76 / 132kV INSULATED SINGLE CORE CABLES

7 6 5 4 3 2 1

DESCRIPTION

Circular stranded compacted copper or aluminium conductor, XLPE insulated, with copper wire screen and PE outer sheath.

Complies with Tenaga Nasional Berhad (TNB) Specification. (Refer to table 6.33)

CONSTRUCTION

1. Conductor

Plain circular compacted copper or aluminium conductor to IEC 228 class 2

2. Conductor Screen

Extruded semi-conductive thermo-setting compound

3. Insulation

Extruded superclean XLPE (cross-linked polyethylene)

4. Insulation screen

Extruded semi-conductive cross-linked polyethylene compound. It is firmly bonded to the insulation by virtue of the

simultaneous cross linking of insulation

The conductor screen, insulation and insulation screen are extruded by simultaneous triple extrusion process.

5. Metallic screen

Concentric round uncoated copper wires applied helically and shall be capable of carrying an earth-fault current of 25kA for 3

seconds

6. Radial water barrier

Laminated Aluminium Tape applied longitudinally or lead extruded

7. Outer sheath

Extruded black PE containing an effective termite repellant

APPLICATIONS

For installationon trays, ducts of direct burial.

NOTE : Cables complying with BS 6622 and customer’s specification are available upon request. Modifications which serve to improve our products will be

implemented without notice.

* Metallic sheath (Lead alloy ‘E’) and/or moisture barrier sheath (Laminated Aluminium foil) available upon request.

40

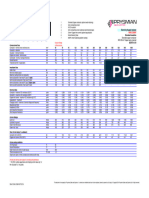

�CONSTRUCTION DATA

Table 6.33 76 / 132kV SINGLE CORE XLPE INSULATED WITH

COPPER WIRE SCREENED AND PE SHEATHED POWER CABLES

Nominal Screening Approx. weight of cable

cross- Nominal Nominal Nominal Approx.

sectional diameter of thickness of Thickness of extruded thickness of overall

area of conductor insulation sheath diameter Copper Aluminium

SC layer

conductor

mm2 mm mm mm mm mm kg/ km kg/ km

300 / 300 20.9 20.0 1.3 4.0 89 10655 8730

400 / 300 23.6 20.0 1.3 4.0 92 11700 9220

500 / 300 26.5 20.0 1.3 4.0 94 12890 9760

630 / 300 30.2 20.0 1.3 4.0 99 14560 10515

800 / 300 35.6 20.0 1.3 4.0 102 16480 11345

1000 / 300 39.0 20.0 1.3 4.0 107 18770 12280

41

� Milliken Conductor

The conductor of this cable is achieved by using a shaped segmental conductor design. Our design consists of five stranded

sector shape conductor segments with one central circular conductors separated by semi-conducting tape used to avoid

“Skin Effect” for an improve current carrying capacity. The conductor also features water-sealed properties which prevent

moisture ingress into and along the conductor for improve cable reliability and durability.

CONSTRUCTION

Conductor

The conductor of this cable is achieved by using a shaped segmental conductor design. It consists of five stranded sector

shape conductor segments with one central circular conductors.

Conductor screen

Extruded semi-conductive thermo-setting compound

Insulation

Extruded superclean cross-linked polyethylene (XLPE)

Insulation screen

Extruded semi-conductive cross-linked polyethylene compound. It is firmly bobded to the insulation by virtue of the

simultaneous cross-linking of insulation

Metallic screen

Concentric round uncoated copper wires applied helically and shall be capable of carrying an earth-fault current of 25kA for 3

second.

Radial water barrier

Laminated aluminium tape applied longitudinally or lead extruded

Outersheath

Extruded black PE containing an effective termite repellent

Graphite coating is provided to cater for on-site test.

42

�CONSTRUCTION DATA

76 / 132 kV MILLIKEN CONDUCTOR XLPE INSULATED WITH COPPER WIRE SCREENED

AND PE SHEATHED POWER CABLES

Nominal cross- Nominal Nominal Nominal area Nominal

Nominal overall Nominal weight of

sectional area of diameter of thickness of of Cu. Wire thickness of

diameter cable

conductor conductor insulation Screening sheath

mm2 mm mm mm2 mm mm kg/ km

1200 43.4 20.0 300 4.0 110.8 21149.0

1600 50.0 20.0 300 4.0 117.0 25510.6

Nominal cross-

Conductor

sectional area of Reactance Capacitance Current carrying capacity *

resistance at 20°C

conductor

mm2 ohm / km ohm / km microF/km kA

1200 0.0151 0.170 0.25 min. 1.23 or 282 MVA

1600 0.0113 0.108 0.27 min. 1.23 or 282 MVA

* The current carrying capacity are based on the following condition

Maximum conductor temperature : 90° C

Maximum ambient temperature : Air 37.2°C

: Ground 30°C

Ground thermal resistivity : 1.2ºC m/W

Laying depth : 1.2m

43

� Table 7.5 CURRENT RATINGS FOR

132 kV SINGLE CORE UNARMOURED XLPE CABLES

Conductor In air In ground

size (mm²) Trefoil (A) Flat (A) Trefoil (A) Flat (A)

Copper Conductors

300 645 695 495 570

400 735 810 555 651

500 850 945 615 745

630 975 1090 675 845

800 110 1260 750 950

1000 1220 1420 800 1030

Aluminium Conductors

300 485 540 400 445

400 560 635 455 510

500 650 745 510 590

630 745 870 570 675

800 845 1015 630 770

1000 970 1155 680 850

48

�TABLE 7.12 METRIC CONDUCTOR SIZES

AND RESISTANCE (20°C) FOR FIXED WIRING

Maximum d.c. resistance Maximum d.c. resistance

Conductor Metal coated Conductor Plain Metal coated

size (mm2) Plain copper Aluminium* size (mm2) Aluminium*

copper (ohm copper copper (ohm

(ohm / km) (ohm / km) (ohm / km)

/ km) (ohm / km) / km)

0.5 36.0 36.7 - 500 0.0366 0.0369 0.0605

0.75 24.5 24.8 - 630 0.0283 0.0386 0.0469

1 18.1 18.2 - 800 0.0221 0.0224 0.0367

1.5 12.1 12.2 -

1000 0.0176 0.0177 0.0291

2.5 7.4 7.56 -

1200 0.0151 0.0151 0.0247

4 4.61 4.70 7.41

6 3.08 3.11 4.61 1400 + 0.0129 0.0129 0.0212

10 1.83 1.84 3.08 1600 + 0.0113 0.0113 0.0186

16 1.15 1.16 1.91 1800 ‡ 0.0101 0.0101 0.0165

25 0.727 0.734 1.20 2000 ‡ 0.0090 0.0090 0.0149

35 0.524 0.529 0.868

50 0.387 0.391 0.641 1150 ‡ 0.0156 - 0.0258

70 0.268 0.270 0.443 1130 ‡ 0.0138 - 0.0228

95 0.193 0.195 0.320

120 0.153 0.154 0.253 380 - - 0.0800

480 - - 0.0633

150 0.124 0.126 0.206

600 - - 0.0515

185 0.0991 0.100 0.164

740 - - 0.0410

240 0.0754 0.0762 0.125

300 0.0601 0.0607 0.100 960 - - 0.0313

400 0.0470 0.0475 0.0778 1200 - - 0.0250

* includes metal-coared and metal clad

+ non prefered sizes in IEC 228

‡ sizes used for O.F. cables (not in IEC 228)

solid sectoral conductors (not in IEC 228 but standard for British

practice, BS 6360)

Except where stated, the data is in accordance with IEC 228 and

British Standards.

51

� Table 7.17 ELECTRICAL CHARACTERISTICS

18 / 30kV ARMOURED XLPE CABLES

Single-core cables* 3-core cables

A.C. resistance

Reactance (50Hz) A.C. resistance at 90°C

Conductor at 90°C Reactance

size (mm2) Capacitance Capacitance

Trefoil (50Hz)

Copper Aluminium Flat # (ohm (µF / km ) Copper Aluminium (ohm / km)

(µF / km )

(ohm /

(ohm / km) (ohm / km) / km ) (ohm / km) (ohm/km)

km )

70 0.342 0.568 0.143 0.194 0.16 0.342 0.568 0.135 0.16

95 0.247 0.411 0.134 0.189 0.18 0.247 0.411 0.127 0.18

120 0.196 0.324 0.129 0.184 0.19 0.196 0.325 0.122 0.19

150 0.160 0.264 0.125 0.178 0.21 0.159 0.265 0.118 0.21

185 0.128 0.211 0.121 0.174 0.22 0.128 0.211 0.114 0.22

240 0.0977 0.1600 0.116 0.169 0.250 0.0978 0.161 0.109 0.24

300 0.0785 0.1290 0.112 0.166 0.270 0.0788 0.130 0.105 0.26

400 0.0624 0.1010 0.107 0.162 0.290 - - - -

500 0.0500 0.0797 0.104 0.158 0.320 - - - -

630 0.0405 0.0630 0.099 0.155 0.350 - - - -

800 0.0388 0.0509 0.095 0.151 0.400 - - - -

TABLE 7.18 ELECTRICAL CHARACTERISTICS

132kV SINGLE CORE UNARMOURED XLPE CABLES

Single-core cables*

Conductor size A.C. resistance at 90°C Reactance (50Hz)

(mm2) Capacitance

Copper Aluminium Trefoil Flat # (µF / km )

(ohm / km) (ohm / km) (ohm / km ) (ohm / km )

300 0.078 0.129 0.147 0.198 0.130

400 0.060 0.099 0.140 0.190 0.140

500 0.049 0.078 0.132 0.182 0.160

630 0.039 0.062 0.127 0.173 0.170

800 0.032 0.050 0.121 0.165 0.195

1000 - 0.041 0.117 0.158 0.210

* Aluminium wire armoured

# Twice cable diameter spacing between centres

56

�Table 7.19 TEMPERATURE CORRECTION FACTORS

FOR CONDUCTOR RESISTANCE

Temperature of conductor (°C) Factor to convert to 20°C Reciprocal to convert from 20°C

5 1.064 0.940

6 1.059 0.944

7 1.055 0.948

8 1.050 0.952

9 1.046 0.956

10 1.042 0.960

11 1.037 0.964

12 1.033 0.968

13 1.029 0.972

14 1.025 0.976

15 1.020 0.980

16 1.016 0.984

17 1.012 0.988

18 1.008 0.992

19 1.004 0.996

20 1.000 1.000

21 0.996 1.004

22 0.992 1.008

23 0.988 1.012

24 0.984 1.016

25 0.980 1.020

26 0.977 1.024

27 0.973 1.028

28 0.969 1.032

29 0.965 1.036

30 0.962 1.040

35 0.943 1.060

40 0.926 1.080

45 0.909 1.100

50 0.893 1.120

55 0.877 1.140

60 0.862 1.160

65 0.847 1.180

70 0.833 1.200

75 0.820 1.220

80 0.806 1.240

85 0.794 1.260

90 0.781 1.280

The manufacturer reserves the right to modify or vary the construction or specification of any of the products at their dis-

cretion and without notice. The information contained herein is in line with the appropriate standards and sound eletrical

practice - it is believed to be reliable but as each application is unique, the manufacturer can accept no responsibility as

to the suitability of any product for a particular use, or for any error of omissions, unintentional or otherwise.

57