Professional Documents

Culture Documents

x9 Sell

Uploaded by

Nur Hasan Al-fayyadhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

x9 Sell

Uploaded by

Nur Hasan Al-fayyadhCopyright:

Available Formats

Using the Pro-Cut takes a fraction of the time compared to the

old bench lathe and you get an all around better cut!

Lou Vieceli · Shop Manager / Joe Rizza Ford of Orland Park, IL

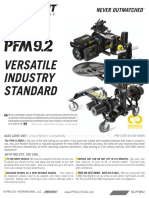

High Performance Platform PFM X9 W/ 6ADP SHOWN

The PFM X9 combines our best existing technologies, like patented PFM one button computerized compensation system and 4

wheel-4 axis fully adjustable trolley, and combines them with a rigid new X-Frame lathe chassis, powerful belt driven high-torque

drivetrain, and super bright 6 LED light to give you a clear path to higher profits! All X9’s come with our famous DRO display that

includes live run-out, productivity tracking, and lathe diagnostics. X9’s are digitally expandable to optional G2X and GYR systems.

WITH PRO-CUT, YOU CAN...

FIT ON EVERY VEHICLE. We have the adapters that will connect you SERVICE ANY CAR ON ANY LIFT IN 6-8 MINUTES. Two post, four

to almost any vehicle on the road today and the power to turn stiff post, drive-on, or even no lift....it doesn’t matter! Pro-Cut’s fully

all-wheel drive and truck axles. And our simple set-up is the same adjustable trolley allows you to roll up and mount your Pro-Cut lathe

from sub compact to dual wheel trucks. with confidence.

MATCHED ROTORS AS A NEW REVENUE SOURCE. Tires need to FREE ON-SITE DEMO. GIVE US A CALL. Still not convinced? Call

be balanced, wheels need to be aligned, and rotors need to be 1-800-543-6618 to set up a free on-site demo! Get hands on with

matched! Adding rotor matching to your service offerings adds a the Pro-Cut X9 Rotor Matching System with no obligations.

new revenue source.

© PRO-CUT INTERNATIONAL, LLC R03-2019 www.PROCUTUSA.com SS-X9

X9 / TECH SPECS

*6 LED ON-BOARD WORK LIGHT & LIGHTWEIGHT “X” BODY

PFM X9 BASE UNIT Free point of sale marketing program included!

STANDARD FEATURES BENEFIT

Includes BrakeSaver Point of Sale Marketing material Provides exceptional Return on Investment (ROI); 4-6 months is common in busier shops!

Patented one touch Lateral Run Out (LRO) compensation Press one button and the latest PFM lathes compensate in less than 20 seconds!

DRO “Live” digital computer display Displays actual live LRO of machine & tracks # of compensations and duration.

Custom Calibrated Rate Sensor Locks lathe in at .001” or less LRO every time you compensate for factory perfect cuts.

Cross Platform Compatible Computer & wiring harness Allows use of plug & play G2X measuring Cutting Head & full GYR Technology Package.

4 Wheel, 4 Axis, Adjustable Trolley Working Range of 21”to 43” allows the use on any lift or no lift!

2 YR parts & labor Warranty, 3 YR body warranty Match Rotors day in and day out with peace of mind.(maintenance & abuse not covered).

*6 LED on-board work light Improves technician safety and efficiency in dark wheel wells.

PFM X9 SPECIFICATIONS

SPEED LOCK CUTTING HEAD (Standard) PRECISION-MATCH CUTTING HEAD (Optional) MACHINE

Maximum Rotor Thickness 1.75” Maximum Rotor Thickness 2.00” Spindle Speed 118 RPM

Minimum Rotor Thickness 0.20” Minimum Rotor Thickness 0.20” Carriage Speed 0.005” / rev.

Maximum Rotor Diameter 16.4” to 17.6” Maximum Rotor Diameter 15.6” to 17.1” Motor 1.00 HP

Maximum Friction Face 3.30” Maximum Friction Face 3.82” Shipping Weight 200 lbs.

Maximum Depth of Cut 0.015” / Side Maximum Depth of Cut 0.020” / Side Electrical Supply 120v / 1ph / 60hz

Weight 7.68 lbs Weight 9.38 lbs Feed Distance 6.70” (7.48”Opt.)

Pro-Cut’s PFM lathes are the first choice of the brake service industry. We have been approved by virtually every auto manufacturer and are considered essential equipment by most OEM’s.

THIS SYSTEM IS SUBJECT TO ONE OR MORE OF U.S. PATENTS: 6,050,160 / 6,101,911 / 6,216,571 / 6,327,947 / 6,330,847 / 6,474,203 / 6,477,928 / 6,895,851 / 5,974,878 / 7,607,377

You might also like

- Fat Don - T FlyDocument87 pagesFat Don - T FlyTomás Tavares75% (4)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualNo ratings yet

- PC138US-8: Hydraulic ExcavatorDocument28 pagesPC138US-8: Hydraulic ExcavatorHitri Pepe100% (1)

- Eaton Performance Differential Application Guide enDocument32 pagesEaton Performance Differential Application Guide enAbhishek BansalNo ratings yet

- 3208 MARINE ENGINE 01Z00001-21746 (SEBP1297 - 07) - Sistemas y ComponentesDocument1 page3208 MARINE ENGINE 01Z00001-21746 (SEBP1297 - 07) - Sistemas y ComponentesalexkidneyNo ratings yet

- HRP Motor Sports Products and Services CatalogDocument16 pagesHRP Motor Sports Products and Services CatalogGus McGrathNo ratings yet

- Zx50u 2Document16 pagesZx50u 2Willington Augusto Ariza100% (1)

- Duo CM 42 DIZALiCADocument28 pagesDuo CM 42 DIZALiCASmisliNestoNo ratings yet

- 1467649249221Document683 pages1467649249221Dev Sigfried0% (2)

- Introducing The D155AX-6 Crawler Dozer: Sigma Dozer + VMR + Cab + 560mmDocument120 pagesIntroducing The D155AX-6 Crawler Dozer: Sigma Dozer + VMR + Cab + 560mmGerardo Marín100% (2)

- Ravi Piaggio Storm125Document4 pagesRavi Piaggio Storm125Syed Adil Javed0% (1)

- 1099935205four SpeedDocument6 pages1099935205four SpeedchzhptopNo ratings yet

- Discos de Friccion ExelDocument148 pagesDiscos de Friccion ExelHania BarajasNo ratings yet

- Markmanship SubjectDocument22 pagesMarkmanship SubjectHarold MendozaNo ratings yet

- Fleet MaintenanceDocument36 pagesFleet MaintenanceRery Dwi SNo ratings yet

- Stanley Level 1 and 2Document92 pagesStanley Level 1 and 2Cristian ZamudioNo ratings yet

- 12.25 QH1RC 627547 PDFDocument1 page12.25 QH1RC 627547 PDFpendexxNo ratings yet

- SS-7157028-18397893-012 SS Page 1 of 6: Page: M-1 of M-4 © 2017 Caterpillar All Rights Reserved MSS-IND-18397893-006 PDFDocument6 pagesSS-7157028-18397893-012 SS Page 1 of 6: Page: M-1 of M-4 © 2017 Caterpillar All Rights Reserved MSS-IND-18397893-006 PDFПавелNo ratings yet

- Introducing The D155AX-6 Crawler Dozer: Sigma Dozer + VMR + Cab + 560mmDocument120 pagesIntroducing The D155AX-6 Crawler Dozer: Sigma Dozer + VMR + Cab + 560mmGerardo Marín100% (1)

- PE12Document3 pagesPE12Katty Cedro Dela Cruz100% (1)

- GTZZ25J Technical OfferDocument24 pagesGTZZ25J Technical OfferPATRICIO FERNANDO MUÑOZ MORENO100% (2)

- ZF Friedrichshafen AG: Planetary Gearbox ForDocument8 pagesZF Friedrichshafen AG: Planetary Gearbox ForIgor Hurco Strahija100% (1)

- Volleyball OfficiatingDocument34 pagesVolleyball OfficiatingJuan Salvador BarcelonNo ratings yet

- C27 Spec SheetDocument5 pagesC27 Spec Sheetavinash_1229No ratings yet

- With Pro-Cut, You Can... : BASE LATHE UNIT / Cross-Platform CompatibilityDocument2 pagesWith Pro-Cut, You Can... : BASE LATHE UNIT / Cross-Platform CompatibilityMilos MilenkovicNo ratings yet

- BiG X 480 580 EN 144dpiDocument28 pagesBiG X 480 580 EN 144dpiAlencar Pedroso FilhoNo ratings yet

- 5hp19eDocument2 pages5hp19eDevine LightNo ratings yet

- CM20200806 Eccff 7f5a8Document4 pagesCM20200806 Eccff 7f5a8Yoyoo SusantoNo ratings yet

- SS-8588179-18397814-018 SS Page 1 of 6: Page: M-1 of M-4 © 2017 Caterpillar All Rights Reserved MSS-IND-18397814-006 PDFDocument6 pagesSS-8588179-18397814-018 SS Page 1 of 6: Page: M-1 of M-4 © 2017 Caterpillar All Rights Reserved MSS-IND-18397814-006 PDFJulio César Ccapcha PumaNo ratings yet

- T Series PDFDocument8 pagesT Series PDFDiego GonzálezNo ratings yet

- SS 7157028 18397893 016Document6 pagesSS 7157028 18397893 016Ali ToamaNo ratings yet

- Small Specalog For Cat D3 Track-Type TractorDocument4 pagesSmall Specalog For Cat D3 Track-Type Tractorlaptop.bmsNo ratings yet

- SS 7154026 18397814 001Document6 pagesSS 7154026 18397814 001Amr Abd ElrahmanNo ratings yet

- 6506 5757 308.8513.3.4-6 Serie6 Serie6.4 GB Low 1Document27 pages6506 5757 308.8513.3.4-6 Serie6 Serie6.4 GB Low 1jose mariaNo ratings yet

- Engine Rated Power: 63 KW (85 PS) Operating Weight ZAXIS110 Backhoe BucketDocument9 pagesEngine Rated Power: 63 KW (85 PS) Operating Weight ZAXIS110 Backhoe BucketEndro_182No ratings yet

- Shimpo Circulute 3000 CatalogDocument35 pagesShimpo Circulute 3000 CatalogElectromateNo ratings yet

- Okuma Industries Oil EnergyDocument17 pagesOkuma Industries Oil EnergySIMON S. FLORES G.No ratings yet

- Catalog Mast Explorer 2011Document32 pagesCatalog Mast Explorer 2011RafaélNo ratings yet

- Range SP9: Single-Wheeled Semi-Mounted PloughsDocument8 pagesRange SP9: Single-Wheeled Semi-Mounted PloughsSimona Nicoleta PaterauNo ratings yet

- 3508 SS 8769325 18377766 017 470kW 1200rpm PDFDocument6 pages3508 SS 8769325 18377766 017 470kW 1200rpm PDFayman akrabNo ratings yet

- 2018 - DVM 2017 - 5 AxesDocument16 pages2018 - DVM 2017 - 5 AxesAbhishek VelagaNo ratings yet

- Matco Tools Promo #19Document8 pagesMatco Tools Promo #19Jamie MiddletonNo ratings yet

- EN DX140W-5 Brochure 21 05 2019Document24 pagesEN DX140W-5 Brochure 21 05 2019LAliNo ratings yet

- Bridgeport Series I - BrochureDocument2 pagesBridgeport Series I - BrochureVVNo ratings yet

- JWX-10 Product Guide: Roland DG CorporationDocument21 pagesJWX-10 Product Guide: Roland DG CorporationSupport BiomedNo ratings yet

- SS-7157026-18377766-010 SS Page 1 of 6: Page: M-1 of M-4 © 2017 Caterpillar All Rights Reserved MSS-IND-18377766-006 PDFDocument6 pagesSS-7157026-18377766-010 SS Page 1 of 6: Page: M-1 of M-4 © 2017 Caterpillar All Rights Reserved MSS-IND-18377766-006 PDFAli mohamedNo ratings yet

- Polisher-ShineMate Catalogue-20187.1-ENDocument19 pagesPolisher-ShineMate Catalogue-20187.1-ENArie WibowoNo ratings yet

- 09 DynoDocument20 pages09 DynoMihaiLimNo ratings yet

- SeriesISellSheet1330D PDFDocument2 pagesSeriesISellSheet1330D PDFRicardo Alberto Ortegon BenjumeaNo ratings yet

- Bomag Single Drum Rollers 40Document12 pagesBomag Single Drum Rollers 40Alex TanNo ratings yet

- GF/LL Forest Machines: Superior Performance Simple OperationDocument4 pagesGF/LL Forest Machines: Superior Performance Simple OperationValery GandelNo ratings yet

- 6.dynomite Dynamometer Accessories Catalog PDFDocument52 pages6.dynomite Dynamometer Accessories Catalog PDFLanggeng PrasetyoNo ratings yet

- Atlas Copco Construction Tools - Facts BookDocument144 pagesAtlas Copco Construction Tools - Facts Bookmnowaq100% (1)

- Mitsubishi FG15N.......Document12 pagesMitsubishi FG15N.......johnNo ratings yet

- Mitsubishi TractorsDocument16 pagesMitsubishi TractorsKrzysztof MarzecNo ratings yet

- Mt700d Scr-Spec enDocument4 pagesMt700d Scr-Spec encouscousriderNo ratings yet

- Brochure XL Gamme Complète - V6Document4 pagesBrochure XL Gamme Complète - V6francoemanuelNo ratings yet

- CM20200806 Eccff 7f5a8Document8 pagesCM20200806 Eccff 7f5a8Maulana IqbalNo ratings yet

- Romp6 8-12Document2 pagesRomp6 8-12iyed dadaNo ratings yet

- PT 7Document127 pagesPT 7LuisMRMXNo ratings yet

- 11 Riveting MachinesDocument4 pages11 Riveting MachinesTecnicas Reunidas de AutomociónNo ratings yet

- 304 CR NGHDocument4 pages304 CR NGHtwrwtrtrNo ratings yet

- Boschrexroth 74200EN 01-03Document16 pagesBoschrexroth 74200EN 01-03ibnuharyNo ratings yet

- 2005 Auto Dyno CatalogDocument24 pages2005 Auto Dyno CatalogPetar MunizabaNo ratings yet

- Eisen: 618B / 818B Series Precision Surface GrindersDocument2 pagesEisen: 618B / 818B Series Precision Surface GrindersRam ViswanathanNo ratings yet

- Router Family BrochureDocument15 pagesRouter Family BrochurealexNo ratings yet

- Rose Parade Bands 1950 - 2006 by YearDocument21 pagesRose Parade Bands 1950 - 2006 by YearVideoteca Futbol Panama - Canal por Carlos KreitzNo ratings yet

- Spoyl - Design ChallengeDocument9 pagesSpoyl - Design ChallengeMadhuri RNo ratings yet

- Complete First For Schools - Test Unit Test 7 (PLUS)Document2 pagesComplete First For Schools - Test Unit Test 7 (PLUS)TheMageNo ratings yet

- English UTS Ganjil X 201819Document6 pagesEnglish UTS Ganjil X 201819Fauziahmuthmainnah FauziahuciNo ratings yet

- Coaster BrochureDocument14 pagesCoaster BrochureŁukasz MałkowskiNo ratings yet

- Bed MakingDocument8 pagesBed MakingV_RN100% (1)

- Dragon Age RPG Prefilled High Fantasy - 4Document3 pagesDragon Age RPG Prefilled High Fantasy - 4JayNo ratings yet

- 11-Year-Old Skateboarding Phenom Sky Brown May Be Heading To The 2020 Tokyo Summer Olympics Kids News ArticleDocument1 page11-Year-Old Skateboarding Phenom Sky Brown May Be Heading To The 2020 Tokyo Summer Olympics Kids News Article興隆國小劉欣頴No ratings yet

- South Asian GamesDocument2 pagesSouth Asian GamesANNENo ratings yet

- Department of Education: Special Program in Sports (SPS) and Physical EducationDocument42 pagesDepartment of Education: Special Program in Sports (SPS) and Physical EducationMikhaila FernandezNo ratings yet

- Harbinger - Beta RulesDocument92 pagesHarbinger - Beta Rulesmixmix1No ratings yet

- I - Fits and ToleranceDocument17 pagesI - Fits and TolerancelightsonsNo ratings yet

- History of ArnisDocument10 pagesHistory of ArnisRizzajoy Catubig CamusNo ratings yet

- Steyn City BrochureDocument36 pagesSteyn City BrochureCorey AcevedoNo ratings yet

- Sanguine DomainDocument1 pageSanguine DomainStefano D'EliaNo ratings yet

- TradingLab Trading JournalDocument21 pagesTradingLab Trading JournalAbayNo ratings yet

- EngDocument11 pagesEngIrfan SahibNo ratings yet

- TF 60 SNDocument5 pagesTF 60 SNTejon AguilarNo ratings yet

- Pe ReviewerDocument3 pagesPe ReviewerJhanela FayeNo ratings yet

- Transmission NoteDocument6 pagesTransmission Notesyariza ismailNo ratings yet

- Girls Outdoor RecordsDocument2 pagesGirls Outdoor Recordsapi-361936956No ratings yet

- General Information: Modification NoticeDocument13 pagesGeneral Information: Modification NoticeAnthonyNo ratings yet

- PhysioEx Exercise 9 Activity 1Document4 pagesPhysioEx Exercise 9 Activity 1MARILYN MARIANA HERNANDEZ MENDOZANo ratings yet