0% found this document useful (0 votes)

1K views1 pageInspection Rigging Equipment

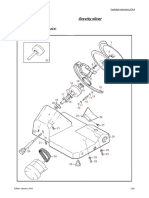

This document provides a pre-use inspection guide for slings, rigging hardware, and rigging blocks. It lists specific items to check for each type of equipment, including cracks, corrosion, damage, and wear. Any failures found during inspection mean the equipment should not be used and the problem reported to a supervisor. Only trained personnel are authorized to conduct inspections and use the equipment.

Uploaded by

wahyu haryadiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views1 pageInspection Rigging Equipment

This document provides a pre-use inspection guide for slings, rigging hardware, and rigging blocks. It lists specific items to check for each type of equipment, including cracks, corrosion, damage, and wear. Any failures found during inspection mean the equipment should not be used and the problem reported to a supervisor. Only trained personnel are authorized to conduct inspections and use the equipment.

Uploaded by

wahyu haryadiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Pre-Use Inspection Guide for Slings and Rigging Hardware