0% found this document useful (0 votes)

1K views16 pagesHACCP Plan for Cascades Hotel Kitchen

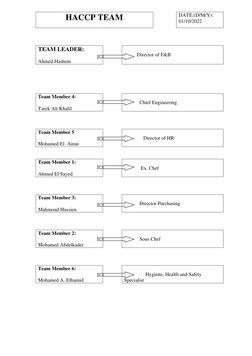

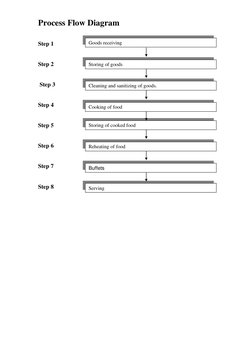

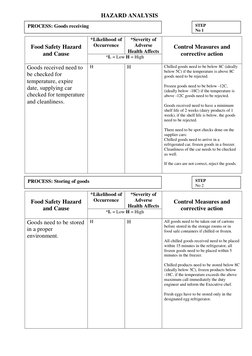

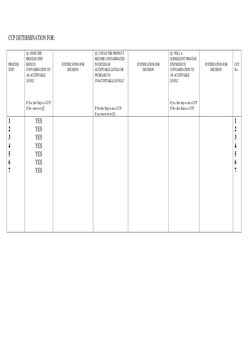

The document outlines a HACCP plan for a hotel kitchen. It details processes like receiving, storing, cooking, reheating food and identifies hazards at each step. Control measures are provided to prevent contamination and ensure food safety. The plan was prepared by the hotel's executive chef.

Uploaded by

محمد عبد الحميدCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views16 pagesHACCP Plan for Cascades Hotel Kitchen

The document outlines a HACCP plan for a hotel kitchen. It details processes like receiving, storing, cooking, reheating food and identifies hazards at each step. Control measures are provided to prevent contamination and ensure food safety. The plan was prepared by the hotel's executive chef.

Uploaded by

محمد عبد الحميدCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd