Professional Documents

Culture Documents

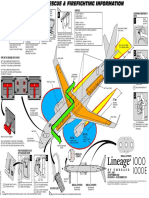

Aircraft Hangar iVFD Fire Protection

Uploaded by

FranciscoVicente0 ratings0% found this document useful (0 votes)

14 views5 pagesOriginal Title

Aircraft-Hangar-iVFD-Fire-Protection

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views5 pagesAircraft Hangar iVFD Fire Protection

Uploaded by

FranciscoVicenteCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

Intelligent Video Flame

Detection for Aircraft Hangars

The Importance of Fire Detection in Aircraft Hangars

Aircraft hangars are themselves valuable — a high-spec han-

gar alone could cost $3M (USD)to construct. That cost pales in

comparison to the value of the items inside. A civilian aircraft like

the Boeing 777-9 is priced at $442M, while the cost of a single US

military aircraft can reach $1B.

Clearly then, the importance of securing a hangar against fire

related accidents that could damage its contents is paramount.

That‘s easier said than done. Aircraft hangars are also hotbeds

for fire hazards. The presence of jet fuel and other hydrocarbons,

refueling, and moving aircraft all pose dangerous risks.

Severe damage to an aircraft from a large fire can occur within

under a minute, but expansion foam can take longer than two The Issue of False Alarms

minutes to sufficiently fill the hangar and suffocate fire at the top

The risks associated with traditional optical flame detectors

of a small aircraft. That‘s why it is critical to accurately identify a

demonstrate the need for a more effective detection system

fire as soon as they start.

with a lower risk of activation caused by false alarms:

Optical Flame Detectors in Hangars CO2

Optical flame detectors are well suited to aircraft hangars‘

Traditional optical flame detectors like MSIRs and IR3s identify

unique conditions and are therefore widely used. Detectors

flames by responding to the presence of hot CO2 in the air.

of this kind have wide fields of vision, allowing them to detect

flames from a distance of over 40m. But in an aircraft hangar environment, where jet engines and

motors are in frequent use, this is hardly an ideal detection

That‘s ideal when you consider hangars‘ high ceilings, where

method.

identifying a fire on the ground from a long distance could

otherwise be difficult. High ceilings also pose a risk of thermal Sunlight Desensitization

stratification, which can often thwart heat detectors‘ ability to

identify fires. While sunlight won‘t generally trigger false alarms in optical

flame detectors, it might impair them, as they can become

An additional benefit of optical flame detectors is their capacity desensitized when exposed to too much sunlight.

to recognize fires faster than smoke or heat detectors: usually

within 10 seconds of a small fire breaking out. That‘s a big problem in hangars, whose wide doors are often

kept open during the day to facilitate the moving and main-

While they have many benefits, traditional optical flame detec- tenance of aircraft.

tors like multi-spectrum infrared detectors have certain key

flaws, mainly related to false alarms. Blackbody Radiation from Planes/Engines

Optical flame detectors may trigger false alarms due to black-

body radiation from aircraft or service vehicles.

Intelligent Video Flame Detectors

Intelligent Video Flame Detectors (IVFD)

IVFDs are an excellent alternative to traditional optical detectors.

While false alarms are still possible when IVFDs are in place, the

risk is significantly lower.

IVFDs use a camera and onboard mechanism to spatially analyze

video for fire. Remote viewing options allow operative person-

nel to visually confirm a fire in the event of an alarm warning or

activation of an automatic suppression system, meaning they

can quickly react and, if necessary, override the response.

IVFDs cannot identify CO2 emissions, so an alarm won‘t be trig-

gered because of exhaust fumes from jet engines or diesel gen-

erators during routine activities including aircraft maintenance.

This fact alone makes a good case for the adoption of IVFDs in

aircraft hangars, as they are better suited to the context.

Recording Incidents with IVFDs

Viking VSF301 Intelligent Video Flame Detector

Viking VSF301 IVFD has the ability to record alarm-triggering

events. This is a valuable asset when identifying the causes of The Viking VSF301 is an explosion-proof video flame detector. It

genuine fires or false alarms. processes live video images to detect the characteristic proper-

ties of flames visually, by means of its FM- and SIL 2-certified

In the event of a real fire, investigation into its origins can take

flame detection algorithms and onboard digital signal process-

place, avoiding the issue of so-called “black-hole” fires, where

ing (DSP). The detector provides live video images for situational

hangars are damaged to the extent that no evidence explaining

awareness and has a Micro-SD memory card slot to record im-

the cause of a fire survives. In the event of a false alarm, the video

ages for forensic analysis.

footage can be reviewed to determine the reason. From the

information gathered, lessons can be learned and new processes The benefits of installing a Viking VSF301 Detector:

put in place to prevent similar false alarms from reoccurring. Ū Live color video image of the aircraft hangar

Ū Not affected by black body radiation (radiated from the

aircraft body)

Ū Not affected by welding/grinding

Ū Not affected by differing light levels

Ū Less affected by dirt/grime/oily deposits on the lens

Ū High temperature rating +185° F (85° C)

Ū Pre- and post-alarm video recording of the event onto an

on-board micro-SD card

Intelligent Video Flame Detectors with 3D Mapping

The benefits of IVFDs can be taken even further when com-

bined with 3D mapping. Using widely available hazard mapping

technology like MICROPAK HazMap3D software, users can assign

a risk grade to every area of the aircraft hangar. A graded area is

typically one to five metres in size. Grading an area’s hazard risk

helps users to explain the likelihood of a fire or the potential im-

pacts of a nearby fire in each area. The risk level can be graded by

area use, checking for factors like aircraft presence, liquid hydro-

carbon presence, refuelling, maintenance, and moving aircraft.

When grading is complete, IVFDs can be positioned for optimal

coverage. This allows users to understand when it is necessary to

change detector positions, run new assessments, and immedi-

ately gauge the impact in coverage.

To ensure compliance with standards such as NFPA 409, a

Given their breadth of coverage, fewer detectors are needed, performance-based design approach must be followed with

resulting in lower up-front maintenance costs compared with the correct detection system used for the hazards present. The

other forms of optical flame and heat detectors. detection system must be coupled with a robust fire protection

system capable of rapid response to ensure the aircraft are pro-

IVFDs with 3D mapping allow for enhanced flame detection at tected. The performance-based design of the detection system

longer ranges and with fewer false alarms than optical flame should be centred around a robust flame detection mapping

detectors like multi-spectrum infrared (MSIR) detectors. study. This should be performed using an approved Fire & Gas

mapping system (i.e. HazMap3D) by either a Fire & Gas

Design Services & Support Information

practitioner or professional fire protection engineer. Viking

provides expert design and support services to facilitate this

process.

Viking Global Engineering Support Services

Center (GESSC)

The Viking GESSC provides expert support and resources to help

with the design, installation, and maintenance of fire protection

systems from start to finish. We work with various engineering

design tools including CAD, 3D modeling software, and our own

calculation software to create design packages that meet code-

compliance, budget, application, and bandwidth requirements.

Our team provides timely, accurate, and complete solutions for

your project needs.

GESSC assists consultants, architects, engineers, contractors,

and building owners with system design. Working with our local

partners, we provide training processes, and support installation,

commission, service, and maintenance operations.

We have extensive, hands-on experience with a focus on life

cycle optimization, simplified facility operation, maintenance,

and efficiency. Our focus on multi-trade coordination, improved

accuracy, clear documentation, reduced waste, and early

decision-making sets our services apart. Additionally, we are able

Contact Us

to support projects in multiple languages and regions. Choose

from supported product lines or custom-order desired products Viking Integrated Safety

to fit your needs. Viking Group, Inc.

5150 Beltway Dr. SE

Buying VIS Solutions Caledonia, Michigan 49316

All VIS solutions are sold through Viking SupplyNet. Established

in 1988, Viking SupplyNet distributes the largest selection Toll Free Phone: (800) 968-9501

of integrated detection, alarm, and suppression systems to Local Phone: (269) 945-9501

customers in over 70 countries. Viking SupplyNet’s state-of-the- Local Fax: (269) 945-9599 (General Inquiries)

art inventory system links all locations worldwide to ensure that Customer Service Fax: (269) 945-5090

every solution is available for timely delivery — to any job site, Web: Safety.SupplyNet.com

anywhere in the world. See VikingGroupInc.com/locations. E-mail: VIS@SupplyNet.com

Safety.SupplyNet.com

You might also like

- Flame Detectors: Key To An Effective Fire Suppression SystemDocument11 pagesFlame Detectors: Key To An Effective Fire Suppression SystemAnonymous bHh1L1No ratings yet

- Astm C11Document8 pagesAstm C11Fitria RindangNo ratings yet

- Substations Design Guide PDFDocument16 pagesSubstations Design Guide PDFM Alim Ur RahmanNo ratings yet

- Operation and Maintenance of Power Plant PDFDocument31 pagesOperation and Maintenance of Power Plant PDFwonderstrikeNo ratings yet

- Airside Safety Handbook 2010Document108 pagesAirside Safety Handbook 2010Ayhan DemirNo ratings yet

- Financial Statements of An Entity That Have Been Reviewed by An AccountantDocument3 pagesFinancial Statements of An Entity That Have Been Reviewed by An AccountantQueen ValleNo ratings yet

- Substations PDFDocument16 pagesSubstations PDFsorry2qaz100% (1)

- Heat and Mass Transfer - E. R. G. Eckert and R. M. Drake PDFDocument46 pagesHeat and Mass Transfer - E. R. G. Eckert and R. M. Drake PDFAnaQatarina50% (4)

- Fire Detection & Alarm SystemsDocument30 pagesFire Detection & Alarm SystemsSiva Saravana Mani100% (1)

- Codex AlexandrinusDocument294 pagesCodex AlexandrinusHevel Cava100% (2)

- To 00-25-172 Ground Servicing of AircraftDocument100 pagesTo 00-25-172 Ground Servicing of AircraftFranciscoVicenteNo ratings yet

- Flame Detector PDFDocument4 pagesFlame Detector PDFAhmed Mahmoud ElgayedNo ratings yet

- Chapter 2 1 Determination of Interest RatesDocument63 pagesChapter 2 1 Determination of Interest RatesLâm Bulls100% (1)

- Fire Safety in Warehouses: CFPA-E Guideline No 35:2015 FDocument22 pagesFire Safety in Warehouses: CFPA-E Guideline No 35:2015 FFranciscoVicenteNo ratings yet

- Multi-Camera Networks: Principles and ApplicationsFrom EverandMulti-Camera Networks: Principles and ApplicationsHamid AghajanRating: 3 out of 5 stars3/5 (1)

- Student Report Card ManagementDocument38 pagesStudent Report Card ManagementKannan Thangaraju41% (17)

- An Aircraft Hangar June06Document8 pagesAn Aircraft Hangar June06Gigy Mathews100% (1)

- Flame Detection Basic PrinciplesDocument5 pagesFlame Detection Basic PrinciplesBenjamin LingNo ratings yet

- Detection and Monitoring of Fire Accidents Using IOTDocument6 pagesDetection and Monitoring of Fire Accidents Using IOTInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Efficient Deep CNN-Based Fire Detection and Localization in Machine Learning Video Surveillance ApplicationsDocument9 pagesEfficient Deep CNN-Based Fire Detection and Localization in Machine Learning Video Surveillance ApplicationsIJRASETPublicationsNo ratings yet

- Human Factors Cabin CrewDocument18 pagesHuman Factors Cabin CrewMiko Judael TaperlaNo ratings yet

- Visual Flame Detection Aircraft HangarsDocument6 pagesVisual Flame Detection Aircraft Hangars1029384765qazwsxNo ratings yet

- Flame Detector Selection: Two Distinct Flame Detection FamiliesDocument4 pagesFlame Detector Selection: Two Distinct Flame Detection Familieseng_moh104No ratings yet

- Flame Detection: Single Frequency InfraredDocument4 pagesFlame Detection: Single Frequency InfraredAbdelhakim ChaouchNo ratings yet

- Visual Flame Detection Turbine EnclosuresDocument6 pagesVisual Flame Detection Turbine Enclosures1029384765qazwsxNo ratings yet

- Datasheet Discovery EngelsDocument2 pagesDatasheet Discovery EngelsfloriskooimanbeveiligingNo ratings yet

- Ee 1c Lesson 8 Auxiliary SystemDocument9 pagesEe 1c Lesson 8 Auxiliary SystemRodrigo BabijisNo ratings yet

- Electronics: Fire Detection Method in Smart City Environments Using A Deep-Learning-Based ApproachDocument17 pagesElectronics: Fire Detection Method in Smart City Environments Using A Deep-Learning-Based Approach백성하No ratings yet

- Flame Detector SelectionDocument9 pagesFlame Detector SelectionAatish ChandrawarNo ratings yet

- Video Flame Detection BrochureDocument8 pagesVideo Flame Detection BrochureranajithdkNo ratings yet

- Ivstruct-O-Gram: Thermal Lmaging CamerasDocument4 pagesIvstruct-O-Gram: Thermal Lmaging CamerasfranciscoNo ratings yet

- DatasheetDocument12 pagesDatasheetmybooks1401No ratings yet

- Visual Flame Detection Silane FiresDocument4 pagesVisual Flame Detection Silane Fires1029384765qazwsxNo ratings yet

- Salwico: Fire Detector RangeDocument4 pagesSalwico: Fire Detector RangeОлегNo ratings yet

- Intelligent Fire Detectors - 5 Response Modes - Drift Compensation - User Programmable - Rejection of Transient SignalsDocument2 pagesIntelligent Fire Detectors - 5 Response Modes - Drift Compensation - User Programmable - Rejection of Transient SignalssupinstrumkkNo ratings yet

- Infrared Thermography (Examples 2009-2) (互換モード)Document20 pagesInfrared Thermography (Examples 2009-2) (互換モード)MELgamiNo ratings yet

- Bosch Whitepaper AviotecDocument8 pagesBosch Whitepaper Aviotecmybooks1401No ratings yet

- FIRE ONLINE en Flame Detectors 2020.04Document51 pagesFIRE ONLINE en Flame Detectors 2020.04robertmithieryNo ratings yet

- A6V10061990 - Flame Detector Addressed or Collective ASAtechnol - enDocument8 pagesA6V10061990 - Flame Detector Addressed or Collective ASAtechnol - enAbdelhak AbdouNo ratings yet

- UV Fire Detector C7050Document30 pagesUV Fire Detector C7050ValdemirfdafonsecaNo ratings yet

- Cerberus® PRO: Detectors and PeripheralsDocument4 pagesCerberus® PRO: Detectors and PeripheralsShashish AshuNo ratings yet

- Using Air Sampling Smoke Detection To Protect Mission Critical Facilities From FireDocument8 pagesUsing Air Sampling Smoke Detection To Protect Mission Critical Facilities From Fire17souravNo ratings yet

- IR Guard EN 1Document4 pagesIR Guard EN 1Phong Hoang LeNo ratings yet

- 01-Flame Detection Paper - GPDocument6 pages01-Flame Detection Paper - GPHJNo ratings yet

- HBT Fire LS10078 000NF E C6Document20 pagesHBT Fire LS10078 000NF E C6ijas ahmedNo ratings yet

- CCTV Systems and Cameras RstahlDocument28 pagesCCTV Systems and Cameras RstahlAmine AminovichNo ratings yet

- Tyco FlameVision - DatasheetDocument4 pagesTyco FlameVision - Datasheetchayan83No ratings yet

- Article Minimising False Alarms Rosemount en 72138Document1 pageArticle Minimising False Alarms Rosemount en 72138Abdelhakim ChaouchNo ratings yet

- VesdaDocument8 pagesVesdaepicenterrulezNo ratings yet

- Cargo Fire Protection Systems For Freighter ConversionsDocument12 pagesCargo Fire Protection Systems For Freighter Conversionsbxlmichael8837No ratings yet

- Fact-Sheet_-ExSite-Pro-PTZ-and-ExSite-Pro-IR-PTZDocument1 pageFact-Sheet_-ExSite-Pro-PTZ-and-ExSite-Pro-IR-PTZPaulina PalmaNo ratings yet

- Fast Smoke Detection For Video Surveillance Using CUDADocument9 pagesFast Smoke Detection For Video Surveillance Using CUDAakash menonNo ratings yet

- Nca-2Document110 pagesNca-2tech11No ratings yet

- FLIR - warehouse asset protectionDocument4 pagesFLIR - warehouse asset protectionrony silvaNo ratings yet

- W-SYNC ManualDocument68 pagesW-SYNC ManualArgenis InfanteNo ratings yet

- Forest Fire Detection Using Computer VisionDocument30 pagesForest Fire Detection Using Computer VisionPRANAV KAKKARNo ratings yet

- IR Seeker Simulator and IR Scene Generation To Evaluate IR Decoy EffectivenessDocument12 pagesIR Seeker Simulator and IR Scene Generation To Evaluate IR Decoy EffectivenessAhmed HamoudaNo ratings yet

- Chapter 10 - Special HazardsDocument28 pagesChapter 10 - Special Hazardssqamar68No ratings yet

- SLC Wiring ManualDocument80 pagesSLC Wiring ManualHye FuentesNo ratings yet

- The Aico Smoke Alarms Questions and AnswersDocument16 pagesThe Aico Smoke Alarms Questions and AnswersSparks Electrical Wholesalers LtdNo ratings yet

- ES-50X ES-50XC: Addressable Fire Alarm Control PanelDocument162 pagesES-50X ES-50XC: Addressable Fire Alarm Control PanelOswaldo BermeoNo ratings yet

- Duiker Flame Detector (DFD) : Improved Safety Realized With The DFD FL Ame DetectorDocument2 pagesDuiker Flame Detector (DFD) : Improved Safety Realized With The DFD FL Ame DetectorIagoVazquezGuerreroNo ratings yet

- Notifier NFS-640 Programming ManualDocument116 pagesNotifier NFS-640 Programming ManualxiaolanNo ratings yet

- ES 1000X Instruction ManualDocument170 pagesES 1000X Instruction Manualjmonarres45No ratings yet

- HBT Fire 51253 U9 SLC WiringDocument88 pagesHBT Fire 51253 U9 SLC WiringsaldanaNo ratings yet

- Fire Fighting Bot To Allow A User To Control A Fire Fighter RobotDocument23 pagesFire Fighting Bot To Allow A User To Control A Fire Fighter RobotLumisense TechnologiesNo ratings yet

- FLIR InfoDocument2 pagesFLIR InfowzgksbvzNo ratings yet

- Early Forest Fire Detection and Verification Using Optical Smoke, Gas and Microwave SensorsDocument11 pagesEarly Forest Fire Detection and Verification Using Optical Smoke, Gas and Microwave SensorsHrutuj ShirkeNo ratings yet

- Design and Development of Heavy Drone For Fire Fighting Operation IJERTV9IS060433Document5 pagesDesign and Development of Heavy Drone For Fire Fighting Operation IJERTV9IS060433Haarish RomeoNo ratings yet

- Vigilon AA Loop DevicesDocument20 pagesVigilon AA Loop DevicesMohd A IshakNo ratings yet

- ISO 45001:2018 Checklist: 4. Context of The Organisation 4.1 Understanding The Organisation and Its ContextDocument16 pagesISO 45001:2018 Checklist: 4. Context of The Organisation 4.1 Understanding The Organisation and Its ContextgiordanoNo ratings yet

- Fire Drills: Safety Code of Practice 5Document18 pagesFire Drills: Safety Code of Practice 5FranciscoVicenteNo ratings yet

- Flammable Liquid Storage Rooms: Room ConstructionDocument2 pagesFlammable Liquid Storage Rooms: Room ConstructionFranciscoVicenteNo ratings yet

- Agency Measures Docs Agency Decisions 2014 201X XXX R AMC GM ADR (DRAFT)Document193 pagesAgency Measures Docs Agency Decisions 2014 201X XXX R AMC GM ADR (DRAFT)FranciscoVicenteNo ratings yet

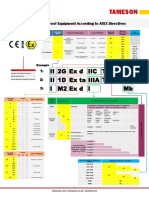

- ATEX en Tameson Understanding Atex LabelingDocument1 pageATEX en Tameson Understanding Atex LabelingFranciscoVicenteNo ratings yet

- Purplek Pyro Chem MsdsDocument6 pagesPurplek Pyro Chem MsdsFranciscoVicenteNo ratings yet

- Fire Extinguisher Cargo Smoke FWD AFT: 4 December 3Document1 pageFire Extinguisher Cargo Smoke FWD AFT: 4 December 3FranciscoVicenteNo ratings yet

- Atila TDS 5.0 enDocument2 pagesAtila TDS 5.0 enFranciscoVicenteNo ratings yet

- TU Cooling of A Hot Smoke Layer by A Sprinkler SprayDocument212 pagesTU Cooling of A Hot Smoke Layer by A Sprinkler SprayFranciscoVicenteNo ratings yet

- Data Sheet: Unit F, 230 Parkway Point, Springhill Parkway, Glasgow Business Park, Glasgow, UK, G69 6GADocument10 pagesData Sheet: Unit F, 230 Parkway Point, Springhill Parkway, Glasgow Business Park, Glasgow, UK, G69 6GAFranciscoVicenteNo ratings yet

- AQUAFILM® EX 10 EngDocument1 pageAQUAFILM® EX 10 EngFranciscoVicenteNo ratings yet

- Applied Sciences: Risk Index Method-A Tool For Building Fire Safety AssessmentsDocument16 pagesApplied Sciences: Risk Index Method-A Tool For Building Fire Safety AssessmentsFranciscoVicenteNo ratings yet

- Boeing aircraft rescue categories by FAA and ICAO length & width standardsDocument1 pageBoeing aircraft rescue categories by FAA and ICAO length & width standardsAbi FaiqNo ratings yet

- Airport Firefighter: Tandard ASKDocument19 pagesAirport Firefighter: Tandard ASKFranciscoVicenteNo ratings yet

- APX. J - Guidance Material On Building Safety Case For ADS-B SeparationDocument20 pagesAPX. J - Guidance Material On Building Safety Case For ADS-B SeparationFranciscoVicenteNo ratings yet

- AERO - 2011 - Q1 - Article3 - Flammability Zones Around An Airplane With Open Fuel Tanks PDFDocument8 pagesAERO - 2011 - Q1 - Article3 - Flammability Zones Around An Airplane With Open Fuel Tanks PDFFranciscoVicenteNo ratings yet

- Zyvax Freshstart™: Solvent-Free Mold and Finished Part CleanerDocument1 pageZyvax Freshstart™: Solvent-Free Mold and Finished Part CleanerFranciscoVicenteNo ratings yet

- Airside Safety Catch: Welcome To This Special Edition Focussing On Airside DrivingDocument9 pagesAirside Safety Catch: Welcome To This Special Edition Focussing On Airside DrivingFranciscoVicenteNo ratings yet

- Npa 2018-15Document48 pagesNpa 2018-15FranciscoVicenteNo ratings yet

- Review of Foam Fire Suppression System Discharges in Aircraft HangarsDocument27 pagesReview of Foam Fire Suppression System Discharges in Aircraft HangarsFranciscoVicenteNo ratings yet

- Fire Drills: Safety Code of Practice 5Document18 pagesFire Drills: Safety Code of Practice 5FranciscoVicenteNo ratings yet

- 2 CFPA-E Courses Organised in Countries: A A A A ADocument3 pages2 CFPA-E Courses Organised in Countries: A A A A AFranciscoVicenteNo ratings yet

- Catalogo General 1 PDFDocument140 pagesCatalogo General 1 PDFZulemaNo ratings yet

- Fire Protection Management System: CFPA-E No 1:2014 FDocument10 pagesFire Protection Management System: CFPA-E No 1:2014 FFranciscoVicenteNo ratings yet

- STANAG 7133eed02Document6 pagesSTANAG 7133eed02FranciscoVicenteNo ratings yet

- Defence Fire Safety Regulator: DSA02 DFSR - Defence Aerodrome Rescue & Fire Fighting (ARFF) RegulationsDocument56 pagesDefence Fire Safety Regulator: DSA02 DFSR - Defence Aerodrome Rescue & Fire Fighting (ARFF) RegulationsFranciscoVicenteNo ratings yet

- 2 CFPA-E Courses Organised in Countries: A A A A ADocument3 pages2 CFPA-E Courses Organised in Countries: A A A A AFranciscoVicenteNo ratings yet

- Install 13 SEER condensing unitDocument9 pagesInstall 13 SEER condensing unitalfredoNo ratings yet

- HP Compaq Notebook Pricelist: Intel Core I3 380 (2.4Ghz) 3Gb 320 GB W7Hb WLBT 15.6" 512 MB GraphicsDocument14 pagesHP Compaq Notebook Pricelist: Intel Core I3 380 (2.4Ghz) 3Gb 320 GB W7Hb WLBT 15.6" 512 MB GraphicsXris Loidz GanadoNo ratings yet

- Principles of Synthetic BiologyDocument21 pagesPrinciples of Synthetic BiologyOpale PapaleNo ratings yet

- ANU Issue 2Document64 pagesANU Issue 2Gideon GreigNo ratings yet

- Statistical Theory and Analysis in Bioassay OverviewDocument11 pagesStatistical Theory and Analysis in Bioassay OverviewEgbuna ChukwuebukaNo ratings yet

- Spark Plug ReadingDocument7 pagesSpark Plug ReadingCostas GeorgatosNo ratings yet

- SGM41542YTQF24G Ic Carga Moto g22Document47 pagesSGM41542YTQF24G Ic Carga Moto g22Gilson PereiraNo ratings yet

- Vapocresolene Fast FactsDocument2 pagesVapocresolene Fast Factsapi-275817812No ratings yet

- Question and AnsDocument33 pagesQuestion and AnsHawa MudalaNo ratings yet

- Teaching Organiser Bi Safeizal 2017Document9 pagesTeaching Organiser Bi Safeizal 2017safeizal100% (1)

- Manual Panasonic AG-DVC7Document4 pagesManual Panasonic AG-DVC7richercitolector01No ratings yet

- Aesseal Capi Dual SealDocument2 pagesAesseal Capi Dual SealSulaiman Kadher KNo ratings yet

- Tamil Nadu Govt Form for Testing Lab EMDocument4 pagesTamil Nadu Govt Form for Testing Lab EMPraveenNo ratings yet

- A Case Study On Strategies To Deal With The Impacts of COVID-19 Pandemic in The Food and Beverage IndustryDocument13 pagesA Case Study On Strategies To Deal With The Impacts of COVID-19 Pandemic in The Food and Beverage IndustryPeyman KazemianhaddadiNo ratings yet

- Economic and Eco-Friendly Analysis of Solar Power Refrigeration SystemDocument5 pagesEconomic and Eco-Friendly Analysis of Solar Power Refrigeration SystemSiddh BhattNo ratings yet

- 2nd Quarter Week 7Document5 pages2nd Quarter Week 7Lymieng LimoicoNo ratings yet

- Nucor at A Crossroads: Group-2, Section - BDocument8 pagesNucor at A Crossroads: Group-2, Section - BHimanshiNo ratings yet

- Critical Factors Influencing Infrastructure ProvisionDocument6 pagesCritical Factors Influencing Infrastructure Provisionlulut falaNo ratings yet

- Incremental Analysis Decision MakingDocument4 pagesIncremental Analysis Decision MakingMa Teresa B. CerezoNo ratings yet

- Flexi Edge Bts SystemDocument25 pagesFlexi Edge Bts SystemMuty Koma67% (3)

- What is Strategic Human Resource ManagementDocument8 pagesWhat is Strategic Human Resource ManagementYashasvi ParsaiNo ratings yet

- Analyzing Memory Bus to Meet DDR Specification Using Mixed-Domain Channel ModelingDocument30 pagesAnalyzing Memory Bus to Meet DDR Specification Using Mixed-Domain Channel ModelingVăn CôngNo ratings yet