Professional Documents

Culture Documents

Volvo 4600B

Volvo 4600B

Uploaded by

JOHN0 ratings0% found this document useful (0 votes)

90 views10 pagesOriginal Title

VOLVO 4600B

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

90 views10 pagesVolvo 4600B

Volvo 4600B

Uploaded by

JOHNCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

4600 B

VOLVO BM 460%

—A HIGH CAPAC

FOR THE REALL

For the fast, effective, high volume handling of heavy mate-

rials, the Volvo BM 4600 B is the economic answer.

You have at your command, a precisely engineered power-

pack composed of carefully matched, smoothly interacting

components. The Volvo Turbo diesel engine, transmission

and the loader unit's hydraulics, all work in total harmony to

give you the penetration and breakout force demanded when

the going gets really tough. The Volvo BM_4600 B is a 21

tonner with bucket volumes of 3.8-13 m? (5-17 yd’) and an

engine developing 185 kW (252 hp) DIN. The operator's

environment is really superb. From the comfortable cab, you

have light, positive, ingertip control over all loader unit move-

ments and steering, plus good allround visibility. This allows

you to work with effortless precision in all appl

IB

ITY LOADER

Y BIG JOBS

POWER

& ENGINEERING

The drive train is made up of Volvo BM com-

ponents manufactured toa very high techni-

al specification. The highest standards of

design engineering plus stringent production and

quality control, are your guarantee of total satisfaction.

In order to achieve good overall economy and maximum

machine utilisation, a good deal of effort has been

devoted to reduci

‘component co-ordin

yn and the exten

every detail.

1g parts stocking requirements through

n i ion of service intervals.

All this gives you an efficient, economical machine, reliable in

LOADER UNIT

The Volvo BM 4600 B has a rugged loader unit

Ideal for hard production work. The liftarms and

linkage geometry have been designed to provide in

abundance, the three qualities essential for a good

production’ loader: superior breakout forces

Ybroughout the ful it rads, excellent iting height

and good reach. These qualities enable the 4600 B

to dump into tall bins and load high sided vehicles

with ease. At the end of the rollback movement, the

bucket accelerates onto a mechanical stop, moving

the heap of a wel filled bucket to the rear. This

refinement reduces spillage and increases machine

stability.

Right attachment

Using the correct attachment for the material or

load to be handled, boosts capacity and profitabil-

ity, The 4600 B has therefore been equipped with a

wide range of quality, purpose-designed attach-

ments well matched to the machine and th

tasks. If the machine is to be used on a variety

of applications requiring frequent attachment

changes, the 4600 B can be fitted with a hydraulic

attachment bracket, enabling you to re-equip your

machine for an entirely different job in under a

minute.

CAB

‘A machine can be no more efficient than the

petson who rating it. Therefore the

‘operator and environment. warrants

special attention. A 4600 B operator works in a

very safe ROPS and FOPS tested cab. It Is

exceptionally comfortable, well insulated and

equipped with an efficient heating and ventilation

system to keep him fresh throughout a long

working shift. Ergonomics engineers, following

theoretical studies, have drawn up_ general

guidelines for the design and location of controls

nd instruments. Practical tests have then been

Carried out to fine-tune the perfect operator envi-

ronment.

Optional:

Automatic Power Shift

Volvo BM is always in the forefront of technologi

cal progress. The Volvo BM loader is available

with AUTOMATIC POWER SHIFT as an optional

extra, A specially programmed computer selects

the appropriate gear for every situation. The

operator works more effectively increasing the

machine’s capacity and improving fuel economy.

The 4600 B has the power fr hard work, combined

with nimble manoeuvrabllty and ample iting

eight and reach. These ar ideal characterities for

‘unloading large volumes of material.

Volvo Bhs ioader unit offers good breakout forces

in allpositions—even at the top. This i via feo

ture for working in timber and pulpwood terminal,

‘or example.

‘The 4600 B also has a high capacity for carrying

‘overfong dstances. The machine's ong wheelbase

‘and good weight dstrbutlon provide a stable ride

with high average speeds.

©

Flywheel rating

Gross rating

Max. torque

No. of eylinders

Bore

Stroke

Displacement

‘Compression ratio

Ac cleaning in.

three stages

Batteries

Voltage

Battery capacity

Alternator

Starter motor

Central warning

lamp fllosing

functions:

Speeds:

(tyres 265-25)

ENGINE

Volvo TD 101 G 6-cylinder, in-

line, direct-injected, turbo-

charged 4-stroke diesel engine

‘with Wet replaceable cylinder linings.

185 kW at 36:7 rps DIN 70020

(252 hp at 2.200 rpm DIN)

194 KW at 36.7 rps SAE J 270

(264 hp at2200 rpm SAE)

962 Nn at 23.3 eps DIN 70020

710 Ib feat | 400 ¢pm DIN)

(0m at 23.3 rps SAE 270

(723 Ibf feat 1400 rpm SAE)

6

120.65 mm (4.75 in)

140 mm (5.5 in)

9.6 litres (586 in?)

15:1

1. Cyclone precleaner with

exhaust ejector

2. Paper fter

3. Catch-all safety filter

ELECTRICAL SYSTEM

2.x 12V (connected in series)

2av

140 Ah

1,540 W (55 A)

6.6 KW (9 hp)

(For certain markets only)

Engine oil pressure, Brake

pressure, Parking brake, Engine

temperature, Transmission

temperature,

‘Transmission oil pressure.

TORQUE CONVERTER

Type Single-

stage

Torque,

multiplication ratio -2.69:1

TRANSMISSION

Type: Power-shift

Designation: VOLVO BM HT 200

Number of gears

forwardireverse 4/4

AXLES

Fully floating axle shafts with

planetary hub reductions.

Frontaxle: Designation Volvo BM.AH 70 A

Differential lock 100% lock-up (dog

clutch)

Rear axle: Designation Volvo BM AH 70D,

Oscillation +£15° (500 mm = 20 in)

BRAKE SYSTEM

Service brakes: Air over

hydraulic operated disc brakes,

dual system

Brake area: Front 792 em? (123 in2)iwheel

Rear 792m? (123 in?)wheel

Airreservoir volume 2X 20 litres + 1 x 10 litres

(254.4 UK gal + 1 x 22 UK gal)

Parking brake Encapsulated wet multiple-plate

brake built into transmission

Parking brake area: 1547 cm® (240 in)

TYRES

26.5R25"

STEERING

Orbityl steering with flow

amplification

Steering angle £37

Lock-to-lockturns ofwheel 43

Steering cylinder, borelstroke | 10/423 mm

em (43/167 in)

Piston tod diameter 50 mm (2.0 in)

Oil pump, type Vane pump

Suiput at 10 MPs

(1.450 psi) and 2.200 rpm

(36.7 ps) 190 vimin (41.8

UK gal'min)

Relief pressure 14 MPa (2.030 psi

1. 0-7. km/h (Q— 43 mph) (0- 1.9 m/s)

3 O14 karin 0-87 mony (0 3:88}

3, 0-27.5krv/h (0-17.0 mph

(0- 7.7 ms)

4. 0-40" krrvh (0-25.0 mph) (0-11.1 mvs)

DIMENSIONS 4600 B

G=2000(6'7")

700 mm (22")with- H = See table below io inner radius 3 810 mm (12°6")

‘utattachment J-=4 120mm (13'6%) a at = Steering ongle 437"

© =3550mm(11'8") KK = 4405 mm 145") Ri= 44°Carry position V = See table below

470mm(V'7) = Seetable below S'= 65° X =2310mm (77)

1220 man (") M= See table below 90 mmm (4°) ¥ = 3000mm (9'10%)

3500 mm (11°6") 2 table below 4iSmm(V'2") 2 = 4000mm(13'2")

‘Attachment Bucket Bucket Basket Bucket

ison hook on

jm? (ys?) 1800(3033) 1800(3033) 1600(2596) 1002528)

sieaee tasers A] fea [SETI (SEO (ESRESTY Fone

ee ee eee eee

vcccnnammmmmmmmmn tans aa sn ens,

Se ee ee ee ee ee

ia

rate ee ee ee

BERRI

oe ee Es a ee

a a

Lent mE!

— ee eee ee Cee cee

‘Specifications are based on a machine equipped with 2 3.6 m? (5

ya!) straight pin-on bucket without teeth and 26.5R25" tyres.

Wherever applicable, specications are in accordance with SAE

Standard J'232.e,9 748 bangs 819.

(C2 Chin rear esi only recommended for stabiling purposes in

feostapele hahding on had and Har grou

‘Aterate tres of Ca hing ‘Change n Beste data ‘Change insta oping load at ul tum kg)

‘Operating weight ig (8) Pinon Hook on

75% Ca Ch in ear tyes 265-25720 +1330 (43373) +2070(+ 4364) + 1820(+ 4012)

DIMENSIONS WITH TRUNCATED

BUCKET WITH TEETH

(Pin-on bucket 98934)

A= 8465 (27'9")

‘A= 670mm (22'10")

withoutattachment

160 mm (7'1")

5°

= 3550 mm (118) iB

B=" 470mm(1'7), 14° Carty position

E = 1500mm (4'11") i

F = 3500mm (1169 90mm (35°)

G = 2000 mm (6°77) 415mm (1'4")

H=2920mm (9°?) 200 mm (10°6")

J =4 120mm (13°67) 310 mm (7°7")

i= 4405mm (14'5) (000 mm (910")

L = 5860mm(19'3") (000 mm (13°1")

M=1430mm(4’8)

DIMENSIONS WITH SORTING GRAPPLE

(99999)

As3lm@G@3t) 1 =7400mm24'3")

B=4040mm(13'3") J =3200mm(10%e)

C= 2250mm(7'5) Kk = 4405 mm (14)

D=3100mm (102) L =2250mm(7'5")

E=1650mm(5'3") 260 mm (30'S)

F = 1900mm (6'3")

= 2950mm (9'8") Operatingload:7 700 kg

H=5050mm(16'7") (16975 1b)

Operating weight:21 400

kg (47 1781b)

HYDRAALIC SYSTEM

Pump, type (worn

| 6 | aul nn

ne pum

Output at 10 MPa

(1480 pal) and

36.7 rps (2200 rpm) 380 in (3.6K

gevmin

Relief pressure 17 MPa (2.465 psi)

Oil fiter:

Full-low filtration through filter cartridge with

magnetic core,

Hydraulic cylinders:

Lift-bore/stroke 170/1107 mm.

(6.7/43.6 in)

Piston rod diameter 80 mm (3.1 in)

Tilt-bore/stroke 140/983 mm,

(55/387 in)

Piston rod diameter 70 mm (2.8 in)

Loader uni

bint ‘SERVICE REFILL

CAPACITIES

Litres UK gal US gal

Crankease 31 68 82

Fuel tank 360-792 95.1

Cooling system 50 1 132

Hydraulic system, total 300 66 793

Hydraulic tank 230 506 608

Transmission and torque

converter, total 45 99 119

Front axle differential andhubs 45 99 119

Rear axle differentialandhubs 56 123 148

Control valve: Double-acting 3-spool valve, Lift func- CAB

tion has hold position for lit ik and float. Automatic Tesiend 5

control of lft and tit functions with cut-outas stand- Bp Tepiecand approved as solely

rd, The control valve is operated by a servo valve bin accordance with Ail.

Raise with SAE workload 78s ico 271-1901 Rae istestonActand

meets ISO 3471-1980, , -

Lower, without load als 1980 FOPS (SS872) and SS/ISO 6055 "Overhead

Dump 40s guards for lif-truck”, The cab is mounted on 4 rubber

ads ands well insulated and weathertight. All win-

Gows have bronze-tinted glass. The windshield is of

laminated safety glass, all other windows have tern-

peted glass

Heater and defroster Heating element with filtered

fresh air and 3-speed fan plus defroster for front, rear

and side windows

Operator's seat ISRIGI6000/575

Mountings for seatbelt Yes

OPTIONAL EQUIPMENT

(Standard equipment on certain markets)

‘© Heating flance © Return line, 3rd hy- © Toolkit © SMY plate

Electrical equipment draulic control © Ollimmersion pre- # Dual brake pedals

Norw ¢ 4th and 5th control, cleaner © Airoperated parking

* Protective giles for electricals ‘© Extractor fan brake

front service lights © Extra fue fiter ‘© Electricheatingflange © Radio panelwithout

Protective giles forrear @ Tyre inflation kit ‘© Lever interlock radio

‘working lg © Hydraulic attachment —@ ‘German version ‘© Low-emission version

Vent, bronze-tinted bracket * Road-dependentsafety Underground version

Passenger seat ‘© Airconditioning steering High-lit version

© Extraworkinglights, © Heated operator's seat @ Airhorn ropical version

front 2) halogen # Electric engine block Reversing alarm ‘Compactor ver

¢ Exteaworking lights, heater © Rotating beacon with xhalis gas coin

rear (2) halogen '* Rain guardforexhaust. collapsible mount ‘© Automatic Power Shift

* Workinglightatach- pipe Intermittent wiper (APs)

ment (halogen ¢ fndustriet hitch Washers, front and rear

o Falydrulccente! —$ Wheel nutwrench set

‘windows

SAFETY & COMFORT

© ROPS and FOPS cab Brake lights

© Cabheating with filtered Taillights

fresh air intake and Cab lightin:

defroster Instrument lighting

‘Openable window Direction indicators

Safety glass, windshield ® Mounting for seat belt

Tinted glass Seat belt

Ergonomically Binder holder

designed and adjust- ily box in cab,

able operator's seat Pressure gauge for air

Rear-view mirrors, brake system

external, 2 ‘© Instrument panel with

© Rear-view mirrors, in- symbols

ternal, 1 Sun visor

# Lights Safety start

Headlights Fenders

High/iowfasym. halogen # Hazard flashers

Parking lights Hom

‘Working lights forward ‘Tyre inflation outlet

(2)halogen Ashtray

Working lights rear (2) Cigarene ghter

Lifting lugs

en

Side marker lights

ENGINE & ELECTRICAL

SYSTEM

Ba

# Fuel gauge pressure, transmission

© Temperature gauge, Oil pressure, differential

engine Tock, parking brake,

© Teiperature gauge,

sdraulic transmission

© Hour meter

Electrical outlet 24 V

brake pressure hazard

flashers, air cleaner

For certain markets only

Batteny ‘disconnect

‘switcl © Central warning lamp:

Altnator Brake pressure,

3 Aircleanerwith ejector Engin oil pressure

* Pilot lamps for engine temperature,

Working lights front and transmission oil

rear, batety charging, pressure,

high beam, direction

transmission tempera

ture, parking brake

[ex] HYDRAULIC SYSTEM

© Control valve (3-spoo)). Servo-operated

© Bucket position indicator

© Bucket positioner and boom kick-out

indicators, engine oil

Vane pumps

Hydraulic oil cooler

‘Automatic lowering

4 POWER TRANSMISSION

Full Power Shift transmission

Differential lock (front axle)

Transmission cut-out valve

ingle-lever control

‘Tyres 265R25°

VOLVO BM

VOLVO BM AB ESKILSTUNA SWEDEN

gene he nit iochange eeeteatns an) 0h

Sionitesanduévarsonaterashac.

ENGELSKA

Ref No.21 2 669 1708 |

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- SM3184-3184XT, SM3884-3884XT, SM4688-4688XTDocument6 pagesSM3184-3184XT, SM3884-3884XT, SM4688-4688XTJOHN0% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Fuchs MHL 320Document2 pagesFuchs MHL 320JOHNNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- Loglift F95S 76,80, T97, T98Document4 pagesLoglift F95S 76,80, T97, T98JOHNNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Hiab 095Document2 pagesHiab 095JOHNNo ratings yet

- BMV LM 1254 211 2175 1970-07Document8 pagesBMV LM 1254 211 2175 1970-07JOHNNo ratings yet

- PROSPECTUS P 3500lDocument1 pagePROSPECTUS P 3500lJOHNNo ratings yet

- Hiab 045 1-2-3Document2 pagesHiab 045 1-2-3JOHNNo ratings yet

- Palfinger PK 13500CDocument1 pagePalfinger PK 13500CJOHNNo ratings yet

- Atlas 35Document1 pageAtlas 35JOHNNo ratings yet

- Palfinger PK 22000 BDocument4 pagesPalfinger PK 22000 BJOHNNo ratings yet

- PROSPECTUS P 2300lDocument1 pagePROSPECTUS P 2300lJOHNNo ratings yet

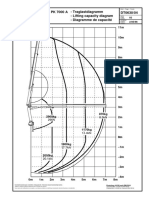

- PK 7000 A DT0630/04: - Traglastdiagramm - Lifting Capacity Diagram - Diagramme de CapacitéDocument1 pagePK 7000 A DT0630/04: - Traglastdiagramm - Lifting Capacity Diagram - Diagramme de CapacitéJOHNNo ratings yet

- KVM 34x br03 EngDocument8 pagesKVM 34x br03 EngJOHNNo ratings yet

- Genie z34.22Document37 pagesGenie z34.22JOHNNo ratings yet

- Liebherr A 932litronicDocument16 pagesLiebherr A 932litronicJOHNNo ratings yet

- LIEBHERR A 902 1986.03 DuitsDocument16 pagesLIEBHERR A 902 1986.03 DuitsJOHNNo ratings yet