Professional Documents

Culture Documents

Base Painting Inspection Record

Base Painting Inspection Record

Uploaded by

Ricardo0 ratings0% found this document useful (0 votes)

4 views8 pagesOriginal Title

Base painting inspection record

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views8 pagesBase Painting Inspection Record

Base Painting Inspection Record

Uploaded by

RicardoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

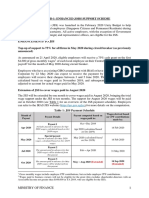

Surface derusting, painting inspection records

Item no. Vatl97SAHU Product model VHP600-381DH40701 Part number 0051386000A/B quantity 2

‘Ambient 5 Bi ' a > substrate s “construction pe

temperaurehumidny | 24% /346 || Dew point Kot teinperture ue dite | 201P.S

Inspection items | technical requirements & Inspection methods [Biopestion secon rete

Sandbastin Achieve SA2.5 above: 7 :

ae” Relersice tirhle Halal ee ato Steel surface after sand blasting derusting, achieve SA2.5 level. o

ae Jotcote Univers a 70-20um mito; clo a 37 qo 4 73

Use the film thickness tester to test ak

6% dE 2 55 fo

Hardtop XP at 50-80 microns; Color: black a3] 352. 24h 29) 35h

anfehes Use the film thickness tester to test;

- ‘The minimum total DFT should be 125 microns or ok,

ante: 303 3) 3} 37 333

Signature: Signature

Holt Sof

Inspector/date Check/date

Surface derusting, painting inspection records

Item no.

Vatl97SAHU | Product model_| VHP600-381DH40702

Partnumber | 0051388000A/B

quantity a:

‘Ambient - ] = Substrate i ‘consiruction

temperauretuniaiy | 24°C / 30% || Dewpoint Rio temperature U2 dae | W/P-.2%

i i inspection

Inspection items technical requirements & Inspection methods 4, Inspection records aie

Sandblasting Achieve SA2.5 above; 1

eka ie exesiltiaple Vill Gointerison wehiod Steel surface after sand blasting derusting, achieve $A2.5 level. Ok

Prine | HOt ives 7ot20um microns: co: | 82 | 4S | fod | foo | 97

white;

Use the film thickness tester to test ok

Ss) 7 (Sil er fle

Hardtop XP_at 50-80

rons; Color: black

Hielaindie Use the film thickness tester to test; is a 28 at Wb

‘The minimum total DFT should be 125 microns or

more.

2-\ us ay 16s

Signature: Signature:

a DelPe. 24.

Inspector/date

Cheek/date Lees

;

Surface derusting, painting inspection records

Item no. | veris7srcu2 | Productmode! | viPIs0-sopvao7o1 | Partnumber (0051263000 ‘quantity 7

“Ambient a % "Substrate a ‘construction al

temperature/humidity Dew poi ae teinperature vee dae | PIPL

Inspection items | technical requirements & Inspection methods

4, Inspection records

inspection results

‘Sandblasting Achieve SA2.5 above; Steel surface after sand blasting derusting, achieve SA2.5

derusting Reference sample visual comparison method level. :

Primer | Jotacote Universal at 70-120um microns: color: white; | __ 4°] Ge 7 v | &

Use the film thickness tester to test = ok

we 83 84 | 3/

Hardtop XP at 50-80 microns; Color: black 2.95) ! 3

ian geet Use the film thickness tester to test; wi 7 m7 3

ee ‘The minimum total DFT should be 125 microns or ok,

ie 26 ay 298 | 232 | 23

Samia

019-52

Inspector/date f aelF: 5.24. Cheek/date

Surface derusting, painting inspection records

tem no.

Vatl975FCU-3 | Product model | VLP1S0-80DV40701 | Part number 0051263000

quantity 1

ase SS j a eee oor | Gasket ff

temperaturefnumidity | 24% /7676 || Pew point g0rt temperature re duc | ARK 2E

Inspection items | technical requirements & Inspection methods 4 Inspection records ‘espera

Sandblasting Achieve SA2.5 above: : ae

denusting Reference sample visual comparison method Steel surface after sand blasting derusting, achieve SA2.5 level. x

ieee Jotacote Universal at 702m micros, cole 7 49 qs aa DA i

Use the film thickness tester to test =

2 34+ xs 835 | &

Hardtop XP at $0-80 microns; Color: black 24 254 27)

Finishing cour ‘Use the film thickness tester to test; ie

pees ‘The minimum total DFT should be 125 microns or

more.

173 230 26)

‘Signature: a

ay

Inspector/date Check/date

Surface derusting, painting inspection records

tem no. Vatl97SFCU-4 Product model VLP150-80D 40702 Part number 0051263000 ‘quantity I

~ Ambient ae F i an ‘substrate ° ‘construction al

eA Bite od) ee | ae ese

aa ea, —

‘Sandblasting Achieve SA2.5 above; “ a 4

i Kiana eee wte eR Steel surface ater sand blasting derustng, achieve SA2.S level. |

a Jae Uva a 70-1200 mons; clo & | 6 78 ae |g

Use the film thickness tester to test ok

Weel S| Abe | aa Be

Hardtop XP at 50-80 microns; Color: black 23 3By: 3 sl 238

rate Use the film thickness tester to test; th a |

ie ‘The minimum total DFT should be 125 microns or ok

more.

242 227 ay 7B 246

Signature: Bir ‘Signatun

Re

Inspectorfdate

Check/date

Surface derusting, painting inspection records

Item no, Vatl975PCU-1 | Product model | VLP150-80DV40701 Part number 0051263000 quantity 1

‘Ambient x oe ‘substrate. * construction z

Da

tempeatucumicivy | °C /30,96 | | Pew point 89 °C nmpatls ae tae [PK

Inspection items technical requirements & Inspection methods. ‘Inspection records inspection results

Sandblasting, Achieve SA2.5 above; Meant

denusting Reference sample visual comparison method Steel surface after sand blasting derusting, achieve SA2.5 level. i

Pri Jotacote Universal at 70-120um microns; color:

me

white:

Use the film thickness tester to test

ie

72 atts

GI

Jo

ok

&4 (eo 76 Soles

Hardtop XP_at 50-80 microns; Color: black Is 270

Finishing coat Use the film thickness tester to test; i I 15 . 34

‘The minimum toil DET should be 125 microns or

as 248 | /70 wb | a9

‘Signature: ” ‘Signature:

rama 34h im

Inspector/date

Check/date

Surface derusting, painting inspection records

Item no. vati975ACCU-1 | Product model VCUAIS6 Part number 1005139000 quantity 1

Ambient Shy " ‘ ‘substrate. % ‘construction | (-

temperanretnumisty | YS /36/ | Dew point Bo eae 22F | OMe | olf >|

ims | chnical requirements & Inspection ; inspection

Inspection ite — Insection records sein

i ‘Achieve SA2.5 above;

ee Reference sample visual comparison Steel surface after sand blasting derusting, achieve SA2.5 level.

a method z

Jotacote Universal at 70-120um microns; % i 3

is color: white; 4 a A if ie ok

Use the film thickness tester to test

ce | leo 7 86 87 | 9

Hardtop XP at 50-80 microns; Color: black 2s 28 232

Finishing coat Use the film thickness tester to test; 24h Ms af

a ‘The minimum total DFT should be 125 ok

‘microns or more

Oe. Ms 233 287 | 34) elas

Seine 3 Signature:

Inspector/date Cheek/date

Surface derusting, painting inspection records

em no vati97SAcCU-2 | Product model YCUAIS6 Partnumber [005139000] quanti 1

Anita | yy ; = a sibsrte | Seton =

temperaurehumicity | DLC (2676 | | Pew point Bet gee are toe” | AP Laz

Inspection items | — technical requirements & Inspection methods © nspection records pe

Sandblasting Achieve $A2.5 above; ‘ :

mmc Ritecice smn eal nese Be Steel surface afier sand blasting derusting, achieve SA2.5 level 3

ae Jotacote Universal at 71 20um microns; color: 27 se 74 ES Sd yt

Use the film thickness tester to test

26 eal s272es ios ie

Hardtop XP_at 50-80 microns; Color: black 2b Be 248

Finishing coat ‘Use the film thickness tester to test: pa ae | 3

io ‘The minimum total DFT should be 125 microns or > ok

eo 174 | 30 24 wo | _xapvan |.

Signature: Hx % Signat is

Inspector/date Check/date 4 e

. Ir.

Ass

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 316L Angle and Channel Steel 3Document1 page316L Angle and Channel Steel 3RicardoNo ratings yet

- P11099-HT ProcedureDocument7 pagesP11099-HT ProcedureRicardoNo ratings yet

- Axess - Global Reference List - 2021Document8 pagesAxess - Global Reference List - 2021RicardoNo ratings yet

- 8215-367S D55 48barg NameplateDocument1 page8215-367S D55 48barg NameplateRicardoNo ratings yet

- BRAZILIAN - RecipesDocument19 pagesBRAZILIAN - RecipesRicardoNo ratings yet

- World Class Solutions: Ricardo Calvet Freire Operations Manager APACDocument11 pagesWorld Class Solutions: Ricardo Calvet Freire Operations Manager APACRicardoNo ratings yet

- Annex B-1: Enhanced Jobs Support Scheme: Ministry of Finance 1Document5 pagesAnnex B-1: Enhanced Jobs Support Scheme: Ministry of Finance 1RicardoNo ratings yet

- Product Sheet - DROPS TrainingDocument2 pagesProduct Sheet - DROPS TrainingRicardoNo ratings yet

- Lyft - Pulsed Eddy CurrentDocument8 pagesLyft - Pulsed Eddy CurrentRicardoNo ratings yet

- Conama 436Document34 pagesConama 436RicardoNo ratings yet

- Axess Group - Brazilian ComplianceDocument1 pageAxess Group - Brazilian ComplianceRicardoNo ratings yet

- 700169-04-271 - Motor Megger TestDocument3 pages700169-04-271 - Motor Megger TestRicardoNo ratings yet

- Alpa - Product Datasheet - 2019Document28 pagesAlpa - Product Datasheet - 2019RicardoNo ratings yet

- RBI Assessment Recommended Work-Ing ProcessDocument1 pageRBI Assessment Recommended Work-Ing ProcessRicardoNo ratings yet