Professional Documents

Culture Documents

Automatic Transmission - 4R100 Diagnosis and Testing 2

Uploaded by

Bailey TincknellCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automatic Transmission - 4R100 Diagnosis and Testing 2

Uploaded by

Bailey TincknellCopyright:

Available Formats

307-01A-1 Automatic Transmission — 4R100 307-01A-1

DIAGNOSIS AND TESTING

Diagnostics Special Tool(s)

Transmission Tester

Special Tool(s) 307-F016 (007-00130) or

equivalent

UV Leak Detector Kit

164-R0756 or equivalent

Alignment Gauge, TR Sensor

307-351 (T97L-70010-A)

Transmission Fluid Pressure

Gauge

307-004 (T57L-77820-A)

MLP-TR Cable

418-F107 (007-00111) or

equivalent

Automotive Meter 73 III

105-R0057 or equivalent

Trans Tester TR/MLP Overlay

and Manual

007-00131 or equivalent

E4OD Transmission Cable

418-F037 (007-00107) or

equivalent

Diagnosing an electronically controlled automatic

transmission is simplified by using the following

Breakout Box, EEC-V Control procedures. One of the most important things to

System remember is that there is a definite procedure to

418-049 (T94L-50-EEC-V) or follow. DO NOT TAKE SHORTCUTS OR

equivalent

ASSUME THAT CRITICAL CHECKS OR

ADJUSTMENTS HAVE ALREADY BEEN

MADE. Follow the procedures as written to avoid

missing critical components or steps. By following

Worldwide Diagnostic System the diagnostic sequence, the technician will be able

(WDS) to diagnose and repair the concern the first time.

418-F224

New Generation STAR (NGS)

Tester

418-F052 or equivalent scan

tool

(Continued)

Copyright 2002, Ford Motor Company

Last updated: 9/23/2004 2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-2 Automatic Transmission — 4R100 307-01A-2

DIAGNOSIS AND TESTING (Continued)

On-Board Diagnostics with Scan Tool After carrying out the Quick Test, use the

NOTE: For detailed instruction and other diagnostic Transmission Drive Cycle Test for checking

methods using the scan tool, refer to the tester continuous codes.

manual and the Powertrain Control/Emissions 1. Record and then erase the Quick Test codes.

Diagnosis (PC/ED) manual 2. Warm the engine to normal operating

These quick tests should be used to diagnose the temperature.

powertrain control module (PCM) and should be 3. Make sure the transmission fluid level is

carried out in order. correct.

• Quick Test 1.0-Visual Inspection 4. With the transmission in OVERDRIVE,

• Quick Test 2.0-Set Up moderately accelerate from stop to 80 km/h (50

mph). This allows the transmission to shift into

• Quick Test 3.0-Key On, Engine Off

fourth gear. Hold speed and throttle open steady

• Quick Test 4.0-Continuous Memory for a minimum of 15 seconds.

• Quick Test 5.0-Key On, Engine Running 5. With transmission in OVERDRIVE, press

• Special Test Mode transmission control switch (TCS) (transmission

— Wiggle Test control illuminator lamp [TCIL] should

illuminate) and moderately accelerate from stop

— Output Test Mode to 64 km/h (40 mph). This allows the

• PCM Reset Mode transmission to shift into third gear. Hold

• Clearing DTCs speed and throttle open steady for a minimum

of 15 seconds (30 seconds above 4,000 ft

• OBD II Drive Cycle altitude).

• Other NGS Features 6. Press TCS (TCIL should turn off) and

• For further information on other diagnostic testing accelerate from 64 km/h (40 mph) to 80 km/h

features using the scan tool, refer to the (50 mph). This allows transmission to shift into

Powertrain Control/Emissions Diagnosis (PC/ED) fourth gear. Hold speed and throttle position

manual. Other diagnostic methods include the steady for a minimum of 15 seconds.

following. 7. NOTE: For 7.3L diesel applications: Tapping

— Parameter Identification (PID) Access Mode the brake pedal in fourth gear during an open

— Freeze Frame Data Access Mode throttle condition will not disengage the torque

converter clutch (TCC). The TCC will

— Oxygen Sensor Monitor Mode

disengage during a 4-3 coast downshift.

Transmission Drive Cycle Test With transmission in fourth gear and

NOTE: If equipped, turn the power take-off (PTO) maintaining steady speed and throttle opening,

unit off for correct test results. For a description of lightly apply and release brake to operate

PTO operation, refer to Transmission Electronic stoplamps. Then hold speed and throttle steady

Control System in this section. for an additional 5 seconds (minimum).

NOTE: Always drive the vehicle in a safe manner 8. Brake to a stop and remain stopped for a

according to driving conditions and obey all traffic minimum of 20 seconds.

laws. 9. Repeat Steps 4 through 8 at least five times.

NOTE: The Transmission Cycle Test must be 10. Carry out Quick Test and record continuous

followed exactly. Malfunctions must occur four codes.

times consecutively for the shift error DTC to be

set, and five times consecutively for the continuous

torque converter clutch code to be set.

NOTE: When carrying out the Transmission Drive

Cycle Test refer to the Solenoid Operation Chart for

correct solenoid operation.

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-3 Automatic Transmission — 4R100 307-01A-3

DIAGNOSIS AND TESTING (Continued)

After On-Board Diagnostics Before Pinpoint Tests

NOTE: The vehicle wiring harness, powertrain NOTE: Prior to entering pinpoint tests, check the

control module and non-transmission sensors can powertrain control module (PCM) wiring harness for

affect transmission operations. Repair these concerns correct connections, bent or broken pins, corrosion,

first. loose wires, correct routing, correct seals and their

After the On-Board Diagnostics procedures are condition. Check the PCM, sensors and actuators

completed, repair all DTCs. for damage. Refer to Powertrain Control/Emissions

Diagnosis (PC/ED) manual.

Always repair all non-transmission-related DTCs

first, then repair any transmission-related DTCs. NOTE: If a concern still exists after electrical

Refer to the following Diagnostic Trouble Code diagnosis has been carried out, refer to Diagnosis

Chart for information on condition and symptoms. By Symptom in this section.

This chart will be helpful in referring to the correct If DTCs appear while carrying out the on-board

manual(s) and to aid in diagnosing internal diagnostics, refer to the Diagnostic Trouble Code

transmission concerns and external non-transmission Chart for the appropriate procedure. Prior to

inputs. The pinpoint tests are used in diagnosing entering pinpoint tests, refer to any TSBs and

electrical concerns of the transmission. Make sure OASIS messages for transmission concerns.

the vehicle wiring harness and the powertrain

control module are diagnosed as well. The

Powertrain Control/Emissions Diagnosis (PC/ED)

manual will aid in diagnosing

non-transmission-related electronic components.

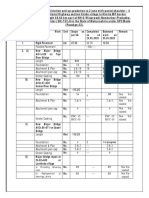

Diagnostic Trouble Code Charts

Diagnostic Trouble Code Chart

Diagnostic

Trouble

Code Component Description Condition Symptom Action

P1111 System Pass No concern Concern not Refer to the

detected. detected by PCM. Powertrain

Control/Emissions

Diagnosis (PC/ED)

manual.

P0340, DI DI system Engine rpm circuit CKP sensor Refer to the

P0341, concern. failure. failure/engine will Powertrain

P0344 stall or not run. Control/Emissions

May flash TCIL. b Diagnosis (PC/ED)

manual.

P0237 Manifold MAP sensor out MAP sensor signal — Rerun On-Board

Absolute of On-Board higher or lower Diagnostics.

Pressure Diagnostics than expected or no

(MAP) range. response during

Sensor Dynamic Response

(Goose) Test.

P0236 Manifold MAP sensor MAP sensor signal Firm shift feel, late Refer to the

Absolute vacuum circuit higher or lower shifts at altitude. Powertrain

Pressure failure. than expected or no Control/Emissions

(MAP) response due to Diagnosis (PC/ED)

Sensor vacuum hose, manual.

circuit damaged,

disconnected or

restricted.

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-4 Automatic Transmission — 4R100 307-01A-4

DIAGNOSIS AND TESTING (Continued)

Diagnostic Trouble Code Chart (Continued)

Diagnostic

Trouble

Code Component Description Condition Symptom Action

P0235 Manifold MAP sensor MAP sensor or Firm shift feel, late Refer to the

Absolute inactive. circuit open, shorted shift at altitude. Powertrain

Pressure to ground or 5V. Control/Emissions

(MAP) Diagnosis (PC/ED)

Sensor manual.

P1124 Throttle TP sensor out of TP sensor (gasoline — Rerun at appropriate

Position On-Board engines) not at idle TP sensor position

(TP) Sensor Diagnostics position during per the engine

range. KOEO. application.

P0500, VSS/ABS Insufficient or PCM detected a Harsh engagements, Refer to the

P1502 intermittent loss of vehicle firm shift feel, Powertrain

vehicle speed speed signal during abnormal shift Control/Emissions

input. operation. schedule, Diagnosis (PC/ED)

unexpected manual.

downshifts may

occur at closed

throttle, abnormal

TCC operation or

engages only at

WOT. May flash

TCIL.

P0500, VSS/ABS Insufficient or PCM detected a Harsh engagements, Refer to the

P1502 intermittent loss of vehicle firm shift feel, Powertrain

vehicle speed speed signal during abnormal shift Control/Emissions

input. operation. schedule, Diagnosis (PC/ED)

unexpected manual.

downshifts may

occur at closed

throttle, abnormal

TCC operation or

engages only at

WOT. May flash

MIL.

P0503 VSS/ABS Vehicle speed PCM detected a Possible fluctuation Refer to the

sensor loss, or an in the speedometer. Powertrain

intermittent. unrealistic change May flash TCIL. Control/Emissions

of vehicle speed Diagnosis (PC/ED)

signal during manual.

operation.

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-5 Automatic Transmission — 4R100 307-01A-5

DIAGNOSIS AND TESTING (Continued)

Diagnostic Trouble Code Chart (Continued)

Diagnostic

Trouble

Code Component Description Condition Symptom Action

P0781, SSA, SSB or 1-2 shift error. Engine rpm drop Incorrect gear GO to Pinpoint Test

P0731 a Internal not detected when selection depending A.

Transmission 1-2 shift was on failure mode and

Components commanded by transmission range

PCM. selector lever

position. Refer to

the Solenoid

Operation Chart.

Shift errors may

also be due to other

internal

transmission

concerns such as

stuck valves or

damaged friction

material. May flash

TCIL.

P0782, SSA, SSB or 2-3 shift error. Engine rpm drop Incorrect gear GO to Pinpoint Test

P0732, Internal not detected when selection depending A.

P0733a Transmission 2-3 shift was on failure mode and

Components commanded by transmission range

PCM. selector lever

position. Refer to

the Solenoid

Operation Chart.

Shift errors may

also be due to other

internal

transmission

concerns such as

stuck valves or

damaged friction

material. May flash

TCIL.

P0783a SSA, SSB or 3-4 shift error. Engine rpm drop Incorrect gear GO to Pinpoint Test

Internal not detected when selection depending A.

Transmission 3-4 shift was on failure mode and

Components commanded by transmission range

PCM. selector lever

position. Refer to

the Solenoid

Operation Chart.

Shift errors may

also be due to other

internal

transmission

concerns such as

stuck valves or

damaged friction

material. May flash

TCIL.

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-6 Automatic Transmission — 4R100 307-01A-6

DIAGNOSIS AND TESTING (Continued)

Diagnostic Trouble Code Chart (Continued)

Diagnostic

Trouble

Code Component Description Condition Symptom Action

P0122 TP or AP TP or AP sensor Voltage above or Harsh engagements, Refer to the

Sensor circuit below below specification firm shift feel, Powertrain

minimum voltage, for On-Board abnormal shift Control/Emissions

(open/shorted to Diagnostics or schedule, abnormal Diagnosis (PC/ED)

ground). during normal TCC operation or manual.

vehicle operation. does not engage.

May flash MIL.

P0123 TP or AP TP or AP sensor Voltage above or Harsh engagements, Refer to the

Sensor circuit above below specification firm shift feel, Powertrain

maximum voltage for On-Board abnormal shift Control/Emissions

(short to vehicle Diagnostics or schedule, abnormal Diagnosis (PC/ED)

power). during normal TCC operation or manual.

vehicle operation. does not engage.

May flash MIL.

P1120 Throttle TP sensor voltage Voltage below Harsh engagements, Refer to the

Position lower than specification. firm shift feel, Powertrain

(TP) Sensor expected. abnormal shift Control/Emissions

schedule, abnormal Diagnosis (PC/ED)

TCC operation or manual.

does not engage.

P1780 TCS TCS not changing TCS not cycled No overdrive cancel Rerun diagnostics

state. during On-Board when switch is and cycle switch.

Diagnostics/circuit cycled. Refer to the

open or shorted. Powertrain

Control/Emissions

Diagnosis (PC/ED)

manual.

P0712 TFT Sensor 157°C (315°F) Voltage drop across TCC and stabilized GO to Pinpoint Test

indicated, TFT TFT sensor exceeds shift schedule may B.

sensor circuit scale set for be enabled sooner

grounded. temperature of after cold start.

157°C (315°F). May flash TCIL.

P0713 TFT Sensor -40°C (-40°F) Voltage drop across TCC and stabilized GO to Pinpoint Test

indicated, TFT TFT sensor exceeds shift schedule may B.

sensor circuit scale set for be enabled sooner

open. temperature -40°C after cold start.

(-40°F). May flash TCIL.

P1711 TFT Sensor TFT sensor out of Transmission not at — Warm vehicle to

On-Board operating normal operating

Diagnostics temperature during temperature and

range. On-Board rerun On-Board

Diagnostics. Diagnostics.

P1713 TFT No change in PCM has detected May flash TCIL. GO to Pinpoint Test

TFT — Low no TFT change at B.

range. low range during

operation.

P1718 TFT No change in PCM has detected May flash TCIL. GO to Pinpoint Test

TFT — High no TFT change at B.

range. high range during

operation.

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-7 Automatic Transmission — 4R100 307-01A-7

DIAGNOSIS AND TESTING (Continued)

Diagnostic Trouble Code Chart (Continued)

Diagnostic

Trouble

Code Component Description Condition Symptom Action

P1783 TFT Sensor Transmission Transmission fluid Slight increase in GO to Pinpoint Test

overtemp temperature electronic pressure B.

condition. exceeded 132°C control pressure

(270°F). when RPMs are

greater than 2,500.

May flash TCIL.

P1460 A/C A/C switch error. DTC can result Failed on — Refer to the

P1463 from A/C being ON electronic pressure Powertrain

P1464 during On-Board control pressure Control/Emissions

Diagnostics. slightly low with Diagnosis (PC/ED)

A/C off. Failed off manual.

— electronic

pressure control

pressure slightly

low with A/C on.

P0705 Digital TR Digital TR circuit Digital TR circuits, Increase in EPC GO to Pinpoint Test

Sensor failure. indicating an pressure (harsh D.

invalid pattern in shifts). Defaults to

TR D. Condition (D) or D for all

caused by a short to gear positions. In

ground or an open (D) position

in TR4, TR3A, transmission stuck

TR2, and/or TR1 in D or manual 2.

circuits. May flash MIL.

P0708 Digital TR Digital TR sensor Digital TR sensor Increase in EPC GO to Pinpoint Test

circuit TR3A circuit TR3A pressure. Defaults D.

open. reading 2.6v - 5.0v to (D)or D for all

(open circuit). gear ranges. May

flash MIL.

P1702 Digital TR Intermittent DTC Refer to DTC codes Refer to DTC codes GO to Pinpoint Test

codes P0705 or P0705 or P0708 P0705 or P0708 D.

P0708. condition. symptom. May

flash TCIL.

P1704 Digital TR Digital TR circuit Digital TR sensor Wrong commanded GO to Pinpoint Test

reading in or shift cable EPC pressure. D.

between gear incorrectly adjusted, Digital TR reading

position during or digital TR circuit the wrong gear

KOEO. failure. position.

P1705 Digital TR Digital TR sensor KOEO/KOER not Rerun on-board GO to Pinpoint Test

Sensor circuits not run in PARK or diagnostic in Park. D.

reading PARK or NEUTRAL, or KOEO/KOER.

NEUTRAL Digital TR circuit

during failure.

KOEO/KOER.

P0102, MAF Sensor MAF sensor MAF sensor system High electronic Refer to the

P0103, DTC. fails to operate in a pressure control Powertrain

P1100, normal manner, pressure. Firm shifts Control/Emissions

P1101 which may cause a and engagements. Diagnosis (PC/ED)

transmission May flash TCIL. manual.

concern.

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-8 Automatic Transmission — 4R100 307-01A-8

DIAGNOSIS AND TESTING (Continued)

Diagnostic Trouble Code Chart (Continued)

Diagnostic

Trouble

Code Component Description Condition Symptom Action

P0107 BARO BARO circuit BARO signal lower Firm shift feel, late Refer to the

failure. than expected. shifts at altitude. Powertrain

Control/Emissions

Diagnosis (PC/ED)

manual.

P0108 BARO BARO circuit BARO signal Firm shifts, late Refer to the

failure. higher or lower shifts at altitude. Powertrain

than expected. Control/Emissions

Diagnosis (PC/ED)

manual.

P1703 BPP Switch Brake not Brake not cycled Failed on or not Rerun On-Board

actuated during during KOER. connected — TCC Diagnostic and

On-Board will not engage at activate BPP switch.

Diagnostics. less than one-third Refer to the

throttle. Powertrain

Control/Emissions

Diagnosis (PC/ED)

manual.

P0730, BPP BPP switch BPP circuit failure. Failed off — TCC Refer to the

P0751 circuit failed. will not disengage Powertrain

when brake is Control/Emissions

applied. Diagnosis (PC/ED)

manual.

P0750 b SSA Shift solenoid SSA circuit failed Incorrect gear GO to Pinpoint Test

circuit failure. to provide voltage selection depending A.

drop across on failure mode and

solenoid. Circuit transmission range

open or shorted or selector lever

PCM driver failure position. Refer to

during KOEO. the Solenoid

Operation Chart.

May flash MIL.

P0753 SSA Shift solenoid SSA circuit failed Incorrect gear GO to Pinpoint Test

circuit failure. to provide voltage selection depending A.

drop across on failure mode and

solenoid. Circuit transmission range

open or shorted or selector lever

PCM driver failure position. Refer to

during KOEO. the Solenoid

Operation Chart.

May flash TCIL.

P0755b SSB SSB circuit SSB circuit fails to Incorrect gear GO to Pinpoint Test

failure. provide voltage selection depending A.

drop across on failure mode and

solenoid. Circuit transmission range

open or shorted or selector lever

PCM driver failure position. Refer to

during KOEO. the Shift Solenoid

Operation Chart.

May flash MIL.

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-9 Automatic Transmission — 4R100 307-01A-9

DIAGNOSIS AND TESTING (Continued)

Diagnostic Trouble Code Chart (Continued)

Diagnostic

Trouble

Code Component Description Condition Symptom Action

P0758 SSB SSB circuit SSB circuit fails to Incorrect gear GO to Pinpoint Test

failure. provide voltage selection depending A.

drop across on failure mode and

solenoid. Circuit transmission range

open or shorted or selector lever

PCM driver failure position. Refer to

during KOEO. the Shift Solenoid

Operation Chart.

May flash TCIL.

P1714 SSA SSA malfunction. Mechanical failure Incorrect gear GO to Pinpoint Test

of the solenoid selection depending H.

detected. on condition, mode

and manual lever

position. Refer to

Solenoid Operation

Chart. May flash

TCIL. May flash

MIL.

P1715 SSB SSB malfunction. Mechanical failure Incorrect gear GO to Pinpoint Test

of the solenoid selection depending H.

detected. on condition, mode

and manual lever

position. Refer to

Solenoid Operation

Chart. May flash

MIL.

P1636 SSA, SSB Inductive PCM has detected Incorrect gear GO to Pinpoint Test

signature chip an internal error. selection depending H.

communication on condition, mode

error. and manual lever

position. Refer to

Solenoid Operation

Chart. May flash

MIL.

P1740 TCC TCC malfunction. Mechanical failure Harsh shift, may GO to Pinpoint Test

of the solenoid flash TCIL. H.

detected.

P1754b CCS CCS circuit CCS failed to Failed off — no GO to Pinpoint Test

failure. provide voltage third gear engine G.

drop across braking in overdrive

solenoid. Circuit cancel. Failed on —

open or shorted or third gear engine

PCM driver failure braking in overdrive

during KOEO. range. Coast clutch

may be damaged

causing eventual

failure. May flash

TCIL.

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-10 Automatic Transmission — 4R100 307-01A-10

DIAGNOSIS AND TESTING (Continued)

Diagnostic Trouble Code Chart (Continued)

Diagnostic

Trouble

Code Component Description Condition Symptom Action

P0743b TCC TCC solenoid TCC solenoid Short circuit — GO to Pinpoint Test

solenoid circuit failure. circuit fails to engine stalls in C.

provide voltage DRIVE or

drop across MANUAL 2 at idle

solenoid. Circuit with brake applied.

open or shorted or Open circuit —

PCM driver failure TCC never

during KOEO. engaged. May flash

MIL.

P0740b TCC TCC solenoid TCC solenoid Short circuit — GO to Pinpoint Test

solenoid circuit failure. circuit fails to engine stalls in C.

provide voltage DRIVE or

drop across MANUAL 2 at idle

solenoid. Circuit with brake applied.

open or shorted or Open circuit —

PCM driver failure TCC never

during KOEO. engaged. May flash

TCIL.

P1746b EPC PCM failure — Current through Open circuit — GO to Pinpoint Test

electronic EPC circuit is causes maximum E.

pressure control checked and electronic pressure

driver. compared after a control, harsh

time delay. An engagements and

error will be noted shifts. May flash

if tolerance is TCIL.

exceeded during

KOEO and

continuous

On-Board

Diagnostics.

P1747b EPC EPC circuit Current through Short circuit — GO to Pinpoint Test

failure, shorted EPC circuit is causes minimum E.

circuit or PCM. checked and electronic pressure

compared after a control pressure

time delay. An (minimum

error will be noted capacity). Limits

if tolerance is engine torque

exceeded during (partial fuel

KOEO and shut-off, heavy

continuous misfire). May flash

On-Board MIL.

Diagnostics.

P1760 EPC EPC signal PCM has detected Short circuit causes GO to Pinpoint Test

intermittent short. an intermittent minimum EPC E.

short. pressure (minimum

capacity). May flash

TCIL.

P0741a TCC TCC slippage The PCM picked up TCC slippage Refer to Diagnosis

detected. an excessive erratic or no torque By Symptom in this

amount of TCC converter clutch section.

slippage during operation. May

normal vehicle flash TCIL.

operation.

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-11 Automatic Transmission — 4R100 307-01A-11

DIAGNOSIS AND TESTING (Continued)

Diagnostic Trouble Code Chart (Continued)

Diagnostic

Trouble

Code Component Description Condition Symptom Action

P1744a TCC TCC slippage The PCM picked up TCC slippage Refer to Diagnosis

detected. an excessive erratic or no torque By Symptom in this

amount of TCC converter clutch section.

slippage during operation. May

normal vehicle flash MIL.

operation.

P1280 ICP Sensor ICP sensor circuit Open/grounded May result in firm Refer to the

failure. Out of circuit, biased shifts. Powertrain

range low. sensor or PCM. Control/Emissions

Diagnosis (PC/ED)

manual.

P1281 ICP Sensor ICP sensor circuit Short circuit to 5 May result in firm Refer to the

failure. Out of volt ref., biased shifts. Powertrain

range high. sensor or PCM. Control/Emissions

Diagnosis (PC/ED)

manual.

P0715 TSS Insufficient input PCM has detected a Harsh shifts. Set GO to Pinpoint Test

from TSS sensor. loss of TSS signal DTC. May flash F.

during operation. TCIL. May flash

MIL Schedule

Operation.

P0717 TSS TSS signal PCM has detected Harsh shifts, or GO to Pinpoint Test

intermittent an intermittent TSS erratic shifts. Set F.

signal DTC. May flash

TCIL.

P0718 TSS TSS signal noisy. PCM has detected a Harsh shifts, or GO to Pinpoint Test

noisy TSS sensor erratic shifts. Set F.

signal. DTC. May flash

TCIL

P0720 OSS Insufficient input PCM has detected a Set DTC. Flash GO to Pinpoint Test

from OSS sensor. loss of OSS signal TCIL. May flash F.

during operation. MIL.

P0721 OSS OSS signal noisy. PCM has detected a Set DTC. May flash GO to Pinpoint Test

noisy OSS sensor TCIL. F.

signal.

P0722 OSS Insufficient input PCM has detected a Set DTC. May flash GO to Pinpoint Test

from OSS sensor. loss of OSS signal TCIL. May flash F.

during operation. MIL.

P1781 4x4L 4x4 low switch Switch closed or Early or delayed Refer to the

failure. shorted during shifts. Powertrain

KOEO. Control/Emissions

Diagnosis (PC/ED)

manual.

P1729 4x4L 4x4 low switch Circuit open/closed. Early or delayed Refer to the

failure. Shorted during shifts. Powertrain

KOEO. Control/Emissions

Diagnosis (PC/ED)

manual.

b Distributor ignition (DI) system.

a May also be generated by other non-electronic-related transmission hardware condition.

b Output circuit check, generated only by electrical conditions.

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-12 Automatic Transmission — 4R100 307-01A-12

DIAGNOSIS AND TESTING (Continued)

Rotunda Transmission Tester 12-Pin PCM

Connector Description Connector

The Transmission Tester is used to diagnose the

electronically controlled transmission and is used in 1 Vehicle Power 71, 97

(VPWR)

conjunction with the pinpoint tests. The tests should

be carried out in order. Installing the Transmission 2 Shift Solenoid B 11

Tester allows separation of the vehicle electronics (2)

from transmission electronics. Refer to the 3 Shift Solenoid A 6

Transmission Tester manual for these tests and (1)

instructions. 4 Torque 54

Converter

• Bench Testing—Engine Off Clutch

• Resistance/Continuity Test 5 Coast Clutch 20

Solenoid

• Solenoid Voltage Test

6 — —

• Dynamic Testing—Engine On

7 Transmission 37

• EPC Solenoid Fluid

• Transmission Engagements Temperature

Sensor

• Upshifts/Downshifts

8 Signal Return 91

• Torque Converter Clutch (TCC) Engagement (SIG RTN)

• Coast Clutch Engagements 9 — —

• Turbine Shaft Speed (TSS) Sensor 10 — —

• Output Shaft Speed (OSS) Sensor 11 Electronic 81

Pressure Control

• Digital Transmission Range (TR) Sensor Testing

12 Electronic 71, 97

• Resistance/Continuity Test Pressure Control

• Sensor Tests Power

• Switch Test—PARK/NEUTRAL, Backup Lamp 13 Solenoid Body —

Connector

and Optional Circuits

14 Harness —

Transmission Connector Layouts Connector

Transmission Vehicle Harness Connector

Digital Transmission Range (TR) Sensor Connector

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-13 Automatic Transmission — 4R100 307-01A-13

DIAGNOSIS AND TESTING (Continued)

Circuit Pin

Pin Number Function PCM Pin Number Circuit Circuit Function

1 Not Used — 1 59 Output Shaft Speed Sensor

2 SIG RTN 91 (OSS)

3 TR3A 64 2 91 Signal Return

4 TR1 17

5 TR2 49 Turbine Shaft Speed Sensor (TSS) Harness Connector

6 TR4 50

7 Not Used —

8 Not Used —

9 FSD PWR FD —

10 STR Control —

11 Back Up —

12 STR to INT —

Output Shaft Speed (OSS) Sensor Harness Connector

Pin

Number Circuit Circuit Function

1 84 Turbine Shaft Speed (TSS)

Sensor

2 91 Signal Return

Digital Transmission Range (TR) Sensor Diagnosis Chart

PID: TR V

PID: TR D (volts)

TR3A (PCM

Selector Pin 64 to

Position PID: TR TR4 TR3A TR2 TR1 SIGRTN)

PARK P/N 0 0 0 0 0.0 Volts

In Between REV 0 1 0 0 1.3 - 1.8 Volts

REVERSE REV 1 1 0 0 1.3 - 1.8 Volts

In Between REV 0 1 0 0 1.3 - 1.8 Volts

NEUTRAL NTRL 0 1 1 0 1.3 - 1.8 Volts

In Between O/D a 1 1 1 0 1.3 - 1.8 Volts

OVERDRIVE O/D a 1 1 1 1 1.3 - 1.8 Volts

In Between MAN 2 1 0 1 1 0.0 Volts

MANUAL 2 MAN 2 1 0 0 1 0.0 Volts

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-14 Automatic Transmission — 4R100 307-01A-14

DIAGNOSIS AND TESTING (Continued)

Digital Transmission Range (TR) Sensor Diagnosis Chart (Continued)

PID: TR V

PID: TR D (volts)

TR3A (PCM

Selector Pin 64 to

Position PID: TR TR4 TR3A TR2 TR1 SIGRTN)

In Between MAN 2 1 0 1 1 0.0 Volts

MANUAL 1 MAN 1 0 0 1 1 0.0 Volts

a Will read DRIVE if O/D is canceled.

A. TR V is the voltage at the PCM pin 64 (TR3A Pinpoint Tests

Circuit) to signal return.

NOTE: If equipped, turn the power take-off (PTO)

B. ‘‘In Between’’ reading could be caused by a unit off for correct test results. For a description of

shift cable or digital TR sensor misaligned or a

digital TR sensor circuit failure of TR1, TR2, PTO operation, refer to Transmission Electronic

TR3A, or TR4. Control System in this section. On-Board Diagnostic

C. TR D: 1= Open Digital TR switch, 0= Closed is not accessible when the PTO unit is in operation.

Digital TR switch. SSB is on when the PTO is in operation.

D. Breakout Box Readings: Taken from PCM signal Any time an electrical connector or solenoid body is

pins for TR1, TR2, TR3A, TR4 to signal return. disconnected, inspect the connector for terminal

•Voltages for TR1, TR2, TR4: condition, corrosion and contamination. Also inspect

•0 = 0.0 volts. the connector seal for damage. Clean, repair or

•1 = 9.0 - 14.0 volts. install a new connector as required.

•Voltage for TR3A: Shift Solenoids Pre-Diagnosis

•0 = 0.0 volts. Use the following shift solenoid operation

•1 = 1.3 - 1.8 volts. information when carrying out Pinpoint Test A.

•1.8 - 5.0 volts = Invalid reading (open in wires

or bad resistor in digital TR sensor).

Wiggle Test Information For Open/Shorts

• TR4, TR3A, TR2, and TR1 are all closed in PARK.

PARK is a good position to check for intermittent open

circuits (with scan tool monitoring TR_D).

• TR4, TR3A, TR2, and TR1 are all open in

OVERDRIVE, so OVERDRIVE is a good position to

check for shorts to ground. To determine the shorted

components while observing TR D, unplug the TR

and see if the short goes away. If the short is still

present, unplug the transmission harness and see if the

short goes away. If the short is still present, then the

short is in the PCM or vehicle harness. Remove the

suspect circuit(s) wire from the PCM vehicle harness.

If the short is still present, then the PCM has an

internal failure. Otherwise the failure is in the vehicle

harness.

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-15 Automatic Transmission — 4R100 307-01A-15

DIAGNOSIS AND TESTING (Continued)

Solenoid Operation Chart

Transmission

Range PCM

Selector Lever Commanded

Position Gear SSA SSB TCC CCS

P/R/N 1 ON OFF a a

(D) 1 ON OFF a OFF

(D) 2 ON ON a OFF

(D) 3 OFF ON a OFF

(D) 4 OFF OFF a OFF

(D) First Through Third Gear Only, SSA, SSB, TCC, Same as OVERDRIVE, CCS Always On.

Cancel

MANUAL 2 2 a a a ON

MANUAL 1 2 OFF OFF OFF ON

MANUAL 1 1 ON OFF OFF ON

a Powertrain control module-controlled.

Shift Solenoid Failure Mode Chart Always OFF SSA Always On

Failed OFF due to PCM/vehicle wiring concerns; Gear Lever Position

solenoid electrically or hydraulically stuck off. PCM Gear

Commanded (D) 2 1

SSA Always Off Actual Gear Obtained

Gear Lever Position 1 1 2 1

PCM Gear

Commanded (D) 2 1 2 2 2 1

Actual Gear Obtained 3 2 2 1

1 4 2 1 4 1 2 1

2 3 2 2

3 3 2 2 SSB Always On *

4 4 2 2 Gear Lever Position

PCM Gear

Commanded (D) 2 1

SSB Always Off *

Actual Gear Obtained

Gear Lever Position 1 2 2 1

PCM Gear

Commanded (D) 2 1 2 2 2 1

Actual Gear Obtained 3 3 2 2

1 1 2 1 4 3 2 2

2 1 2 1 * PTO will always be on.

3 4 2 2 * PTO will always be on.

4 4 2 2

* PTO will not operate.

* PTO will not operate.

Shift Solenoid Failure Mode Chart Always ON

Failed ON due to PCM/vehicle wiring concerns;

solenoid electrically or hydraulically stuck on.

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-16 Automatic Transmission — 4R100 307-01A-16

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST A: SHIFT SOLENOIDS

NOTE: Refer to the Transmission Vehicle Harness Connector illustration preceding these

pinpoint tests.

Test Step Result / Action to Take

A1 ELECTRONIC DIAGNOSTICS

• Check to make sure the transmission harness connector is fully

seated, terminals are engaged in the connector and in good

condition before proceeding.

• Connect the diagnostic tool. Yes

• Carry out the KOEO Test until continuous DTCs have been REMAIN in OTM. GO to A2.

displayed. No

• Enter the Output Test Mode (OTM). PRESS START. If the vehicle does not

• Select the ALL ON mode. Push START to turn outputs on. Push enter OTM, REFER to the Powertrain

STOP to turn outputs off. Control/Emissions Diagnosis (PC/ED)

• Does the vehicle enter OTM? manual.

A2 CHECK THE ELECTRICAL SIGNAL OPERATION

• Disconnect: Transmission Connector.

CAUTION: Remove the heat shield, if so equipped,

from the transmission before removing the connector.

Remove the solenoid body connector by pushing on the

center tab and pulling on the harness connector. Do not

attempt to pry the tab with a screwdriver. Always reinstall

the heat shield when the procedure is completed.

• Use a mirror to inspect both ends of the connector for damage

or pushed-out pins, corrosion, loose wires and missing or

damaged seals.

• Measure the voltage between the VPWR pin 1 and the

appropriate solenoid signal circuit pins 2 and 3 at the

transmission vehicle harness connector.

• Place VOM on the 20-volt scale.

• While observing the VOM, press START and STOP to cycle the Yes

solenoid output on and off. GO to A5.

• Is the solenoid output voltage changed to approximately No

battery voltage? GO to A3.

A3 CHECK THE CONTINUITY OF THE SOLENOID SIGNAL AND

VPWR CIRCUITS

• Key in OFF position.

• Disconnect: Powertrain Control Module (PCM).

Inspect for damaged or pushed-out pins, corrosion or loose

wires.

• Install the EEC-V Control System Breakout Box.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-17 Automatic Transmission — 4R100 307-01A-17

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST A: SHIFT SOLENOIDS (Continued)

Test Step Result / Action to Take

A3 CHECK THE CONTINUITY OF THE SOLENOID SIGNAL AND

VPWR CIRCUITS (Continued)

• Measure the resistance between PCM signal test pins 11 and 6

at the EEC-V Control System Breakout Box and the signal pins

2 and 3 at the transmission harness connector.

• Measure the resistance between the VPWR test pins 71 or 97 at

the EEC-V Control System Breakout Box and the VPWR pin 1

at the transmission harness connector.

Yes

GO to A4.

No

REPAIR the open circuit(s). REMOVE the

EEC-V Control System Breakout Box.

RECONNECT all of the components.

• Is each resistance less than 5 ohms? REPEAT the Quick Tests.

A4 CHECK THE SHIFT SOLENOID CIRCUITS FOR SHORTS TO

POWER AND GROUND

• Measure the resistance between PCM signal test pins 11 and 6

and the VPWR test pins 71 and 97 at the EEC-V Control

System Breakout Box.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-18 Automatic Transmission — 4R100 307-01A-18

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST A: SHIFT SOLENOIDS (Continued)

Test Step Result / Action to Take

A4 CHECK THE SHIFT SOLENOID CIRCUITS FOR SHORTS TO

POWER AND GROUND (Continued)

• Measure the resistance between PCM signal test pins 11 and 6

and test pins 51, 76, 77, 103 and 91 at the EEC-V Control

System Breakout Box and chassis ground.

Yes

GO to A5.

No

REPAIR the short circuit(s). REMOVE the

EEC-V Control System Breakout Box.

RECONNECT all of the components.

• Is each resistance greater than 10,000 ohms? REPEAT the Quick Tests.

A5 SOLENOID FUNCTIONAL TEST

• Install the Transmission Tester to the transmission connector.

• NOTE: The LED will turn GREEN when the solenoid activates

and turn off when deactivated. The LED will turn RED if an

ACTIVATED solenoid is shorted to battery positive. The LED will

remain off if an ACTIVATED solenoid is shorted to ground or no Yes

continuity (open circuit). GO to A6.

Carry out the Solenoid Voltage Test. No

• Does the solenoid (LED GREEN) activate? GO to A7.

A6 TRANSMISSION DRIVE TEST

• Connect: Powertrain Control Module (PCM). Yes

• Carry out the Dynamic Testing — Engine On. INSTALL a new PCM. ERASE all codes

• Does the vehicle upshift when commanded by the tester? and CARRY OUT the Transmission Drive

Cycle Test. RERUN the Quick Tests. If

DTCs are still present, REFER to the

Powertrain Control/Emissions Diagnosis

(PC/ED) manual in this section.

No

GO to A7.

A7 CHECK THE RESISTANCE OF THE SOLENOIDS

NOTE: Refer to the Transmission Tester for terminal locations.

• Place the bench/drive switch to the BENCH mode.

• Rotate the gear select switch to the OHMS CHECK position.

• Measure the resistance between the SSA/SS-1 jack and the

VPWR jack on the transmission tester. This is to test SSA.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-19 Automatic Transmission — 4R100 307-01A-19

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST A: SHIFT SOLENOIDS (Continued)

Test Step Result / Action to Take

A7 CHECK THE RESISTANCE OF THE SOLENOIDS (Continued)

• Record the resistance. (The resistance should be between 18

and 26 ohms.)

• Measure the resistance between the SSB/SS-2 jack and the

VPWR jack on the transmission tester. This is to test SSB.

Yes

GO to A8.

• Record the resistance. (The resistance should be between 18 No

and 26 ohms.) INSTALL a new solenoid body assembly.

• Is the resistance for each solenoid between 18 and 26 RECORD and ERASE the codes.

ohms? REPEAT the Quick Tests.

A8 CHECK THE SOLENOIDS FOR SHORT TO GROUND

• Check for continuity between the BAT(-) jack (engine ground)

and the appropriate jack with a digital ohmmeter or other low

current tester (less than 200 milliamps). Connection should show

infinite resistance (no continuity).

Solenoid Tester Jack

SSA/SS1 SSA/SS1/VPWR

SSB/SS2 SSB/SS2/VPWR

Yes

INSTALL a new solenoid body assembly.

RECORD and ERASE the codes.

REPEAT the Quick Tests.

No

REFER to Diagnosis By Symptom in this

• Does the connection show continuity? section.

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-20 Automatic Transmission — 4R100 307-01A-20

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST B: TRANSMISSION FLUID TEMPERATURE (TFT) SENSOR

NOTE: Refer to the Transmission Vehicle Harness Connector illustration preceding these

pinpoint tests.

NOTE: This vehicle is equipped with a transmission fluid temperature gauge in the dash. The

transmission fluid temperature gauge may be used as a quick reference to the operating

temperature. It should not be used as a diagnostic tool to tell the temperature of the

transmission. The WDS, NGS or transmission tester should be used to obtain the actual

temperature of the transmission.

Test Step Result / Action to Take

B1 ELECTRONIC DIAGNOSTICS

• Check to make sure the transmission harness connector is fully

seated, terminals are fully engaged in the connector and in good

condition before proceeding.

• Connect the diagnostic tool.

• Key in ON position. Yes

• Select Diagnostic Data Link. REMAIN in PID/Data Control. GO to B2.

• Select PCM. No

• Select PID/Data Monitor and Record. REPEAT procedure to enter PID. If vehicle

• Enter the following diagnostic mode on the diagnostic tool: PIDs; did not enter PID, REFER to the

TFT, TFTV. Powertrain Control/Emissions Diagnosis

• Does the vehicle enter PID/Data Monitor and Record? (PC/ED) manual for diagnosis of PCM.

B2 WARM-UP/COOL-DOWN CYCLE

• While monitoring the TFT PIDs, carry out the following test: If Yes

transmission is cold, run transmission to warm it up. If If the TFT PIDs increase as the

transmission is warm, allow transmission to cool down. transmission is warmed or decrease as

• Do the TFT PIDs increase as the transmission is warmed up the transmission is cooled, CLEAR all

or decrease as the transmission is cooled or does the TFT DTCs. ROAD TEST to verify if concern is

or TFTV drop in and out of range? still present. If concern is still present,

REFER to Diagnosis By Symptom in this

section to diagnose transmission

overheating.

If the TFT or TFTV drop in and out of

range, INSPECT for intermittent concern in

the internal/external harness, sensor or

connector.

No

GO to B3.

B3 CHECK THE ELECTRICAL SIGNAL OPERATION

• Key in OFF position.

• Disconnect: Transmission Connector.

CAUTION: Remove the heat shield, if so equipped,

from transmission before removing the connector. Remove

the solenoid body connector by pushing on the center tab

and pulling on the harness connector. Do not attempt to pry

the tab with a screwdriver. Always reinstall the heat shield

when the procedure is completed.

• Use a mirror to inspect both ends of the connector for damage

or pushed-out pins, corrosion, loose wires and missing or

damaged seals.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-21 Automatic Transmission — 4R100 307-01A-21

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST B: TRANSMISSION FLUID TEMPERATURE (TFT) SENSOR (Continued)

Test Step Result / Action to Take

B3 CHECK THE ELECTRICAL SIGNAL OPERATION (Continued)

• Measure the voltage between TFT signal circuit pin 7 and the

SIG RTN circuit pin 8 at the transmission harness connector.

Yes

• Place the VOM on the 20-volt scale. GO to B7.

• Key in ON position. No

• Is the voltage between 4.75 and 5.25 volts? GO to B4.

B4 CHECK THE CONTINUITY OF THE TFT SIGNAL AND SIG RTN

CIRCUITS

• Key in OFF position.

• Disconnect: Powertrain Control Module (PCM).

Inspect for damaged or pushed-out pins, corrosion or loose

wires.

• Install the EEC-V Control System Breakout Box.

• Measure the resistance between the PCM signal test pin 37 at

the EEC-V Control System Breakout Box and the signal pin 7 at

the transmission harness connector.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-22 Automatic Transmission — 4R100 307-01A-22

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST B: TRANSMISSION FLUID TEMPERATURE (TFT) SENSOR (Continued)

Test Step Result / Action to Take

B4 CHECK THE CONTINUITY OF THE TFT SIGNAL AND SIG RTN

CIRCUITS (Continued)

• Measure the resistance between the PCM SIG RTN test pin 91

at the EEC-V Control System Breakout Box and the SIG RTN

pin 8 at the transmission harness connector.

Yes

GO to B5.

No

REPAIR the open circuits. REMOVE the

EEC-V Control System Breakout Box.

RECONNECT all of the components.

• Is each resistance less than 5 ohms? REPEAT the Quick Tests.

B5 CHECK THE TFT SIGNAL CIRCUIT FOR SHORT TO VPWR AND

GROUND

• Measure the resistance between the PCM signal test pin 37 and

VPWR test pins 71 and 97 at the EEC-V Control System

Breakout Box.

• Measure the resistance between the PCM signal test pin 37 and

test pins 51, 76, 77, 103, 91 at the EEC-V Control System

Breakout Box and chassis ground.

Yes

GO to B6.

No

REPAIR the short circuit(s). REMOVE the

EEC-V Control System Breakout Box.

RECONNECT all of the components.

• Is each resistance greater than 10,000 ohms? REPEAT the Quick Tests.

B6 CHECK THE RESISTANCE OF THE TFT SENSOR

• Install the Transmission Tester to the transmission connector.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-23 Automatic Transmission — 4R100 307-01A-23

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST B: TRANSMISSION FLUID TEMPERATURE (TFT) SENSOR (Continued)

Test Step Result / Action to Take

B6 CHECK THE RESISTANCE OF THE TFT SENSOR (Continued)

• Set the bench/drive switch to the BENCH mode.

• Rotate the gear select switch to the OHMS CHECK position.

• NOTE: While carrying out Tests 1 and 2 below, observe

resistance. DTC P0713 is set if the resistance value exceeds

1,062 ohms (open circuit). DTC P0712 is set if the resistance

value falls below 597 ohms (short circuit).

Measure the resistance between the TFT- jack and the TFT+

jack on the tester.

• TEST 1

• Record the resistance. Resistance should be approximately in

the following ranges:

Transmission Fluid Temperature

°C °F Resistance (Ohms)

-40 to -20 -40 to -4 1,062 k-284 k

-19 to -1 -3-31 284 k-100 k

0-20 32-68 100 k-37 k

21-40 69-104 37 k-16 k

41-70 105-158 16 k-5 k

71-90 159-194 5 k-2.7 k

91-110 195-230 2.7 k-1.5 k

111-130 231-266 1.5 k-0.8 k

131-150 267-302 0.8 k-0.54 k

• TEST 2

• Check for an intermittent short or open.

• If the resistance was between 0.8 k and 100 k ohms, carry out

the following test. If the transmission is cold, start and run the

engine until transmission reaches its normal operating

temperature. If the transmission is warm, allow the transmission

to cool. Check the TFT sensor resistance again. Compare the Yes

resistance with the initial resistance. The resistance should GO to B7.

decrease if the transmission was warmed and should increase if No

the transmission was allowed to cool. If the correct change in INSTALL a new solenoid assembly.

resistance occurs, repeat the Quick Test. RECORD and ERASE the codes.

• Is the resistance in the specified range? REPEAT the Quick Tests.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-24 Automatic Transmission — 4R100 307-01A-24

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST B: TRANSMISSION FLUID TEMPERATURE (TFT) SENSOR (Continued)

Test Step Result / Action to Take

B7 CHECK THE TFT SENSOR FOR SHORT TO GROUND

• Check for continuity between the BAT(-) jack (engine ground)

and the appropriate jack (-TFT or +TFT) with a digital ohmmeter

or other low current tester (less than 200 milliamps). Connection

should show infinite resistance (no continuity).

Yes

INSTALL a new solenoid assembly.

REPEAT the Quick Tests.

No

INSTALL a new PCM. REPEAT the Quick

Tests. If the DTC is still present and

overtemp condition exists, CHECK the

fluid condition. CHECK the overheat

condition. REFER to Diagnosis By

Symptom in this section. REPAIR as

• Does the connection show continuity? required. REPEAT the Quick Tests.

PINPOINT TEST C: TORQUE CONVERTER CLUTCH (TCC) SOLENOID

NOTE: Refer to the Transmission Vehicle Harness Connector illustration preceding these

pinpoint tests.

Test Step Result / Action to Take

C1 ELECTRONIC DIAGNOSTICS

• Check to make sure the transmission harness connector is fully

seated, terminals are engaged in the connector and in good

condition before proceeding.

• Connect the diagnostic tool. Yes

• Carry out KOEO Test until continuous DTCs have been REMAIN in OTM. GO to C2.

displayed. No

• Enter Output Test Mode (OTM). PRESS START. If vehicle does not enter

• Select the ALL ON mode. Push START to turn the outputs on. OTM, REFER to the Powertrain

Push STOP to turn the outputs off. Control/Emissions Diagnosis (PC/ED)

• Does the vehicle enter OTM? manual.

C2 CHECK THE ELECTRICAL SIGNAL OPERATION

• Disconnect: Transmission Connector.

CAUTION: Remove the heat shield, if so equipped,

from the transmission before removing the connector.

Remove the solenoid body connector by pushing on the

center tab and pulling on the harness connector. Do not

attempt to pry the tab with a screwdriver. Always reinstall

the heat shield when the procedure is completed.

• Use a mirror to inspect both ends of the connector for damaged

or pushed-out pins, corrosion, loose wires and missing or

damaged seals.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-25 Automatic Transmission — 4R100 307-01A-25

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST C: TORQUE CONVERTER CLUTCH (TCC) SOLENOID (Continued)

Test Step Result / Action to Take

C2 CHECK THE ELECTRICAL SIGNAL OPERATION (Continued)

• Measure the voltage between the VPWR circuit pin 1 and the

TCC signal circuit pin 4 at the transmission vehicle harness

connector.

• Place the VOM on the 20-volt scale.

• While observing the VOM, press START and STOP to cycle the Yes

solenoid output on and off. GO to C6.

• Is the solenoid output voltage changed to approximately No

battery voltage? GO to C3.

C3 CHECK THE CONTINUITY OF THE TCC SIGNAL AND VPWR

CIRCUITS

• Key in OFF position.

• Disconnect: Powertrain Control Module (PCM).

Inspect for damaged or pushed-out pins, corrosion or loose

wires.

• Install the EEC-V Control System Breakout Box.

• Measure the resistance between the PCM signal test pin 54 at

the EEC-V Control System Breakout Box and the signal pin 4 at

the transmission harness connector.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-26 Automatic Transmission — 4R100 307-01A-26

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST C: TORQUE CONVERTER CLUTCH (TCC) SOLENOID (Continued)

Test Step Result / Action to Take

C3 CHECK THE CONTINUITY OF THE TCC SIGNAL AND VPWR

CIRCUITS (Continued)

• Measure the resistance between the VPWR test pin 71 or 97 at

the EEC-V Control System Breakout Box and the VPWR pin 1

at the transmission harness connector.

Yes

GO to C4.

No

REPAIR the open circuits. REMOVE the

EEC-V Control System Breakout Box.

RECONNECT all of the components.

• Is each resistance less than 5 ohms? REPEAT the Quick Tests.

C4 CHECK THE TCC CIRCUIT FOR SHORT TO POWER

• Measure the resistance between the PCM signal test pin 54 and

VPWR test pins 71 and 97 at the EEC-V Control System

Breakout Box.

Yes

GO to C5.

No

REPAIR the open circuits. REMOVE the

EEC-V Control System Breakout Box.

RECONNECT all of the components.

• Is each resistance greater than 10,000 ohms? REPEAT the Quick Tests.

C5 CHECK THE TCC CIRCUIT FOR SHORT TO GROUND

• Measure the resistance between the PCM signal test pin 54 and

test pins 51, 76, 77, 103 and 91 at the EEC-V Control System

Breakout Box and chassis ground.

Yes

GO to C6.

No

REPAIR the short circuit(s). REMOVE the

EEC-V Control System Breakout Box .

RECONNECT all of the components.

• Is each resistance greater than 10,000 ohms? REPEAT the Quick Tests.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-27 Automatic Transmission — 4R100 307-01A-27

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST C: TORQUE CONVERTER CLUTCH (TCC) SOLENOID (Continued)

Test Step Result / Action to Take

C6 SOLENOID FUNCTIONAL TEST

• Install the Transmission Tester to the transmission connector.

• NOTE: The LED will turn GREEN when the TCC solenoid

activates and turn off when deactivated. The LED will turn RED

if an ACTIVATED solenoid is shorted to battery positive. The

LED will remain off if an ACTIVATED solenoid is shorted to

ground or no continuity (open circuit). Yes

Carry out the Solenoid Voltage Test. GO to C7.

• Does the solenoid (LED GREEN) activate when tester switch No

is pressed? GO to C8.

C7 TRANSMISSION DRIVE TEST

• Connect: Powertrain Control Module (PCM). Yes

• Carry out the Dynamic Testing — Engine On. INSTALL a new PCM. ERASE all DTCs.

• Does the torque converter clutch solenoid activate (LED CARRY OUT the Transmission Drive

GREEN) and does the engine rpm drop? Cycle Test. REPEAT the Quick Tests. If

the symptoms are still present, REFER to

Diagnosis By Symptom — Torque

Converter Clutch Operation Concerns in

this section.

No

GO to C8.

C8 CHECK THE RESISTANCE OF THE SOLENOID

NOTE: Refer to the Transmission Tester for terminal locations.

• Place the bench/drive switch to the BENCH mode.

• Rotate the gear select switch to the OHMS CHECK position.

• Measure the resistance between the TCC jack and the VPWR

jack on the transmission tester.

Yes

• Record the resistance. The resistance should be between 13 GO to C9.

and 20 ohms. No

• Is the resistance between 13 and 20 ohms? INSTALL a new solenoid body assembly.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-28 Automatic Transmission — 4R100 307-01A-28

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST C: TORQUE CONVERTER CLUTCH (TCC) SOLENOID (Continued)

Test Step Result / Action to Take

C9 CHECK THE SOLENOID FOR SHORT TO GROUND

• Check for continuity between the BAT(-) jack (engine ground)

and the appropriate jack with a digital ohmmeter or other low

current tester (less than 200 milliamps). Connection should show

infinite resistance (no continuity).

Yes

INSTALL a new solenoid body assembly.

No

REFER to the Diagnosis By Symptom —

Torque Converter Clutch Operation

• Does the connection show continuity? Concerns in this section.

PINPOINT TEST D: DIGITAL TRANSMISSION RANGE (TR) SENSOR

NOTE: Refer to the Digital Transmission Range (TR) Sensor Connector illustration preceding

these pinpoint tests.

NOTE: Refer to the Digital Transmission Range (TR) Sensor Diagnosis Chart preceding these

pinpoint tests.

Test Step Result / Action to Take

D1 VERIFY DIAGNOSTIC TROUBLE CODES

• Key in OFF position.

• Select PARK.

• Carry out on-board diagnostic test. DTC codes P0705 and Yes

P0708 cannot be set by an incorrectly adjusted digital TR GO to D4.

sensor. No

• Are only DTC codes P0705, P0708 present? GO to D2.

D2 VERIFY DIGITAL TRANSMISSION RANGE SENSOR ALIGNMENT

• Key in OFF position.

• Select PARK.

• Check to make sure the digital TR sensor harness connector is

fully seated, terminals are fully engaged in connector and in

good condition before proceeding. Yes

• Apply the parking brake. GO to D3.

• Select NEUTRAL. No

• Disconnect the shift cable/linkage from the manual lever. ADJUST the digital TR sensor. PLACE

• Verify that the TR Sensor Alignment Gauge fits in the transmission range selector lever into

appropriate slots. PARK and CLEAR DTCs. RERUN OBD

• Is the digital TR sensor correctly adjusted? Tests.GO to D3.

D3 VERIFY SHIFT CABLE/LINKAGE ADJUSTMENT

• Place the manual lever in the OVERDRIVE position.

• Select DRIVE. Yes

• Reconnect the shift cable/linkage. GO to D4.

• Verify that the shift cable/linkage is correctly adjusted. Refer to No

Section 307-05. ADJUST the shift cable/linkage. REFER to

• Is the shift cable/linkage correctly adjusted? Section 307-05. GO to D4.

D4 CHECK ELECTRICAL SIGNAL OPERATION

• Select PARK.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-29 Automatic Transmission — 4R100 307-01A-29

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST D: DIGITAL TRANSMISSION RANGE (TR) SENSOR (Continued)

Test Step Result / Action to Take

D4 CHECK ELECTRICAL SIGNAL OPERATION (Continued)

• Disconnect: Digital TR Sensor.

CAUTION: Do not pry on connector. This will damage

Yes

REPAIR as required. CLEAR DTCs and

the connector and result in a transmission concern. RERUN OBD Tests.

Press the button and pull out on the digital TR harness

connector. No

• Inspect both ends of the connector for damage or pushed-out If diagnosing a DTC, GO to D5.

pins, corrosion, loose wires and missing or damaged seals. If diagnosing a starting concern or a

• Is there damage to the connector, pins or harness? backup lamp concern, GO to D10.

D5 CHECK ELECTRICAL SYSTEM OPERATION (DIGITAL TR AND

PCM)

• Key in OFF position.

• Connect the diagnostic tool.

• Connect: Digital TR Sensor.

• Key in ON position.

• Enter the following diagnostic mode on the diagnostic tool: TR

PIDS TR, TR D, TR V.

• Move transmission range selector lever into each gear and stop.

• Observe any of the following PIDs, TR and TR D, TR V

(vehicle dependent) while wiggling harness, tapping on sensor, Yes

and/or driving the vehicle. Use PIDs TR, and TR D for DTCs The problem is not in the digital TR sensor

P0705, P1704, and P1705. Use PIDs TR, and TR V for DTC system. REFER to Diagnosis By Symptom

P0708. in this section for further diagnosis.

• Compare the PIDs to the Digital Transmission Range (TR)

Sensor Diagnosis Chart. No

• Do the PIDs TR, TR D and TR V match the Digital If TR D changes when wiggling harness,

Transmission Range (TR) Sensor Diagnosis Chart, and does tapping on the sensor, or driving the

the TR D PID remain steady when the harness is wiggled, vehicle, the problem may be intermittent.

the sensor is tapped, or the vehicle driven? GO to D6.

D6 CHECK THE DIGITAL TRANSMISSION RANGE SENSOR

OPERATION

• Disconnect: Digital TR Sensor.

CAUTION: Do not pry on the connector. This will

damage the connector and result in a transmission concern.

Press the button and pull out on the harness connector.

• Connect the tester cable E to the Transmission Tester. Connect Yes

the tester cable E black connector marked DIGITAL to the digital The concern is not in the digital TR

TR sensor. sensor. GO to D7.

• Place the Digital TR Overlay onto the Transmission Tester. No

• Carry out the sensor test as instructed on the Digital TR INSTALL and ADJUST a new digital TR

Overlay. sensor. REFER to Digital Transmission

• Do the status lamps on the tester TR-E cable match the Range (TR) Sensor in this section. CLEAR

selected gear positions? the DTCs. REPEAT the Quick Tests.

D7 CHECK THE PCM HARNESS CIRCUITS FOR OPENS

• Key in OFF position.

• Disconnect: Powertrain Control Module.

Inspect for damaged or pushed-out pins, corrosion or loose

wires.

• Disconnect: Digital TR Sensor.

CAUTION: Do not pry on the connector. This will

damage the connector and result in a transmission concern.

Press the button and pull out on the digital TR sensor

harness connector.

Disconnect digital TR sensor connector.

• Install the EEC-V Control System Breakout Box.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-30 Automatic Transmission — 4R100 307-01A-30

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST D: DIGITAL TRANSMISSION RANGE (TR) SENSOR (Continued)

Test Step Result / Action to Take

D7 CHECK THE PCM HARNESS CIRCUITS FOR OPENS

(Continued)

• Measure the resistance between PCM test pin 91 at the EEC-V

Control System Breakout Box and the signal return circuit pin 2

at the vehicle harness connector.

• Vehicles equipped with 7.3L (Cal.) DI diesel, and all gasoline

engines, measure the resistance between PCM test pin 34 at

the EEC-V Control System Breakout Box, and TR1 circuit pin 4

at the vehicle harness connector.

• Vehicles equipped with 7.3L (49-state) DI diesel engine,

measure the resistance between PCM test pin 17 at the EEC-V

Control System Breakout Box, and TR1 circuit pin 4 at the

vehicle harness connector.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-31 Automatic Transmission — 4R100 307-01A-31

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST D: DIGITAL TRANSMISSION RANGE (TR) SENSOR (Continued)

Test Step Result / Action to Take

D7 CHECK THE PCM HARNESS CIRCUITS FOR OPENS

(Continued)

• Measure the resistance between PCM test pin 49 at the EEC-V

Control System Breakout Box and TR2 circuit pin 5 at the

vehicle harness connector.

• Measure the resistance between PCM test pin 50 at the EEC-V

Control System Breakout Box and TR4 circuit pin 6 at the

vehicle harness connector.

• Measure the resistance between PCM test pin 64 at the EEC-V

Control System Breakout Box and TR3A circuit pin 3 at the

vehicle harness connector.

Yes

GO to D8.

No

REPAIR the open circuit(s). RECONNECT

all of the components. CLEAR the DTCs.

• Is each resistance less than 5 ohms? REPEAT the Quick Tests.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-32 Automatic Transmission — 4R100 307-01A-32

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST D: DIGITAL TRANSMISSION RANGE (TR) SENSOR (Continued)

Test Step Result / Action to Take

D8 CHECK THE PCM HARNESS CIRCUITS FOR A SHORT TO

GROUND OR TO POWER

• Vehicles equipped with 7.3L (Cal.) DI diesel, and all gasoline

engines, measure the resistance between PCM test pins 91, 34,

49, 50 and 64, and VPWR test pins 71 and 97 at the EEC-V

Control System Breakout Box.

• Vehicles equipped with 7.3L (49-state) DI diesel engine,

measure the resistance between PCM test pins 91, 17, 49, 50

and 64, and VPWR test pins 71 and 97 at the EEC-V Control

System Breakout Box.

• Vehicles equipped with 7.3L (Cal.) DI diesel, and all gasoline

engines, measure the resistance between PCM test pins 34, 49,

50 and 64, and test pins 51, 76, 77, 103 and 91 at the EEC-V

Control System Breakout Box.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-33 Automatic Transmission — 4R100 307-01A-33

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST D: DIGITAL TRANSMISSION RANGE (TR) SENSOR (Continued)

Test Step Result / Action to Take

D8 CHECK THE PCM HARNESS CIRCUITS FOR A SHORT TO

GROUND OR TO POWER (Continued)

• Vehicles equipped with 7.3L (49-state) DI diesel engine,

measure the resistance between PCM test pins 17, 49, 50 and

64, and test pins 51, 76, 77, 103 and 91 at the EEC-V Control

System Breakout Box.

Yes

GO to D9.

No

REPAIR the short circuit(s). RECONNECT

all of the components. CLEAR the DTCs.

• Is each resistance greater than 10,000 ohms? REPEAT the Quick Tests.

D9 CHECK FOR A SHORT BETWEEN THE TR/PCM INPUT SIGNAL

CIRCUITS

• Vehicles equipped with 7.3L (Cal.) DI diesel, and all gasoline

engines, measure the resistance between test pin 34 and test

pins 49, 50 and 64 at the EEC-V Control System Breakout Box.

• Vehicles equipped with 7.3L (49-state) DI diesel engine,

measure the resistance between test pin 17 and test pins 49, 50

and 64 at the EEC-V Control System Breakout Box.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-34 Automatic Transmission — 4R100 307-01A-34

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST D: DIGITAL TRANSMISSION RANGE (TR) SENSOR (Continued)

Test Step Result / Action to Take

D9 CHECK FOR A SHORT BETWEEN THE TR/PCM INPUT SIGNAL

CIRCUITS (Continued)

• Vehicles equipped with 7.3L (Cal.) DI diesel, and all gasoline

engines, measure the resistance between test pin 49 and test

pins 34, 50 and 64 at the EEC-V Control System Breakout Box.

• Vehicles equipped with 7.3L (49-state) DI diesel engine,

measure the resistance between test pin 49 and test pins 17, 50

and 64 at the EEC-V Control System Breakout Box.

• Vehicles equipped with 7.3L (Cal.) DI diesel, and all gasoline

engines, measure the resistance between test pin 50 and test

pins 34, 49 and 64 at the EEC-V Control System Breakout Box.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-35 Automatic Transmission — 4R100 307-01A-35

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST D: DIGITAL TRANSMISSION RANGE (TR) SENSOR (Continued)

Test Step Result / Action to Take

D9 CHECK FOR A SHORT BETWEEN THE TR/PCM INPUT SIGNAL

CIRCUITS (Continued)

• Vehicles equipped with 7.3L (49-state) DI diesel engine,

measure the resistance between test pin 50 and test pins 17, 49

and 64 at the EEC-V Control System Breakout Box.

• Vehicles equipped with 7.3L (Cal.) DI diesel, and all gasoline

engines, measure the resistance between test pin 64 and test

pins 34, 49 and 50 at the EEC-V Control System Breakout Box.

• Vehicles equipped with 7.3L (49-state) DI diesel engine,

measure the resistance between test pin 64 and test pins 17, 49

and 50 at the EEC-V Control System Breakout Box.

Yes

INSTALL a new PCM. RECONNECT all of

the components. CLEAR the DTCs.

RERUN the Quick Tests.

No

REPAIR shorts on the circuits having less

than 10,000 ohms resistance between

other TR/PCM input signal circuits.

RECONNECT all of the components.

CLEAR the DTCs. REPEAT the Quick

• Is each resistance greater than 10,000 ohms? Tests.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-36 Automatic Transmission — 4R100 307-01A-36

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST D: DIGITAL TRANSMISSION RANGE (TR) SENSOR (Continued)

Test Step Result / Action to Take

D10 CHECK THE NON-PCM INTERNAL CIRCUITS OF SENSOR

• Connect the tester cable E to the Transmission Tester. Yes

• Connect the cable E connector marked DIGITAL to the digital The concern is not in the digital TR

TR sensor. sensor. For starter system concerns,

• Place the Digital TR Overlay onto the Transmission Tester. REFER to Section 303-06A for gasoline

• Carry out the switch test as instructed on the Digital TR Overlay. engines and Section 303-06B for diesel

• Does the status lamp on the tester indicate RED for the engines. For backup lamp concerns,

correct gear position? REFER to Section 417-01.

No

INSTALL and ADJUST a new digital TR

sensor. REFER to Digital Transmission

Range (TR) Sensor in this section. CLEAR

the DTCs. REPEAT the Quick Tests.

PINPOINT TEST E: ELECTRONIC PRESSURE CONTROL (EPC) SOLENOID

NOTE: Refer to the Transmission Vehicle Harness Connector illustration preceding these

pinpoint tests.

Test Step Result / Action to Take

E1 ELECTRONIC DIAGNOSTICS

• Check to make sure the transmission harness connector is fully

seated, terminals are engaged in the connector and in good

condition before proceeding.

• Connect the diagnostic tool. Yes

• Carry out KOEO Test until continuous DTCs have been REMAIN in OTM. GO to E2.

displayed. No

• ENTER Output Test Mode (OTM). PRESS START. If the vehicle does not

• Select the ALL ON mode. Push START to turn the outputs on. enter OTM, REFER to the Powertrain

Push STOP to turn the outputs off. Control/Emissions Diagnosis (PC/ED)

• Does the vehicle enter OTM? manual.

E2 CHECK THE ELECTRICAL SIGNAL OPERATION

• Disconnect: Transmission Connector.

CAUTION: Remove the heat shield, if so equipped,

from the transmission before removing the connector.

Remove the solenoid body connector by pushing on the

center tab and pulling on the harness connector. Do not

attempt to pry the tab with a screwdriver. Always reinstall

the heat shield when the procedure is completed.

• Use a mirror to inspect both ends of the connector for damage

or pushed-out pins, corrosion, loose wires and missing or

damaged seals.

• Measure the voltage between EPC PWR pin 12 and EPC signal

circuit pin 11 at the transmission vehicle harness connector.

• Place the VOM on the 20-volt scale.

• While observing the VOM, press START and STOP to cycle the Yes

solenoid output on and off. GO to E5.

• Is the solenoid output voltage changed to approximately No

battery voltage? GO to E3.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-37 Automatic Transmission — 4R100 307-01A-37

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST E: ELECTRONIC PRESSURE CONTROL (EPC) SOLENOID (Continued)

Test Step Result / Action to Take

E3 CHECK THE CONTINUITY OF THE SOLENOID SIGNAL AND

VPWR CIRCUITS

• Key in OFF position.

• Disconnect: Powertrain Control Module (PCM).

Inspect for damaged or pushed-out pins, corrosion or loose

wires.

• Install the EEC-V Control System Breakout Box.

• Measure the resistance between the VPWR test pins 71 and 97

at the EEC-V Control System Breakout Box and the EPC PWR

circuit pin 12 at the transmission harness connector.

• Measure the resistance between the PCM signal test pin 81 at

the EEC-V Control System Breakout Box and the EPC signal pin

11 at the transmission harness connector.

Yes

GO to E4.

No

REPAIR the open circuit(s). REMOVE the

EEC-V Control System Breakout Box.

RECONNECT all of the components.

ERASE the codes. REPEAT the Quick

• Is each resistance less than 5 ohms? Tests.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-38 Automatic Transmission — 4R100 307-01A-38

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST E: ELECTRONIC PRESSURE CONTROL (EPC) SOLENOID (Continued)

Test Step Result / Action to Take

E4 CHECK THE HARNESS FOR SHORTS TO POWER AND

GROUND

• Measure the resistance between the PCM signal test pin 81 and

VPWR test pins 71 and 97 at the EEC-V Control System

Breakout Box.

• Measure the resistance between the PCM signal test pin 81 and

test pins 51, 76, 77, 103 and 91 at the EEC-V Control System

Breakout Box.

Yes

GO to E5.

No

REPAIR the short circuit(s). REMOVE the

EEC-V Control System Breakout Box.

RECONNECT all of the components.

ERASE the codes. REPEAT the Quick

• Is each resistance greater than 10,000 ohms? Tests.

E5 TRANSMISSION FUNCTIONAL TEST

• Connect: Powertrain Control Module (PCM).

• Install a Line Pressure Gauge at the line tap on the case.

• Install the Transmission Tester to transmission connector.

• Set the bench/drive switch to the DRIVE mode.

• Rotate the gear select switch to the first gear position.

• NOTE: The LED will turn GREEN when the EPC solenoid

activates and turn off when deactivated. The LED will turn RED

if an ACTIVATED solenoid is shorted to battery positive. The

LED will remain off if an ACTIVATED solenoid is shorted to

ground or no continuity (open circuit).

Carry out the EPC Solenoid Functional Test. Yes

• Observe line pressure on the gauge while pressing the EPC INSTALL a new PCM. REPEAT the Quick

switch (engine must be running). Tests.

• Does the EPC (GREEN LED) activate and line pressure drop No

when the EPC switch is pressed? GO to E6.

E6 CHECK THE RESISTANCE OF THE SOLENOID

NOTE: Refer to the Transmission Tester for terminal locations.

• Set the bench/drive switch to the BENCH mode.

• Rotate the gear select switch to the OHMS CHECK position.

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-39 Automatic Transmission — 4R100 307-01A-39

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST E: ELECTRONIC PRESSURE CONTROL (EPC) SOLENOID (Continued)

Test Step Result / Action to Take

E6 CHECK THE RESISTANCE OF THE SOLENOID (Continued)

• CAUTION: Make sure the tester power is off or

damage to the ohmmeter can result.

Measure the resistance between the VPWR jack and the EPC

jack on the transmission tester.

Yes

GO to E7.

No

• Record the resistance. (The resistance should be between 3.0 INSTALL a new solenoid body assembly.

and 5.0 ohms.) RECORD and ERASE all codes. REPEAT

• Is the resistance between 3.0 and 5.0 ohms? the Quick Tests.

E7 CHECK THE SOLENOID FOR SHORT TO GROUND

• Check for continuity between the BAT(-) jack (engine ground)

and the appropriate jack with a digital ohmmeter or other low

current tester (less than 200 milliamps). The connection should

show infinite resistance (no continuity).

Solenoid Tester Jack

EPC VPWR

EPC PWR

(Continued)

2003 Excursion, F-Super Duty 250-550, 1/2003

307-01A-40 Automatic Transmission — 4R100 307-01A-40

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST E: ELECTRONIC PRESSURE CONTROL (EPC) SOLENOID (Continued)

Test Step Result / Action to Take

E7 CHECK THE SOLENOID FOR SHORT TO GROUND (Continued)

Yes

INSTALL a new solenoid body assembly.

RECORD and ERASE codes. REPEAT

the Quick Tests.

No

REFER to Diagnosis By Symptom in this

• Does the connection show continuity? section.

PINPOINT TEST F: TURBINE SHAFT SPEED (TSS) AND OUTPUT SHAFT SPEED (OSS) SENSORS

NOTE: Refer to the Output Shaft Speed (OSS) Sensor Connector illustration preceding these

pinpoint tests.

Test Step Result / Action to Take

F1 ELECTRONIC DIAGNOSTICS

• Check to make sure the transmission harness connector is fully

seated, terminals are fully engaged in connector and in good

condition before proceeding.

• Connect the diagnostic tool.

• Key in ON position. Yes

• Enter the following diagnostic mode on the diagnostic tool: REMAIN in PID/Data. GO to F2.

Diagnostic Data Link. No

• Enter the following diagnostic mode on the diagnostic tool: PCM. REPEAT procedure to ENTER PID. If

• Select PID/Data Monitor and Record. vehicle did not enter PID, REFER to