Professional Documents

Culture Documents

Installsheet - 77 - 629c 01 CH p1 E1 s1

Uploaded by

Mc EswaranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installsheet - 77 - 629c 01 CH p1 E1 s1

Uploaded by

Mc EswaranCopyright:

Available Formats

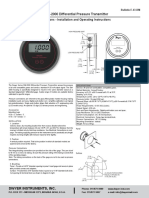

Bulletin P-629C

Series 629C Wet/Wet Differential Pressure Transmitter

®

Specifications - Installation and Operating Instructions

43/64

[17.15]

1-11/32

[34.29]

3-7/64 5-15/16 [150.88]

[78.83] 1/4 NPT FEMALE FITTI

Conduit housing 7 [177.80]

with remote sensor OPTIONAL 1/4 NPT MALE F

43/64

available in

[17.15]

10´ or 20´ shielded

or armored cable

629C-RS 1-11/32 1-27/64

Option [34.29] [35.98]

3-7/64 5-15/16 [150.88] 1-31/32 [50.16]

[78.83] 1/4 NPT FEMALE FITTING OPTIONAL LCD

7 [177.80]

OPTIONAL 1/4 NPT MALE FITTING

The Series 629C Wet/Wet Differential Pressure Transmitter monitors differential SPECIFICATIONS

pressure of compatible gases and liquids with 0.5% accuracy. The design employs Service: Compatible gases and liquids.

dual pressure sensors converting pressure changes into a 4 to 20 mA or voltage output Wetted Materials: Without valve: 316, 316L SS. Additional wetted parts with

signal. Small internal volume and minimal moving parts result in exceptional response valve option: Buna-N, silicone grease, PTFE, brass 360, copper, and reinforced

and reliability. The wiring terminals and zero adjustment button are easily accessed copolymer.

under the removable cover. The Series 629C is designed to meet NEMA 4X (IP66) Accuracy: ±0.5% FS (includes linearity, hysteresis & repeatability).

weatherproof construction. Stability: ±1% FS/year.

Temperature Limits: 0 to 200°F (-18 to 93°C).

Compensated Temperature Limits: 0 to 175°F (-18 to 79°C).

RANGE Pressure Limits: See Table 1.

Range Number Range Working Pressure* Over Pressure Thermal Effects: Avg 0.04%/°F (0.072%/°C) (includes zero and span).

01 0 to 5 psid 10 psi 50 psi Power Requirements: 2-wire: 10 to 35 VDC; 3-wire: 13 to 35 VDC or isolated 16 to

02 0 to 10 psid 20 psi 50 psi 33 VAC (reverse polarity protected).

03 0 to 25 psid 50 psi 120 psi Output Signal: 2-wire: 4 to 20 mA; 3-wire: Field selectable 0 to 5, 1 to 5, 0 to 10, or

04 0 to 50 psid 100 psi 250 psi 2 to 10 VDC.

05 0 to 100 psid 200 psi 500 psi Zero and Units: Push buttons inside conduit enclosure.

06 0 to 150 psid 300 psi 750 psi Response Time: 400 msec.

07 0 to 200 psid 400 psi 1000 psi Loop Resistance: Current output: 0 to 1250 Ω (max), Rmax = 50(Vps-10); Voltage

08 0 to 300 psid 600 psi 1200 psi output: Minimum load resistance = 5 kΩ.

09 0 to 500 psid 1000 psi 2000 psi Current Consumption: 28 mA (max).

11 0 to 0.5 bar differential 1 bar 3 bar Electrical Connections: Removable terminal block; 1/2˝ female NPT conduit.

12 0 to 1 bar differential 2 bar 8 bar Process Connections: 1/4˝ female or male NPT.

13 0 to 2 bar differential 4 bar 8 bar Display: Optional 4-1/2 digit LCD field attachable display.

14 0 to 4 bar differential 8 bar 18 bar Enclosure Rating: Designed to meet NEMA 4X (IP66) for non-LCD models.

15 0 to 6 bar differential 12 bar 18 bar Mounting Orientation: Not position sensitive.

16 0 to 10 bar differential 20 bar 50 bar Weight: 10.1 oz (286 g).

17 0 to 15 bar differential 30 bar 60 bar Agency Approvals: CE.

18 0 to 20 bar differential 40 bar 80 bar

19 0 to 30 bar differential 60 bar 120 bar

*Pressures exceeding the working pressure limit may cause a calibration shift of up

to ±3% of full scale.

Note: Over pressure of all models with 3-way valve is 100 psi.

Table 1: Pressure Limits

DWYER INSTRUMENTS, INC. Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

MODEL CHART

Example 629C -01 -CH -P1 -E1 -S1 -3V 629C-01-CH-P1-E1-S1-3V

Series 629C Wet/wet differential pressure transmitter

Range 01 0 to 5 psid

02 0 to 10 psid

03 0 to 25 psid

04 0 to 50 psid

05 0 to 100 psid

06 0 to 150 psid

07 0 to 200 psid

08 0 to 300 psid

09 0 to 500 psid

11 0 to 0.5 bar differential

12 0 to 1 bar differential

13 0 to 2 bar differential

14 0 to 4 bar differential

15 0 to 6 bar differential

16 0 to 10 bar differential

17 0 to 15 bar differential

18 0 to 20 bar differential

19 0 to 30 bar differential

Housing CH Conduit housing, NEMA 4X (IP66)

R1 Conduit housing, NEMA 4X (IP66), with remote sensor and 10´ shielded cable

R2 Conduit housing, NEMA 4X (IP66), with remote sensor and 20´ shielded cable

R5 Conduit housing, NEMA 4X (IP66), with remote sensor and 10´ armored cable

R6 Conduit housing, NEMA 4X (IP66), with remote sensor and 20´ armored cable

Process P1 1/4˝ male NPT

Connection P2 1/4˝ female NPT

P3 1/4˝ male BSPT

P4 1/4˝ female BSPT

Electrical E1 Cable gland with 3´ of prewired cable

Connection E2 Cable gland with 6´ of prewired cable

E3 Cable gland with 9´ of prewired cable

E5 1/2˝ female NPT conduit

E9 M-12 4 pin connector (not UL)

Signal Output S1 4 to 20 mA

S3 Field selectable 0 to 5, 1 to 5, 0 to 10, 2 to 10 VDC

Options 3V 3-way valve

AT Aluminum tag

FC Factory calibration certificate

LCD LCD indication

NIST NIST traceable certificate

*Pressures exceeding the working pressure limit may cause a calibration shift of up to ±3% of full scale.

INSTALLATION Optional 3-Way Valve

1. Location: Select a location where the temperature of the unit will be between For applications where higher line pressures may be encountered at installation or

0 and 200°F (-18 to 93°C). Distance from the receiver is limited only by total loop when it is necessary to remove the transmitter for maintenance without interrupting the

resistance (see electrical connections). The tubing feeding pressure to the instrument process, the optional three way valve is recommended. (See Figure 1)

can be practically any length required, but long lengths will increase the response

time slightly. Mount the instrument in a location that will not be subject to excessive

temperature, shock, or vibration. 7-17/64 [184.66]

2-13/32

[60.96]

2. Position: A vertical position is recommended (pressure connections pointing

horizontally) since that is how all standard models are spanned and zeroed at the

factory. They can be used at other angles, but may require final zeroing. Due to

potential condensation buildup that may travel down conduit or cable and into the

housing, it is recommended to install with the electrical conduit or cable gland pointing

downward.

3. Pressure Connection: Dual 1/4˝ NPT pressure connections are provided. Use pipe

thread sealant tape or other suitable pipe joint compound when making connection to 5-19/32

3-63/64 [142.11]

the pressure source. Avoid excess sealant which could block the pressure passage.

[101.02]

When monitoring liquid pressures, air trapped in the lines can cause incorrect readings.

Bleed fittings or similar mechanisms should be used to bleed off any trapped air. 4-17/64

[108.33]

2-25/64

[60.84] 1-37/64

[40.14]

3 [76.19]

Figure 1: 629C with Optional 3-Way Valve

Installation with 3-way valve option. Begin with valve V1 open and valves V2 and Install the high and low remote sensors in respective locations in the process. Use

V3 closed. (See Figure 2) Slowly open valves V2 and V3. Once the pressure has of thread sealant is recommended to prevent leaks. During installation, care must be

stabilized and is equal on the high and low side of the transmitter, valve V1 can be taken to ensure that the serial number on the sensor matches the serial number on

closed and normal operation can proceed. the transmitter housing. Additionally, a check must be made to ensure that the check

box for high or low pressure on the sensor matches the check box for high or low

pressure on the cable tag. The sensor with a mark in the “High Pressure” box should

BLEED FITTING BLEED FITTING be connected to the higher pressure, and the sensor with a mark in the “Low Pressure”

HIGH SIDE LOW SIDE box should be connected to the lower pressure in order to ensure accurate readings.

The vent hole on the side of the unit should not be covered by anything aside from

the fiber filter installed from the factory. Do not remove the fiber filter installed over the

vent hole.

After sensor installation, attach the cable to the sensor by means of the M-12 connector

shown in Figure 4. The cables connecting the sensors to the transmitter housing can

only be disconnected at the sensor by means of the M-12 connectors. No attempt

should be made to disconnect remote cables at the transmitter housing.

TERMINAL 4: (-)

TERMINAL 1: (+) TERMINAL 3:

(GROUND)

Figure 2: Bleed Fitting Connections

To ensure proper pressures will be detected by the 629C, use the bleed fittings

provided with this package to free media of bubbles. Before applying pressure to the Figure 4: M-12 Connector

process connections, turn V1 to the open position and back off either the low or high

side bleed hex nut. Next, apply pressure. After the flowing liquid is free of bubbles, For applications where differential pressure is measured at high line pressure, it is

retighten the bleed hex nut. recommended to install pressure sensor with a valve in each line and a shunt valve

across the high and low pressure ports (see Figure 5).

Before removing the transmitter from operation, open valve V1, then close valves V2

and V3.

629C-RS

Optional Remote Sensor Installation

For both shielded cable and armored cable versions of remote sensors option, follow

standard installation procedures. HIGH LOW

PRESSURE PRESSURE

REMOTE SHUNT SHUNT REMOTE

SENSOR VALVE VALVE SENSOR

CAUTION:

ALWAYS USE WRENCH ON PRESSURE BLOCK

WHEN TIGHTENING FITTING.

PIPE

NEVER PUT STRESS ON HOUSING.

Figure 5: Sensor Installation with Valves

ELECTRICAL CONNECTIONS

Shielded cable is recommended for control loop wiring. Electrical connections to the

Series 629C pressure transmitters are made to the terminal block located inside the

housing. Remove the screws and lift off the cover. Wire as shown in Figure 6 or 7. Use

Figure 6 for current output connection. Use Figure 7 for current output with optional

LCD display. If ordering pre-wired cable, black wire is negative (-) and red wire is

positive (+).

Figure 3: 629C with Remote Sensor VIN +

1

PRESSURE 2 COM - POWER

TRANSMITTER 3 SUPPLY

+ - 10-35 VDC

4

RECEIVER

SHIELD

Figure 6: Current Output Connection

UNIT BUTTON-PRESS TO TOGGLE THE ZERO BUTTON- PRESS AND For voltage outputs, wire as shown in Figure 9 for voltage output connection. Use

UNIT [PSID/BARD] ON THE LCD HOLD TO ZERO THE GAGE Figure 10 for voltage output with optional LCD display. Terminal 1 is positive (+),

LOW [-] HI [+] terminal 2 is negative (-), and terminal 3 is +Vout. If ordering optional prewired cable,

PRESSURE PRESSURE

CONNECTION CONNECTION black wire is negative (-), red wire is positive (+), and white wire is +Vout. For optimal

accuracy, use a separate common wire for the receiver.

POWER

SUPPLY VIN +

10-35 VDC 1

+ Vin [TERM #1] PRESSURE 2 COM - POWER

Com [TERM #2] LCD CONNECTOR TRANSMITTER 3 SUPPLY

VO 13-35 VDC

- - +

4 + - OR 16-33 VAC

RECEIVER SHIELD [TERM #4]

RECEIVER

RED ORANGE SHIELD

BLACK YELLOW

BLUE WHITE

Figure 9: Voltage Output Connection

UNIT BUTTON-PRESS TO TOGGLE THE ZERO BUTTON-PRESS AND

UNIT [PSID/BARD] ON THE LCD HOLD TO ZERO THE GAG

LOW [-] HI [+]

PRESSURE PRESSURE

TRANSMITTER CONNECTION INSTRUCTION: CONNECTION CONNECTION

- TURN OFF POWER SUPPLY.

- CONNECT THE POWER SUPPLY AND RECEIEVER TO Vin [TERM #1] AND Com

[TERM #2] OF THE GAGE AS SHOWN.

- INSTALL THE LCD'S CONNECTOR TO THE GAGE AS SHOWN.

- TURN ON POWER.

+ Vin [TERM #1]

CAUTION: BE SURE TO TURN OFF POWER WHEN CONNECTING OR REMOVING Com [TERM #2]

THE LCD CONNECTOR. FAILURE TO DO SO CAN RESULT IN GAGE DAMAGE. - LCD CONNECTOR

- + Vo [TERM #3] VOLTAGE SELECTION

RECEIVER DIP SWITCH

Figure 7: Current Output with Optional LCD SHILED [TERM #4]

POWER

SUPPLY

13-35 VDC RED ORANGE

Wire Length – The maximum length of wire connecting transmitter and receiver is

OR ISOLATED BLACK YELLOW

a function of wire size and receiver resistance. Wiring should not contribute to more

16-33 VAC BLUE WHITE

than 10% of receiver resistance to total loop resistance. For extremely long runs (over

1000 ft or 305 m), choose receivers with higher resistance to minimize size and cost

of connecting leads. When wiring length is under 100 ft (30.5 m), lead wire as small

as 22 AWG can be used.

Current (4 to 20 mA) Output Operation – An external power supply delivering 10 to

35 VDC with minimum current capability of 40 mA DC (per transmitter) is required to TRANSMITTER CONNECTION INSTRUCTION:

- TURN OFF POWER SUPPLY.

power the control loop. See Figure 9 for connection of the power supply, transmitter, - CONNECT THE POWER SUPPLY [+] TO Vin [TERM #1] AND [-] TO Com [TERM #2] OF

and receiver. The range of the appropriate receiver load resistance (RL) for the DC THE GAGE AS SHOWN.

power supply voltage available is expressed by the formula - CONNECT THE RECEIVER [+] TO Vo [TERM #3] OF THE GAGE AND RECEIVER [-] TO

POWER SUPPLY [-].

vps - 10 - INSTALL THE LCD'S CONNECTOR TO THE GAGE AS SHOWN.

RL max = - SET VOLTAGE SELECTION DIP SWITCH TO DESIRED VOLTAGE OUTPUT.

20 mA DC

- TURN ON POWER.

VOLTAGE (0 TO 5, 1 TO 5, 0 TO 10, OR 2 TO 10 V) OUTPUT OPERATION

CAUTION: BE SURE TO TURN OFF POWER WHEN CONNECTING OR REMOVING THE

To select the voltage output that is going to be used, configure the dip switches LCD CONNECTOR. FAILURE TO DO SO CAN RESULT IN GAGE DAMAGE.

according to the Figure 8 below. Power must be cycled whenever dip switches are

changed to select output. Figure 10: Voltage Output with Optional LCD Display

0 to 5 VDC 1 to 5 VDC

1 2 1 2 MAINTENANCE/REPAIR

Upon final installation of the Series 629C Wet/Wet Differential Pressure Transmitter,

ON ON no routine maintenance is required. The Series 629C is not field serviceable and is not

possible to repair the unit. Field repair should not be attempted and may void warranty.

This symbol indicates waste electrical products should not be disposed

of with household waste. Please recycle where facilities exist. Check with

OFF OFF

your Local Authority or retailer for recycling advice.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sale” in our catalog and on our website. Contact

0 to 10 VDC 2 to 10 VDC customer service to receive a Return Material Authorization number before shipping

the product back for repair. Be sure to include a brief description of the problem plus

1 2 1 2

any additional application notes.

ON ON

OFF OFF

Figure 8: Voltage Output Dip Switch Selection

©Copyright 2019 Dwyer Instruments, Inc. Printed in U.S.A. 2/19 FR# 443277-10 Rev. 6

DWYER INSTRUMENTS, INC. Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

You might also like

- Interface Lab ReportDocument8 pagesInterface Lab ReportSharfuddin ZishanNo ratings yet

- Series 629C Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument4 pagesSeries 629C Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsjguerrerosperuNo ratings yet

- 616wl 14 Manual PDFDocument2 pages616wl 14 Manual PDFcoolguy19895No ratings yet

- Series 647 Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument2 pagesSeries 647 Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating Instructionsindra_onevisionNo ratings yet

- P - 616KD Manual TransmiterDocument2 pagesP - 616KD Manual TransmiterFR PERANo ratings yet

- WWDPDocument1 pageWWDPJose ItzmoyotlNo ratings yet

- Digital Indicating Transmitter: 0.25% Full Scale Accuracy, Optional Switch OutputsDocument1 pageDigital Indicating Transmitter: 0.25% Full Scale Accuracy, Optional Switch Outputsluat1983No ratings yet

- Series DX Differential Pressure Switch: Specifications - Installation and Operating InstructionsDocument2 pagesSeries DX Differential Pressure Switch: Specifications - Installation and Operating InstructionsEdmarNo ratings yet

- Series AVUL Air Velocity Transmitter: Specifications - Installation and Operating InstructionsDocument12 pagesSeries AVUL Air Velocity Transmitter: Specifications - Installation and Operating InstructionsMINH NHHUT LUUNo ratings yet

- Model CMT200 Carbon Monoxide Transmitter: Specifications - Installation and Operating InstructionsDocument4 pagesModel CMT200 Carbon Monoxide Transmitter: Specifications - Installation and Operating Instructionsmanhquyet711No ratings yet

- Conductivity Controller: Single Point or Differential Level Service, Compact Size, Up To 6 Ft. (1.82 M) ProbesDocument1 pageConductivity Controller: Single Point or Differential Level Service, Compact Size, Up To 6 Ft. (1.82 M) ProbesANGEL FLORESNo ratings yet

- Electronic Pressure Controller: 2 Switches, Indicating Gauge, and Transmitter in One PackageDocument1 pageElectronic Pressure Controller: 2 Switches, Indicating Gauge, and Transmitter in One Packageluat1983No ratings yet

- 616 Pressure Transmitter DwyerDocument2 pages616 Pressure Transmitter Dwyerbrodystun66No ratings yet

- Monitor air quality and detect carbon monoxide with CMT200 transmitterDocument1 pageMonitor air quality and detect carbon monoxide with CMT200 transmitterQuyết Nguyễn MạnhNo ratings yet

- 629 - Cat-Chenh AP NuocDocument1 page629 - Cat-Chenh AP NuocMinh Nhut LuuNo ratings yet

- Wet/Wet Differential Pressure Switch: NEMA 4X Enclosure, Low Differential Set PointsDocument1 pageWet/Wet Differential Pressure Switch: NEMA 4X Enclosure, Low Differential Set Pointscarlos perdomoNo ratings yet

- Series 673 Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument1 pageSeries 673 Pressure Transmitter: Specifications - Installation and Operating InstructionsallaadeenNo ratings yet

- DWYER_1630-PRESOSTATO SWITCHDocument2 pagesDWYER_1630-PRESOSTATO SWITCHomorales.cyvsaNo ratings yet

- DOWYER Transmisor Temperatura-HumedadDocument4 pagesDOWYER Transmisor Temperatura-Humedadian_gushepiNo ratings yet

- Din Rail Differential Pressure Transmitter: Mounts On 35 MM DIN Rail, 0.25% Full-Scale AccuracyDocument1 pageDin Rail Differential Pressure Transmitter: Mounts On 35 MM DIN Rail, 0.25% Full-Scale AccuracyMike Alex Herrera DominguezNo ratings yet

- DS RHPRev.7Document2 pagesDS RHPRev.7gerardoNo ratings yet

- Series PFT Paddlewheel Flow Sensor: Specifications - Installation and Operating InstructionsDocument4 pagesSeries PFT Paddlewheel Flow Sensor: Specifications - Installation and Operating InstructionsJoão AlvesNo ratings yet

- DWYER DS 626 628 Rev.6 PDFDocument2 pagesDWYER DS 626 628 Rev.6 PDFmarinaadduciNo ratings yet

- Series 626 & 628 Pressure Transmitters: Specifications - Installation and Operating InstructionsDocument4 pagesSeries 626 & 628 Pressure Transmitters: Specifications - Installation and Operating InstructionsmquaiottiNo ratings yet

- Series 616W Differential Pressure Transmitter Specifications - Installation and Operating InstructionsDocument4 pagesSeries 616W Differential Pressure Transmitter Specifications - Installation and Operating InstructionsErwin Gonzalez MedinaNo ratings yet

- Transmisor Presion Diferencial dm-2007-lcdDocument2 pagesTransmisor Presion Diferencial dm-2007-lcdhanshr87No ratings yet

- CMT200 DatasheetDocument1 pageCMT200 DatasheetleonardobhtNo ratings yet

- Dwyer Tte ManualDocument4 pagesDwyer Tte ManualFatih Al BaridNo ratings yet

- Din Rail Differential Pressure Transmitter: Mounts On 35 MM DIN Rail, 0.25% Full Scale AccuracyDocument1 pageDin Rail Differential Pressure Transmitter: Mounts On 35 MM DIN Rail, 0.25% Full Scale AccuracyNic DziemianNo ratings yet

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument2 pagesSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsJorge Renato Chirinos QuiñonezNo ratings yet

- Dwyer-1910-1-Product OverviewDocument1 pageDwyer-1910-1-Product OverviewRusty AllenNo ratings yet

- 616&616C CatDocument1 page616&616C CatDaniel GomesNo ratings yet

- Wet/Wet Differential Pressure Transmitter: Series 629CDocument2 pagesWet/Wet Differential Pressure Transmitter: Series 629CElmer Ramón Murillo MejiaNo ratings yet

- Series 616Kd - : Differential Pressure Transmitter 0.25, 1 or 2% AccuracyDocument2 pagesSeries 616Kd - : Differential Pressure Transmitter 0.25, 1 or 2% AccuracyOperacao RDBrasilandiaNo ratings yet

- Photo Helic Ps PDFDocument4 pagesPhoto Helic Ps PDFSoumen PaulNo ratings yet

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument2 pagesSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsJuan Carlos Chara VelazcoNo ratings yet

- Inverter R 410a Cooling Only Type 201709142324162961Document4 pagesInverter R 410a Cooling Only Type 201709142324162961Minh Nhut LuuNo ratings yet

- DS 616KDRev.2Document2 pagesDS 616KDRev.2Carlos TorresNo ratings yet

- CDT Duct Mount ManualDocument4 pagesCDT Duct Mount ManualHùng ĐỗNo ratings yet

- Dwyer 626 13 GH P1 E4 S1 User Manual 0 300Document4 pagesDwyer 626 13 GH P1 E4 S1 User Manual 0 300Anonymous QxmwZz4No ratings yet

- Temperature Transmitter Enclosure: Fits Series 651 and 659 TransmittersDocument1 pageTemperature Transmitter Enclosure: Fits Series 651 and 659 TransmittershenryNo ratings yet

- Series 1630 Differential Pressure Switch: Specifications - Installation and Operating InstructionsDocument2 pagesSeries 1630 Differential Pressure Switch: Specifications - Installation and Operating InstructionseeeNo ratings yet

- SCD CatDocument1 pageSCD CatHussainAlkwitiNo ratings yet

- Series 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsDocument4 pagesSeries 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsAlberto Angel Mora ZavalaNo ratings yet

- Aq CDT CDTRDocument4 pagesAq CDT CDTRDon Roseller DumayaNo ratings yet

- Carbon Monoxide/Nitrogen Dioxide Gas TransmittersDocument1 pageCarbon Monoxide/Nitrogen Dioxide Gas TransmittersWali Ahmed KhanNo ratings yet

- Compressed Air Meter: Steady-State and Cumulative Totals PNP/4-20 Ma OutputDocument1 pageCompressed Air Meter: Steady-State and Cumulative Totals PNP/4-20 Ma OutputMohamed HammamNo ratings yet

- H.V.A.C. Differential Pressure Switch: With Dual Scale Field Adjustable Set Point KnobDocument1 pageH.V.A.C. Differential Pressure Switch: With Dual Scale Field Adjustable Set Point KnobIng TéllezNo ratings yet

- DCT500ADCDocument1 pageDCT500ADCPalomino Vergara100% (1)

- Catalog Gp50 311 CryoDocument2 pagesCatalog Gp50 311 CryoMAnhNo ratings yet

- AFS DDocument1 pageAFS DGonzalo AlvarezNo ratings yet

- Manual Dwyer MS-111 Pressure TransmitterDocument4 pagesManual Dwyer MS-111 Pressure TransmitterSunko MachineryNo ratings yet

- 1.3-Manual Tablero de Control Ref DCT1000 para ColectorDocument9 pages1.3-Manual Tablero de Control Ref DCT1000 para ColectorPablo Garzon GalvisNo ratings yet

- Series 626 & 628 Pressure Transmitters: Specifications - Installation and Operating InstructionsDocument2 pagesSeries 626 & 628 Pressure Transmitters: Specifications - Installation and Operating InstructionsMinh Nhut LuuNo ratings yet

- Industrial Pressure Transmitter: 0.13% FS Accuracy, External Adjustments, 4 To 20 Ma OutputDocument3 pagesIndustrial Pressure Transmitter: 0.13% FS Accuracy, External Adjustments, 4 To 20 Ma OutputAsif BhatiNo ratings yet

- Humidity/Temperature Transmitter: Passive Temperature Outputs, Sintered Filter OptionsDocument1 pageHumidity/Temperature Transmitter: Passive Temperature Outputs, Sintered Filter OptionsMinh Nhut LuuNo ratings yet

- Photohelic Pressure Switch/Gages: 3-In-One Indicating Gage, Lo-Limit and Hi-Limit ControlDocument2 pagesPhotohelic Pressure Switch/Gages: 3-In-One Indicating Gage, Lo-Limit and Hi-Limit ControlAnonymous u0wETydFNo ratings yet

- Explosion-Proof Differential Pressure SwitchDocument1 pageExplosion-Proof Differential Pressure SwitchTadau EnergyNo ratings yet

- Magnesense Ii Differential Pressure Transmitter: Series Ms2Document2 pagesMagnesense Ii Differential Pressure Transmitter: Series Ms2SafiaMohamedNo ratings yet

- Lizards - Flow SwitchDocument1 pageLizards - Flow SwitchKiệt TrầnNo ratings yet

- User Manual: Bacnet/Ip Slave / Modbus Slave - Converter Bacnet MS/TP Slave / Modbus Slave - ConverterDocument32 pagesUser Manual: Bacnet/Ip Slave / Modbus Slave - Converter Bacnet MS/TP Slave / Modbus Slave - ConverterMc EswaranNo ratings yet

- Kw-Multiprog DSDocument1 pageKw-Multiprog DSMc EswaranNo ratings yet

- Enhancing Energy Efficiency in MalaysiaDocument35 pagesEnhancing Energy Efficiency in MalaysiaMc Eswaran100% (1)

- XR UPS BrochureDocument2 pagesXR UPS BrochureMc EswaranNo ratings yet

- Installation and User's Guide: System x3200 M3 Types 7327 and 7328Document118 pagesInstallation and User's Guide: System x3200 M3 Types 7327 and 7328Mc EswaranNo ratings yet

- Instructions !!!Document1 pageInstructions !!!Mc EswaranNo ratings yet

- Installation and User's Guide: System x3200 M3 Types 7327 and 7328Document118 pagesInstallation and User's Guide: System x3200 M3 Types 7327 and 7328Mc EswaranNo ratings yet

- Mini ProjectDocument6 pagesMini ProjectMc EswaranNo ratings yet

- Q2) A) Input: Original Salary B) Expected Output: Remaining SalaryDocument2 pagesQ2) A) Input: Original Salary B) Expected Output: Remaining SalaryMc EswaranNo ratings yet

- Nilai Polytechnic, Negeri Sembilan Department of Mechanical EngineeringDocument1 pageNilai Polytechnic, Negeri Sembilan Department of Mechanical EngineeringMc EswaranNo ratings yet

- The Hubbard Energy Transformer by Gaston BurridgeDocument6 pagesThe Hubbard Energy Transformer by Gaston BurridgepboserupNo ratings yet

- LP 30 Self Monitoring Level ProbeDocument2 pagesLP 30 Self Monitoring Level ProbeCardoso MalacaoNo ratings yet

- Ge - Mpact Mpro Acb (400a - 4000a)Document48 pagesGe - Mpact Mpro Acb (400a - 4000a)Sugumaran100% (1)

- Dilan Jayaweera Eds. Smart Power Systems and Renewable Energy System IntegrationDocument207 pagesDilan Jayaweera Eds. Smart Power Systems and Renewable Energy System IntegrationkalokosNo ratings yet

- Partial Discharge Theory and Applications To Electrical SystemsDocument15 pagesPartial Discharge Theory and Applications To Electrical Systemsreza515heiNo ratings yet

- Bandgap ReferencesDocument15 pagesBandgap ReferencesAyaz Masud SezanNo ratings yet

- Computer-Aided Analysis of Linear Circuits Y-Matrix ApproachDocument17 pagesComputer-Aided Analysis of Linear Circuits Y-Matrix ApproachAnuradha ChathurangaNo ratings yet

- Methods For Coordinating System Protective EquipmentDocument17 pagesMethods For Coordinating System Protective EquipmentMichael Parohinog GregasNo ratings yet

- Jimma University: Jimma Institute of Technology (Jit)Document40 pagesJimma University: Jimma Institute of Technology (Jit)Haymanot LegesseNo ratings yet

- T.D.A 1560 PDFDocument16 pagesT.D.A 1560 PDFJose M PeresNo ratings yet

- FanTech FR BrochureDocument2 pagesFanTech FR BrochureUBHappyNo ratings yet

- R6 Hotel Project Electrical, Mechanical and Plumbing Works SpecificationDocument42 pagesR6 Hotel Project Electrical, Mechanical and Plumbing Works SpecificationGabriella EllaNo ratings yet

- 220kV Da Bac - TEL, SER, FR, FL, TN48, INV Panel Drawing - R7Document200 pages220kV Da Bac - TEL, SER, FR, FL, TN48, INV Panel Drawing - R7Văn Ngọc NguyễnNo ratings yet

- Cavity Magnetron OscillatorDocument3 pagesCavity Magnetron OscillatorsuriyaNo ratings yet

- Jennifer Boyce, "Scroop, Luster, and Hand: The Science and Sensuality of Silk"Document45 pagesJennifer Boyce, "Scroop, Luster, and Hand: The Science and Sensuality of Silk"MIT Comparative Media Studies/WritingNo ratings yet

- On-Load Tap-Changer Vacutap® Vv-Ex: Operating InstructionsDocument106 pagesOn-Load Tap-Changer Vacutap® Vv-Ex: Operating InstructionsBijay Kumar SwainNo ratings yet

- 3 Phase R-L LoadDocument2 pages3 Phase R-L LoadSanjay DeegwalNo ratings yet

- 1.5V Double Layer Gans Cell (DLGC) : Alekz SystemDocument10 pages1.5V Double Layer Gans Cell (DLGC) : Alekz Systemhallo1234100% (3)

- AP3064Document13 pagesAP3064José CalzadillaNo ratings yet

- Applications of First Order ODE Word ProblemsDocument36 pagesApplications of First Order ODE Word Problemsgreg hansNo ratings yet

- Cba 2000 enDocument8 pagesCba 2000 enRodrigoNo ratings yet

- Spec PA1049 (5720-5830+MHz+200W) Ver+1.3 180730Document2 pagesSpec PA1049 (5720-5830+MHz+200W) Ver+1.3 180730phamNo ratings yet

- A VHF-UHF Television Turret Tuner-ujCDocument15 pagesA VHF-UHF Television Turret Tuner-ujCjulio perezNo ratings yet

- Reference: XT2N160 Code: 1SDA067019R1 XT2N 160 TMA 125-1250 3p F FDocument3 pagesReference: XT2N160 Code: 1SDA067019R1 XT2N 160 TMA 125-1250 3p F FOel NaubNo ratings yet

- Zelio Plug-In Relays RXM2AB1JDDocument6 pagesZelio Plug-In Relays RXM2AB1JDAhmedNo ratings yet

- Power Generation Through Gym EquipmentDocument6 pagesPower Generation Through Gym EquipmentMufid SyedNo ratings yet

- Liebert Gxt3 208V, 5000-10,000VA, 6000RTL630: User ManualDocument52 pagesLiebert Gxt3 208V, 5000-10,000VA, 6000RTL630: User ManualMasterC3012No ratings yet

- Stacker ManualDocument60 pagesStacker ManualAkhtar QuddusNo ratings yet

- Measuring Principles Lecture on Sources of ErrorDocument18 pagesMeasuring Principles Lecture on Sources of ErrorAbhinav SinglaNo ratings yet