Professional Documents

Culture Documents

Nitronic 60 (S21800)

Nitronic 60 (S21800)

Uploaded by

geoanburaja0 ratings0% found this document useful (0 votes)

31 views1 pageOriginal Title

NITRONIC 60 (S21800)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views1 pageNitronic 60 (S21800)

Nitronic 60 (S21800)

Uploaded by

geoanburajaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

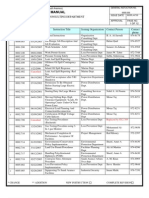

(") UNIVERSAL fe

LABORATORY \ Ni, 7 ip

¢ 4 ) BUREAU ee Dunkirk Specialty Steel, LLC. adcap

BUREAU vous

COED seeecen 830 Brigham Road | Dunkirk, NY 14048 IMoteriots

ing Loboratory

(716) 366-1000 eat Treating

Material Certification

maf onoer wore “cae oF trae Pe Tal] THAT FAGENTNRERS TT

PARANUATBER: 723118

SEHUAL RUMI DNKCAI7S402.623506 92938 v.0.pates 122s pruyrep: sat7 143s

Hate] ‘SPAINLESS STEEL ROUND BAR NEO RAFWACO AWWEALED CE SS GROUND ASIN AGA4-16, ASTM AI62-15

(ocaeree a), aus S040, asta nave Ica (520800 consition a), Aut 3168-16 Qogp/s9inod Clase 10), ASDA AA79~ iba (921800

SSealimen A)! tesa s2iso, abs SIAL 23 67 52 na. 1 tOB/as)

ise] 4.5000 pant x 132.0000 207 186.0000 wax naxea FF

ols 006) a ae To oe

Gye maw G38 OOS 08) Ot? a O40

Sty Olea [te 0.03

| mn Seo foe [x :

ae a Poe an &

af deter “aap we few

tome 109.3 fe se: braas

asomnss: 200 now K

cram e128: 7.5 (enommr: 40/30/30 act xcro/acenre nexpywearc acl waGKTFTCATTON 106%)

wacko H7CH: as-received TUS WAS PEAUOIGUD HH UNIVEREAL STRINIESS, BRIDGEVELA, PA

TOUTERQRAMULAR CORROSION TEST: O.K. (ASTH-AZ62~1S PRACTICE S| - TEST WAS + os BY USL METALLURGICAL THSzaNG LAB

OP 1980°F 4/- 25°F FOR 2N AVEROPRIATE TIME, POLIOWED RY MATER QUENCH

incions WE. mice

‘Nec! Shah, Metallursst

Meltes DPARS 252.225-7009 ALT 1, Melted and chemistry testedjby USAP is Bridgeville, PA,, USA. Material Manufactured

USA Pica tat Dd i

Dv resfctht weve serve from ein stipes the mata Rests mest appa seeiex ne

Orr Matus tee rom mercy contamination Mater hs aut era clea pre het Wat

rake kik Specialty Stes! Quality Managetnent Systems documented fe OP Ma

c

SD ODIEN 10204 3.4, Material eomplics with EU directive 208259816C (Rolf), The tex realte shown are ceriled to ea correct atom

(9 weld was perfortued on the atrial sepplied ow Ms

, Maeva! sof NAFTA origi, This material yas produced

NG, comforming to NCA 3800, Matera ating wan

perfordagds applicable ‘ASEM AS, AGD4,E8, E10, E185 E23,

SANGRE Ther

Tie |

-arding of ase, fettons 9° Tr

ler 47 Tes esis ar¢ mainiained i company reord. This cerieatan sall aot be prodaced, excep in ful, wibout writen ap

cable: Decarb fest furnace

IX, Uae there sate,

‘Stet Material i tree trorn Kadkcacive Cantaminatin. Safety Data Sheets (SDS) areavalabe a} wiv.anvstalnes.can 14

fee Argon Corvesion Tes (ASTAL A262 Practice A) -Elchant wsed-10% Onalic Acid; Microstructure @ magaliation 250 ~

Percentage Elongation frenearered in 4D. Speed of Testing: 0.08 iainining QOS iain

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MSDS - Avesta Passivator 601Document8 pagesMSDS - Avesta Passivator 601geoanburajaNo ratings yet

- MSDS - Avesta Cleaner 401Document8 pagesMSDS - Avesta Cleaner 401geoanburajaNo ratings yet

- 60 MM SA 516 GR 70 MTCDocument21 pages60 MM SA 516 GR 70 MTCgeoanburajaNo ratings yet

- MSDS - Avesta Pickling Gel 122Document9 pagesMSDS - Avesta Pickling Gel 122geoanburajaNo ratings yet

- Holiday Memo DubaiDocument1 pageHoliday Memo DubaigeoanburajaNo ratings yet

- Hazard Identification and Assessment: PurposeDocument3 pagesHazard Identification and Assessment: PurposegeoanburajaNo ratings yet

- Hazard Identification and Assessment: PurposeDocument4 pagesHazard Identification and Assessment: PurposegeoanburajaNo ratings yet

- Hazard Identification and Assessment: PurposeDocument2 pagesHazard Identification and Assessment: PurposegeoanburajaNo ratings yet

- GI IndexDocument12 pagesGI IndexgeoanburajaNo ratings yet

- IPS Sample Verbal Reasoning Practice PaperDocument7 pagesIPS Sample Verbal Reasoning Practice Paperasha100% (1)

- Hazard Identification-Incident Reporting FormDocument3 pagesHazard Identification-Incident Reporting FormgeoanburajaNo ratings yet

- Pallet Safety TipsDocument3 pagesPallet Safety TipsgeoanburajaNo ratings yet

- Explanatory Notes For BC1-2008Document14 pagesExplanatory Notes For BC1-2008geoanburajaNo ratings yet