Professional Documents

Culture Documents

Pressure Gauge WIKA

Uploaded by

Muhammad IhsanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Gauge WIKA

Uploaded by

Muhammad IhsanCopyright:

Available Formats

Pressure

Bourdon tube pressure gauge, copper alloy

Stainless steel case, case filling

Model 213.53, NS 50 [2"], 63 [2 ½"] and 100 [4"]

WIKA data sheet PM 02.12

for further approvals,

see page 7

Applications

■ For measuring locations with high dynamic pressure loads

and vibrations

■ For gaseous and liquid media that are not highly viscous

or crystallising and will not attack copper alloy parts

■ Hydraulics

■ Compressors, shipbuilding

Special features

■ Very good vibration and shock resistance

■ Especially robust design

■ Type approval for the shipbuilding industry

■ Scale ranges to 0 ... 1,000 bar or 0 ... 15,000 psi

Bourdon tube pressure gauge, model 213.53.100,

lower mount

Description

The liquid-filled model 213.53 mechanical Bourdon tube The cases of the model 213.53 are available in nominal

pressure gauge is constructed with a case from stainless sizes of 50 [2"], 63 [2 ½"] and 100 [4"] and fulfil IP65 ingress

steel and wetted parts from copper alloy. protection. With an accuracy of up to class 1.0, this pressure

gauge is suitable for a wide range of applications in industry.

WIKA manufactures and qualifies the pressure gauge in

accordance with the standards EN 837-1 and ASME B40.100. For mounting in control panels, the pressure gauges with a

As a safety function, this instrument has a blow-out device. In back mount process connection can be fitted with a mounting

the event of a failure, overpressure can escape there. flange or with a triangular profile ring and mounting bracket.

Due to the case filling, the pressure element and movement

are efficiently damped. Therefore, these instruments are

particularly suited to measuring locations with high dynamic

loads, such as fast load cycles or vibrations.

WIKA data sheet PM 02.12 ∙ 03/2023 Page 1 of 12

Data sheets showing similar products:

Stainless steel case, liquid filling, NS 40, 80 and 100; model 113.53; see data sheet PM 01.08

Specifications

Basic information

Standard ■ EN 837-1

■ ASME B40.100

For information on the “Selection, installation, handling and operation of pressure

gauges”, see technical information IN 00.05.

Further version Special design, model 213.57

Nominal size (NS) ■ Ø 50 mm [2"]

■ Ø 63 mm [2 ½"]

■ Ø 100 mm [4"]

Connection location ■ Lower mount (radial)

■ Centre back mount (only for NS 50 [2"] and NS 63 [2 ½"])

■ Lower back mount (only for NS 100 [4"])

Window ■ Plastic, crystal-clear

■ Laminated safety glass

Case

Design NS 50 [2"], 63 [2 ½"] Safety level “S2” per EN 837-1: With blow-out device

NS 100 [4"] Safety level “S1” per EN 837-1: With blow-out device

Position of blow-out device:

NS 50 [2"]: Case back, at 12 o'clock

NS 63 [2 ½"], 100 [4"]: Case circumference, at 12 o'clock

Filling plug can be vented and resealed for internal pressure compensation

Sealing towards process connection with O-ring

Material Stainless steel, natural finish

Ring Crimp ring, stainless steel

Mounting ■ Without

■ Panel mounting flange, stainless steel 1)

■ Panel mounting flange, polished stainless steel 2)

■ Triangular profile ring with mounting bracket, polished stainless steel 3)

■ Surface mounting flange, stainless steel 4)

Case filling ■ Glycerine

■ Glycerine-water mixture for scale range ≤ 0 ... 2.5 bar [≤ 0 ... 40 psi]

■ Silicone oil

Movement Copper alloy

1) Only for back mount

2) Only for NS 63 [2 ½"] and NS 100 [4"], back mount

3) Only for NS 63 [2 ½"]

4) Only for NS 63 [2 ½"] and NS 100 [4"]

Measuring element

Type of measuring element Bourdon tube, C-type or helical type

Material

NS 50 [2"] ≤ 600 bar Copper alloy

> 600 bar Stainless steel 316L

NS 63 [2 ½"], NS 100 [4"] ≤ 400 bar Copper alloy

> 400 bar Stainless steel 316L

Leak tightness Leakage rate: < 5∙10-3 mbar l/s

WIKA data sheet PM 02.12 ∙ 03/2023 Page 2 of 12

Accuracy specifications

Accuracy class

NS 50 [2"], 63 [2 ½"] ■ EN 837-1 Class 1.6

■ ASME B40.100 ±2 % │ ±1 % │ ±2 % of measuring span (grade A)

NS 100 [4"] ■ EN 837-1 Class 1.0

■ ASME B40.100 ±1 % of measuring span (grade 1A)

Temperature error On deviation from the reference conditions at the measuring system:

≤ ±0.4 % per 10 °C [≤ ±0.4 % per 18 °F] of full scale value

Reference conditions

Ambient temperature +20 °C [68 °F]

WIKA data sheet PM 02.12 ∙ 03/2023 Page 3 of 12

Scale ranges

bar kg/cm2

0 ... 0.6 0 ... 30 0 ... 0.6 0 ... 40

0 ... 1 0 ... 40 0 ... 1 0 ... 60

0 ... 1.6 0 ... 60 0 ... 1.6 0 ... 70

0 ... 2 0 ... 70 0 ... 2 0 ... 100

0 ... 2.5 0 ... 100 0 ... 2.5 0 ... 140

0 ... 4 0 ... 140 0 ... 4 0 ... 160

0 ... 6 0 ... 160 0 ... 6 0 ... 200

0 ... 7 0 ... 200 0 ... 7 0 ... 250

0 ... 10 0 ... 250 0 ... 10 0 ... 315

0 ... 12 0 ... 315 0 ... 14 0 ... 400

0 ... 14 0 ... 400 0 ... 16 0 ... 600

0 ... 16 0 ... 600 0 ... 20 0 ... 700

0 ... 20 0 ... 700 0 ... 25 0 ... 1,000

0 ... 25 0 ... 1,000 0 ... 30

kPa MPa

0 ... 60 0 ... 4,000 0 ... 0.06 0 ... 4

0 ... 70 0 ... 6,000 0 ... 0.1 0 ... 6

0 ... 100 0 ... 7,000 0 ... 0.16 0 ... 7

0 ... 160 0 ... 8,000 0 ... 0.2 0 ... 10

0 ... 200 0 ... 10,000 0 ... 0.25 0 ... 14

0 ... 250 0 ... 14,000 0 ... 0.4 0 ... 16

0 ... 400 0 ... 16,000 0 ... 0.6 0 ... 20

0 ... 600 0 ... 20,000 0 ... 0.7 0 ... 25

0 ... 700 0 ... 25,000 0 ... 1 0 ... 31.5

0 ... 800 0 ... 31,500 0 ... 1.4 0 ... 40

0 ... 1,000 0 ... 40,000 0 ... 1.6 0 ... 60

0 ... 1,400 0 ... 60,000 0 ... 2 0 ... 70

0 ... 1,600 0 ... 70,000 0 ... 2.5 0 ... 100

0 ... 2,500 0 ... 100,000 0 ... 3

0 ... 3,000

psi

0 ... 10 0 ... 600

0 ... 15 0 ... 800

0 ... 30 0 ... 1,000

0 ... 60 0 ... 1,500

0 ... 100 0 ... 2,000

0 ... 150 0 ... 3,000

0 ... 160 0 ... 4,000

0 ... 200 0 ... 5,000

0 ... 300 0 ... 6,000

0 ... 400 0 ... 7,500

WIKA data sheet PM 02.12 ∙ 03/2023 Page 4 of 12

Vacuum and +/- scale ranges

bar kg/cm2

-0.6 ... 0 -1 ... +9 -0.6 ... 0 -1 ... +5

-1 ... 0 -1 ... +10 -1 ... 0 -1 ... +7

-1 ... +0.6 -1 ... +15 -1 ... +0.6 -1 ... +9

-1 ... +1 -1 ... +24 -1 ... +1 -1 ... +10

-1 ... +1.5 -1 ... +25 -1 ... +1.5 -1 ... +15

-1 ... +2 -1 ... +30 -1 ... +2 -1 ... +24

-1 ... +3 -1 ... +32 -1 ... +3 -1 ... +30

-1 ... +4 -1 ... +40 -1 ... +4

-1 ... +7

kPa MPa

-60 ... 0 -100 ... +500 -0.06 ... 0 -0.1 ... +0.5

-100 ... 0 -100 ... +700 -0.1 ... 0 -0.1 ... +0.9

-100 ... +60 -100 ... +900 -0.1 ... +0.06 -0.1 ... +1.5

-100 ... +100 -100 ... +1,000 -0.1 ... +0.15 -0.1 ... +2.4

-100 ... +150 -100 ... +1,500 -0.1 ... +0.3

-100 ... +200 -100 ... +2,400

-100 ... +300 -100 ... +3,000

-100 ... +400

psi

-15 inHg ... 0 -30 inHg ... +100

-30 inHg ... 0 -30 inHg ... +160

-30 inHg ... +15 -30 inHg ... +200

-30 inHg ... +30 -30 inHg ... +300

-30 inHg ... +60

Further details on: Scale ranges

Special scale ranges Other scale ranges on request

Unit ■ bar

■ psi

■ kg/cm²

■ kPa

■ MPa

Increased overload safety ■ Without

■ 2 times

The possibility of selection depends on the scale range

Dial

Scale colour Black

Material Aluminium

Special scale ■ Without

■ With temperature scale for refrigerant, e.g. for NH3: R 717

Other scales or customer-specific dials, e.g. with red mark, circular arcs or circular

sectors, on request

WIKA data sheet PM 02.12 ∙ 03/2023 Page 5 of 12

Further details on: Scale ranges

Pointer

Instrument pointer Aluminium, black

Mark pointer/drag pointer ■ Without

■ Red mark pointer on dial, fixed

■ Red mark pointer on window, adjustable

■ Mark pointer on bayonet ring, adjustable

■ Red drag pointer on window, adjustable

Pointer stop pin ■ Without

■ At zero point (only for NS 50 [2"] and NS 63 [2 ½"])

■ At 6 o‘clock (only for NS 100 [4"])

Process connection

Standard ■ EN 837-1

■ ISO 7

■ ANSI/B1.20.1

Size

EN 837-1 ■ G ⅛ B, male thread

■ G ¼ B, male thread

■ G ½ B, male thread

■ M12 x 1.5, male thread

■ M20 x 1.5, male thread

ISO 7 ■ R ¼, male thread

■ R ½, male thread

ANSI/B1.20.1 ■ ¼ NPT, male thread

■ ½ NPT, male thread

Restrictor ■ Without

■ ∅ 0.5 mm [0.02"], copper alloy

■ ∅ 0.3 mm [0.012"], copper alloy

Material (wetted)

Process connection Copper alloy

Bourdon tube → See table “Measuring element”, page 2

Other process connections on request

Operating conditions

Medium temperature

Instruments with glycerine filling -20 ... +100 °C [-4 ... +212 °F]

Instruments with silicone oil filling -40 ... +100 °C [-40 ... +212 °F]

Ambient temperature

Instruments with glycerine filling -20 ... +60 °C [-4 ... +140 °F]

Instruments with silicone oil filling -40 ... +60 °C [-40 ... +140 °F]

Pressure limitation

NS 50 [2"], 63 [2 ½"] Steady 3/4 x full scale value

Fluctuating 2/3 x full scale value

Short time Full scale value

NS 100 [4"] Steady Full scale value

Fluctuating 0.9 x full scale value

Short time 1.3 x full scale value

Ingress protection per IEC/EN 60529 ■ IP65

■ IP66 (only selectable for scale ranges ≥ 0 ... 20 bar [≥ 0 ... 400 psi])

WIKA data sheet PM 02.12 ∙ 03/2023 Page 6 of 12

Approvals

Logo Description Region

EU declaration of conformity European Union

Pressure equipment directive

PS > 200 bar, module A, pressure accessory

UKCA United Kingdom

Pressure equipment (safety) regulations

- CRN Canada

Safety (e.g. electr. safety, overpressure, ...)

For scale ranges ≤ 1,000 bar

Optional approvals

Logo Description Region

PAC Kazakhstan Kazakhstan

Metrology, measurement technology

- MChS Kazakhstan

Permission for commissioning

- PAC Ukraine Ukraine

Metrology, measurement technology

PAC Uzbekistan Uzbekistan

Metrology, measurement technology

- PAC China China

Metrology, measurement technology

DNV GL International

Ships, shipbuilding (e.g. offshore)

Manufacturer's information and certificates

Logo Description

- Pressure equipment directive (PED) for maximum allowable pressure PS ≤ 200 bar

- Suitability of wetted materials for drinking water in accordance with the European 4MS initiative

Certificates (option)

Certificates

Certificates ■ 2.2 test report per EN 10204 (e.g. state-of-the-art manufacturing, indication accuracy)

■ 3.1 inspection certificate for indication accuracy per EN 10204

■ PCA calibration certificate, traceable and accredited in accordance with ISO/IEC 17025

■ Calibration certificate by a national accreditation body, traceable and accredited in accordance with

ISO/IEC 17025 on request

Recommended calibration 1 year (dependent on conditions of use)

interval

→ For approvals and certificates, see website

WIKA data sheet PM 02.12 ∙ 03/2023 Page 7 of 12

Dimensions in mm [in]

NS 50 [2"] and NS 63 [2 ½"], lower mount (radial)

b

⌀D e

□SW □SW

S3

S3

G G a

ANSI ISO NS Weight

1224557.03

NS 50 [2"] 0.15 kg [0.33 lb]

NS 63 [2 ½"] 0.21 kg [0.46 lb]

1224557.03

Process connection with thread per EN 837-1

NS G Dimensions in mm [in]

h ±1 [0.04] S3 a b ±0.5 [0.02] e D SW

NG 50 [2"]

h±1 G⅛B 45 [1.77] 10 [0.39] 12 [0.47] 30 [1.18] 5.5 [0.22] 55 [2.17] 14 [0.55]

S3

NS h [±0.04] G¼B 48 [1.89] 13 [0.51] 12 [0.47] 30 [1.18] 5.5 [0.22] 55 [2.17] 14 [0.55]

50 [2] 48 [1.89]

B 13M12

[0.51]x 1.5 48 [1.89] 13 [0.51] 12 [0.47] 30 [1.18] 5.5 [0.22] 55 [2.17] 14 [0.55]

63 [2.5] 54 [2.13]

50 [2] 63 [2 ½"]

45 [1.77] G ⅛ B 51 [2.01] 10 [0.39] 13 [0.51] 32 [1.26] 6.5 [0.26] 68 [2.68] 14 [0.55]

B 10 [0.39]

63 [2.5] 51 [2.01] G¼B 54 [2.13] 13 [0.51] 13 [0.51] 32 [1.26] 6.5 [0.26] 68 [2.68] 14 [0.55]

PT 50 [2] 48 [1.89]

13M12

[0.51]x 1.5 54 [2.13] 13 [0.51] 13 [0.51] 32 [1.26] 6.5 [0.26] 68 [2.68] 14 [0.55]

SO7 63 [2.5] 54 [2.13]

PT 50 [2] 45 [1.77]

10 [0.39]

SO7 63 [2.5] Process

51 [2.01] connection with thread per ISO 7

50 [2] 48 [1.89]

NS

1,5 13G[0.51] Dimensions in mm [in]

63 [2.5] 54 [2.13]

h ±1 [0.04] S3 a b ±0.5 [0.02] e D SW

50 [2"] R⅛ 45 [1.77] 10 [0.39] 12 [0.47] 30 [1.18] 5.5 [0.22] 55 [2.17] 14 [0.55]

R¼ 51 [2.01] 13 [0.51] 12 [0.47] 30 [1.18] 5.5 [0.22] 55 [2.17] 14 [0.55]

63 [2 ½"] R⅛ 51 [2.01] 10 [0.39] 13 [0.51] 32 [1.26] 6.5 [0.26] 68 [2.68] 14 [0.55]

R¼ 54 [2.13] 13 [0.51] 13 [0.51] 32 [1.26] 6.5 [0.26] 68 [2.68] 14 [0.55]

Process connection with thread per ANSI/B1.20.1

NS G Dimensions in mm [in]

h ±1 [0.04] S3 a b ±0.5 [0.02] e D SW

50 [2"] ⅛ NPT 45 [1.77] 10 [0.39] 12 [0.47] 30 [1.18] 5.5 [0.22] 55 [2.17] 14 [0.55]

¼ NPT 51 [2.01] 13 [0.51] 12 [0.47] 30 [1.18] 5.5 [0.22] 55 [2.17] 14 [0.55]

63 [2 ½"] ⅛ NPT 51 [2.01] 10 [0.39] 13 [0.51] 32 [1.26] 6.5 [0.26] 68 [2.68] 14 [0.55]

¼ NPT 54 [2.13] 13 [0.51] 13 [0.51] 32 [1.26] 6.5 [0.26] 68 [2.68] 14 [0.55]

WIKA data sheet PM 02.12 ∙ 03/2023 Page 8 of 12

NS 100 [4"], lower mount (radial)

⌀D b

e

h

□SW □SW

S3

S3

14597764.01

G G a NS Weight

ANSI ISO NS 100 [4"] 0.8 kg [1.76 lb]

14597764.01

Process connection with thread per EN 837-1

NS G Dimensions in mm [in]

h ±1 [0.04] S3 a b ±0.5 [0.02] D SW

gen in mm [inch]

ns in mm [inch] NS 100 [4"] G¼B 80 [3.15] 13 [0.51] 15.4 [0.61] 48 [1.89] 107 [4.21] 22 [0.87]

h ±1 G ½ B 87 [3.43] 20 [0.79] 15.4 [0.61] 48 [1.89] 107 [4.21] 22 [0.87]

e S3 SW

] h [±0.04]

87 20

[3.43] Process [0.79]

connection with thread per ISO 7

80 NS 13 G Dimensions in mm [in]

[3.15] 8 [0.51] 22

86 [0.32] 19 [0.87] h ±1 [0.04] S3 a b ±0.5 [0.02] D SW

[3.39] NS 100 [4"]

[0.75] R ¼ 80 [3.15] 13 [0.51] 15.4 [0.61] 48 [1.89] 107 [4.21] 22 [0.87]

80 13 R½ 86 [3.39] 19 [0.75] 15.4 [0.61] 48 [1.89] 107 [4.21] 22 [0.87]

[3.15] [0.51]

Process connection with thread per ANSI/B1.20.1

NS G Dimensions in mm [in]

h ±1 [0.04] S3 a b ±0.5 [0.02] D SW

NS 100 [4"] ¼ NPT 80 [3.15] 13 [0.51] 15.4 [0.61] 48 [1.89] 107 [4.21] 22 [0.87]

½ NPT 86 [3.39] 19 [0.75] 15.4 [0.61] 48 [1.89] 107 [4.21] 22 [0.87]

WIKA data sheet PM 02.12 ∙ 03/2023 Page 9 of 12

NS 50 [2½"] and NS 63 [2½"], centre back mount

b2

b

⌀D S3 e

ISO

G

ANSI □SW

G

NS Weight

31059155.03

NS 50 [2½"] 0.15 kg [0.33 lb]

S3 □SW

NS 63 [2½"] 0.21 kg [0.46 lb]

Process connection with thread per EN 837-1

NS G Dimensions in mm [in]

b2 ±0.5 [0.02] b ±0.5 [0.02] S3 e D

31059155.03 SW

50 [2"] G⅛B 52 [2.17] 30 [1.18] 10 [0.39] 5.5 [0.22] 55 [2.17] 14 [0.55]

G¼B 55 [2.17] 30 [1.18] 13 [0.51] 5.5 [0.22] 55 [2.17] 14 [0.55]

M12 x 1.5 55 [2.17] 30 [1.18] 13 [0.51] 5.5 [0.22] 55 [2.17] 14 [0.55]

63 [2 G½"] GNG⅛ B b2±1 54 [2.13] 32 [1.26] 10 [0.39] 6.5 [0.26] 68 [2.68] 14 [0.55]

S3

NS b2 [±0.04]

G¼B 57 [2.24] 32 [1.26] 13 [0.51] 6.5 [0.26] 68 [2.68] 14 [0.55]

50 [2] 55 [2.17]

G1/4B 13 [0.51]

63M12

[2.5]x 1.5 57 [2.24]57 [2.24] 32 [1.26] 13 [0.51] 6.5 [0.26] 68 [2.68] 14 [0.55]

50 [2] 52 [2.05]

G1/8B 10 [0.39]

63 [2.5] 54 [2.13]

Process connection with thread per ISO 7

1/4NPT 50 [2] 55 [2.17]

SW 13 [0.51]

NSR1/2 ISO7 63G[2.5] 57 [2.24]Dimensions in mm [in]

1/8NPT 50 [2] 52 [2.05]b2 ±0.5 [0.02] b ±0.5 [0.02] S3 e D SW

10 [0.39]

14 R1/4 ISO7 63 [2.5] 54 [2.13]

50 [2"] R⅛ 52 [2.17] 30 [1.18] 10 [0.39] 5.5 [0.22] 55 [2.17] 14 [0.55]

[0.55] 50 [2] 55 [2.17]

M12x1,5 R [2.5]

¼ 13 [0.51]

63 57 [2.24]55 [2.17] 30 [1.18] 13 [0.51] 5.5 [0.22] 55 [2.17] 14 [0.55]

63 [2 ½"] R⅛ 54 [2.13] 32 [1.26] 10 [0.39] 6.5 [0.26] 68 [2.68] 14 [0.55]

R¼ 57 [2.24] 32 [1.26] 13 [0.51] 6.5 [0.26] 68 [2.68] 14 [0.55]

Process connection with thread per ANSI/B1.20.1

NS G Dimensions in mm [in]

b2 ±0.5 [0.02] b ±0.5 [0.02] S3 e D SW

50 [2"] ⅛ NPT 52 [2.17] 30 [1.18] 10 [0.39] 5.5 [0.22] 55 [2.17] 14 [0.55]

¼ NPT 55 [2.17] 30 [1.18] 13 [0.51] 5.5 [0.22] 55 [2.17] 14 [0.55]

63 [2 ½"] ⅛ NPT 54 [2.13] 32 [1.26] 10 [0.39] 6.5 [0.26] 68 [2.68] 14 [0.55]

¼ NPT 57 [2.24] 32 [1.26] 13 [0.51] 6.5 [0.26] 68 [2.68] 14 [0.55]

WIKA data sheet PM 02.12 ∙ 03/2023 Page 10 of 12

NS 100 [4"], lower back mount

b2

⌀D b

e

S3

f

ISO

G

14571332.02

□SW

ANSI

G

NS Weight

S3 NS 100 [4"] 0.8 kg [1.76 lb]

Process connection with thread per EN 837-1

14571332.02

NS G Dimensions in mm [in]

b2 ±0.5 [0.02] b ±0.5 [0.02] S3 e f D SW

NS 100 G¼B 76.5 [3.01] 50 [1.97] 13 [0.51] 9 [0.36] 30 [1.18] 107 [4.21] 22 [0.87]

[4"][inch]

Abmessungen in mm

Dimensions in mm [inch] G½B 83.5 [3.29] 50 [1.97] 20 [0.97] 9 [0.36] 30 [1.18] 107 [4.21] 22 [0.87]

5 b2±1

e f S3 SW

2] b2 [±0.04] Process connection with thread per ISO 7

83,5 20

[3.21] NS G [0.79] Dimensions in mm [in]

76,5 13 b2 ±0.5 [0.02] b ±0.5 [0.02] S3 e f D SW

[2.93] 9 30 [0.51] 22

NS 100 R¼ 76.5 [3.01] 50 [1.97] 13 [0.51] 9 [0.36] 30 [1.18] 107 [4.21] 22 [0.87]

82,5 [0.36] [1.18] 19 [0.87]

[4"]

[3.17] R ½ [0.75] 82.5 [3.25] 50 [1.97] 20 [0.97] 9 [0.36] 30 [1.18] 107 [4.21] 22 [0.87]

76,5 13

[2.93] [0.51]

Process connection with thread per ANSI/B1.20.1

NS G Dimensions in mm [in]

b2 ±0.5 [0.02] b ±0.5 [0.02] S3 e f D SW

NS 100 ¼ NPT 76.5 [3.01] 50 [1.97] 13 [0.51] 9 [0.36] 30 [1.18] 107 [4.21] 22 [0.87]

[4"]

½ NPT 82.5 [3.25] 50 [1.97] 20 [0.97] 9 [0.36] 30 [1.18] 107 [4.21] 22 [0.87]

WIKA data sheet PM 02.12 ∙ 03/2023 Page 11 of 12

Ordering information

Model / Nominal size / Scale range / Process connection / Connection location / Options

© 09/2008 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

03/2023 EN

WIKA data sheet PM 02.12 ∙ 03/2023 Page 12 of 12

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

info@wika.de

www.wika.de

You might also like

- OrificeMaster Single Chamber Orifice FittingDocument8 pagesOrificeMaster Single Chamber Orifice FittingPaul Wowor100% (1)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Kingmaker With Mike Rashid - 4 Weeks To Fighting ShapeDocument6 pagesKingmaker With Mike Rashid - 4 Weeks To Fighting ShapeRayNo ratings yet

- Bourdon Tube Pressure Gauge, Stainless Steel For The Process Industry, Standard Version Models 232.50, 233.50, NS 63 (2 "), 100 (4") and 160 (6")Document11 pagesBourdon Tube Pressure Gauge, Stainless Steel For The Process Industry, Standard Version Models 232.50, 233.50, NS 63 (2 "), 100 (4") and 160 (6")chienncNo ratings yet

- Datasheet For WIKA Pressure GuageDocument11 pagesDatasheet For WIKA Pressure GuageOware JnrNo ratings yet

- Capsule Pressure Gauge, Stainless Steel For The Process Industry Models 632.50 and 633.50, NS 63 (2 "), 100 (4"), 160 (6")Document12 pagesCapsule Pressure Gauge, Stainless Steel For The Process Industry Models 632.50 and 633.50, NS 63 (2 "), 100 (4"), 160 (6")greatNo ratings yet

- Wika 213.53 Pressure Gauge Catalog PageDocument4 pagesWika 213.53 Pressure Gauge Catalog PageM MNo ratings yet

- Bourdon Tube Pressure Gauge, Stainless Steel For The Process Industry, Safety Version Models 232.30 and 233.30Document12 pagesBourdon Tube Pressure Gauge, Stainless Steel For The Process Industry, Safety Version Models 232.30 and 233.30TÀi VÕNo ratings yet

- WIKA Pressure Gauges-DS PM0101 en Co 3997Document11 pagesWIKA Pressure Gauges-DS PM0101 en Co 3997farhanbaig125319No ratings yet

- Bourdon Tube Pressure Gauge, Copper Alloy For Welding, Cutting and Allied Processes Models 111.11, 111.31Document7 pagesBourdon Tube Pressure Gauge, Copper Alloy For Welding, Cutting and Allied Processes Models 111.11, 111.31Parth BhattNo ratings yet

- Bourdon Tube Pressure Gauge, Stainless Steel Xsel Process Pressure Gauge Models 232.34 and 233.34, NS 4 " and 6"Document8 pagesBourdon Tube Pressure Gauge, Stainless Steel Xsel Process Pressure Gauge Models 232.34 and 233.34, NS 4 " and 6"rosemaryNo ratings yet

- Bourdon Tube Pressure Gauge Stainless Steel Case Type 212.53 - Dry Case Type 213.53 - Liquid-Filled CaseDocument3 pagesBourdon Tube Pressure Gauge Stainless Steel Case Type 212.53 - Dry Case Type 213.53 - Liquid-Filled CasecarlosNo ratings yet

- Bourdon Tube Pressure Gauges Model 213.53, Liquid Filling, Stainless Steel CaseDocument2 pagesBourdon Tube Pressure Gauges Model 213.53, Liquid Filling, Stainless Steel CaseAhrian BenaNo ratings yet

- Ds pm0215 en CoDocument7 pagesDs pm0215 en CoMsach RoysNo ratings yet

- Bourdon Tube Pressure Gauge, Stainless Steel Compact Version, NS 40, 50 and 63 Model 131.11Document4 pagesBourdon Tube Pressure Gauge, Stainless Steel Compact Version, NS 40, 50 and 63 Model 131.11Parth BhattNo ratings yet

- Anchor-Bolts in CMU Wall DesignDocument26 pagesAnchor-Bolts in CMU Wall DesignWenxuan WangNo ratings yet

- Bimetal Thermometer Process Version Per ASME B40.200 Model TG53Document10 pagesBimetal Thermometer Process Version Per ASME B40.200 Model TG53SAM AZNo ratings yet

- Bourdon Tube Pressure Gauge Stainless Steel Construction Model 21X.53Document3 pagesBourdon Tube Pressure Gauge Stainless Steel Construction Model 21X.53Dennis MendozaNo ratings yet

- Manometer Air DryerDocument4 pagesManometer Air DryerBerryNo ratings yet

- Capsule Pressure Gauge, Stainless Steel For The Process Industry Models 632.50, 633.50, NS 63, 100, 160Document4 pagesCapsule Pressure Gauge, Stainless Steel For The Process Industry Models 632.50, 633.50, NS 63, 100, 160RaniardianNo ratings yet

- Bourdon Tube Pressure Gauge, Stainless Steel For The Process Industry, Safety Version, NS 63, 100 and 160 Models 232.30, 233.30Document4 pagesBourdon Tube Pressure Gauge, Stainless Steel For The Process Industry, Safety Version, NS 63, 100 and 160 Models 232.30, 233.30Chau TranNo ratings yet

- Specification For Carbon Steel Piping MaterialsDocument8 pagesSpecification For Carbon Steel Piping MaterialsAmro HarasisNo ratings yet

- MS-01-179 Tubing Tools and AccessoriesDocument12 pagesMS-01-179 Tubing Tools and AccessoriesJacques StrappeNo ratings yet

- Anchor BoltsDocument27 pagesAnchor Boltsセリロ しわぁb ぱtNo ratings yet

- Bourdon Tube Pressure Gauges Model 213.53, Liquid Filling, Stainless Steel CaseDocument2 pagesBourdon Tube Pressure Gauges Model 213.53, Liquid Filling, Stainless Steel CaseElectrohidraulica PchNo ratings yet

- S1.4.5.) Datasheet PRESSURE GAUGEDocument3 pagesS1.4.5.) Datasheet PRESSURE GAUGEEkoNo ratings yet

- Load-Bearing (Transverse and Axial) Steel Studs, Runners (Tracks), and Bracing or Bridging For Screw Application of Gypsum Panel Products and Metal Plaster BasesDocument4 pagesLoad-Bearing (Transverse and Axial) Steel Studs, Runners (Tracks), and Bracing or Bridging For Screw Application of Gypsum Panel Products and Metal Plaster BasesJesús Luis Arce GuillermoNo ratings yet

- Wika F73.100 DS TM7301 en Co 2146Document15 pagesWika F73.100 DS TM7301 en Co 2146NCNo ratings yet

- Input ValuesDocument5 pagesInput ValuesmasoodNo ratings yet

- Pressure GaugeDocument2 pagesPressure Gaugeriteshsamantray521383No ratings yet

- BXINDDocument6 pagesBXINDKrunalNo ratings yet

- SCV30 31 Rev02Document3 pagesSCV30 31 Rev02Muhammad RidwanNo ratings yet

- Notes For - Process Level GaugesDocument8 pagesNotes For - Process Level GaugesDavid BaughNo ratings yet

- Rupture Disk: SKR-U Rupture Disk Partnered With A Threaded Union-Type HolderDocument4 pagesRupture Disk: SKR-U Rupture Disk Partnered With A Threaded Union-Type HolderJulio Cesar ReyesNo ratings yet

- Input ValuesDocument38 pagesInput ValuesArjunNo ratings yet

- KG Brochure Globo GL2Document10 pagesKG Brochure Globo GL2mmmlormamNo ratings yet

- Transductor AIRMAR Cat - 65 PDFDocument2 pagesTransductor AIRMAR Cat - 65 PDFpatron de alturaNo ratings yet

- Welcome To Honingcraft: Total Support in Hydraulic Cylinder ManufacturingDocument34 pagesWelcome To Honingcraft: Total Support in Hydraulic Cylinder ManufacturingSHANENo ratings yet

- Yarway Wye Type Pipeline StrainersDocument12 pagesYarway Wye Type Pipeline StrainersLuis CartageneaNo ratings yet

- Landing-Valve - NaffcoDocument2 pagesLanding-Valve - NaffcoNOMAN100% (2)

- Ws Scheda Tecnica enDocument8 pagesWs Scheda Tecnica enAnonymous KRS4mebjxYNo ratings yet

- WRC For NozzleDocument43 pagesWRC For NozzleSachin55860% (1)

- Capsule Pressure Gauge, Copper Alloy Stainless Steel Case Model 612.20, NS 63, 100 and 160Document4 pagesCapsule Pressure Gauge, Copper Alloy Stainless Steel Case Model 612.20, NS 63, 100 and 160Akshay SetlurNo ratings yet

- Spesifikasi Teknik Double Arifice Air Relief Valve PN16Document2 pagesSpesifikasi Teknik Double Arifice Air Relief Valve PN16Cendrawasih PrNo ratings yet

- Modentic - AsiaValves CatalogDocument32 pagesModentic - AsiaValves CatalogLê Cẩm Hoàng Tuấn100% (1)

- Avk Gate Valve, Flanged, Pn10/16 02/59-003: EN 558-2 S.15/DIN F5, Position Indicator, Replaceable Stem Sealing, NBRDocument2 pagesAvk Gate Valve, Flanged, Pn10/16 02/59-003: EN 558-2 S.15/DIN F5, Position Indicator, Replaceable Stem Sealing, NBRbrilian pungkyNo ratings yet

- Creusabro MDocument4 pagesCreusabro MhealgoseNo ratings yet

- Rapid Allweiler Data BookDocument6 pagesRapid Allweiler Data BookJoNo ratings yet

- Wellhead Dual Cyclone DesanderDocument2 pagesWellhead Dual Cyclone DesanderAhmed MusallamNo ratings yet

- SS Case Brass Pressure Gauge - Economical - India Pressure GaugeDocument6 pagesSS Case Brass Pressure Gauge - Economical - India Pressure GaugeIndiapressure gaugeNo ratings yet

- Elephant ProWall Catalog and Installation Manual Gypsum Board Made in ThailandDocument8 pagesElephant ProWall Catalog and Installation Manual Gypsum Board Made in ThailandsabbirNo ratings yet

- NUTRON Forged Steel Floating Ball Valve Model T3 & B3 - XDocument32 pagesNUTRON Forged Steel Floating Ball Valve Model T3 & B3 - XElinton SarmientoNo ratings yet

- 113AR CompressedDocument2 pages113AR CompressedAbdul RahmanNo ratings yet

- Fig 520 High Lift Safety Valve: Features & BenefitsDocument3 pagesFig 520 High Lift Safety Valve: Features & Benefitst_rajith1179No ratings yet

- Bolted Bonet ValveDocument32 pagesBolted Bonet ValveRiza Ahmad Sofikul IrfanNo ratings yet

- AN3000 SeriesDocument2 pagesAN3000 SeriesdanishaslNo ratings yet

- Differential Pressure Gauges Diaphragm Element Series Type 732.51 All-Welded ConstructionDocument4 pagesDifferential Pressure Gauges Diaphragm Element Series Type 732.51 All-Welded Constructionsamira ameriNo ratings yet

- Bourdon Tube Pressure Gauge Model 131.11, Stainless Steel VersionDocument3 pagesBourdon Tube Pressure Gauge Model 131.11, Stainless Steel VersionChau TranNo ratings yet

- Branch CalculationDocument9 pagesBranch CalculationricardoNo ratings yet

- Bourdon Tube Safety Pressure Gauges Type D8 With Glycerine Filling DB enDocument5 pagesBourdon Tube Safety Pressure Gauges Type D8 With Glycerine Filling DB enj8164322No ratings yet

- Handle Breaker - 230403 - 03.51.00Document23 pagesHandle Breaker - 230403 - 03.51.00Muhammad IhsanNo ratings yet

- 5-We 10 RexrothDocument24 pages5-We 10 RexrothMuhammad IhsanNo ratings yet

- Product Data Sheet: Code No.: 4CT5A7-1Document1 pageProduct Data Sheet: Code No.: 4CT5A7-1Muhammad IhsanNo ratings yet

- weller1224201643500PM1 PDFDocument356 pagesweller1224201643500PM1 PDFMuhammad IhsanNo ratings yet

- AI Unit 4 Lecture Notes ItDocument15 pagesAI Unit 4 Lecture Notes IttonyNo ratings yet

- IC Project Management Dashboard 8579Document3 pagesIC Project Management Dashboard 8579carolisdwi permanaNo ratings yet

- APT9601 By: Serge Bontemps Phillipe Cussac Henry Foch Denis GrafhamDocument14 pagesAPT9601 By: Serge Bontemps Phillipe Cussac Henry Foch Denis GrafhamEduardo JoseNo ratings yet

- Biografi Seniman IndonesiaDocument15 pagesBiografi Seniman IndonesianajmiyyamiyaNo ratings yet

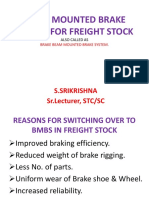

- BMBS For Freight Stock-SKDocument25 pagesBMBS For Freight Stock-SKSoumen BhattaNo ratings yet

- Chapter Three: Basic Cost Management ConceptsDocument23 pagesChapter Three: Basic Cost Management ConceptsAli AquinoNo ratings yet

- CT042-3-1-IDB-Week 10Document42 pagesCT042-3-1-IDB-Week 10小垃圾No ratings yet

- Treasury Code Lower Paper IV July 2017Document14 pagesTreasury Code Lower Paper IV July 2017Sunil SalimNo ratings yet

- Latest Battery DatasheetDocument4 pagesLatest Battery Datasheetابوحبيب النجارNo ratings yet

- Quality Assurance PlanDocument7 pagesQuality Assurance Planjoe sandoval quirozNo ratings yet

- Connecting Tomcat Server in Eclipse IDEDocument13 pagesConnecting Tomcat Server in Eclipse IDEAKHILA KHODAYNo ratings yet

- On Cooldown For Gas Turbine - Automation & Control Engineering ForumDocument1 pageOn Cooldown For Gas Turbine - Automation & Control Engineering ForumnboulegrouneNo ratings yet

- STAT 714 Linear Statistical Models: Lecture NotesDocument150 pagesSTAT 714 Linear Statistical Models: Lecture NotesFucKerWengieNo ratings yet

- An Introduction To Cooja Contiki-Os - Contiki WikiDocument8 pagesAn Introduction To Cooja Contiki-Os - Contiki WikiFaisal AliNo ratings yet

- DX DiagDocument25 pagesDX DiagOkta DarmawanNo ratings yet

- E207 - Communication Systems: Worksheet For Lesson 07: Standing WavesDocument8 pagesE207 - Communication Systems: Worksheet For Lesson 07: Standing Waves张瑜征No ratings yet

- ALLDBQUERIESDocument32 pagesALLDBQUERIESகார்த்திகேயன் பழனிச்சாமிNo ratings yet

- Manhole EstimateDocument5 pagesManhole EstimateEngr TahseenNo ratings yet

- Swift Standards Masterclass 2019 PresentationDocument120 pagesSwift Standards Masterclass 2019 PresentationSanip SuharyanaNo ratings yet

- Oil Recovery & Treatment: Megator System - 3 Restoring The Quality of WaterDocument2 pagesOil Recovery & Treatment: Megator System - 3 Restoring The Quality of WaterAhmedRamadanNo ratings yet

- Synchronization of Speed of DC Motors For Rolling Mills: D.Reddy PranaiDocument5 pagesSynchronization of Speed of DC Motors For Rolling Mills: D.Reddy PranaiBandi GaneshNo ratings yet

- Låtlo R/0F: - SubjectiveDocument11 pagesLåtlo R/0F: - SubjectiveAnil BasnetNo ratings yet

- Htk-Caravan 08-2018 en PDFDocument52 pagesHtk-Caravan 08-2018 en PDFJose Manuel MarinNo ratings yet

- Easy Watercolour Painting Tutorial - HNDMD BlogDocument7 pagesEasy Watercolour Painting Tutorial - HNDMD BlogsandeepNo ratings yet

- Servicenow Certified System Administrator Exam SpecificationDocument6 pagesServicenow Certified System Administrator Exam Specificationibmkamal-1No ratings yet

- OpAudCh03 CBET 01 501E Toralde, Ma - Kristine E.Document5 pagesOpAudCh03 CBET 01 501E Toralde, Ma - Kristine E.Kristine Esplana ToraldeNo ratings yet

- BLUESTAR Ni AgDocument78 pagesBLUESTAR Ni Ag2562923No ratings yet

- Manual KV Studio V9 PDFDocument542 pagesManual KV Studio V9 PDFMiguel Hitos100% (1)

- Concrete Slump Tests - Measuring The Workability of Concrete - Total ConcreteDocument7 pagesConcrete Slump Tests - Measuring The Workability of Concrete - Total ConcreteMOHAMED ELMASLAMANYNo ratings yet