Professional Documents

Culture Documents

Industrisl Structures 3

Industrisl Structures 3

Uploaded by

Rohan ARK0 ratings0% found this document useful (0 votes)

2 views4 pagesOriginal Title

Industrisl structures 3 (1)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views4 pagesIndustrisl Structures 3

Industrisl Structures 3

Uploaded by

Rohan ARKCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

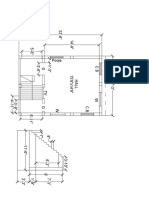

Example 9.9 Design an L-section purlin, for an industrial building situated

in the outskirts of Allahabad, to support a galvanised corrugated iron sheet

toof for the following data:

Spacing of the truss c/c = 6.0 m

Span of truss = 12.0 m

Slope of truss = 30°

Spacing of purlins c/c

Intensity of wind pressu

Weight of galvanised sheets =

Grade of steel = Fe 410

=15m

re = 2 kN/m?

130 N/m?

‘Scanned wih CamScanner

494 Limit State Design of Steel Structures

Solution For steel of grade Fe 410: f= 250 MPa

Weight of galvanised Corrugated iron sheets = 130 x

Assume dead load of purlin = 100 N/m

Total dead load = 195 + 100= 295 Nim

195 Nim

The dead load acts vertically downwards.

‘The component of dead load parallel to roof = 295 sin 30° = 147.5 Nim

‘The component of dead load normal to roof = 295 cos 30° = 255.477 Nim

Wind load is assumed to act normal to the roof.

Wind load 2x 10°X 1.5 «1 = 3000 Nin

Total load on purlin normal to the roof

= 3000 + 255.477 = 3255.477 Nim

Factored load normal to roof,

P = 1.5 x 3255.477 = 4883.20 N/m (Table 4.3, y= 15)

Factored load parallel to roof,

H=15x1475=221.25N/im — (Table 43, y=15)

PL _ (4883.20 x 6) x 6 x 10"

to +10

(221.25 x 6) x 6 x 10%

TE = a = 0.796 kN

Let us try a section with flange width by=75 mm and depth, d = 150 mm

Maximum moment, — M,, = M-

7.579 kNm

Maximum moment, M,,=M,

Plastic section modulus required, Zy. y= Mz ie #25 (2) (™ e)

[From Eq, 34)

17.579 x 10° x ate 25x we x 0.796 x 10° x ie 94.85 x 10'mm"

From Appendix VIII, ISMB 150 @ N/m furnishing plastic section modulus wis

tried (Z,, = 110.48 x 10° mm’), but it failed in deflection. Hence, let us provide

ISWBI50 @ 166.77 N/m with higher /, and Z,. values.

‘The sectional properties of ISWB 150 @ 166.77 Nim are:

Area, A= 2167 mm +

Depth of section, h

Zrcreq =

50mm «

Width of flange, by = 100 mm *

Thickness of flange, 0mm *

Thickness of web, 1,=5.4mm *

Radius at root, Ry, =8.0mm

Depth of web, d =h-2 (y+ Ry) = 150-2 (7 +8) = 120mm

Moments of inertia: 1, = 839.1 x 10° mm*, 1, = 94.8 x 10% mm*

126.86 x 10° mm?

Plastic section modulus, Z,

111.9 x 10° mm?, Z,, = 19.0 x 10° mn

Elastic section modulus, Z,

‘Scanned wih CamScanner

e

Beams

fean fics

sion classification

‘The outstand of flange,

section is plastic,

vign bending strength

= 126.86 x 10° x 29 x 19°

I 250

SH 12x 19x 108 2

Yo eT

shich is all right.

Also, My. 3. kN

> 17.579 kNm

shich is as should be.

7 oO

May = 2p 75S Ue Fig

= 6.477 kNm

Hence, M, lay = O-ATT kNm > 0.796 kNm

“hich is all right.

| capacity):

Check for overall member strength (local caps

M,

17.579 , 0.796 9733 <1

28.83 +6477

Which is all right.

‘Scanned wih CamScanner

= LLimix State Design of Stee! Structures

Check for deflection Deflection will be checked at service loads.

yt

477 x 102 x (6x 10°

2x 10° x 839.1 x 10°

= 32.73 mm

< 33.33 mm

‘Scanned wih CamScanner

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Analysis of Beams - 3rd ClassDocument6 pagesAnalysis of Beams - 3rd ClassRohan ARKNo ratings yet

- Analysis of SFD and BMDDocument8 pagesAnalysis of SFD and BMDRohan ARKNo ratings yet

- Types of BuklingDocument1 pageTypes of BuklingRohan ARKNo ratings yet

- UgghDocument1 pageUgghRohan ARKNo ratings yet

- Plan 3 ModelDocument1 pagePlan 3 ModelRohan ARKNo ratings yet

- FinalDocument1 pageFinalRohan ARKNo ratings yet