Professional Documents

Culture Documents

Cummins Genset PM Plan

Uploaded by

Umair A. KhanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cummins Genset PM Plan

Uploaded by

Umair A. KhanCopyright:

Available Formats

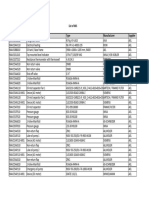

52 SEBU7833

Refill Capacities

Maintenance Interval Schedule

i05927155 “Fuel System Primary Filter (Water Separator)

Element - Replace”..................................................73

Maintenance Interval Schedule

“Fuel System Secondary Filter - Replace” ..............77

When Required “Hoses and Clamps - Inspect/Replace”...................80

“Radiator - Clean” ....................................................81

“Battery - Replace”...................................................55 Every 1000 Service Hours

“Battery or Battery Cable - Disconnect”...................56 “Engine Valve Lash - Inspect/Adjust” ......................69

“Engine - Clean”.......................................................62

Every 2000 Service Hours

“Engine Air Cleaner Element (Dual Element) - Clean/

Replace” ..................................................................63 “Aftercooler Core - Inspect” .....................................53

“Engine Air Cleaner Element (Single Element) - “Alternator - Inspect” ................................................54

Inspect/Replace”......................................................65

“Engine Mounts - Inspect” .......................................66

“Engine Oil Sample - Obtain”...................................67

“Starting Motor - Inspect” .........................................83

“Fuel Injector - Test/Change” ...................................69

“Turbocharger - Inspect” ..........................................83

“Fuel System - Prime”..............................................71

“Water Pump - Inspect”............................................84

“Severe Service Application - Check”......................82

Every 2 Years

Daily

“Cooling System Coolant - Change”........................60

“Cooling System Coolant Level - Check” ................60

Every 3000 Service Hours

“Driven Equipment - Check” ....................................62

“Fuel Injector - Test/Change” ...................................69

“Engine Air Cleaner Service Indicator - Inspect” .....65

“Engine Oil Level - Check”.......................................66

Every 3000 Service Hours or 2

Years

“Fuel System Primary Filter/Water Separator -

Drain” .......................................................................75 “Cooling System Coolant (Commercial Heavy-Duty) -

Change” ...................................................................56

“Fuel System Secondary Filter/Water Separator -

Drain” .......................................................................76 Every 4000 Service Hours

“Walk-Around Inspection”........................................84 “Aftercooler Core - Clean/Test”................................52

Every 50 Service Hours or Weekly Every 6000 Service Hours or 3

“Fuel Tank Water and Sediment - Drain” .................80 Years

Every 500 Service Hours “Cooling System Coolant Extender (ELC) - Add” ....60

“Alternator and Fan Belts - Inspect/Adjust/Replace”54 Every 12 000 Service Hours or 6

Years

Every 500 Service Hours or 1 Year

“Cooling System Coolant (ELC) - Change” .............58

“Battery Electrolyte Level - Check” ..........................55

“Engine Air Cleaner Element (Dual Element) - Clean/ i02322260

Replace” ..................................................................63

Aftercooler Core - Clean/Test

“Engine Air Cleaner Element (Single Element) -

Inspect/Replace”......................................................65

“Engine Ground - Inspect/Clean”.............................66 1. Remove the core. Refer to the OEM information for

“Engine Oil and Filter - Change”..............................67 the correct procedure.

SEBU7833 53

Refill Capacities

Aftercooler Core - Inspect

2. Turn the aftercooler core upside-down in order to 9. Inspect the core in order to ensure cleanliness.

remove debris. Pressure test the core. If necessary, repair the

core.

10. Install the core. Refer to the OEM information for

the correct procedure.

Personal injury can result from air pressure.

11. After cleaning, start the engine and accelerate the

Personal injury can result without following prop- engine to high idle rpm. This will help in the

er procedure. When using pressure air, wear a removal of debris and drying of the core. Stop the

protective face shield and protective clothing.

engine. Use a light bulb behind the core in order to

Maximum air pressure at the nozzle must be less inspect the core for cleanliness. Repeat the

than 205 kPa (30 psi) for cleaning purposes. cleaning, if necessary.

3. Pressurized air is the preferred method for i02322295

removing loose debris. Direct the air in the

opposite direction of the fan's air flow. Hold the Aftercooler Core - Inspect

nozzle approximately 6 mm (.25 inch) away from

the fins. Slowly move the air nozzle in a direction

that is parallel with the tubes. This will remove Note: Adjust the frequency of cleaning according to

debris that is between the tubes. the effects of the operating environment.

4. Pressurized water may also be used for cleaning. Inspect the aftercooler for these items: damaged fins,

The maximum water pressure for cleaning corrosion, dirt, grease, insects, leaves, oil and other

purposes must be less than 275 kPa (40 psi). Use debris. Clean the aftercooler, if necessary.

pressurized water in order to soften mud. Clean

the core from both sides. For air-to-air aftercoolers, use the same methods that

are used for cleaning radiators.

NOTICE

Do not use a high concentration of caustic cleaner to

clean the core. A high concentration of caustic Personal injury can result from air pressure.

cleaner can attack the internal metals of the core and

cause leakage. Only use the recommended concen- Personal injury can result without following prop-

tration of cleaner. er procedure. When using pressure air, wear a

protective face shield and protective clothing.

5. Back flush the core with a suitable cleaner. Maximum air pressure at the nozzle must be less

than 205 kPa (30 psi) for cleaning purposes.

6. Steam clean the core in order to remove any

residue. Flush the fins of the aftercooler core.

After cleaning, start the engine and accelerate the

Remove any other trapped debris. engine to high idle rpm. This will help in the removal

of debris and drying of the core. Stop the engine. Use

7. Wash the core with hot, soapy water. Rinse the a light bulb behind the core in order to inspect the

core thoroughly with clean water. core for cleanliness. Repeat the cleaning, if

necessary.

Inspect the fins for damage. Bent fins may be opened

with a “comb”.

Personal injury can result from air pressure. Note: If parts of the aftercooler system are repaired

Personal injury can result without following prop- or replaced, a leak test is highly recommended.

er procedure. When using pressure air, wear a

protective face shield and protective clothing. Inspect these items for good condition: Welds,

mounting brackets, air lines, connections, clamps and

Maximum air pressure at the nozzle must be less seals. Make repairs, if necessary.

than 205 kPa (30 psi) for cleaning purposes.

8. Dry the core with compressed air. Direct the air in

the reverse direction of the normal flow.

You might also like

- CAT G3516 Generator Maintenance ManualDocument70 pagesCAT G3516 Generator Maintenance ManualAnie Ekpenyong88% (43)

- CAT C 32 Marine Maintenance Schedule PDFDocument48 pagesCAT C 32 Marine Maintenance Schedule PDFRei_bud100% (1)

- C18 Marine Engine-Maintenance IntervalsDocument55 pagesC18 Marine Engine-Maintenance IntervalsJose Medina73% (11)

- Cat 246cDocument50 pagesCat 246cYerko Enzo100% (7)

- 3408C,+3412,+3412C+and+3412D+High+Performance+Marine+Engines Maintenance+IntervalsDocument40 pages3408C,+3412,+3412C+and+3412D+High+Performance+Marine+Engines Maintenance+IntervalsKyle Erspamer88% (17)

- Caterpillar 3512b Operation and Maintenance Manual 56Document56 pagesCaterpillar 3512b Operation and Maintenance Manual 56Petro Osangiri100% (3)

- 3412 Cat EngineDocument41 pages3412 Cat EngineIsmail Adenan73% (11)

- C15 Industrial Engines-Maintenance IntervalsDocument39 pagesC15 Industrial Engines-Maintenance Intervalsislam.egpower100% (2)

- HL757 7 PDFDocument459 pagesHL757 7 PDFazze bouz100% (1)

- 3208Document51 pages3208Daniel Ardila100% (2)

- 3306B Industrial Engine-Maintenance Intervals PDFDocument36 pages3306B Industrial Engine-Maintenance Intervals PDFanon_485665212100% (1)

- 3054C Industrial Engine - Maintenance IntervalsDocument34 pages3054C Industrial Engine - Maintenance IntervalsAlberto Migraña80% (5)

- (ELECS2) Exp5 - Class A and Class B Power Amplifier - The GWAPINGSDocument12 pages(ELECS2) Exp5 - Class A and Class B Power Amplifier - The GWAPINGSFrodolfre Reginald LazoNo ratings yet

- Man TGSDocument2 pagesMan TGSPaul CiobanuNo ratings yet

- C11 and C13 Industrial Engines-Maintenance IntervalsDocument39 pagesC11 and C13 Industrial Engines-Maintenance Intervalsktmsmr67% (6)

- C32 Marine Engines (RND) - Maintenance IntervalsDocument48 pagesC32 Marine Engines (RND) - Maintenance IntervalsEstarlin Alvarez Martinez100% (9)

- Sebu7877-08 M PDFDocument60 pagesSebu7877-08 M PDFGerardo Esteban Lagos Rojas100% (2)

- 345B ExcavadoraDocument55 pages345B ExcavadoraTeo Deustch100% (6)

- 307D Excavator-Maintenance IntervalsDocument41 pages307D Excavator-Maintenance IntervalsMecatrónico80% (5)

- 277C, 287C, 297CDocument56 pages277C, 287C, 297CGustavo Vargas100% (2)

- SSP-384 2nd Edition Lycoming Engine ToolsDocument53 pagesSSP-384 2nd Edition Lycoming Engine ToolsKamal Jit DhimanNo ratings yet

- 1103&1104 Maintenance SchudualDocument1 page1103&1104 Maintenance Schudualmoh asalanyNo ratings yet

- 3054C Industrial Engine - Maintenance IntervalsDocument34 pages3054C Industrial Engine - Maintenance IntervalsIvan Avelar PereiraNo ratings yet

- Caterpillar C9Document40 pagesCaterpillar C9Daniel Ardila100% (4)

- 3512B Engines: Maintenance IntervalsDocument50 pages3512B Engines: Maintenance IntervalsHaerul Latif100% (2)

- 3512B Engine-Maintenance IntervalsDocument56 pages3512B Engine-Maintenance IntervalsAnonymous VNu3ODGavNo ratings yet

- 3512C and 3516C MARINE Auxiliary Engines: Maintenance IntervalsDocument55 pages3512C and 3516C MARINE Auxiliary Engines: Maintenance IntervalsMohamed Sharawey100% (2)

- Manual Motor Cat c9 (073 127) 1Document55 pagesManual Motor Cat c9 (073 127) 1Edgar MaldonadoNo ratings yet

- Maintenance Intervals: Operation and Maintenance Manual ExcerptDocument44 pagesMaintenance Intervals: Operation and Maintenance Manual Excerpthidayat rachmatNo ratings yet

- Maintenance Interval ScheduleDocument1 pageMaintenance Interval ScheduleGazetoNo ratings yet

- Maintenance Intervals: Operation and Maintenance Manual ExcerptDocument41 pagesMaintenance Intervals: Operation and Maintenance Manual ExcerptМаксим ВолкановNo ratings yet

- Maintenance Intervals: Operation and Maintenance Manual ExcerptDocument41 pagesMaintenance Intervals: Operation and Maintenance Manual ExcerptМаксим ВолкановNo ratings yet

- G3408C and G3412C Engines Operation and Mtce ManualDocument44 pagesG3408C and G3412C Engines Operation and Mtce ManualAnie EkpenyongNo ratings yet

- Sebu7201-04 M PDFDocument55 pagesSebu7201-04 M PDFboubakerNo ratings yet

- Manual C18 PDFDocument42 pagesManual C18 PDFRannier CazagrandeNo ratings yet

- C1.5 Sebu8136-02 MDocument37 pagesC1.5 Sebu8136-02 MMd ShNo ratings yet

- Om Part Book D7G 11Document840 pagesOm Part Book D7G 11antoeNo ratings yet

- 3176C and 3196 Marine Engines: Maintenance IntervalsDocument38 pages3176C and 3196 Marine Engines: Maintenance IntervalsGael VelizNo ratings yet

- Maintenance Interval Schedule: This Document Has Been Printed From SPI2. NOT FOR RESALEDocument1 pageMaintenance Interval Schedule: This Document Has Been Printed From SPI2. NOT FOR RESALEAHMADNo ratings yet

- Maintenance Intervals: Operation and Maintenance Manual ExcerptDocument46 pagesMaintenance Intervals: Operation and Maintenance Manual ExcerptMira RedaNo ratings yet

- C 12 MaintenanceDocument45 pagesC 12 Maintenancedelta.supplieNo ratings yet

- 3126B Marine Engines: Maintenance IntervalsDocument38 pages3126B Marine Engines: Maintenance IntervalsjoelsanchezcamachoNo ratings yet

- Maintenance Intervals: Operation and Maintenance Manual ExcerptDocument43 pagesMaintenance Intervals: Operation and Maintenance Manual ExcerptPramodNo ratings yet

- Maintenance Intervals: Operation and Maintenance Manual ExcerptDocument63 pagesMaintenance Intervals: Operation and Maintenance Manual ExcerptTrajano GabrielNo ratings yet

- Maintenance Intervals: Operation and Maintenance Manual ExcerptDocument56 pagesMaintenance Intervals: Operation and Maintenance Manual ExcerptmusebladeNo ratings yet

- Maintenance Intervals: Operation and Maintenance Manual ExcerptDocument56 pagesMaintenance Intervals: Operation and Maintenance Manual ExcerptAmr Abd ElrahmanNo ratings yet

- 3600 Heavy Fuel Engines-Maintenance IntervalsDocument65 pages3600 Heavy Fuel Engines-Maintenance IntervalsAlvin Ey-Pi Peralta100% (1)

- 3054E and 3056E Industrial Engines-Maintenance IntervalsDocument36 pages3054E and 3056E Industrial Engines-Maintenance IntervalsprabumnNo ratings yet

- 3618 Engine-Maintenance IntervalsDocument43 pages3618 Engine-Maintenance Intervalsvic13rNo ratings yet

- C2.2 Sebu8137-04 MDocument36 pagesC2.2 Sebu8137-04 MMd Sh100% (1)

- C18 Marine Engine: Maintenance IntervalsDocument55 pagesC18 Marine Engine: Maintenance IntervalsArtyrNo ratings yet

- Wester BekeDocument90 pagesWester BekeMAYINNNo ratings yet

- C27 and C32 Generator Sets-Maintenance IntervalsDocument57 pagesC27 and C32 Generator Sets-Maintenance IntervalsRktBatamNo ratings yet

- Sebu6617-04 MDocument38 pagesSebu6617-04 MCDDPPJNo ratings yet

- 3408E and 3412E Industrial Engines: Maintenance IntervalsDocument36 pages3408E and 3412E Industrial Engines: Maintenance IntervalsJoselito Flores PastorNo ratings yet

- CAT Maintenance CDocument59 pagesCAT Maintenance Cdjohnso9No ratings yet

- Caterpillar c18 Marine Engine-Maintenance Intervals PDFDocument55 pagesCaterpillar c18 Marine Engine-Maintenance Intervals PDFRafa D'voxNo ratings yet

- Variable Speed Pumping: A Guide to Successful ApplicationsFrom EverandVariable Speed Pumping: A Guide to Successful ApplicationsRating: 3 out of 5 stars3/5 (2)

- Application of Optimal Control Theory to Enhanced Oil RecoveryFrom EverandApplication of Optimal Control Theory to Enhanced Oil RecoveryRating: 4.5 out of 5 stars4.5/5 (3)

- Power Electronics Design: A Practitioner's GuideFrom EverandPower Electronics Design: A Practitioner's GuideRating: 4.5 out of 5 stars4.5/5 (3)

- Making Everyday Electronics Work: A Do-It-Yourself Guide: A Do-It-Yourself GuideFrom EverandMaking Everyday Electronics Work: A Do-It-Yourself Guide: A Do-It-Yourself GuideRating: 4 out of 5 stars4/5 (2)

- Commissioning Procedure - Man Genset (LCS)Document13 pagesCommissioning Procedure - Man Genset (LCS)Umair A. KhanNo ratings yet

- Gas Chromotograph Log SheetDocument1 pageGas Chromotograph Log SheetUmair A. KhanNo ratings yet

- Commissioning Procedure - Man Genset (LCS)Document13 pagesCommissioning Procedure - Man Genset (LCS)Umair A. KhanNo ratings yet

- ES1002-0509-Compressor Lube RecommendationsDocument8 pagesES1002-0509-Compressor Lube RecommendationsUmair A. KhanNo ratings yet

- 14-Commissioning & StartupDocument15 pages14-Commissioning & StartupUmair A. KhanNo ratings yet

- 15-Pressure Safety ValvesDocument33 pages15-Pressure Safety ValvesUmair A. KhanNo ratings yet

- AJAX 2801 17in CylinderDocument17 pagesAJAX 2801 17in CylinderUmair A. KhanNo ratings yet

- 01-Superior Compressor Workshop-IntroDocument11 pages01-Superior Compressor Workshop-IntroUmair A. KhanNo ratings yet

- 09-Compressor Piston Rings & RidersDocument34 pages09-Compressor Piston Rings & RidersUmair A. KhanNo ratings yet

- AJAX 2801 15in CylinderDocument18 pagesAJAX 2801 15in CylinderUmair A. KhanNo ratings yet

- Waukesha VHP L5794gsi Product SheetDocument2 pagesWaukesha VHP L5794gsi Product SheetUmair A. KhanNo ratings yet

- Vibration Monitoring SheetDocument2 pagesVibration Monitoring SheetUmair A. KhanNo ratings yet

- AJAX 2801 15in CylinderDocument18 pagesAJAX 2801 15in CylinderUmair A. KhanNo ratings yet

- I Thought: Safety Rules Are PainDocument1 pageI Thought: Safety Rules Are PainUmair A. KhanNo ratings yet

- Attendance - Consolidated 2021 (UAK)Document13 pagesAttendance - Consolidated 2021 (UAK)Umair A. KhanNo ratings yet

- Western ADR Strapping Chart 10ARTDocument2 pagesWestern ADR Strapping Chart 10ARTUmair A. KhanNo ratings yet

- DM4000 Accessories Fact SheetDocument4 pagesDM4000 Accessories Fact SheetSydney Sam S PhiriNo ratings yet

- Datasheet Ic Carga Moto E4Document48 pagesDatasheet Ic Carga Moto E4Xvier100No ratings yet

- Wireless Receivers With Relay Outputs RF RX SW915-4S 24VDC Material Number: 1370677Document2 pagesWireless Receivers With Relay Outputs RF RX SW915-4S 24VDC Material Number: 1370677asepNo ratings yet

- Tutorial 3 - Gear FundamentalsDocument3 pagesTutorial 3 - Gear FundamentalssharleenNo ratings yet

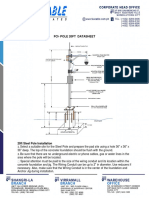

- 20ft Steel Pole DatasheetDocument3 pages20ft Steel Pole DatasheetDVTech EngineeringNo ratings yet

- (Notes For Students) Power Engineering - 7 DistributionDocument48 pages(Notes For Students) Power Engineering - 7 DistributionKendall Birjue100% (1)

- Go Supporter 17.03.22Document5 pagesGo Supporter 17.03.22Yashini SathiaselanNo ratings yet

- PT9420 PDFDocument6 pagesPT9420 PDFMichael LinNo ratings yet

- Bs 6004 BasecDocument2 pagesBs 6004 BasecMOHAMMED. HAKAMINo ratings yet

- High Voltage On ShipsDocument12 pagesHigh Voltage On ShipsDeni Kurnia One100% (1)

- Hydro-Mast Weight Indicator System: Service ManualDocument64 pagesHydro-Mast Weight Indicator System: Service ManualAbdallah Elhendy100% (1)

- Daytona CockpitDocument1 pageDaytona Cockpitxavierr190% (1)

- Equipment TP MAV AEL Oil Supply UnitDocument1,392 pagesEquipment TP MAV AEL Oil Supply UnitMuhammad Hasbi AsidiqiNo ratings yet

- Replacement Parts Catalog: Basic, Advanced, and Pro and Pro+ ModelsDocument22 pagesReplacement Parts Catalog: Basic, Advanced, and Pro and Pro+ ModelsWilliam CorreaNo ratings yet

- Dual Range 7 & 8 Speed Transmission - Gears & Related Parts - 5600, 6600, 7600, 5700, 6700, 7700Document8 pagesDual Range 7 & 8 Speed Transmission - Gears & Related Parts - 5600, 6600, 7600, 5700, 6700, 7700Cristian Ivan Grageda YocupicioNo ratings yet

- Service and Maintenance Manual: Models 3369LE 4069LE M3369 M4069Document146 pagesService and Maintenance Manual: Models 3369LE 4069LE M3369 M4069Vũ Đình HậuNo ratings yet

- Hwids - 2016 02 23 - 10 43 12Document8 pagesHwids - 2016 02 23 - 10 43 12Angel UshcaNo ratings yet

- Cat Telehandler Th360b Service ManualDocument20 pagesCat Telehandler Th360b Service Manualjoyce100% (48)

- OMM DozerDocument238 pagesOMM DozerAmir Bambang YudhoyonoNo ratings yet

- Power TransistorDocument37 pagesPower Transistorsaikarthick023No ratings yet

- General Engine Info Aircraft Information Limiting Part InformationDocument1 pageGeneral Engine Info Aircraft Information Limiting Part InformationAHAMEDNo ratings yet

- Renr5807renr5807 01 Sis PDFDocument2 pagesRenr5807renr5807 01 Sis PDFLeonardo Romero JimenezNo ratings yet

- China NEMA23 2phase Hybrid Stepper Motor With Advanced Technology - China NEMA 23 Stepper Motor, Step MotorDocument6 pagesChina NEMA23 2phase Hybrid Stepper Motor With Advanced Technology - China NEMA 23 Stepper Motor, Step MotororegondaveNo ratings yet

- Datasheet PDFDocument8 pagesDatasheet PDFSaad LehlouNo ratings yet

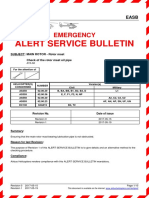

- Alert Service Bulletin: EmergencyDocument13 pagesAlert Service Bulletin: EmergencyRaymond ZamoraNo ratings yet

- Im Gotdamn RichDocument64 pagesIm Gotdamn Richstan leeNo ratings yet