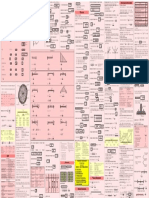

Complete Formula Chart Civil Engineering

Uploaded by

Kanav SharmaComplete Formula Chart Civil Engineering

Uploaded by

Kanav Sharma(v1 v 2 )2 Note: On principle plane shear stress will always 0.

Note: On principle plane shear stress will always 0. By Rate of introduction of super elevation: Surveying Chain: Revenue chain (33 ft), Gunter’s chain ENVIRONMENTAL ENGINEERING

Open-channel Flow

f p f c f 0 f c e kt Member max

Sudden expension: h l 2g Type of Structure Degree of Indeterminacy Ds

4PL , (66 ft), Engineer’s chain (100 ft), Metric chain

Radius of Mohr’s Circle (max): R

max min

max. 2. Circular Tapering Bar: L= D1D2 LS e.N. w w e (Rotation about inner edge) A member carrying compressive load

Steady unsteady

2D (plane) frames (3m+r)-3j 2 fp = Infiltration capacity at any time t, Equipments for Measurement Right Angles: Cross Variation of Demand resulting from dead load and imposed load 180

v2 v2 staff, optical square, Prism square. Max. daily Consump. = 1.8 × Annual avg. daily consump.

Entry Loss: h entry 0.5 2g , Exist of Pipe: h exit 2g 3D frames (6m + r)-6j Normal stress at Location of (max) (max-max shear f0 = initial infiltration,

A tension member in which reversal of

Uniform Gradually Rapidly Spatially Gradually Rapidly Spatially

PL e.N. w w e Tap Corrections:

canal flow Varied Varied Varied Varied Varied Varied

fc = Final steady state infiltration. LS (Rotation wrt centre line) direct stress due to load other than 180

2D (plane) Defection of Composit Bar: L1 =L 2 A1E1 A 2E 2

(GVF) (RVF) (SVF) (GVUF) (RVUF) (SVUF) 1 2 2 Maximum Weekly Consumption = 1.48 ×Avg. weekly

v v 2 2

c

Backing up Hydraulic Flow River flow in A surge Surface runoff

pin-jointed truss

(m+r)-2j stress): n

Correction for Slope: CS= L L2 h 2

wind and seismic force

Sudden Contraction: h contraction of water due Jump over alluvial reach moving due to 2 Maximum Monthly Consumption = 1.28 × Avg. monthly.

2g to dam side weir during rising

flood

upstream rainfall

3D truss (m+r)-3j Volumetric Strain of Rectangular: Deflection due to Self Weight of Bar: IRRIGATION 2

v2 Population Forecasting Mehtod A member subjected to compressive

2.7v

h2 forces resulting from wind EQ force 250

v2 Empirial Formula: LS R (Plain & Rolling) , LS R (Hilly area)

h fitting k. x y z Methods of Irrigation Correction for alignment or bad ranging: Cal = provide deformation of such member

Bending of the Pipe: 2g , k = constant, 1 2 / 3 1/ 2

Slope Deflection Equations V WL L2 2L Arithmetic Increase Method: P n = Po nx (For old cities) does not affect stress

Chezy’s Formula: V C RS , Manning equation V

n

R S0 v (1 2) 1. Prismatic Bar: 2AE 2E , Free flooding, Border flooding, Check flooding, Basin

T-Bend, k = 1.8, 90º-Bend, k = 1.2, 45º-Bend, k = 0.4 V E Correction for Temperature: Ct = (Tm-To)L Compression flange of Beam against

Dimension of C = L1/2 T–1, n = L–1/3 T1, f = Dimensionless flooding, Furrow Irrigation, sprinkler Irrigation, Drip 4.4 n

300

2EI 3 Length of Summit Curve: L 2S (L<SSD) r laterial torsional buckling.

M AB M FAB 2A B (Continuous Beam) Irrigation. N P P0 L Geometric Increases Method: Pn = Po 1 (For new cities)

l l Volumetric Strain of Cylindrical: v e 2 D WL L2 Correction for pull or Tension: CP= 100 A member normally act as a tie in

AE 350

Chart for Most Economical Sections

2. Conical Bar: 2AE 6E Roof Truss

MAB 3EI é d ù Volumetric Strain of Spherical: v 3 D Na NS2 n(n 1)

M BA = M BA - + êq - ú (one end is pin supported) Sodium Absorption Ratio: S.A.R L L(wL) 2 Tension member other than Pre-tension 400

GEDMETRICAL RECTANGULAR TRIANGULAR TRAPEZOIDAL 2 L ëê B L ûú Thermal Expansion: = ET, = LT Ca Mg 4.4 (L > SSD) Correction for Sag: CS = Incremental Increase Method: P n = Po nx

2

y

Relationship Between Elastic Constant: 24P 2

Important Points Coefficient of Thermal expansion (Aluminium > 2 Strength of plate between rivet holes in Tension =

PARAMETERS Important Terms Physical characteristics

E E Brass > Copper > Steel) 1/ 2

at × (p-d)x t

k 2G 9kG Nv 3 Bearing: Direction of a line with respect to fixed me- Turbidity: (limit 1-5 NTU) Baylis, Jackson, Nephelometer

my my G K E Length of Valley Curve: LS 2 C

y shear plane () 2(1 ) , 3(1 2) , 6k 2G , 3k G 2EA

(Comfort criteria) Bearing strength of rivet = at × d × t or = Pb×d×t.

1V:MH Pcr 2 (Euler's Theory) PR

c A

(Rankine 's Formula) Depth of water stored in root zone: dw

d. d

(FC M 0 )

ridian is called bearing. Colour: Tintometer (limit 5-15 TCU), Taste & odour: T.O.N = 1 ( | 3)

y IV:mH 1 . 2

y Number of independent Elastic Constant: w True Meridian/Bearing Temperature: 10ºC desirable ( | 25ºC)

DIAGRAM 1 Principle Shear Strength of rivet = Tvf d

2

(in single

plane () Homogenous & Isotropic = 2, Anisotropic = 21, NS2 NS2 True meridian is a line joining True North pole, Total solid = Dissolved solids + Suspended solids

B (n, max)

L > SSD: L (2h1 2Stan ) (1.5 0.035S) (h1 = 0.75, = 1°) True South Pole end and point of reference. It never

B Orthotropic = 9 3

(Gravimetric Method)

In case of Pure Bending: Z D .

Axial Elongation of the Prismatic Bar: Relation b/w duty and Delta: D (meter) , changes with time.

x x Chemical Characteristics 2

shear), 2 Tvf d in double shear), d = gross di-

B min (n,0) max PL 2PL (2h1 2S. tan ) Angle measured for any line w.r.t True Meridian is

Condition for most Economical y m = 1, = 45º Total solids & suspended solids: Limit 500-2000 ppm

2 L=

AE ,

L=

AE (for Instantaneous loading) T 16T 3 B = Base period in days, D = Duty in hectare/cumec L< SSD: L 2S N called Ture bearing.

PH = – log H+ (6.6 to 8.5) Methyl Orange & Phenolphthalein

In case of pure Torsion: max Zp D3 Zp

D

Irrigation Efficiency Bearing Taken W.r.t magnetic meridian is called mag- ameter of rivet, d 6.01 t (unwins formula)

2y 1 60º Hor. Deflection In Non-Prismtic Bars:

B m n Basic Capacity of Single lane, Vehicle Per hours: v netic Bearing. 50 50

3 3 30º Vert. Total Hardness: [Ca 2 ] + [Mg 2 ] (EDTA using EBT) Diameter: Grosss diameter = nominal diameter + 1.5

P1L1 P2L 2 f W vf k j 20 12

3600

y 1. Stepped Bar: L=

A1E1 A 2 E 2

b M E

(a) Water conveyance Efficiency: n c Wr 100 , = speed kmph, T(Sec/km) = , qmax , TM mm (if 25mm), Nominal diameter + 2mm (if >

Bending Equation: v 4 N M.M MM A Carbonate Hardness: min of total hardness or alkalinity

y I R

Where, Chloride: limit – 120mg/L (Water), 250 mg/L (Sewage) 25mm)

2

A (B my) y wf = water delivered to the farm, wr = water supplied A

Area A = B.y = 2y.y A my w Nitrogen Content: Limits: Free ammonia | 0.15mg/ Pitch: Should not exceed 16t or 200mm, which ever

SLOPE & DEFLECTION vf = Free mean speed, (Maximum speed at zero density.),

E

W kj = jam density, (Maximum density at zero speed), Maximum L, Organic Nitrogen | 0.3 mg/l, nitrite should be is less in tension member, and 12t or 200mm, which

s W E W E

2y 1 (b) Water appliacation Efficiency (na): na Wf 100 O O zero, nitrate | 45 mg/l ever is less in Compression Members. Tacking riv-

A 2y 2 Ay

2

A

3

yy

3

3 y 2

flow qmax occurs when the speed is

Vf

and density is kj/2.

2 Measurement (i) Free Ammonia-by simple boiling of ets should not exceed 32 t or 300 mm which ever is

P

L Number of potential conflicts: Both roads are two way water. (ii) Organic Ammonia – By adding Kmno 4 , less. Minimum pitch = 2.5d

B B Below the farm root-zone Wf Ws R f D f ,

Perimeter P 4y p 2 2y P 2 3y M = 24, Both road one way = 6, One road is two way, S S (i+ii) are known as kjeldahl Nitrogen Nitrite and

W

WS = Water stored in the root zone, other one way = 11 Eastern Declination Western Declination Nitrate by - colour Matching Method. Force due to axial load on each rivet: Fa =

n

y y A B Wf = Water delivered to the farm, Chemical: (Mn = 0.05 mg/L) (Iron – 0.3 mg/L),

Hydraullic Radius R y/2 R2 2 R

2 M.L PL2 WL3 Rf = Surface run off, Df = deep percolation e p

280w 1 1 Magnetic Declination (Fluride : 1.0 –1.5 mg/L) (Sulphate : 250 mg/L) (Cya- Mr

A = 0 B = B = B = w 3 , W e1 e2 Types of interchange: Trumpet,

EI 2EI 24EI Q

w weaving

2

3.5 Diamond, Full Cloverleaf,

At any place horizontal angle b/w True Meridian and nides = 0.2mg/L) (Arsenic : 0.01 ppm) Force due to moment M on any rivet: Fm = h 2

1 Partial Cloverleaf

(R = A/P) w l Magnetic Meridian is called magnetic Declination.

(c) Water use efficiency (nu): n u u 100 , Screening: Velocity | 0.8 to 1m/sec

ML2 PL3 WL4 wd For Eastern Declination: = B + E or T.B = M.B +E

4y A = 0 B = A = B = Floating Car Method: For Speed and delay study. 2 2

Area along Section: Ant = t b n d S1 S2

Top width (T) T 2y T 2y T

3

2EI 3EI 30EI For western Declination: = B – w or T.B = M.B – w Based on stokes law. Setting velocity: VS Q 4g 4g

wu = water used beneficialy, Note .L 1 2

w/m w2

100 Q

A B A B wd = water delivered. Aggregate crushing value: (+) Sign is used for declination is to the east, sign (–) Net Effective Area:

3 w1 Design Criteria: Over flow rate = BH , 500–750 lit/

Hydraullic Depth Dy D y/2 D y B M M L/2 c L/2 is used if declination is to west

4

s w hr/m2 for plain sedimentation, Depth = 03 to 4.5m

(d) Water Storage Efeiciency (ns): n s w n 100 , Fore bearing and Back Bearing: B.B = F.B 180º 3 A1

Loss of wt. in gm Width B 10 m A net A1 A 2 k1 k 1

A WL 3

ML ML Coefficient of Hardness: 20 Local Attraction: F.B – B.B 180º 3 A A 1 2

D B = A = B = A = B = 3 Coagulants

T 6EI 2EI 24EI

ws = water needed in the root zone prior to Irrigation, Latitude and Departure

Projection of a line on N-S direction is called lati- 1. Use of Alum l1

wn = (field capacity–Available moisture) A 1 (l1 t / 2 d ' )t A 2 (l 2 t / 2) t

WL4 ML2 ML Contact Pr essure 2. Use of copperas: (FeSo4,7H2O)

B = max @1/2 = c =

12EI

(e) Water Distribution Efficiency (n d ): Rigidity factor: R.F Tyre Pr essure tude: L l cos

8EI 8EI 3. Use of chlorinated copperas (Fe2(So4)3+FeCl3),

Heart Wood A net (l1 l 2 t)t

Note: Circular section (a) For maximum discharge 2 Outer Bark Projectione of a line on E-W direction is called 4. Use sodium Aluminate (Na 2Al 2O 4 )

w/m Y

n d 100 1 , Y = average numerical deviation in

l2

d k.(T.I)(90 R) deparature: D l sin Comparision of slow sand and Rapid Gravity Filters.

= 302º22, d = 0.938 D, (b) For maximum velocity 2 w/m

Pith A L/2 L/2 B California Resistance Value: t C1/ 5

Slow sand filter Rapid sand filter

c depth of water average depth stored during Irrigation (d). Adjustment of closing Error. Cu = 3—5 Cu = 1.2–1.6

A C B A B For pair of Angle Placed back to back connected by

= 257º27, d = 0.81 D Elastic Modulus: is maximum vertical deflection of Sum of all internal Angles of a closed Traverse: (2n– D10 = (0.2–0.3) mm D10 = (0.35–0.55) mm

Consumption Irrigation Requirements (CIR): CIR C u R e 4)×90º where n = No. of sides. Frequency of cleaning = (1–3) Cleaned through Back washing only one lag of each angle.

Type of flow Depth of Velocity of Froude Comments p.a

PL2 WL3 5 WL3 the flexible plate, , Rigid circular plate is Sum of all deflection Angle = 360º months

A = B = A = B = A = B = Fs

flow flow No 16EI 24EI 192 EI NIR Design period = 10 year n = 1.22 Q 5 A1

FIR Sum of latitude: L 0 A net A1 A 2 k 2 , K 2

Subcritical y > yc v < vc Fr < 1 As streaming or transquil Sap Wood Inner Bark Field Irrigation Requirement (FIR): na 5P.a

Use for smaller plants in village Rate of filtration (3000-6000)

5 A A 1 2

flow PL3 5 WL

4 used instead of flexible FS , a = radius of plate,

C = C = 384 EI Sum of departure: D 0 Design on max. daily demand. l/m2/hr The area of a web of Tee = Thickness of web × (depth

Critical y = yc v = vc Fr = 1 48EI p = pressure at deflection, Es = young’s modulus of

FIR Rate of filtration (100-200) l/m2/hr Operational Troubles– - thickness of flange)

Super Critical y < yc v > vc Fr > 1 Shooting flow, rapid P Gross Irrigation Requirement: GIR nc pavement material. Closing error In the Traverse: e = ( L) 2 ( D) 2 is very low as compared to (a) Air Binding

Medullary Rays 2L/3 max w/m

flow, torrential flow Cambium Layer M 1.75P A

1/ 2

R.S.F., but efficiency is High (b) Mud ball formations

A L/2 L/2

L B A B California Bearing Ratio M/D: t CBR , Bowditch’s Method (Compass Rule) (c) Cracking of filter Tacking rivet

C

NIR CIR LR PSR NWR , (GIR > FIR > NIR > CIR)

t = Pavement thickness in Cm, P = wheel load in kg, Permissible error in linear Measurment e 1. Minor Methods.

dy So Sf ROCK Classification

ML

Dynamic eq. for G.V.F.: B = A = B = C = A = B = C = 0 CBR = California Bearing Ratio (%), A = Contact Area (i) Boiling, (ii) Treatment with excess lime, (iii) Treat-

dx q2 4EI Kennedy’s theory: Vo 0.55.my0.64

1 3 in cm2 1 ment with ozone (KMNO4), (iv) Treatment with silver

gy

Gelogical Physical

Chemical

Permissible error in angular measurement e . Process.

Agrillaceous Silicious Calcareous 2L ML2 PL3 WL4

Stratified Unstratified foliated Max@ from A. C = C @ l/2 0.00155 1 Load or pressure Substained 2. Major Method Chlorination (Disinfection with Cl2)

Hydraulic Jump Eq. Igneous Sedimentary Metamorphic 3 27EI 192EI 384EI 23 at2.5 or 5.0 mm Penetration Gusset plate

S n RS

Rock Types Chemically Physically Geologically V CBR TEST: CBR pH 5

Cl2 H2O HOCl HCl , pH 8

H OCl

Kutter’s/ chezy’s Formula: 0.00155 n Load or pressure Substained Correction to latitude: CL = L HOCl M a z z

2q 2 (y 2 y1 )3

Granite Siliceous Unstratified Igneous P MAB 1 23 by standard aggregate at p y p p

y1y 2 (y1 y2 ) , 2. Energy Loss E = Quartzite Siliceous foliated/Stratified Metamorphic S R Shape Factor: S = M = a z

1. g L 4y1y 2 Marble Calcarious Stratified Metamorphic b B M W

corresponding pressure level. pH 7

HOCl H OCl– , NH3 HOCl 2 Cl H 2 O y yz

Limestone Calcarious Stratified Sedimentary c c A L B A B

Sandstone Siliceous Stratified Sedimentary a l/2 l/2 1/ 6 Correction due to departure: CD = D NH3 + HOCl is called combined chlorine. (Load factor = FOS × S)

Slate Argillacous Stratified Metamorphic Qf 2 Shape factor For different Shapes

y2 1 y3

Chlorine forms: Free chlorine, Hypochlorites (Swim-

3.

y1 2

1 8F12 1 , 4. y3 y1y2 (y1 y 2 )

c

Laterite Argillacous Stratified Sedimentary. MBA Lacey’s Theory: V

140

, f 1.76 d mm

Tri Axial Method:

3p. y

TP

2S

2 E

d S t1 E 2

1/ 3

ming Pool), Chloramines, Chlorine dioxide Section Shape factor

2

EP

t 2 E1 L D

Tools for Quarrying stones Transit Method: CL = L , C D D 1. Rectangular Section 1.5

11 2 Lr Dr

Jumper, Dipper, Crow bar, Tamping bar Pa 2 Pa 3 Pa2b ML

C = ’ BTotal = + (C = B) B = MAB = wl f 5/ 3 Formation of free chlorine and 2. Solid circular Section 1.7

Types of Jump Fr E L /E 1 Water surface 2EI 3EI 2EI 3EI 192 5 V2 Q Axis Method. Presence of chloro-organic

Test Purpose R S A p P 3. Triangular Section 2.34

Chlorine residual (p.p.m)

2 f 3340 Q1/ 6 0.5 compounds not destroyed

Undular 1-1.7 0 Undulating Smith test for presence of soluble matter

v Design of Rigid Pavement: k 0.125 II (vertex upward)

Weak 1.7-2.5 5 –1 8 % Small rollers form Pa 2 ML 5 1 Destruction of chloramines al

Brard’s test for frost resistance B = C + 1, 1 = b. A = = B /2 MBA = wl 2 closing error 0.4 and chloro organic comp du

Free residual

I resi 1 k3

Oscillating 2.5-4.5 1 8– 45 % Water oscillates in random

Acid test To check weather resistance

2EI 6EI 192

1/3

Correction of any length: That length 2 0.3 Formation of chloro-organic bine

d

4. Hallow circular Section 1.7

4

manner 2 1/ 4 Length of Axis compounds and chloramines m 1 k

d co

Steady 4.5-9 4 5– 70 % Roller and jump action Hardness test Mohr scale Pa 3 Pa 2 L ML 2

wetted perimeter P 4.75 Q scour depth 1.35 q Eh 3 C III

e an

Radius of Relative Stifiness: I 12K 1 2

0.2 Destruction of

B = b. max@ from A, max = 9 3 EI f , Direct levelling methods

chlorine by idu

al Fre 5. a. Diamand Section Rhombus 2.00

strong 9 70% Very rough and choppy 1 3EI 2EI 3 reducing compound res

ed

[Width of room Height of Room] 0.1 mbin

b. Thin Hollow Rhombus 1.50

Window Width = Difference B/W Lacey & Kennedy Theory Co D Break Combined residual

8 point 6. Thin Circular ring Solid 1.27

N P N Q Simple check Profile Reciprocal 0

4. DS < Dk 4. Dk < Ds Kennedy Lacey levelling levelling levelling levelling 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 7. I section

NS = (H)5/4 (for Turbine), NS = (H )3 / 4 (for Pump) • The sill of a window should be located about (70 – Pure Torsion Equation For Circular Shaft:

m pD Force Method/Flexibility Method/ Displacement Method/Stiffness 1. Trapezoidal channel 1. Semi elliptical channel Chlorine Added (p.p.m) a. About strong Axis 1.12

80) cm above floor level of the room. Hoop Strain: H (2 ) 2. Applicable for alluvial 2. Applicable for alluvial channels

b 1.6a 2 h 2 0.675h when (a < 1.724 h) Differential

levelling

Fly

levelling

cross-section

levelling

Precise

levelling b. About weak Axis 1.55

Laminar Transition Turbulent T G 4tE Compatibility Method Method/Equilibrium Method

channels as well as for rivers. Treatment With Water 8. T Section. 1.90 to 1.95

Flow in pipe Re < 2000 2000 < Re < 4000 Re > 4000 • Generally Height of a Door should not be less than J r L 5. (i) Virtual work/Unit load method (i) Slope deflection method Sensitivity: Angle b/w the line of sights in radius

3. Silt is kept in suspension 3. Silt is kept in suspension 3P

Flow between Re < 1000 1000 < Re < 2000 Re > 2000 (1.8 – 2) m (ii) Method of consistent deformation (ii) Moment distribution method St (Glodbeck’s formula) 1. Treatment with Copper Sulphate (CuSO4.H2O)

Combined Bending & Torsion: pD (iii) Elastic centre method (iii) Minimum potential energy

due to eddies generated due to eddies generated both h2 S l S Method of Analysis:

parallel plate

Longitudinal Strain: L 4tE (1 2) from bottom. from side slope and the bottom n 206265

Added to open reservoir and lakes to kill algae

Flow in open channel Re < 500 500 < Re < 2000 Re > 2000 • Commonly Width height relation used in India: method D R R nD

Flow through soil Re < 1 1 < Re < 2 Re > 2 i.e. through out the parameter. or to check the growth.

16 16 (iv) Column analogy method 365A [(1 r) n 1]

(i) Width = (0.4 – 0.6) Height max M M 2 T 2 , max M 2 T 2 4. No eq. for bed slope 4. Gave eq. to calculate bed slope N= × FD D = Distance of the instrument from the staff 2. Treatment with KMNO4 Plastic moment

D3 D3 (v) Three moment theorem r condition

pD 5. Recommended Kutter eq. 5. Gave his own velocity equation n = Number of divisions Acts as oxidizing agent to remove to taste, odour

BMC (ii) Height = (Width + 1.2) m Thin Spherical Pressure Vessels: n L 4t (vi) Castigliano’s theorem of

to find velocity Bankelman Beam Deflection Method l = length of one divison (2mm) and colour and to kill bacteria. (a) Lower bound theorem

minimum strain energy

Test of Cement • Doors of residential Buildings:

Equivalent Moment:

1

M eq M M 2 T 2

6. Trial & error procedure 6. Diret procedure

R = Radius of curvature 3. Aerations (P Pu )

2 (vii) Maxwell-Mohr equation. Dc Equilibirim

FINENESS TEST Sieve Method (a) External Door – (1 × 2) to (1.1 × 2) m pD Overlay Thickness: h0 = 550 log10 S = Staff intercept. For increasing Di-oxygen to remove CO 2, upto condition

S.SOROUT, 9255624029 Da

or t z 4t Check in Height of Instrument Method

Air permeability Method some extent removal of Fe and Mn. (a) Upper bound theorem

(Nurse and Blaine’s method)

(b) Internal Door – (0.9 × 2) to (1 × 2) m

Equivalent Torque: Teq M 2 T 2

HYDROLOGY FOLLOWING BOOKS Test

CBR test

Purpose

For classifying & evaluating soil subgrade & base BS– FS = Rise – Fall = Last RL–First RL 4. Fluoridation (P Pu )

Sedimentation mehtod (c) Doors for bathrooms and Water closets: E I

AVAILABLE BY course materials for flexible pavements Necessary if F < 1mg/L. Add Naf or Na2 SiF6 or H2SiF6 Mechanism

min

d2 1 d2 condition

(Wanger Turbidimeter Method)

– (0.7 × 2) to (0.8 × 2) m Euler’s Buckling Load: P 2eff . Water Budget Equation. P R G E T S

CIVIL Ki GOLI PUBLICATION:

Crushing test Strength of Aggregates

Curvature: CC = – = –0.0785d2. Refraction: Cr = to keep fluorine content between 1 to 1.5 mg/L

Theory Given by Remark Abrasion test Hardness of Aggregate 2R 7 2R

CONSISTENCY TEST Vicat’s Apparatus. Impact test Toughness of Aggregate (1) De-Fluoridation. (if F > 1.5 mg/L) In India, Treat-

Maximum Principle Rankine Suitable for Instruments used in measurement

SETTING TIME Vicat’s Apparatus. • Public Buildings (School, Hospital, library) End Condition of column: 1. CIVIL Ki GOLI Soundness test Durability of Aggregate Final Combination Correction: W

Stress or Brittle Shape test Gives idea of workability & stability of mix ment is done by Nalgonda Technique (Use Alum for

SOUNDNESS TEST Le-chatelier Method (a) (1.2 × 2) m (b) (1.2 × 2.1) m (c) 1.2 × 2.25) m Maximum Normal 2. CIVIL BOOSTER Bitumen Adhesion test Gives stripping value of Aggregates 6 d2 reducing flurides) Simply supported Beam

Relative humidity Psychrometer Name Isopleth L/2 L/2

Auto clave test Softening point test It is done by Ring & ball apparatus to ensure safety C = Cc– Cr = – = –0.06735d2

stress Humidity Hygrometer Isobar Pressure 3. REASONING Ki GOLI of Bitumen

7 2R 5. Removal of Radioactive Substances By coagulation & filtration.

TENSILE STRENGTH Briquette test Designation of Door = Length × Type of Door × Height

Maximum Principle St. Venant Can be applied for Wind speed Anemometer Isohyets Rainfall Float test for viscosity of Bitumen.

End One end fixed Both end Both end One end fixed • Distance of Visible Horizon 6. Desalination (i) By evaporation and distillation 4M P

HEAT OF HYDRATION Calorimeter test 8 DS 20 – A door opening Having width (8 × 100 mm) × Strain Brittle and Ductile condition one end free Hinged Fixed one end Hinged Rainfall depth Ombrometer Isonif Snowfall 4. HARYANA Ki GOLI Wu

(ii) Electrodialysis (iii) Reverse Osmosis. L

SPECIFIC GRAVITY TEST Le-chatelier’s Flask. Height (20 × 100 mm) with S (Single SHutter) D (Door) Maximum shear Guest and Suitable for Ductile Leff 2L L L/2 L

Transpiration

Evapotranspiration

Phytometer

Lysimeter

Isotherm Temperature

Isopleths Evapotranspiration

5. SOLUTION OF CIVIL Ki GOLI RAILWAY ENGINEERING d = 3.85 h , d = in km and h = in meter. 1 2 / 3 1/ 2

Test On Concrete Types of Window Stress Treseca (Theoretical) 2

Hydraulic design of sewers: V = R S W

Evaporation Atmometer Isohaline Salinity 6. ELECTRICAL & MECHANICAL Reciprocal Levelling: The true difference Elevation: n

Wc

8M P

WORKABILITY Slump test Maximum Strain Haigh and Ductile S + 10H dLt Fixed Beam

1. fixed 2. Pivoted 3. Sliding 4. Bay 5. Corner 6. Cable (7) ENGINEERING ROCKET CHART CSI = , Sleeper density = M + x, Oxgen Demand: = KL, L t L 10

k Dt

, L/2 L/2 L

Compacting factor Test Energy Beltrami 20 1 dt 0

Dormer (8) Skylights (9) Louvered (10) Lantern (11) Gable Annual Rainfall 7. CIVIL’S CAPSULE H= (h a h b ) (h a ' h b ') Eccentric Load

Vee-bee consistometer method Maximum shear Vonmises and Ductile 2

S–W GV 2 BODt = L 0 L t L 0 1 10 kDt [BOD5 = 0.684L0],

DIRECT TENSILE Cylinder Splitting Test Stairs Strain energy Hencky The Coefficient of var iation Dmin = ,e= Determining Areas: Mid ordinate rule (Area) = Av-

,

W

2 127R 2M PL

STRENGTH OF • No of steps are not more than 12 and not less than K DTº = KD20 [1.047]T-20 Fixed Beam: Wc

CONCRETE 3 in a flight. VAy Leff (As per

2L L 0.65L 0.8L

100 standard deviation 100 m-1 HIGHWAY ENGINEERING Length of transition curve erage ordinate × Length of base, =

O1 O2 .... On

L a b ab

Shear Stress: IS code.) Cv = = n Disinfection

BOND B/W CONCRETE Pull out Test • Angle of Inclination (Pitch) – (25° – 40). Ib mean P Roman Roads Tresaguet Construction Metcalf Construction Oil and Grease Trap Biological Unit SST Uniformly Load At Centre

Average ordinate Rule: Area D = Average ordinate of Bar Grit (Skimming Tank)

& STEEL • Head room must not be less than 2.05 m. Telford Construction Macadam Construction Screen chamber

I approach II approach W 8M

COMPRESSIVE Rebound hammer Test 2

m

(Pi P) 2 Nov. 1927 Jayakar Committee formed L Wc 2 P

• Minimum width of stairs in residential building – 2 6s d 2 Number of Stations

C

N v , 10%, m 1 i

,

Maximum of the following the base= O 0 O1 .... O n L, D D , SST L L

STRENGTH Shear Stress In Rectangular Section: q bd 3 4 y (q = ), Shaft In series: E m 1 Feb. 1928 Recommendations by Jayakar Committee n 1 (n 1) Sludge

85 cm and in commercial building is 1 m.

Screening PST studge

DYNAMIC MODULUS Resonant Frequency Test 1929 Central Road Fund 7.2e Grits

• Some Thumb rule: P1 = Precipitation magnitude in the ith station, D = D0 +....+On. Oil/Grease Underdrain 16M P

OF ELASTICITY TABLAB TBCLBC TCD LCD L = max 0.073eVmax (i) Railway board formula water Drying Beds Sludge Digester Wc

1934 Indian Road Congress Optional Unit L L2

(a) (2R + T) = 60 3 S S AD AB BC CD , AD 0.073D Vmax Simpson’s One-Third Rule: Wastewater Flow Dried sludge

Note: NDT Test on Hardened Concrete Where S = shear -force, qmax max q avg avg G ABJ AB G BCJ BC G CDJ CD 1 1939 Motor Vehicle act Gases

bd , (P

m

2 bd P Sludge Flow for disposal

(b) (R + T) = (40 – 45) m i i = mean precipitation d

Effluent for

6M P

Maturity test, Pull-out test, Penetration test, 1956 National Highway act e = S.E in cm L = 4.4 R

= 3 (Oo On ) 4 O1 O3 .... On 1 2(O 2 O4 ...O n 2 )

Gases final disposal L/2 L/2

Wc

(c) R × T = (400 – 450) Nagpur Plan Bombay Plan Lucknow Plan L

Ultrasonic pulse velocity T1L TL Normal ppt. = 30 years data, avg. annual ppt. = 35 years data L, R m Design Criteria for Grit Chamber: Setting veloc-

where R – Rise in cm, T – Tread in cm max

1.5 Shaft In parallel: 1 2 2 1943–1963 1961–1981 1981–2001 D = cant deficiency in cm (ii) Change of radial acceleration Trapezoidal Formula (Area mean area Method):

Manufacturing of Concrete aug G1J1 G 2J 2 Method for Calculation of Average Depth: Arithmetic w/m

• For residential building, common size of steps is Mean, Thiessen Polygon, Isohyetal Method

Road density Road density Road density ( S w )d2

Batching Mixing Transporting Placing 3.28V 3 A1 An ity VS (Min. VSelf = 0.45 m/s.)

(16 × 26) cm, IN Hospital etc. –(10 × 30) cm. 16 km/100 km2 32 km/100 km2 82 km/100 km2 L= V = d A2 A3 ... An 1 18 18 3M P

Compacting Finishing Curing Note: Shear stress at top & Bottom is always 0. Hyetograph (Time Vs Intensity), R 2 Wc

• In case of straight staircase, No. of Trade = (No. of Recommended Construction of A B L2

Workability Test 32P2 R 3 n

Mass curve (Time Vs Accumulated ppt) (iii) Rate of change of super Detention Time: 30-60S, Horizontal velocity of L

Riser – 1) 4 S 4S star & grid 1600 km of elevation f

In Circular Beam: q 3 R 4 R y

2 2

max Strain Energy in Spring: U Gd 4 Estimate of Missing Data: Fixed Hair Method: D = k × S + C, K= i 100 flow–15-30 cm/sec. Length to breath ratio of cham-

Slump test, compacting factor test, flow test, Vee-Bee

Total Height between floor and Roof 3R 2 , pattern Expressway L = 3.6e

consistometer No. of riser = ber varies from 6 to 15 and length to depth ratio var-

P1 P2 .... P1 ..... Pn 1 N (M ultiplying Constant), Addition Constent C = (f + 11.656M P

stock rail

Height of One Riser Stretcher bar A Wc

Pi v2 V2 ies form 40 to 30, cleaning interval = 1 or 2 weeks,

End of

Defects in Concrete 64PR 3 n P = N

=

N i 1 SSD: v.t 0.278v.t Over all length d),S = Staff intercept, i = Stadia interval, f = focal length B L2

4 Deflection : 2g(f 0.01n) 254(f 0.01n) Channel length = detention time × velocity of flow

Cracks, Crazing, Efflorescence, Segregation, Bleeding max avg. Gd 4 AB – Stock rail of object

STRENGTH OF MATERIAL 3

ht lead rail

A Comparision of Low-Rate and High- Rate Trickling Filters

Thiessen Mean Method : P = P1A1 P2 A2 ..... P6 A6 Outer straig tongue D B v Parameter Low rate High rate Lacings

Admixtures Superplasticizers, Air entrainers, Acceleraters, Retarders OSD: Vb .t (Vb .T 2S) V.T rve C CD Facing

NORMAL STRESS WHEN: x, Y & xyare given, Gd 4 (A1 A2 ..... A6 ) er cu rail direction v trickling filter Trickling filter 1. = between 40º to 70º, 2. Slenderness ration.

3S 2S Stiffness in spring: K 64R 3 n Check rail H O ut rail F

Property 1st class 2nd class 3rd class Lead

Compressive 10.5 7.0 x y y In Triangular Section: qmax / Imax bh avg / q avg

bh ,

Wing rail O Inner straight lead rail E Hydraullic loading in 1-4 10-40

x cos 2 sin2. Isohyetal Method : Most accurate 4S C L e Throw of m3/m2/d le

You might also like

- 14 - 3500 MCQs Practice Book - JDLCCE - SampleNo ratings yet14 - 3500 MCQs Practice Book - JDLCCE - Sample19 pages

- IES OBJ Civil Engineering 2003 Paper IINo ratings yetIES OBJ Civil Engineering 2003 Paper II16 pages

- Important Question Environmental EngineeringNo ratings yetImportant Question Environmental Engineering3 pages

- APPSC Assistant Engineer (Environmental Engineering) Official Paper-II (Held On - 14 May, 2022 Shift 2)No ratings yetAPPSC Assistant Engineer (Environmental Engineering) Official Paper-II (Held On - 14 May, 2022 Shift 2)38 pages

- Construction Equipments by Jaspal Sir - 220918 - 172529No ratings yetConstruction Equipments by Jaspal Sir - 220918 - 1725292 pages

- K Subramanyam - Hydrology - Abbreviation and AnswersNo ratings yetK Subramanyam - Hydrology - Abbreviation and Answers15 pages

- Syllabus - AE (Civil) PWD - Modified PDFNo ratings yetSyllabus - AE (Civil) PWD - Modified PDF2 pages

- Odisha OSSC JE CIVIL 2014 Paper 1 With Solution100% (1)Odisha OSSC JE CIVIL 2014 Paper 1 With Solution27 pages

- Ce8020 Maintenance Repair and Rehabilitation of Structures Reg 2017 Question BankNo ratings yetCe8020 Maintenance Repair and Rehabilitation of Structures Reg 2017 Question Bank7 pages

- Concrete Technology One Session One Subject by Sandeep JyaniNo ratings yetConcrete Technology One Session One Subject by Sandeep Jyani130 pages

- Civil Engineering RCC & Steel Design Exam Paper50% (2)Civil Engineering RCC & Steel Design Exam Paper4 pages

- Civil Engineering Model Exam: (Level-04 and Level-05)No ratings yetCivil Engineering Model Exam: (Level-04 and Level-05)3 pages

- Strength of Materials: Key Concepts & QuestionsNo ratings yetStrength of Materials: Key Concepts & Questions833 pages

- Chapter - 11 - Dam - Irrigation - Engineeriny Harshna VermaNo ratings yetChapter - 11 - Dam - Irrigation - Engineeriny Harshna Verma113 pages

- Sub Assistant Engineers Exam 2001 Questions100% (1)Sub Assistant Engineers Exam 2001 Questions7 pages

- Gate Material - Civil Engineering, Environmental Engineering Book100% (2)Gate Material - Civil Engineering, Environmental Engineering Book12 pages

- MPSC Civil Paper 1 and Paper 2 Descriptive100% (1)MPSC Civil Paper 1 and Paper 2 Descriptive22 pages

- GATE Civil Engineering Old Papers - Extract - ExtractNo ratings yetGATE Civil Engineering Old Papers - Extract - Extract402 pages

- 12 STD (Basic Civil Engineering - Theory & Practical)No ratings yet12 STD (Basic Civil Engineering - Theory & Practical)248 pages

- Short Notes: Engineers Wallah Civil Engineering Subject: Soil MechanicsNo ratings yetShort Notes: Engineers Wallah Civil Engineering Subject: Soil Mechanics65 pages

- Environmental Engineering-I Question BankNo ratings yetEnvironmental Engineering-I Question Bank11 pages

- Ce8701 Estimation, Costing and Valuation Engineering MCQNo ratings yetCe8701 Estimation, Costing and Valuation Engineering MCQ39 pages

- B.Tech 7th Sem (Civil) Question Papers-2019 BatchNo ratings yetB.Tech 7th Sem (Civil) Question Papers-2019 Batch12 pages

- Industrial Internship Report: Civil EngineeringNo ratings yetIndustrial Internship Report: Civil Engineering29 pages

- Assistant Engineer - Overseer Gr.1: Civil Engineering Exam SyllabusNo ratings yetAssistant Engineer - Overseer Gr.1: Civil Engineering Exam Syllabus12 pages

- Jharakhand JSSC JE PAPER With Key General Engineering 3 JulNo ratings yetJharakhand JSSC JE PAPER With Key General Engineering 3 Jul27 pages

- CIVIL ROCKET? CHART Civil Ki Goli (Civil Junction)67% (3)CIVIL ROCKET? CHART Civil Ki Goli (Civil Junction)1 page

- Fill in The Data For The Grey Shaded Areas Only: 2019 Inlet Spacing - Curb and Gutter Spreadsheet (English Units)No ratings yetFill in The Data For The Grey Shaded Areas Only: 2019 Inlet Spacing - Curb and Gutter Spreadsheet (English Units)3 pages

- Electrical Symbols and Abbreviations GuideNo ratings yetElectrical Symbols and Abbreviations Guide1 page