

(a) The use of large piping can be avoided by placing the reheater near the

turbine.

() As less piping is required, more than one reheating can be employed.

(0) Since the change in combustion does not affect the live steam reheater

performance, temperature control is simple.

(@) Wet steam can also be reheated.

ee of 1 and 2: The disadvantage of reheating by live steam

iets steam ue be reheated to its initial throttle temperature. So, a combi

praca laeed to have the advantages of the gas reheating and live ste#

cate pang Ce ne ‘The steam to be reheated is first passe?

dings eahown in ig an fer and then through the gas reheater. The fo"

Modem fossil-fuelled

of reheat. Some power Sees Pave employ superheat and at least one stage

not justified by improvements in ene and increased capital costs that a

efficiency. Gas cooled nuclear reactor po"

‘Scanned wih CemScanner

Heat Cycles // 185

r"

[Condenser

‘plants often employ one ‘Super Heater

age of reheat. Waters"

fooled and sodium cooled

nuclear reactor power

plants often employ one

stage of reheat, except that

the steam to be reheated is

not returned to the steam

enerator. Instead a Circulating Pump,

separate heat exchanger

that employs a portion of

steam (original) is used to

reheat the steam from the Fig. 6.8. Combined gas and live steam reheating.

outlet of the high pressure "

turbine, which is then fed to the low-pressure turbine (See Fig. 6.7).

6.4. REGENERATIVE CYCLE

In this cycle, the feed water is preheated by means of steam taken from some

sections of the turbine, before it enters the boilers from the condenser. This

process of draining steam from the turbine at certain point during its expansion

and using this steam for heating the feed water supplied to the boiler, is known

as “Bleeding”. The effect of this process is to supply the boiler with hotter water

while a small amount of work is lost: by the turbine. There is a slight increase in

efficiency but there is also a decrease in the power developed. The incidental

advantages of improved thermal efficiency and reduced steam flow to the

condenser are:

(2) Smaller condenser and boiler.

(b) The difficulty of passing large volumes of steam through the last stage in

the low pressure turbine is lessened.

(©) Improved turbine drainage, hence less trouble from erosion.

(@ Increased blade heights in the high pressure turbine to accommodate the

initial increased steam consumption.

Fig. 6.9 shows the flow diagram for the regenerative cycle.

Generator

[Condenser]

Fig. 6.9. Regenerative cycle.

‘Scanned wih CemScanner

156 // Power Plant Engineering

ni

6.4.1. How Regenerative Cycle Improves peel Eick : hors c

To know this we will have to compare the Seren Pe — MOL oye,

2—3—4 and the Rankine cycle is 1—2—3—9—?- or the highs

efficiency of carnot cycle is that heat from the ae ead is adage

to the working fluid at the highest temperature 7, fron fo 2 Tis makes

cycle reversible, In the Rankine cycle, part of the peat fo the working fay

supplied during 5—1. During this operation, the oe ‘ppl ata hight

temperature than feed water, hence, the erases re ot revere, :

tsa on cen pet ol he Re 2 yep ee

external source during this operat = 5 i

from the Rankine yale, then, the efficiency of the en ee zal 7 avai

the Carnot cycle efficiency. In practice this is impossi ae ve hod

can reduce this area will result in better cycle thermal et eS oping acti, hy

is done by extracting small fractions of total steam expan ing down the turbine

at suitable pressures and then transferring the heat energy Aes a to feed

water in feed water heaters, before the feed water enters a oiler. The bes

energy of bled steam is used in feed water heaters and it never leaves the cycle

hence, the term regenerative feedwater heating’.

ro

roq

rot

to

rot

os

+

Fig. 6.10, Fig. 6.11.

in Fig. 6.11, it has been shown that the temperature of feed water has been

raised from point 3 to point 4 with the help of three feed water heaters. Points

7, 8 and 9 are the extraction points on the turbine. Now there is no need to add

heat along line 3—4 from an external heat source. Also, the mean temperature

at which heat is added from the external source (along 4—5—6—1) increases

and this makes the operation more efficient,

Now, the feed water heating by extracted steam always results in

simultaneous reduction in the useful workdone by the steam in the turbine. In

Fig. 6.12, draw a horizontal line from point 4 to meet the expansion line 1—2 at

point 4’. Then, draw 4’—3' exactly parallel to 4—3. Now area under 42’ will

be exactly equal to area under 4—3. The heat rejected to condenser has been

reduced by the area under 3—2' and 3'—2 which are equal. But, the small triangle

of useful work 4’ 3° 2 has to be sacrificed. The heat rejected from the cycle gets

reduced at a greater rate (in simple Rankine cycle, the heat rejected to the

condenser is about 40 to 60% of total heat) than the reduction in useful work, 5,,

there is always an improvement in cycle thermal efficiency,

‘Scanned wih CamScanner

Heat Cycles // 157

Number of Feed Water Heaters:

qo get to the idea of deciding the

number of feed water heaters, let us

consider the following case:

Let the temperature of the feed

water leaving the condenser be 32°C.

Let this condensate be heated to 60°C

in the first /.p. heater. For this, steam

will be bled from Lp. turbine at a

pressure where the saturation

temperature of steam is about 65°C.

This will leave a temperature

difference of 5°C between the

condensing bled steam and the Fig. 612

outgoing feed water which would be

sufficient to transfer the heat in the heater. This difference in temperature is

known as ‘Terminal temperature difference’, (TTD).

TTD = Saturation temp. of extracted steam—out let feed water temperature.

TTD should be as low as possible. Now let the condensate at 32°C be heated

to 60°C in two heaters instead of one heater. Let its temperature be raised to

46°C in the first heater and from 46°C to 60°C in the second heater. Now, about

half the bled steam could be expanded down the turbine to a pressure

condensation Back Pressure = 12.7 mm of Hg

60

corresponding to a

temperature of 51°C and the other half

extracted at a pressure corresponding to

et the

faa {maximum thermal efficiency, an

With ber of feed heating stages and

iis noe Et is ideal. In practice, however,

7 or feag nam W provide more than 6,

IW wouty healers because of capital costs. SSeS

chow abergi ee economic to reduce TID GF eS

Heating surface too, DY putting more Number of Heaters ——>

Of eye a face in the heaters. The variati Fig. 6.13.

I showe itieney with number of heaters

y the mae 6.13. It is clear that the greatest increment

crease org a of the first heater. The increments in efficiency succe ively

sam iy beg ct additional heater. At the present time, about 30% of the working

Imes the atl olf for feed heating. Usually, feed water is heated to 0.65 to 0.75

‘aturation temperature in 5 to 9 heaters by regenerative heating

65°C as before. Now, since half the steam :

Was expanded down the turbine before aor shoe}

being extracted, more useful work has been | 59

Pee out of steam by using two feed water _ a sg

ica instead of one. It is also clear, that >

fae reduced, more work could be got §

cape bled steam because it could be

itscleme aoe down the turbine. Thus, 8 40| verpoasabe

from the above discussion that to & | eT

i

8

é

{

efficiency occurs

‘Scanned wih CemScanner

158. // Power Plant Engineering

4 abnormally (above about 27,

I the temperature ofthe feed water is raised abort Tat

by feed water heaters, a serious reduction in po"

: : 1 power ible to reclaim the hen ®

feed water temperature produced makes it impossible he hear :

outgoing flue gases by using economisers. h

In practice, the extraction points are selected £0 tha eae pene shy

about the same amount of heat to the feed oe Se geal nec

for efficient regenerative heating and permit the us To

aoe 7

poems : ‘Ceney, the positioning of the heaters

the maximum merease in therm efficiency, he Pe or heatee®

respect to the extraction points can be obtaine’ :

below: a

: “tet Io, = specific enthalpy of saturated liquid at the max. pressing

Jo, = specific enthalpy of saturated liquid at the min. pressuy,

ao :

n = number of heaters.

Then, ‘Alo = increase in specific enthalp;

heater

yy of feed water across each,

To, - 10

nde

The specific enthalpy of the sat

for the i'® heater is

rated liquid at the desired extraction pressure

Io, = lo, + i x Alo

for the ith heater

ding to Iw, (from steam tables)

also be determined on the basis of

‘Then optimum extraction pressure

= saturation pressure correspon

The placement of feed water heaters can

optimum temperature rise per heater:

If one feed water heater is to be employed, then the pressure of bleeding is

found by finding the temperature that is half way between the boiler temperature

Ty and the condenser temperature T,. For two feed water heaters, the optimun

placement is at temperatures that would divide T, - Tc into three equal parts.

‘Thus for n feed water heaters, the otpimurn temperature rise per heater would

be given by

Ta-Te

n+1

(AD opt

6.4.2. Disposal of the Feed Water Heater Drains

The two common methods to dispose off the heater drains are:

1. ade Method: In this method, the drain from one heater is led to the

aa lower heater. On its passage through this heater, the steam is

ne lensed in heating the feed. As the drain is flowing from high pressu®

2 pea ter e low pressure heater, no pump is needed in this method.

- Drain Pump: The drain from each heater may be pumped directly inl

thes ine at a point immediately after the heater.

'wo methods are explained in Fig. 6.14.

To save the cost of pumy

5, th i

The heaters may be ether of closed enon 8, of heater as often been ws

don’t mix with each oth

; er !

water mix with each other, °Pe® ‘¥P® in which the bled steam

‘Scanned wih CamScanner

losed type in which the bled steam and feed watt! |

Heat Cycles // 159

my

fp oe

ab A AL

my +m,

(a) Cascade arrangement (b) Drain pump

Fig. 6.14.

The open feed water heater has got the following advantages:

1. It is essentially a tank and is, so, less expensive than a closed heater

(which is a tube and shell heat exchanger).~

2. The heat transfer is excellent since the steam and feed water are mixed

directly.

However, it is impossible to increase the exit feed water temperature above

the saturation temperature of the extraction steam. In a closed heater which is

properly designed, the feed water exit temperature may exceed the saturation

temperature of the extraction steam, if this steam is superheated. Each open

heater must be accompanied by a feed water pump. Every regenerative cycle

incorporates at least one open heater that operates at a pressure slightly higher

than the atmospheric pressure. This heater (called the deaerating heater) is used

to remove any dissolved gases, particularly O, from the water before it is fed to

boiler.

64.3, Regenerative Cycle Efficiency

For calculating the efficiency of the regenerative cycle, the following

assumptions are made:

1. Bled steam is condensed and cooled to the temperature of the entering

feed water at the stage considered. And the feed water is heated to the

saturation temperature at the pressure of the bled steam.

2. The bled steam just condenses i. gives up its superheat if any and all its

latent heat only, The condensed steam leaves the heater at the saturation

temperature corresponding to the bleeding pressure.

The first assumption will be considered while calculating the efficiency of

the cycle. Two cases will be considered, closed heater and open heater.

Case 1. Bled Steam does not Mix with Feed Water (Closed Heater)

The flow diagram for this case is shown in Fig. 6.15

Let Js, and Ja, represent conditions of boiler steam

Is, and Jay, represent conditions of steam exhausted to hot well

_, Sy ty} represent conditions of steam at the points

fo 15) a, b and c at which bleeding occurs.

Sy ty)

‘Scanned wih CemScanner

160 // Power Plant Engineering |

Boiler

1

ae

Isa) tha aay

H

Tot tem,-m,-mg|

(Condenser

Feed Water

eee

Fig. 6.15. Flo

Consider the bleeding at point a. Let

feed water heated. Then

Heat lost by steam

or my(I8 - 10)

.e total heat o!

sv diagram for closed heaters

be the mass of bled steam peri

e

at gained by feed water

= (o, - 103)

f the feed water

where [ig is thi coming from the previous bleeds,

5 ,

stage at &.

Jo, los

™ = Tey Tos ad

ext consider the bleeding at point b where the mass of bled steam is m,pe

ig of feed water heated. Then

~ log) = (103 ~ 10) |

ingly ~ 104) + m4 (203

vp, = liga toademutles Fa)

ce (Is3 — a4)

+ the bleeding at point c where the amoun

ig per kg of the feed water heated. Then

iy (Isg~ Hg) + (+ M) (lag ~ Tos) = (IO Ios)

(ong —Tog)~ (0m +g (log — los)

a (i54=T0s)

Now total workdone = work done between entrance

and a + workdone between a and b + workdone betwee!

+ workdone between c and exhaust

Similarly consider tof bled stexx

is ms

nb and ¢

= (Is, ~ Is) + (=m) (Is, ~ 155)

+ (l= my ~ my) (15, ~ Is) + (E= my = my =m) S- ¥

Total heat supplied per kg of feed water = Is, ~ lo,

_ Total workdone

Efficiency =

Total heat supplied

Case 2. Bled Stem Mixes with Feed Water. (Open Heater) *

the mixt™

In this case, the bled steam is allowed to mix with the feed water;

then proceeds direct to the boiler. The flow diagram is shown in Fig: 6.16

‘Scanned with CamScanner

Heat Cycles // 161

Pump(J) [Condenser]

Fig. 6.16. Flow diagram for open heaters.

As in the previous case, consider the bleeding at point a

Imy(Isp ~ Tog) = ({~ m,) (loz ~ Io,)

Consider the bleeding at point b. Then

mr{ls lo) = (I = my ~ my) (Img - Toy)

Consider the bleeding at point c. Then

ms (Isq ~ Tong) = (I — my ~ my ~ mg) (Img - Tog)

From the above equations, the weights of bled steam my. m, and m; can be

‘ound out. Then the total workdone, heat supplied and hence the efficiency can

be calculated as in the previous case.

85. REHEAT REGENERATIVE CYCLE

Modifications of the basic vapour cycle have occasionally been used in the interest

Sreater economy of operation. We know that for cycles with a throttle pressure

‘s than about 8.5 N/mm2, reheat is not applied. However, for pressures higher

4 this value, reheat would be employed and invariably combined with a

"generative cycle as shown in Fig. 6.17.

Reheater

LP

Turbine

Generator

[Condenser

Fig. 6.17. Combined reheat and regenerative cycle.

‘Scanned wih ComScanner

162 // Power Plant Engineering

6.6. BINARY VAPOUR CYCLE .

We know that the maximum possible efficiency of any engine is given by

equation, Ly

Roh

qT,

Since T, is fixed by atmospheric conditions, the cern! efficiency of

plant can only be improved by increasing 7,. In a steam plant an increase g

tay entail the use of a corresponding high pressure, which is one of the limig,!

factors in its design. By using mercury vapour in place of steam in the wg

temperature range of the cycle an increase in T, is obtained without any ing

in maximum pressure. A power plant using two vapours in this way is

as a binary vapour plant, The mercury-steam is the only binary vapour oy,

operated on a commercial scale at the present time. Mercury has many advantay,

as a vapour cycle fluid. Its vapour pressure is low at high temperatures, big

9.6 bar gauge at 524°C and 20.6 bar gauge at 593°C. A mercury boiler can.

therefore, by easily constructed and its operation will be less troublesome, Since

mercury is element, it is stable at temperatures well above the limit imposed

materials now available. The liquid has high density, a desirable property ig

securing separation of vapour from liquid in the boiler in feeding liquid back

the boiler under hydrostatic rather than ‘pumping head. It has low specific

enthalpy which results in moderate jet velocities in the turbine, enabling simple

turbines of few stages to be used. The chief objection to the mercury vapour

plant is the danger due to its poisonous fumes if any leakage of mercury vapour

occurs, Cost of the mercury is high. Liquid mercury does not wet the surface of

the container. There is a tendency for a film of mercury vapour to form at the

tube surface which prevents a good heat transfer to the liquid. However this

difficulty can be overcome by using a 0.002 per cent solution of magnesium and

titanium in the boiler as a surface wetting agent. Moreover mercury can seep

through joints or cracks that would be impervious to water or steam. The other

fluids which can be used with water are diphenyl, diphenyl oxide, aluminiun

bromide and zinc aluminium chloride.

The binary vapour plants are not so attractive now as they were a few yea

ago due to the improvements of the last few years in the steam cycle by thet

of high temperatures and pressures and the use of reheat cycle.

The binary vapour cycle is shown in Fig. 6.18.

STEAM

Boiler

[Condenser

[Conaenser]

Condensate:

Circulating

Pump)

Fig. 6.18. Binary vapour cycle.

‘Scanned with CemScanner

Heat Cycies // 109

‘The mercury vapours from the mercury

ile are expanded in the mercury vapour

bovine and are then condensed in the

repvdenser boiler. ;

In the condenser boiler the mercury

vapours give their heat to the condensed

wp from the steam turbine. The steam is

seivfed tothe steam turbine, The condensed

thet any vapours from the condenser boiler

fe again circulated to the mercury boiler — ain aaa

with the help of mercury circulating pump. is, 619.1 nary enpour cy

The binary vapour cycle on T - $ ‘gram.

diagram is shown in Fig. 6.19.

The mercury cycle is represented by abcd. The lines ab and bc represent the

heating and evaporation of liquid mercury. At c the mercury is expanded

adiabatically through a mercury vapour turbine to d. From d it is condensed to

4, its latent heat being utilised for evaporating a corresponding amount of steam.

The steam cycle is represented by gadef. ga represents the heating of the feed

water, adits evaporation by the condensing mercury, and de the superheating of

the steam by the flue gases. Ate the steam is expanded adiabatically through a

steam turbine to f; fg represents the condensing of the exhaust steam in the

condenser. This completes the steam cycle. To obtain the correct amount of heat

from the condensing mercury for evaporating the steam it is found that 8.196 kg

of mercury are required per kg of steam.

67, TOPPING CYCLE

The purpose of this cycle is to improve the heat :ato ef the exis!

arrangement, back pressure turbine is used ss hic i swon-condes

‘o another turbine Operating at a lower pressure ‘ie ba

4 topping or superimposed turbine. ‘Ihe exhaust ste

Hurbine flows to some or all of the previously inst

This arrangeme

“conomics of hi

In this

‘yy end exhaust

© unit is called

«: superimposed

alled low pressure turbines,

‘nt increases the capacity of a given plant and makes possible the

igh pressure operation. Topping cycle is shown in Fig, 6.20.

Reduction

‘Super —— Gear

HP

a

Tae serrate | |

Boiler q |

pl

HP. Feed Pump—

|

_| [Condenser]

LP.

[Her T Condensate

Hl Pump

HP. Heater

LP. Feed Pump

Fig, 6.20. Topping eycte

‘Scanned wih CamScanner

164 // Power Plant Engineering

ON

™ SOLVED EXAMPLES =

Example 6.1. Determine the thermal efficiency of the basic cycle of a ste,

power plant (Rankine cycle), the specific and hourly steam consumption ;.

a 50 MW steam turbine operating at inlet conditions: pressure 90 bar al

temperature 500°C. The condenser pressure 1S 0.040 bar.

Solution: From Mollier diagram,

Is, = 3386.24 KJ/kg and Jo,

From steam tables, la, = 121.42 KJ/kg

= 2006.2 kJ/kg,

Is,- Isp

(a) Thermal Efficiency = Ts, Toy,

_ 3386.24-2006.2 _ yy 704

3386.24 121.42

() Specific steam consumption is the amount of steam in kg per kW—h,

Now 1 kW—hr = 3600 kJ

-Specific steam consumption = 7

. 3600

© 3386.24 ~ 2006.2

(c) Hourly steam consumption = 2.61 x kilowatts

= 2.61 x 50,000 = 1.305 tonnes/hr.

= 2.61 kg/kW-hr

Example 6.2. In a simple Rankine cycle, the maximum temperature and pressure

are 540°C and 7.0 MPa respectively, and the minimum pressure is 10 kPa.

‘Asume the turbine and pump efficiency both as 85%, determine (a) Thermal

efficiency, (b) Specific work, (c) Work Ratio.

Solution: Refer Fig. 6.2. From Mollier Chart,

1, (at 7 MPa and 540°C = 3506.9 kJ/kg.

Ip (at 10 kPa) = 2389.2 kJ/kg

2lgg = Ig = 191.8 KJ (from Steam tables)

Now Tog = los + 25(P4 ~ P2)/My

Now V3 = specific volume

= 0.0010102 m3/kg (from steam tables)

Py = 7MPa ; py = 10 kPa; n, = 0.85

Joy = 191.8 + 8.3 = 200.1 kj/kg

Wp = Pump work = Ia, ~ Io, = 8.3 kJ/kg

Lai = tea) Wo

° (Tan) = Wp

_ 3506.9 ~ 2389.2 - 8,3

~ "35069 - 1918-83 = 33.55%

‘Scanned wih CemScanner

Heat Cycles // 165

(Net specific work = Wy - Wp

(I, ~ Ig) ~ Wp = 1109.4 kJ/kg.

2)

gxample 6.3. Steam at a pressure of 13.73 bar abs, and temperature of 250°C

js expanded through a turbine to a pressure of 4.12 bar abs, it is then reheated

;ta constant pressure to a temperature of 200°C and then it completes its

expansion through the turbine to an exhaust pressure of 0.206 bar abs. Calculate

the ideal efficiency of the plant and workdone (a) taking the reheating into

account (0) if the steam is expanded direct to the exhaust pressure without

reheating.

Solution: Draw the expansion and reheating processes on the Mollier diagram

as shown in Fig. 6.5. From the Mollier diagram,

Is, = 2930.9 kJ Is, = 2679.7 kj

sq = 2369.8 KJ

Is, = 2235.86 KJ Jo, = log = 255.4 ky

1. Taking Reheating into Account

Workdone = (I5y — Is) + (Is5~ Is.)

(2930.9 — 2679.7) + (2861.8 - 2369.8)

[5 - lw,) + (Is5 ~ 153)

(2930.9 - 255.4) + (2861.8 - 2679.7)

= 26755 + 182.1

= 2857.6 kJ/kg

WD. 743.2

Weal efficiency = Fezesupplied = 285767

Heat supplied

26%

2. Without Reheating

WD. = (Is, - 15s)

= (2930.9 - 2235.86) = 695 kJ/kg

Heat supplied = (Is, - Jos)

= 2930.9 - 255.4 = 2675.5 kJ/kg

Ideal efficiency = = 25.9%

695

t 26755

Exar

singe Ee: Determine the improvement of efficiency which would result if

‘erming oe Of regenerative feed heating were added to a steam cycle having

The re Conditions of 13.73 bar (abs), 93.5°C superheat, and 0.0686 bar (abs).

Solaen™ £0" feed heating is to be extracted at 1.72 bar (abs)

ot Saturation temperature of steam at 13,73 bar (abs.

steam tables = 194.3°C

Temperature of steam = 194.3 + 93.5 = 287.8°C

“Fig. 6.21,

‘Scanned wih CamScanner

166 // Power Plant Engineering

Q

=—=F

Fig. 6.21.

. ansion of steam to be isentropic, the total heat of Steam »

frets ponte 25 (entry, bleeding and exhaust), are from Is—4 chart,

Is, = 3014.64 kJ/kg

Isy = 2604.3 kJ/kg

Is, = 2147.93 kJ/kg,

Writing the heat balance for the feed water heater,

Heat entering = Heat leaving

Now heat of water at exhaust = 161.7 kJ/kg] From Steam

and heat of water at point 2 = 484.6 kJ/kg] Tables

Making the usual assumptions

mi x 2604.3 + (1 = m) x 161.7 = 484.6 x m + (1 — m) x 484.6

From here, m =0.131 kg

Workdone = 1 x (3014.64 ~ 2604.3) + (1 - 0.132) x (2604.3 - 214793

10.34 + 396.13 = 806.47 kJ/kg

Heat supplied = 3014.64 - 484.6 = 2530 kJ/kg

AT

Thermal efficiency = 2 = 31.88%

Without feed water heating, thermal efficiency

= 3014.64-214793 _ 886.71

3014.64-161.7 ~ 2852.94

31.88 - 30.38

30.38

operating with one regenerative feed Wat!

‘onditions of 35.0 bar and 440°C with exha

led from the turbine for feed water heatité

= 30.38%

* Improvement in efficiency =

= 4.94%

Example 6.5. A steam power plant,

heating is run at the initial steam c

Pressure of 0.040 bar. Steam is bl

at a pressure of 1.226 bar. Determine:

1. Specific steam consumption |

2. Thermal efficiency of the cycle.

3. Econom: . in

power plants 8° Compared with the cycle of a simple condens"é

‘Scanned wih CamScanner

Heat Cycles // 167

solution: From Is ~ § diagram and steam tables, Refer to Fig. 6.21.

Is, = 3314.0 kJ/kg Is, = 2560 kJ/kg

2100 Wi/kg Ing = 439.43 kJ/kg

Io, = 121.42 KJ/kg

From the heat balance for the feed water heater,

m (Isy ~ I) = (1 - m) (lo, - Ja3)

«+. m (2560 ~ 439.43) = (1 ~ m) (439.43 - 121.42)

From here, nt = 0.1304 kg

Total workdone 1 x (Is, ~ Is,) + (I - m) (Is, - Is)

= (3314 - 2460) + (1 - 0.1304) (2560 - 2100)

= 754 + 400 = 1154.0 KI/kg

1. Specific steam consumption = = = 3.12 kg/kW-hr

2. Thermal efficiency = ——!1°4 _- 40.15%

3314 - 439.43

3. Without regeneration feed water heating, the workdone will be

Is, - Is, = 3314.0 - 2100.0 = 1214 kJ/kg

Steam consumption = =~ = 2.94 kg/kW hr

Without regeneration heating, the thermal efficiency

n _ inks

5, -Io3

1

Now from steam tables

Tog = 121.42 kJ/kg

in _ 3314-2100

~ 3314-12142

-. Increase in thermal efficiency due to regeneration feed water heating is

_ 04015-0:38 _ 5 59,

0.4015

Example 6.6. A steam power plant operates with two regenerative feed water

the 18 Points, with closed heaters. The bled steam, condensed to water in

beatae Pressure heater, is drained into the steam space of the low-pressure

conden he combined condensate from the two heaters is then drained to the

ser, see Fig, 6.22, The following data is given:

Total heat in ki/kg,

Steam entering turbine = 3228.64

Steam entering h.p. heater = 2830.87

Steam entering Jp. heater = 2598.24

Steam entering condenser = 2319.18

= 0.38

‘Scanned wih CemScanner

168 // Power Plant Engineering

Temperature, °C

Feed water entering Lp. heater =

7.8

Feed water entering /.p. heater = 75

Feed water leaving fp. heater = 122.8

Drain water leaving /.p. heater = 78.3

= 126.7

Drain water leaving Ip. heater

2319.18

3228.64

2830.87} m,

122.8°C

mommy

Fig. 6.22.

If the mass of feed water flowing through the heaters is equal to the mass

of steam entering the turbine each being 136,00 kg per hr find:

(1) the amount of steam passing into each heater,

(2) the power developed by the turbine,

(3) the thermal efficiency of the process.

Solution : Heat balance for /.p. heater,

2830.87m, + 75 x 4.187 = 126.7 x 4.187m, + 122.8 x 4.187

: m, = 0.087 kg/kg of feed

Heat balance for l.p heater,

2598,24m, + 27.8 x 4.187 = 78.3 x 4.187 (m, + m,) + 75 x 4.187

From here, m, = 0.0793 kg/kg of feed

(1) Amount of steam through itp. heater,

tity = 0.087 x 13600 = 1183.20 kg/hr

‘Amount of steam through Lp. heater,

.0793 x 13600 = 1078.48 kg/hr

x (3228.64 - 2830.87) + (1 - 0.087)

(2830.87 ~ 2598.24) + (1 - 087 - 0.0793)

(2598.24 - 2319.18)

= 842.84 KJ/kg

s. Power = £42.84%13600

3600

my

(2) Total workdone

= 3184 kW

‘Scanned with CemScanner

Heat Cycles // 169

84

6) Thermal "= S7agi-imexaiey ~°1”

sample 67. A steam turbine plant employs two regenerative feed water

Baie. The steam is supplied to turbine at a pressure of 24.03 bar and 80°C

heatperheat. The condenser pressure is 0.0824 bar and the expansion in the

or ibe is isentropic. The other conditions are shown in the Fig. 6.23.

Determine:

1. the amounts of steam bled at the two bleeding points of turbine.

2 the thermal efficiency of the plant.

Solution: From Is - > chart,

Is, = 3014.64 kJ/kg

Isy = 2810 kJ/kg

Isq, = 2430.76 kJ/kg

Is, = 2089.94 kJ/kg

For high pressure heater,

m, x 2810 + 95 x 4.187 = m, x 4.187 x 100 + 165 x 4.187

From here

m, = 0.1225 kg

For low pressure heater,

m, x 2430.76 +h =m, x 100 x 4.187 + 95 x 4.187 (1)

For hot well

35 x 4.187 (1 - 0.1225 -m,) + 100 x 4.187 (0.1225 + m2) =1xh (2)

From (1) and (2)

0.0954 kg

hh = 205.79 kJ/kg, and mt,

8

5

0.0824 bar

™ Hot Well

Fig. 6.23.

Totalwork done =1 x (3014.64 ~ 2810) + (1 — 0.1225) (2810 - 243076)

ae eer (= 0.1225 ~ 0.0954) (2430.76 - 2089.94)

= 803.9 kJ/kg

‘Scanned with CamScanner

170 // Power Plant Engineering

803.9

____ 2 __"._ = 34.6%

Thermal, = 3014,64- 165 4.187

4 with steam at 27.46 bar and 120° C sy

the pressure and the amount ofa

ion the turbine. Ifthe thermal effcien™

, respectively, compare the therm.

hat of a simple turbine having yy

e

Example 6.8. A turbine is supplied w

and exhausts at 0.0343 bar. Determin®

to be bled from the three tapping Poin's

of the expansions is 70, 75, 80 and 85 ae

efficiency of the regenerative turbine witl

same expansion

fficiencies.

Fig. 6.24.

Solution: In practice, the tapping points are selected so that each heater transfers

about the same amount of heat to the feed water.

Now saturation temperature of steam at 27.46 bar

and saturation temperature of steam at 0.0343 ba

<. Temperature difference = 202.9°C

This temperature difference is to be divided equally over four stages of

expansion. Hence the temperature drop during each stage is about 50°C.

Therefore, temperatures at heaters I, IL and III will be respectively 450°C, 400°C

and 350°C. From steam tables, the corresponding pressures will be, 9.27 bar, 240

bar and 0.412 bar.

‘The expansion of steam is shown in the Fig. 6.24. The dotted line shows the

actual expansion line.

Without Regeneration

From Is ~ @ chart,

Is, = 3127.69 KJ/kg,

Isy (at 9.27 bar) = 2863.91 kJ/kg,

Heat drop (Isentropic) in expansion number I

= 3127.69 - 2863.91 = 263.78 kJ/kg.

Actual heat drop = 263.78 x 0.7 = 184.65 kJ/kg

Isy, = 3127.69 ~ 184.65

= 2943.04 kJ/kg

sy (at 2.40 bar) = 2683.87 kj/kg

‘Scanned wih CamScanner

Heat Cycles // 171

». Isentropic, heat drop in expansion number 2

= 2943.04 ~ 2683.87 = 259.17 kJ/kg

Actual heat drop = 0.75 x 259,17 194.38 kJ/kg

Isy = 2943.04 - 194.38 = 2748.66 kJ/kg

Is, (at 0.412 bar) = 2461.96 kJ/kg

.. Isentropic heat drop in expansion 3

= 2748.66 ~ 2461.96 = 286.70 kJ/kg

Actual heat drop = 0.8 x 286.7 = 229.36 KJ/kg

sy! = 2748.66 ~ 229.436 = 2519.3 kJ/kg

Iss (at 0.0343 bar) = 2202.36 KJ/kg

+: Isentropic heat drop in last expansion

~ = 2519.3 ~ 2202.36 = 316.94 kJ/kg

Actual heat drop = 0.85 x 316.94 = 269.4 kJ/kg

Total useful heat drop = 184.65 + 194.38 + 229.36 + 269.4

= 8778 KJ/kg

Now Tos = 110.24 K)

8

77.8

7 —————— = 29%

Thermal n = S97 69-1024

With Regeneration

Heater I, m, (Is, - Io,) = Io, - lo,

itv, (at 9.27 bar) = 749.05 kJ/kg

25.9 Kj /kg

) = Actual value, Is,

= 2943.04 kJ/kg

749.05 - 525.9 5

2943.04-74905 2194

Heater Il, m, (Is3 - las) = (lo; - lo,)

Now lo, (at 0.412 bar) = 320.72 kJ/kg

525.4-320.72 _ 204.68

2748.66-525.4 2223.26

Heater Il, mls, — o,) = (lo, - h) (1)

For hot well, m, lo, + mo + my lo, + (I~ Mh ~ my ~ my) log = (2)

Now Tos (at 0.0343 bar) = 110.12 kJ/kg,

9954 P#0™ (2), 0.102 x 749.05,+ 0.0923 x 110.12 + my x 320.72 + (I~ 0.102 ~

10923 ~ ms) x 110.12 =

- N= 7641 + 48.53 + 320.72 my + 88.72 - 110.12;

= 213.66 + 210.6 my

* Prom (1), my (2519.3 - 320.72)

= (320.72 ~ 213.66 - 210.6 m)

mm, = 0.0444 kg

0.102 kg

= 0.0923 kg

‘Scanned wih CamScanner

172 // Power Plant Engineering

x 184.65 + (1 - 0.102) x 194.38

4 (1 — 0.102 - 0.0923) x 229.36 +

(1 ~ 0.102 ~ 0.0923 - 0.0444)

D % 2654

Total work done

= 748.55 kJ/kg

_ —78855_ _ _748.55__

Thermal 1 = 3797.69-10, _ 3127.69-749.05

748.55

31.47%

3147-29

% gain due to generation = —55—— = 8.5%

9 A steam turbine is supplied with steam at 20.6 bar and 3990,

(0 4.04 bar, it is reheated to 315.5°C and the

i

Example 6.

rmine the thermal efficiency a

After the steam has expanded t

expands down to a pressure of 0.065 bar. Dete:

the cycle and the mass of steam required per kW-hr. The efficiency of eag,

expansion may be take as 75%.

Solution : The complete cycle is shown in Fig. 6.25. The dotted lines show thy

actual expansion. From Is ~ 6 chart,

Is, = 324.925 kJ/kg Is, = 2840 kJ/kg

Jil < 975

15, — pq

Is, = Is, = 324.925 ~ (3244.925 ~ 2840) x 0.75

. = 2941.23 kJ/kg

3 - 4 is the reheating process. Again, from Is —} chart,

Is, = 3100.68 kJ/kg,

B5gq = 2349.33 kJ/kg,

Now

Ise-I55 _ 75

Again,

Bay sg = TSq

Fig. 6.25

Is = Is = 3100.68 ~ (3100.68 x 2349.33) x 0.75

= 2537.11 kJ/kg

Total workdone = (Is, ~ Is,) + (Is4- Is3)

(3244.925 - 2941.23)

+ (100.68 - 2587:

‘Scanned wih CamScanner

—— te

Total workdone = 316.22 + 563.57 = 879.8 kJ/kg

Total heat supplied = (Is, - 1o,) + (Is, ~ Is)

From steam tables, It, (at 0.065 bar) = 157.72 kJ/kg

‘1 Total heat supplied = (3244.925 157.72) + (3100.68 - 2941.23)

= 3087.2 + 159.45 = 3246.65 kJ/kg

879.8

Thermal y = ~~" = 26.

: 3246.65, sel

The specific steam consumption

3600

= 9708 * 4,092 kp/kW-hr

Example 6.10. Steam is admitted to a steam turbine at 27.46 bar and 315°C and

expands adiabatically without friction to 5,492 bar. The steam is then reheated

at constant pressure to 260°C and then throttled to 2.746 bar before admission

to Lp turbine where it expands down to 0,06865 bar with an overall efficiency

of 78% Determine:

1. the heat supplied in the reheater.

2. Power of the [.p turbine for a steam

Solution: The complete process is shown in Fi

flow of 1100 kg per hour.

ig. 6.26.

Fig. 6.26.

Line 1 — 2 is the expansion in lip. turbine.

Line 2 — 3 is the reheat process.

Line 3 — 4 is the throttling operation (Total heat remains constant)

Line 4 — 5a is the adiabatic expansion in Lp. turbine.

ai 4 — 6 is the actual expansion in Ip turbine.

tom Is — } diagram,

; Is, = 3087.67 KJ/kg Is = 26935 w/e

Igy = ly = 297947 K/kg 5, = 2389 W/kg

Now Js=h5 _o78

154 —lgg

47 ~ 2349.33) * 0-78

Iss F

sg = 2979.47 - (2979

= 2487.92 kJ/kg

‘Scanned wih CemScanner

174 // Power Plant Engineering

in the reheater = (Is3 ~ 15;)

= 2979.47 ~ 2693.5 = 286 J/kg

2. in Lp. turbine = 15 - 156

aan as “ 2979.47 * 2487.92 = 491.55 KI/kg

1, Heat suppl

491.55x1100 _ 150.2 KW

= A91.55xUO" =

Power 3600

Example 6.11. In a steam power plant of capacity 110 MW, the steam at 98)

bar and 400°C is supplied to the steam Pee

turbine. After the steam has expanded to

19.61 bar, it is taken out of the turbine and

taken to a reheater where it is heated to

50°C and then expanded down to

condenser pressure of 0.049 bar. The

pressure loss in reheater is 0.981 bar.

Determine the amount of steam flowing

through the system per hour. Take

mechanical efficiency of turbine as 95%,

the generator efficiency as 98%, and the

adiabatic efficiency as 85% for each Fig. 6.27.

expansion.

Solution: From Is — @ diagram, Fig. 6.27

098.38 KI/kg Isp, = 2734-11 kJ/kg,

Is.

Is = 3140.25 kJ/kg. I5yq = 2127 KI/kg

Now, Si = 0.85

Is, — [53g

3098.38-I5,_ _ g gs

3098.38 — 2734.11

Is, = 2788.75 kJ/kg,

Isy Is

i = 0.85

Again Tey Baa

3140.25- sy _ 9 gs

3140.25-2127

. Is, = 2279 kJ/kg,

Now total workdone = (Is, ~ Is) + (Is - Is,)

(3098.38 ~ 2788.75) + (3140.25 - 2279)

= 309.63 + 861.25 = 1170.55 kJ/hg

Now 1 kW hr = 3600 kj

Fs 1 KW = 3600 kJ/hr

If m is mass of steam per hour, then,

Net output = 1170.55 x m x 0,95 x 0.98 kJ/hr

+. 1170.55 x m x 0.95 x 0.98 = 110 x 1000 x 3600

m = 363.35 tonnes/hr

‘Scanned wih CemScanner

Heat Cycles // 175

Example 6.12. A steam turbine is supplied with steam at 20.6 bar and 95°C of

super heat and expands to 0.0343 bar. Steam is bled off 4.9, 1.373 and 0.275 bar,

the bled steam being cascaded from heater to heater until it discharges through

a drain cooler to the condenser. Assuming that the turbine expansion is

isentropic and the drain cooler raises the combined heater condensate to

condenser temperature, find:

(a) total amount of bled steam per kg of feed.

(b) the gain in efficiency over the corresponding Rankine cycle.

(o) the steam cosumption per kW hr with and without feed heating.

(@ the amount of heat carried away by the condenser cooling water per

kW-hr with and without feed heating.

Solution: From the Mollier diagram and steam tables, Fig. 6.28.

Is, = 3046 KJ/kg

Is, = 2734. 11 KJ/kg

Is, = 2516.39 kJ/kg

Is, = 2286 KI/kg,

Iss = 2032.8 kJ/kg

Tw, = 633.5 kJ/kg

To, = 455.96 kJ/kg

To, = 280.95 kJ/kg

Ios = 110.54 kJ/kg

(a) For heater 1, Heat lost by steam = Heat gained by water

m, (Is, - Ia) = Io, - Io,

“1m(2734.11 - 633.5) = 633.5 - 455.96

17.54

= > = 0.0845 k

™s = Fron = 0.9845 ke

For heater, 2 Heat in = Heat out

Sy x Is, + mh, x Io, + Io, = og + (my + mp) Ios

+ My x 2516.39 + 0.0845 x 633.5 + 280.95 = 455.96 + (0.0845 + m,) x 455.96

Fig. 6.28.

‘Scanned wih CemScanner

176 // Power Plant Engineer

< From here my = 0.0776 kg

For heater 3, Heat in = Heat out

Img x 154 + (mt, + m,) Tog +H = Tog + (im + my + My) Hey

-. 2286 my + (0.0845 + 0.0776) x 455.96 + h

= 280.95 + (0.0845 + 0.0776 + ms) x 280.95

<. 2286 m, + 0.1621 x 455.96 +h = 280.95 + (0.1621 + ms) x 280.95

2005 my +h = 252.58

To find h consider the drain cooler.

Heat in = Heat out

) og = + (my + a + Ma) Ts

= ht + (0.0845 + 0.0776 + mis) x 11054

h + (0.1621 + mg) x 110.54

Teng + (0m, +p + my)

110.54 + (0.0845 + 0.776 + m3) Tog

110.54 + (0.1621 + m,) x 280.95 =

= TIOSA + 45.54 + 280.96 m, = b+ 1792 + TOK,

= 138.16 + 170.4m,

Jue of i in the equation for heater 3

Substituting this val

2005, + 138.16 + 170.4m, = 252.58

+». From here, My = 0.0526 kg

Total steam bled =m, + my +

= 0.0845 + 0.076 + 0.0526

= 0.2147 kg per kg of steam

‘The above analysis is based upon the assumption that the bled steam just

condenses ive. gives up its super heat, if any, and all its latent heat only: The

Condensed steam leaves the heater at the saturation temperature corresponding

to the bleeding pressure and the feed water is heated to the saturation temperature

at the pressure of bled steam.

()) WD. = (ls, = 15,) + (1 - my) (Isq ~ 153) + (1 ~ my = mm) (I53 ~ 15)

+ (1 =m, ~ my - ms) (Is4 - I55)

= (3046 ~ 2734.11) + (1 - 0.0845) (2734.11 - 2516.39)

+ (1 ~ 0.0845 - 0.0776) (2516.39 - 2286) + (1 - 0.0845 - 0.0776

— 0.0526) (2286 ~ 2032.8)

= 903.136 kJ/kg of feed.

Heat supplied = (Is, - Io,)

= 3046 - 633.5

= 24125 kJ/kg of feed

Thermal efficiency = ——W-P __ 903.136 _ 55 44,

* “ Heat Supplied ~ 24125 ~~”

oe

1s ~los

_ 3046-2032.8 1013.2

= 34.5%

3046-11054 ~ 2935.46 ~

‘Scanned wih ComScanner

Heat Cycles // 177

(c) With heaters,

3600

903.136

Steam consumption per kW hr = = 3.986 kg

3600

1013.2

= 3.553 kg/KW hr.

(@) Heat carried away by the condenser cooling water per kW-hr

With heaters = (I - m, - my - ms) (Is; - Ios) * 3.986

0.7853 x (2032.8 — 110.54) x 3.986

0.7853 x 1922.26 x 3.986

6017 kj/kW hr

1922.26 x 3.553

6830 kj/kW-hr

Example 6.13. A binary vapour plant uses mercury between a temperature

range of 205°C and 540°C; the mercury being just dry at the higher limit. The

pressure range for the steam is between 936.6 mm vacuum (56°C) and 17.015

bar (204.66°C) and it is superheated to 370°C at its upper limit. The feed water

is raised to 205°C in the economiser and is evaporated to dry steam in the

mercury condenser boiler; it is superheated by the gases. Assuming adiabatic

expansion in the mercury and steam turbines, find

(a) the required amount of mercury per kg of steam used.

(b) the workdone by the mercury.

(c) the workdone by steam.

(d) the ideal efficiency of the plant.

Solution: The following are the required values of the total heat and entropies

of the mercury and steam.

Without heaters =

MERCURY:

Total heats, KUikg

I L Iv ol L/T ov

28.97 300.63 329.52 0.0188 = 0.1487 (0.1675,

754 29058 _-365.53 0.0363_—0.0854 0.1217

205°C

5a

wessure Total heats, Ki/kg Entropy

73.66 cm vac. 11054 2436.83 2547.37 0.0924 (2.0367

870.9 1926.0.2 2796.92 0.8666 1.5284

At

17.015 bar and 370°C 3182.12 1.6961

Solution:

‘ition: Refer to the T - 6 diagram, Fig. 6.29 dryness fraction of mercury at d,

‘Scanned wih CemScanner

178 // Power Plant Engineering

=

9, =

4° G7 %

=

%-%

0.1211 - 0.0188

01675 - 0.0188

= 0.693

(a) Let m,, = Amount of mercury required per

kg of steam

<. Loss of heat of mercury between d and a

= gain of heat by steam between a and d

Fig 6.29,

Iiy, X qc, =, for steam at 17.015 bar

“+ My % 0.693 x 300.63 = 1926.02

im, = 192602

™ ~ 0,693 x 300.63

() Workdone by mercury = m,, » area abed

= thy, ¥ Ul, — fq) ~ Qe - $4) Ta * 4-187]

= 9.24 x [(365.53 ~ 28.97) - (0.1217 - 0.0188) x 478 x 4.187)

= 9.24 x [336.56 — 206] = 9.24 x 130.56

= 1206.37 KJ

= 9.24 kg

() Workdone by steam = area gadej

= (y= Ip) = (b. = 4) Ty * 4.187

= (3182.12 ~ 110.54) ~ (1.6961 — 0.0924) x 299 x 4.187

= 3071.58 ~ 2009.76 = 1061.82 kJ

(d) Total workdone = 1206.37 + 1061.82 = 2268.2 kJ

Heat supplied by fuel = [heat supplied to mercury] + heat to feed water]

+ [heat to superheated steal

= My, (I, ~ I,) + (lo, - Ig) + (Is, - 154)

n)

= 9.24 (365.53 - 28.97) + (870.9 - 110.54) (3182.12 - 279697

+ 9.24 x 336.56 + 760.36 + 385.

= 3109.8 + 760.36 + 385.2 = 4255.37 KJ

_ Total workdone_ __2268.2

Total heat supplied 4255.37

1. Ideal n

‘Scanned wih CamScanner

Heat Cycles // 179

Example 6.14. A steam turbine is supplied with steam at 76 bar and 400°C. It

expands to 25.5 bar where some steam is bled for regenerative feed heating,

The remaining steam expands to 16.67 bar where it passes to a reheater to

enter the turbine again at 16.67 bar and 427°C. The expansion further proceeds

toa condenser pressure of 0.0343 bar. Assuming the expansion of steam to be

isentropic, find the percentage of steam bled under ideal conditions and the

thermal efficiency of the cycle. (Panjab University)

Solution: The problem is on Reheat-Regenerative cycle. The cycle is fully

explained in Fig. 6.30.

From Mollier chart

Is, = 3161.185 kJ/kg Isy = 2934.46 kJ/kg Is, = 2822 KI/kg

Js, = 3316.1 kJ/kg Is5 = 2164.68 kJ/kg

From steam tables

Tog = 110.54 kJ/kg Io, = 966.78 kJ/kg

Heat balance at feed water heater,

mils, + (1 - m) log = milo, + (1 - m) lo,

Here assumption (2) is made (Art. 6.4.3)

m x 2943.46 + (I - m) x 110.54 = 1 x 966.78

From here, —m = 0.3022 kg = 30.22%

___WD.

Heat supplied

= Lx (Is, ~ Isp) + (1—m) (Isp 5) + (L=m (154 ~ 155)

(Isq —Is3) (1—m) + (Is, -J@2)

= )%(8161.185 - 2943.46) + (10.3022) (2943.46 - 2822) + (1 = 0.3022) (3316.1 - 2164.68)

(1-0.3022) (8316.1 — 2822) + (3161.85 - 966.78)

n

= 43.55%

‘Scanned wih CemScanner

= EXERCISES =

1. What is the function of a heat power cycle in a steam power plan?

2. Define the thermal efficiency of the heat cycle.

3. Draw the Rankine vapour cycle on P — Vand T — diagrams, and oy,

4. Derive the expression for thermal efficiency of Rankine cycle.

5. Discuss the various methods of increasing the thermal efficiency of the 4,

Rankine cycle. it

6. Explain the necessity of reheating of steam.

7. Explain the reheat cycle with the help of an

8 Discuss the advantages and limitations of reheat cycle

9. Derive an expression for the thermal efficiency of a reheat cycle,

10. Contrast gas reheating and live steam reheating,

11. What is done in the regenerative cycle?

12. Explain how regenerative feed heating improves the thermal efficiency oy,

simple Rankine cycle?

13. Explain how the number of

14. Contrast the two methods of disposal of the fet

thermal efficiency of a regenerative cycle, using oy,

Phin

eat line diagram

feed water heaters is selected?

ed water heater drains

15. Derive expressions for

heaters and using closed heaters.

16. What has been the necessity of adopting Binary vapour cycle?

17. Explain the topping cycle.

18, Steam at 20.6 bar abs with 100°C of superheat is generated from water at 264

and supplied to a high pressure turbine. The turbine exhausts at 2.746 bar a,

‘and the steam is reheated at this constant pressure until it has 180°C of superhea,

It is then supplied to a low-pressure turbine and expanded to a final pressure,

0.0343 bar abs. Sketch the whole process on T — § diagram, and estimate the

efficiency of the cycle. [Ans. 5334)

19, Steam is supplied to a turbine at a pressure of 58.84 bar abs, and temperature

440°C. It is expanded in a H.P. turbine to 6.865 bar abs the internal efficiency of

the turbine being 0.85. The steam is reheated at constant pressure upto 307°C.

is then expanded to 0.049 bar abs, in L-P. turbine having internal efficiency ¢

0.80. If the mechanical efficiency of the turbine is 98% and the generator efficieny

is 96%, calculate the amount of steam generated by the boiler per kWh output

20. Steam at a pressure of 39.23 bar and 400°C is supplied to a steam turbine ands

exhausted at a pressure of 0.0687 bar. A single bleed is taken between the H?

and LP. cylinder of the turbine at 2.45 bar for regenerative feed heating. Tre

isentropic efficiency for both the cylinders of the turbine is 85%. The temperatut

of the bleed condensate coming out of feed heater is 10°C lower than the

temperature of the bleed steam. Determine

(a) Amount of bleed steam per kg of steam supplied to the steam turbine

(b) The thermal efficiency of the plant.

21. A triple expansion marine engine was supplied with steam at 13.73 bar abs, and

0.97 dry. The back pressure on HP. piston 5.25, on LP. 1.373 and on LP. 024s

The efficiency ratios of the cylinders were found to be: H.P. 0.8, LP. 0.76, LP.0%

Steam for feed heating was bled from the LP. and LP. steam chests, and

‘Scanned wih CemScanner

n

a.

Heat Cycles // 181

heater drains are led to hot well. Estimate the correct amount of steam to be bled

at each tapping point per kg of steam supplied to the engine, the percentage

reduction in the power developed and the percentage increase in thermal

efficiency.

Asteam plant receives steam at 41.2 bar and 400°C. After expansion to 17.16 bar,

it is reheated to 400°C, and then expanded to 6.865 bar. It is then reheated to

400°C, after which it expands down to a back pressure of 0.055 bar. Assuming

frictionless adiabatic expansion, find the thermal efficiency of the plant and

compare that obtained without reheating.

Tw

stages of feed heating are employed in a steam turbine installation, steam

being bled for these at pressures of 3.43 bar and 0.6865 bar respectively. Tne

steam supplied to the turbine is at 17.16 bar with 5°C superheat, and the condenser

pressure is 0.0687 bar. The stage efficiency between 17.16 bar and 3.43 bar is 0.7

and in the other two stages 0.65.

Estimate

(@) amount of steam bled for each heater.

() total workdone per kg of steam supplied to the turbine.

(© the overall thermal efficiency

of the cycle.

Ina binary turbine plant using mercury and steam. The mercury turbine works

between limits of 10.984 bar and 0.206 bar and the steam turbine between 41.2

bar and 0.0687 bar. The mercury vapour is supplied to its turbine in the dry

saturated condition, but the steam is superheated 93°C, its total heat and entropy

being 3127.7 KJ and 1.5785 respectively. Steam is tapped at 4.12 bar and used for

feed heating in an open type heater.

Taking the efficiency ratio of each turbine as 80%, find the quantity of mercury

circulated per kg of steam and the thermal efficiency of the system.

Values for mercury are as below:

Pressure ‘Saturation Total heat of

bar temperature Kg. Entropy of

°c Liquid | Vapour | Liquid Vapour

10.984 527 73.7 364.27 | 0.0358 | 0.1225

0.206 2795 39.57, 33705 | 0.0233 | 0.1521

A turbine is supplied with 29500 kg. of steam per hour and after expanding to

2746 bar abs and 165°C, steam is bled off for feed heating, the drains from the

first heater being cascaded to the second which receives steam at 0.6865 bar abs.

and 0.975 dry. The combined drains from this heater pass to a drain cooler before

being discharged into the condenser at a temperature of 49°C. The draincooler,

ffcond heater and first heater are arranged in series on the feedline, the two

‘eaters have sufficient surface to raise the temperature of the feed to within 5°C

of the

saturation temperature of the bled steam. If the temperature of the

Sondensate is 37°C, obtain the temperature of the feed leaving the drain cooler

and also

‘pping point.

in kg. per hour, the amount of steam which must be bled from each

‘ .2™ Power plant, operating with one regenerative feed water heating is run

Press, initial steam conditions of 350 bar pressure and 440°C temperature. Back

Wan is 0.040 bar. Steam is bled from a turbine stage for regenerative feed

ther eating a a pressure of 1.196 bar Determine the specifi team consumption

mal efficiency of the regenerative cycle and the economy percentage.

°mpared, compared with the cycle of a simple condensing power plant.

gag

‘Scanned wih CemScanner

You might also like

- Rankine and Otto Cycle Problem SolutionsNo ratings yetRankine and Otto Cycle Problem Solutions12 pages

- Lecture 4 Performance Analysis of Diesel Power Plant100% (1)Lecture 4 Performance Analysis of Diesel Power Plant35 pages

- Understanding Vapor Absorption RefrigerationNo ratings yetUnderstanding Vapor Absorption Refrigeration97 pages

- Ch.2.Regenerative Rankine Cycle With Closed Feed Water HeaterNo ratings yetCh.2.Regenerative Rankine Cycle With Closed Feed Water Heater55 pages

- Guidebook in Air Conditioning Design and AnalysisNo ratings yetGuidebook in Air Conditioning Design and Analysis20 pages

- Midterm Exam: Rankine Cycle CalculationsNo ratings yetMidterm Exam: Rankine Cycle Calculations1 page

- Cafeteria Air Conditioning Design ProjectNo ratings yetCafeteria Air Conditioning Design Project23 pages

- Understanding Theoretical Cycles in Engines100% (1)Understanding Theoretical Cycles in Engines56 pages

- Refrigeration Lab Report: Cooling AnalysisNo ratings yetRefrigeration Lab Report: Cooling Analysis25 pages

- Industrial Plant Design: Edsel G. Anyayahan, PMENo ratings yetIndustrial Plant Design: Edsel G. Anyayahan, PME85 pages

- Simple (Ideal) Vapor Compression Refrigeration Cycle ProblemsNo ratings yetSimple (Ideal) Vapor Compression Refrigeration Cycle Problems2 pages

- ME 354 Tutorial, Week#9 Brayton Cycle With Intercooling, Reheat & RegenerationNo ratings yetME 354 Tutorial, Week#9 Brayton Cycle With Intercooling, Reheat & Regeneration7 pages

- ME432 Unit4 Ch2-VAPOUR COMPRESSION REFRIGERATIONNo ratings yetME432 Unit4 Ch2-VAPOUR COMPRESSION REFRIGERATION32 pages

- Pressure Measurement Techniques ExplainedNo ratings yetPressure Measurement Techniques Explained18 pages

- ME 522 - Power Plant Engineering - Steam Power Plant - Part 1 - LectureNo ratings yetME 522 - Power Plant Engineering - Steam Power Plant - Part 1 - Lecture56 pages

- Medium Head Turbine Design CalculationsNo ratings yetMedium Head Turbine Design Calculations31 pages

- Kinematics of Machine Elements Take Home ProblemsNo ratings yetKinematics of Machine Elements Take Home Problems3 pages

- Thermodynamic Cycles (Power Plant Engineering)100% (1)Thermodynamic Cycles (Power Plant Engineering)6 pages

- Steam Power Cycles: Efficiency AnalysisNo ratings yetSteam Power Cycles: Efficiency Analysis32 pages

- 4-Bit Binary to Excess-3 Converter ReportNo ratings yet4-Bit Binary to Excess-3 Converter Report3 pages

- TASK:2: 1.generators and Motors 2.trasnformersNo ratings yetTASK:2: 1.generators and Motors 2.trasnformers24 pages

- Balanced Faults in Power Systems AnalysisNo ratings yetBalanced Faults in Power Systems Analysis31 pages