Professional Documents

Culture Documents

Engines 1000.3.4 W Euroiii

Uploaded by

Akos FeherOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engines 1000.3.4 W Euroiii

Uploaded by

Akos FeherCopyright:

Available Formats

WORKSHOP MANUAL

1000.3 WT E III

1000.3 WTI E III

1000.4 WTI E III

307.W.M300.en.0.02-Motori EURO I1 1 1/15/2010 8:09:21 PM

307.W.M300.en.0.02-Motori EURO ISec1:2 Sec1:2 1/15/2010 8:09:22 PM

TABLE OF CONTENTS

0 - INTRODUCTION

0.1 - Introduction 0-2

0.1.1 - Safety notes 0-3

0.1.2 - General safety rules 0-4

0.1.3 - Safety precautions for removal and refitting operations 0-6

0.1.4 - Lifting instructions 0-7

0.1.5 - Tightening torques 0-9

0.1.6 - Threadlockers, adhesives, sealants and lubricants 0-13

0.1.7 - Conversion factors 0-15

0.2 - Identification of the engine type and serial number position, Europe version 0-17

0.3 - Identification of the engine type and serial number position, EPA version 0-19

0.4 - Identification of the injection pump type 0-21

0.5 - Identification of the injector type 0-22

0.6 - Injector type identification 0-23

10 - TECHNICAL CHARACTERISTICS

10.1 - Engine 10-2

10.1.1 - Engine block technical data 10-2

10.1.2 - Crankshaft technical data (1000.3 WT E III,1000.3 WTI E III) 10-4

10.1.3 - Crankshaft technical data (1000.4 WTI E III) 10-6

10.1.4 - Piston technical data - Piston rings (1000.3 WT E III) 10-8

10.1.5 - Technical data for pistons - Piston rings (1000.3 WTI E III,1000.4 WTI E III) 10-10

10.1.6 - Connecting rod technical data 10-12

10.1.7 - Camshaft technical data - static advance of 11° (1000.3 WT E III) 10-13

10.1.8 - Camshaft technical data - static advance of 12° (1000.3 WTI E III,1000.4 WTI E III) 10-14

10.1.9 - Timing gears technical data 10-15

10.1.10 - Counter-rotating weights technical data (1000.4 WTI E III) 10-17

10.1.11 - Technical data and dimensions of valves - valve springs (1000.3 WT E III) 10-18

10.1.12 - Technical data and dimensions of valves - valve springs (1000.3 WTI E III) 10-20

10.1.13 - Technical data and dimensions of valves - valve springs (1000.4 WTI E III) 10-22

10.1.14 - Technical data and dimensions of cylinder heads - valve guide - valve seats (1000.3

WT E III) 10-24

10.1.15 - Technical data and dimensions of cylinder heads - valve guide - valve seats (1000.3

WTI E III,1000.4 WTI E III) 10-26

10.1.16 - Technical data and dimensions of rocker arms - rocker shafts - tappets 10-28

10.1.17 - Engine injector technical data (1000.3 WT E III) 10-29

10.1.18 - Engine injectors technical data (1000.3 WTI E III,1000.4 WTI E III) 10-30

10.1.19 - Hydraulic tappets diagram 10-31

20 - METHOD OF INTERVENTION

20.1 - B0 - Engine 20-2

20.1.1 - Operations prior to removal 20-2

20.1.2 - Checking engine block 20-4

20.1.3 - Crankshaft 20-5

20.1.4 - Crankshaft checks 20-12

307.W.M300.en.0.02-Motori EURO II I 1/15/2010 8:09:22 PM

TABLE OF CONTENTS

20.1.5 - Flywheel checks 20-14

20.1.6 - Renewal of crankshaft rear oil seal 20-15

20.1.7 - Pistons and cylinder liners 20-16

20.1.8 - Pistons and rings check 20-20

20.1.9 - Cylinder liners check 20-22

20.1.10 - Check connecting rods - gudgeon pins - rod cap screws 20-23

20.1.11 - Camshaft checks 20-25

20.1.12 - Camshaft 20-26

20.1.13 - Valve timing 20-31

20.1.14 - Timing gear checks 20-33

20.1.15 - Adjusting timing gears backlash 20-35

20.1.16 - Counter-rotating weights (1000.4 WTI E III) 20-37

20.1.17 - Counter-rotating weight checks (1000.4 WTI E III) 20-39

20.1.18 - Overhaul of counter-rotating weights assembly (1000.4 WTI E III) 20-40

20.1.19 - Valves check 20-41

20.1.20 - Valve seats check 20-42

20.1.21 - Valves sealing check 20-43

20.1.22 - Adjusting valve clearance (1000.3 WT E III,1000.3 WTI E III) 20-44

20.1.23 - Adjusting valve clearance (1000.4 WTI E III) 20-45

20.1.24 - Valve guides check and replacement 20-46

20.1.25 - Inspecting the rocker arms and rocker shafts 20-47

20.1.26 - Cylinder heads 20-48

20.1.27 - Calculation of cylinder head gasket thicknesses 20-58

20.1.28 - Valve springs check 20-60

20.1.29 - Heat exchanger removal 20-61

20.1.30 - Lubrication pump 20-62

20.1.31 - Lubrication pump disassembly (1000.3 WT E III,1000.3 WTI E III) 20-64

20.1.32 - Lubrication pump disassembly (1000.4 WTI E III) 20-65

20.1.33 - Oil sump 20-66

20.1.34 - INJECTION PUMPS, GOVERNOR AND FUEL SUPPLY 20-67

20.1.35 - Injection pump timing 20-70

20.1.36 - Injectors assembly 20-75

20.1.37 - Checking injectors protrusion - Renewal of copper bushes 20-76

20.1.38 - Injectors check 20-78

20.1.39 - Injection pumps control rod 20-80

20.1.40 - Mechanical governor overhaul (standard and with L.D.A.) 20-83

20.1.41 - Electronic governor adjustment 20-105

20.1.42 - Installation of electronic governor support 20-107

20.1.43 - Engine coolant pump 20-108

20.1.44 - Engine coolant pump 20-109

20.1.45 - Thermostatic valve 20-111

20.1.46 - Checking the thermostat valve 20-112

20.1.47 - Cooling and intake ducts 20-113

20.1.48 - Final engine checks 20-116

20.1.49 - Final refitting operations 20-119

II

307.W.M300.en.0.02-Motori EURO III II 1/15/2010 8:09:22 PM

0 - INTRODUCTION

307.W.M300.en.0.02-Motori EURO I0-1 0-1 1/15/2010 8:09:23 PM

INTRODUCTION

0.1 - INTRODUCTION

The purpose of this workshop manual is to provide instructions for repair technicians and a practical guide for improvement of the

quality of repairs. This manual enables repair technicians to acquire a thorough knowledge of the engine, indicating the correct

methods for fault diagnosis, for working in safety and for accurate dimensional checks and visual inspections of parts subject to repair.

The instructions also indicate the products to use, the tightening torques and the adjustment data. The technical material contained in

this manual is reserved for Authorised Dealers and Service Centres who will be duly informed of any technical changes to the engines

in question through the issue of documents regarding modifications, updates and supplements for optional equipment. All technicians

and their colleagues are expressly forbidden from reproducing any part of this manual in any form or from communicating the

contents to third parties without the express written permission of the Manufacturer, which remains the sole owner of this document

with all rights reserved in accordance with applicable laws.

0-2

307.W.M300.en.0.02-Motori EURO I0-2 0-2 1/15/2010 8:09:23 PM

INTRODUCTION

0.1.1 - Safety notes

To ensure that engines entrusted to Authorised Service Centres for repair or overhaul continue to function correctly, it is very important

that all repair work is carried out in the prescribed manner. The procedures for checks and repairs indicated in this manual are safe

and effective. Some of the operations described require the use of special tools and equipment; these tools have been specifically

designed for the intended purpose and may be ordered directly from the Manufacturer. DO NOT USE MAKESHIFT TOOLS; not only

is there a risk of personal injury, but such tools are rarely suited to the purpose for which they are used. In potentially hazardous

situations, always give priority to personal safety and take the necessary actions to eliminate the danger

0-3

307.W.M300.en.0.02-Motori EURO I0-3 0-3 1/15/2010 8:09:23 PM

INTRODUCTION

0.1.2 - General safety rules

● Even if you have a thorough knowledge of the engine as regards its components, operation and controls, always take particular

care when carrying out manoeuvres or movements; Remember that the engine you are working on is in need of repair or

overhaul and consequently may not always behave as expected.

● Before starting work, clean the engine thoroughly to remove all mud, dust and road dirt.

● When carrying out checks and repairs, wear close-fitting clothing, safety goggles and protective gloves that are suitable for

the task (cleaning, draining fluids, repairs). When working near moving parts, long hair should be gathered up and tied back

safely under a cap to prevent the risk of entanglement and severe injury.

● Do not allow anyone who is not directly involved in the work to come near the engine; ensure that they remain at a safe

distance.

● Keep well clear of moving parts; when the engine is running, some moving parts are not easily visible and therefore present a

risk of entanglement, even if protected by safety guards.

● Ensure that the area is well ventilated before starting the engine in order to avoid the formation of dangerous concentrations

of toxic gases; always connect suitable fumes extraction equipment to the exhaust pipe.

● Do not start the engine with the safety guards removed under any circumstances; all repair and adjustment operations must

be carried out with the engine stopped.

● Do not top up fuel, oil or coolant levels when the engine is running.

● Never smoke and ensure there are no naked flames nearby when topping up fuel or oil.

● Before checking or removing the battery, stop the engine and remove the key from the starter switch.

● Remove the battery and recharge in a well-ventilated area where the temperature exceeds 0°C.

● When checking or recharging the battery, do not smoke or allow naked flames in the vicinity as the hydrogen gas given off by

the battery is highly explosive.

● The liquid (electrolyte) contained in the battery is very harmful if it comes into contact with the skin and the eyes; for this

reason, always wear gloves and safety goggles with side shields when checking or topping up the battery. Should any

electrolyte accidentally come into contact with your skin, wash the affected areas immediately with plenty of fresh water; if

electrolyte comes into contact with your clothing, this should be removed as soon as possible. In case of accidental ingestion

of electrolyte, drink plenty of water, milk or vegetable oil, take antacids such as magnesium, bicarbonate, etc. and seek

medical attention immediately.

● Before working on the electrical systems, always disconnect the battery terminals.

DANGER

Always disconnect the negative lead (--) before the positive lead (+); when re-connecting the battery on completion

of the work, first connect the positive terminal (+) and then the negative (--).

● No welding is permitted on the engine.

● When topping up lubricants, always wear suitable protective gloves.

● Do not wear clothing contaminated by engine oil or hydraulic oil; prolonged contact with the skin can be harmful and may

cause allergic reactions.

● Used engine oil and hydraulic oil must be disposed of properly; recover used lubricants and dispose of them in accordance

with the applicable regulations.

● Before carrying out any work on the hydraulic or pneumatic systems, discharge all residual pressure from the circuits.

● Before carrying out any work on the hydraulic system or engine, allow the oil and engine coolant to cool down.

● When removing and refitting certain assemblies, it will be necessary to support the engine; use stands, jacks or blocks capable

of supporting the weight and arrange them in a triangular pattern to prevent the engine from overturning.

0-4

307.W.M300.en.0.02-Motori EURO I0-4 0-4 1/15/2010 8:09:23 PM

INTRODUCTION

● To lift heavy components, use a hoist or crane. Check that wire ropes, chains or fibre slings are not worn and that hooks are

not damaged.

● Always use lifting equipment of suitable capacity for the weight of the components to be removed. Ensure lifting equipment is

attached correctly.

● When lifting or supporting an assembly or component, manoeuvre the parts slowly and carefully to avoid swinging movements

or collision with other components.

● Never work on components suspended from a hoist or crane.

● When removing the retaining bolts of a component that could fall, always leave two opposing bolts in place for safety; before

removing these last two screws, attach the component to suitable lifting equipment or position support blocks.

● Any oil or fuel spilled during removal or dismantling operations should be cleaned up as soon as possible to prevent the risk

of slipping and fire.

● When refitting electrical wiring looms and wires, ensure that they are properly secured with their original retaining straps or

brackets to prevent the possibility of damage caused by vibration.

● Never insert your fingers or hands to check the alignment between fixing holes in components; always use a suitable dowel

of soft material.

● When refitting assemblies or components, always use the specified tightening torques; the tightening torques indicated in the

headings regarding assembly/refitting operations have been determined through experimentation and must be scrupulously

adhered to.

● When refitting parts that are subject to vibration or that rotate at high speed, take particular care when carrying out final

installation checks.

0-5

307.W.M300.en.0.02-Motori EURO I0-5 0-5 1/15/2010 8:09:23 PM

INTRODUCTION

0.1.3 - Safety precautions for removal and refitting operations

When removing or refitting parts, always take the following safety precautions.

Precautions for removal operations

● After disconnecting hydraulic and fuel system pipes, always fit plugs to the open ends of the pipes to prevent ingress of dirt.

● Use containers of sufficient capacity when draining oil, coolant or fuel.

● Before removing a part from the machine, check for alignment markings indicating the correct assembly position. If necessary,

make new markings to ensure correct assembly.

● When unplugging electrical connectors, always grip the connectors firmly to avoid pulling on the wires.

● Where necessary, label wires and pipes before removal to avoid confusion when reconnecting.

● Check the number and thickness of any shims removed and keep them together in a safe place.

● To lift the engine or any of its main components, use lifting equipment of suitable capacity.

● When using eyebolts for lifting components, first check that they are not deformed; screw them fully home and then turn the

bolt so that the eye is aligned with the lifting hook.

● Before removing a part, clean the surrounding area and, after removing the part, cover it to protect it from dirt and dust.

Precautions for refitting operations

● Tighten nuts and screws to the specified tightening torques.

● When refitting flexible pipes and cables, take care not to twist or tangle them.

● Always fit new seals, O-rings, split pins and safety stop rings; make sure that the ends of the split pins are separated and bent

back so that the pin cannot be withdrawn from the hole.

● Ensure that circlips are correctly installed in their grooves.

● When applying threadlocking compound, first clean the part to remove all oil and grease, then cover the thread evenly applying

a few drops of the compound.

● When applying sealant, first clean the surface removing all traces of oil and grease and check for dirt or indentations, then

apply the sealant evenly making sure that it forms a continuous film around any fixing holes.

● Clean all parts, removing dirt, oxidisation, carbon deposits, burrs and indentations.

● Coat all moving parts with a thin film of engine oil.

● When reconnecting electrical wiring connectors, first remove all traces of oil, dust and water from the inside of the connector

and then push the two halves together firmly; connectors with locking tabs should be pushed together until the tab engages

the keeper.

● Bolt down flanged fittings evenly, tightening the screws gradually in a crosswise pattern.

Precautions to be taken on completion of removal/refitting operations

● If coolant has been drained from the engine, refit the drain plug and pour in new coolant to the correct level. Start the engine

to circulate the coolant and then check the level again and top up.

● After removing hydraulic components, top up the hydraulic oil to the specified level. Start the engine to circulate the oil in the

hydraulic circuits and then recheck the level and top up as necessary.

● After having removed a variable displacement pump, connect the drain pipe and fill the pump casing with oil through the filler

hole provided.

● Grease stub axle housings, cylinder pivot mountings and drive shafts thoroughly after assembly.

0-6

307.W.M300.en.0.02-Motori EURO I0-6 0-6 1/15/2010 8:09:23 PM

INTRODUCTION

0.1.4 - Lifting instructions

DANGER

Components weighing over 25 kg or of significant size must be supported and removed using suitable lifting equipment

with wire rope or polyester slings.

Wire ropes - slings

● Use wire ropes or polyester slings of suitable capacity for the parts to be lifted, referring to the following tables:

Tab.1

WIRE ROPES (standard twisted “S” or “Z” type) POLYESTER SLINGS (eye-and-eye - simple loop)

Ø rope mm Capacity (kg) Width (mm) Capacity (kg)

60° 90° 60° 90°

8 650 620 500 25 500 400 860 700

10 1000 1740 1420 50 1000 800 1730 1410

12 1450 2500 2050 62 1250 1000 2160 1760

14 2000 3460 2820 75 1400 1120 2420 1980

16 2600 4500 3670 100 2000 1600 3460 2820

18 3300 5710 4660 150 2500 2000 4330 3530

Lifting capacities are calculated with a safety coefficient.

● The lifting hook should be attached to the central part of the rope or sling; if the hook is attached near the ends of the rope/

sling, this could cause the load to slip during lifting.

● Never lift a heavy load using a single rope; always use two or more symmetrically arranged ropes.

DANGER

Suspension of a load from a single rope could cause the load to start rotating and consequently cause the rope

strands to untwist or the load to slip; this could lead to serious injury.

● Never lift a heavy load when the two legs of the ropes form a wide angle. The permitted load (kg) decreases in inverse

proportion to the angle of suspension; the table below indicates how the permitted load varies according to the angle of

suspension for two Ø 10 mm ropes each with a load capacity of 1000 kg.

0-7

307.W.M300.en.0.02-Motori EURO I0-7 0-7 1/15/2010 8:09:23 PM

INTRODUCTION

2000

1900

Capacità di carico: kg 1700

2000

1400

1000

1000

500

30° 60° 90° 120° 150°

Angolo di sospensione:

Fig.1

0-8

307.W.M300.en.0.02-Motori EURO I0-8 0-8 1/15/2010 8:09:24 PM

INTRODUCTION

0.1.5 - Tightening torques

Screws and nuts

DANGER

The tightening torques for certain specific components and special tightening methods are indicated in the relative

assembly headings.

The tightening torques indicated below refer to screws and nuts assembled without lubrication and, where applicable, with anaerobic

threadlocking compound. the values apply to tightening on steel or cast iron components; for soft materials such as aluminium,

copper, plastic, sheet metal or panels, the indicated tightening torques must be reduced by 50%.

Tab.2

SCREW SIZE SCREW CLASS

8.8 10.9 12.9

Nm lb.ft. Nm lb.ft. Nm lb.ft.

M6x1 8.0 - 8.8 5.9 - 6.5 11.8 - 13.0 8.7 - 9.6 13.8 - 15.2 10.2 - 11.2

M8x1.25 19.4 - 21.4 14.3 - 15.8 28.5 - 31.5 21.0 - 23.2 33.3 - 36.9 24.5 - 27.2

M10x1.5 38.4 - 42.4 28.3 - 31.2 56.4 - 62.4 41.6 - 46.0 67.4 - 74.4 49.7 - 54.8

M12x1.75 66-5 - 73-5 49.0 - 54.2 96.9 - 107 71.4 - 78.9 115 - 128 84.8 - 94.3

M14x2 106 - 117 78.1 - 86.2 156 - 172 115.0 - 126.8 184 - 204 135.6 - 150.3

M16x2 164 - 182 120.9 - 134.1 241 - 267 117.6 - 196.8 282 - 312 207.8 - 229.9

M18x2.5 228 - 252 168.0 - 185.7 334 - 370 246.2 - 272.7 391 - 432 288.2 - 318.4

M20x2.5 321 - 355 236.6 - 261.6 472 - 522 347.9 - 384.7 553 - 611 407.6 - 450.3

M22x2.5 441 - 487 325.0 - 358.9 647 - 715 476.8 - 527.0 751 - 830 553.5 - 611.7

M24x3 553 - 611 407.6 - 450.3 812 - 898 598.4 - 661.8 950 - 1050 700.2 - 773.9

M27x3 816 - 902 601.4 - 664.8 1198 - 1324 882.9 - 975.8 1419 - 1569 1045.8 - 1156.4

FINE M8x1 20.8 - 23.0 15.3 - 17.0 30.6 - 33.8 22.6 - 24.9 35.8 - 39.6 26.4 - 29.2

M10x1.25 40.6 - 44.8 29.9 - 33.0 59.7 - 65.9 44.0 - 48.6 71.2 - 78.6 52.5 - 57.9

M12x1.25 72.2 - 79.8 53.2 - 58.8 106 - 118 78.1 - 87.0 126 - 140 92.9 - 103.2

M12x1.5 69.4 - 76.7 51.1 - 56.5 102 - 112 75.2 - 82.5 121 - 134 89.2 - 98.8

M14x1.5 114 - 126 84.0 - 92.9 168 - 186 123.8 - 137.1 199 - 220 146.7 - 162.1

M16x1.5 175 - 194 129 - 143 257 - 285 189.4 - 210.0 301 - 333 221.8 - 245.4

M18x1.5 256 - 282 188.7 - 207.8 375 - 415 276.4 - 305.9 439 - 485 323.5 - 357.4

M20x1.5 355 - 393 261.6 - 289.6 523 - 578 385.5 - 426.0 611 - 676 450.3 - 498.2

M22x1.5 482 - 532 355.2 - 392.1 708 - 782 521.8 - 576.3 821 - 908 605.1 - 669.2

M24x2 602 - 666 443.7 - 490.8 884 - 978 651.5 - 720.8 1035 - 1143 762.8 - 842.4

Fittings

The tightening torques indicated below refer to fittings assembled on any material.

Tab.3

MET- Straight end fittings “T” end fittings “L” end fittings 90° end fittings

RIC

0-9

307.W.M300.en.0.02-Motori EURO I0-9 0-9 1/15/2010 8:09:24 PM

INTRODUCTION

Thread Wrench Torque Nm Wrench Torque Nm Wrench Torque Nm Wrench Torque Nm

±10% ±10% ±10% ±10%

M10x1.25 17 14 14 14 14 14 14 14

19 14 17 14 17 14

M12x1.25 19 30 17 30 17 30 17 30

M14x1.5 19 40 19 40 19 40 19 40

M16x1.5 22 48 22 48 22 48 22 48

M18x1.5 24 58 24 58 24 58 24 58

M20x1.5 27 65 27 65 27 65 27 65

M22x1.5 30 73 30 73 30 73 30 73

M26x1.5 36 95 36 95 36 95 36 95

M27x2 36 100 36 100 36 100 36 100

M33x2 41 160 41 160 41 160 41 160

M42x2 50 250 50 250 50 250 50 250

M48x2 60 305 60 305 60 305 60 305

G 1/8” 17 13 14 13 14 13 14 13

19 13

G 1/4” 19 37 19 37 19 37 19 37

22 37

G 3/8” 24 53 24 53 24 53 24 53

G 1/2” 27 73 27 73 27 73 27 73

30 73

G 3/4” 36 100 36 100 36 100 36 100

G 1” 41 160 41 160 41 160 41 160

46 160

G 1 1/4” 50 250 50 250 50 250 50 250

G 1 1/2” 60 305 60 305 60 305 60 305

Plugs

Tab.4

Hex plugs Threaded plugs with hex socket head

Thread Wrench Torque Nm ±10% Wrench Torque Nm ±10%

0-10

307.W.M300.en.0.02-Motori EURO I0-10 0-10 1/15/2010 8:09:24 PM

INTRODUCTION

MET- M6x1 10 10 - -

RIC M8x1 13 12 - -

M10x1 13 14 5 14

M10x1.25 13 14 - -

M10x1.5 13 14 - -

M12x1.25 17 30 - -

M12x1.5 17 30 6 30

M12x1.75 17 30 - -

M14x1.5 19 40 6 40

M14x2 19 40 - -

M16x1.5 22 48 8 48

M16x2 22 48 - -

M18x1.5 17 58 10 58

M18x2.5 17 58 - -

M20x1.5 19 65 - -

M22x1.5 - - 12 73

M24x1.5 22 80 12 80

M24x2 22 80 - -

M27x2 22 100 - -

M28x1.5 - - 17 110

M30x1.5 22 130 - -

M32x1.5 - - 19 150

M35x1.5 - - 22 180

M40x1.5 - - 24 225

G 1/8” 14 13 - -

G 1/4” 19 37 - -

G 3/8” 22 53 - -

G 1/2” 19 73 - -

G 5/8” 22 85 - -

G 3/4” 22 100 - -

G 1” 22 160 - -

Fittings with seal at 37°

Tab.5

Thread Wrench Torque Nm ±10%

7/16” - 20 14 13

1/2” - 20 16 19

9/16” - 18 17 28

3/4” - 16 22 47

7/8” - 14 27 76

1 1/16” - 12 32 110

36 110

0-11

307.W.M300.en.0.02-Motori EURO I0-11 0-11 1/15/2010 8:09:25 PM

INTRODUCTION

1 3/16” - 12 36 138

1 5/16” - 12 38 155

1 5/8” - 12 50 215

1 7/8” - 12 60 290

2 1/2” - 12 75 345

Fittings for pipes with banjo union

These tightening torques refer to tightening the fitting with new copper sealing washers.

Tab.6

Unions for one-way fittings Unions for three-way fittings Unions for four-way fittings

Thread Wrench Torque Nm Wrench Torque Nm Wrench Torque Nm

±10% ±10% ±10%

M8x1 - 12 14 - -

M8x1.25 13 14

M10x1 - - 14 20 14 20

M10x1.25 13 20 - - - -

M12x1.25 17 30 - - - -

M12x1.5 - - 17 30 17 30

M14x1.5 19 40 19 40 19 40

M16x1.5 22 48 22 48 22 48

M18x1.5 22 58 24 58 24 58

M20x1.5 27 65 - - - -

M22x1.5 – – 27 73 27 73

M24x1.5 32 80 – – – –

M26x1.5 – – 32 95 32 95

M28x1.5 36 110 – – – –

M30x1.5 – – 36 130 36 130

M35x2 41 180 – – – –

M38x1.5 – – 46 200 46 200

M42x2 50 250 – – – –

M45x1.5 – – 55 280 55 280

M50x2 60 320 – – – –

M52x1.5 – – 60 320 60 320

M65x2 – – 75 450 75 450

0-12

307.W.M300.en.0.02-Motori EURO I0-12 0-12 1/15/2010 8:09:25 PM

INTRODUCTION

0.1.6 - Threadlockers, adhesives, sealants and lubricants

Tab.7

FUNCTION NAME DESCRIPTION

THREADLOCKER Loctite 222 Colour: opaque fluorescent purple Anaerobic product suitable for low-strength locking of retaining,

adjustment and precision fasteners. All traces of lubricant must first be

removed using the specific activator.

Loctite 242 Colour: fluorescent blue Anaerobic product that prevents loosening of all types of nut and bolt;

used in place of conventional mechanical locking systems. Used for

medium-strength locking. All traces of lubricant must first be removed

using the specific activator.

Loctite 243 Colour: opaque fluorescent blue Alternative product to 242 ; oil tolerant and so can be used on lightly

lubricated surfaces without prior use of activator.

Loctite 270 Colour: fluorescent green Anaerobic product for high-strength locking of bolts and studs that do

not normally require disassembly. Parts must be heated to approxi-

mately 80°C for removal. All traces of lubricant must first be removed

using the specific activator.

DEGREASERS AND Loctite 703 Product used for degreasing and cleaning parts prior to application of

ACTIVATORS Loctite anaerobic products; after drying, promotes uniform curing of

threadlockers

Loctite 747 Product used specifically for treatment of passive metals prior to use of

slow-cure anaerobic threadlockers (series 5 and 6). Can also be used

to increase cure speed at low temperatures or in applications where

there are large gaps between the parts.

SEALANTS (for faces Loctite 510 Colour: red Super-rapid anaerobic sealant for sealing between rigid metal faces;

and fittings) can eliminate the need for conventional gaskets as it can fill gaps up

to 0.4 mm. Does not shrink and therefore fasteners do not need re-

tightening to specified torque values after curing.

Loctite 542 Colour: brown Anaerobic product used as a liquid sealant for threaded fittings up to

3/4” gas; rapid curing and parts may be disassembled with ordinary

tools.

Loctite 554 Colour: red Anaerobic sealant and locking compound used for sealing cooling and

industrial fluid circuits. Slow curing, also suitable for use on non-fer-

rous alloys

Loctite 572 Colour: white Anaerobic sealant and locking compound used for sealing pipes and

threaded fittings up to 2” in diameter. Very slow curing on most metal

surfaces.

Loctite 573 Colour: green Thixotropic anaerobic product used for sealing joints between metal

faces. Ensures total contact between surfaces with maximum toler-

ance of 0.10 mm, filling microvoids caused by flatness errors. Very

slow curing on most metal surfaces and requires prior application of an

activator.

Loctite 576 Colour: brown Anaerobic product used as a liquid thread sealant for large diameter

threaded fittings (up to 2”). Very slow curing; also suitable for non-fer-

rous alloys and parts requiring subsequent removal.

INSTANT ADHE- Loctite 401 Colour: colourless Cyanoacrylate instant adhesive suitable for bonding a wide range of

SIVES acidic and porous materials including, ceramics, wood, rubber and

plastic (excluding polyolefin). Curing takes place in a few seconds

as an effect of the condensed humidity present on the surfaces to be

bonded, and is independent of environmental conditions.

Loctite 495 Colour: colourless Cyanoacrylate instant adhesive suitable for bonding a rubber, plastics

and metal in any combination.

0-13

307.W.M300.en.0.02-Motori EURO I0-13 0-13 1/15/2010 8:09:26 PM

INTRODUCTION

SILICONE SEAL- Silastic 738 (Dow Corning) Colour: milky white One-part silicone adhesive/sealant, non shrinking, ready for use.

ANTS Cures on exposure to air to form a rubbery solid and obviates the need

for conventional seals on flexible joints, filling gaps of up to 1 mm or

more.

Dirko Transparent Colour: transparent One-part silicone adhesive/sealant, shrinking, ready for use. Cures

rapidly when exposed to humidity in the air to form a rubbery solid;

resistant to high temperatures.

POLYURETHANE Betaseal HV3 (Gurit Essex) Colour: black Polyurethane prepolymer based adhesive/sealant, high viscosity, suit-

SEALANTS able for permanent, high-strength flexible bonding. Slow curing, used

for bonding glass to frames, wire mesh, metal plates, etc. surfaces

must be degreased with primer.

RETAINING COM- Loctite 601 Colour: fluorescent green Anaerobic, fast-curing, high-strength adhesive. Suitable for sealing

POUNDS and retaining cylindrical assemblies with gap clearances of up to 0.10

mm; used for retaining rotors, gears, bearings, pulleys, bushes etc. on

shafts.

Loctite 638 Colour: fluorescent green Anaerobic structural adhesive, quick-curing, very high strength; suit-

able for bonding cylindrical parts in non-ferrous alloys.

Loctite 648 Colour: fluorescent green Anaerobic structural adhesive, quick-curing, high-strength; suitable

for bonding cylindrical parts, permanent retention of threaded parts,

sealing of refrigeration systems, retention of bearings, etc. Alternative

to Loctite 601 in high-temperature applications.

Loctite 986/AVX Colour: fluorescent red Anaerobic sealant/retaining compound for metal cylindrical parts.

Slow-curing, high-strength, heat-resistant and resistant to chemical

attack. Parts must be first treated with an activator.

LUBRICANTS Grease (NLGI 2 EP ASTM D217: 265/295) Multi-purpose Lithium grease used for lubrication of seals, to prevent

oxidation and to facilitate assembly operations.

Molikote (Dow Corning) Anti-wear compound, contains Molybdenum bisulphate, used neat or

diluted with engine oil for assembly of main engine bearings.

Vaseline Neutral pH compound used to protect battery terminals against oxidi-

zation and corrosion.

Engine oil 10W - 30 Used to dilute Molikote anti-wear lubricant during assembly of main

engine bearings.

0-14

307.W.M300.en.0.02-Motori EURO I0-14 0-14 1/15/2010 8:09:26 PM

INTRODUCTION

0.1.7 - Conversion factors

Conversion from British to metric units

Tab.8

inch x 25.40 = mm

foot x 0.305 =m

yard x 0.914

Brit.miles x 1.609 = km

Sq.in. x 6.452 = cm²

Sq.ft. x 0.093 = m²

Sq.yard x 0.835

Cu.in. x 16.39 = cm³

Cu.ft. x 28.36 = m³

Cu.yard x 0.763

Imp.gall. x 4.547 = litres

US gall. x 3.785

pint x 0.568

quart x 1.137

US.gpm x 3.785 = ,/min

oz. x 0.028 = kg

lb. x 0.454

lb.ft. x 0.139 = kgm

lb.in. x 17.87 = kg/m

psi x 0.070 = kg/cm²

lb./Imp.gall x 0.100 = kg/,

lb./US.gall x 0.120

lb./cu.ft. x 16.21 = kg/m³

lb.ft. x 1.356 = Nm

psi x 1.379 = bar

Conversion from British to metric units

Tab.9

mm x 0.0394 = inch

m x 3.281 = foot

m x 1.094 = yard

km x 0.622 = Eng.miles

cm² x 0.155 = Sq.in.

m² x 10.77 = Sq.ft.

m² x 1.197 = Sq.yard

cm³ x 0.061 = Cu.in.

m³ x 0.035 = Cu.ft

m³ x 1.311 = Cu.yard

litres x 0.220 = Imp.gall.

litres x 0.264 = US gall.

litres x 1.762 = pint

litres x 0.880 = quart

,/min x 0.2642 = US.gpm

kg x 35.25 = oz.

kg x 2.203 = lb.

kgm x 7.233 = lb.ft.

0-15

307.W.M300.en.0.02-Motori EURO I0-15 0-15 1/15/2010 8:09:26 PM

INTRODUCTION

kg/m x 0.056 = lb.in.

kg/cm² x 14.22 = psi

kg/, x 10.00 = lb./Imp.gal.

kg/, x 8.333 = lb./US.gal.

kg/m³ x 0.062 = lb./cu.ft.

Nm x 0.737 = lb.ft.

bar x 14.503 = psi

0-16

307.W.M300.en.0.02-Motori EURO I0-16 0-16 1/15/2010 8:09:26 PM

INTRODUCTION

0.2 - IDENTIFICATION OF THE ENGINE TYPE AND SERIAL NUMBER POSITION,

EUROPE VERSION

NOTE

The expressions RIGHT-HAND and LEFT-HAND are referred to the engine viewed from the timing side.

The engine type and serial number (included between the symbols *) are punched on the identification plate fixed to the right-hand

side of the crankcase next to the starter motor.

The identification plate shows, in addition to the Constructor’s logo:

1. Engine type

2. Serial number (always included between the symbols*)

3. Approval number

4. Injection advance

5. Constructor

6. Serial number

The engine’s serial number (always included between the symbols*) is also punched on the left-hand side of the crankcase.

Fig.2 - Identification plate

0-17

307.W.M300.en.0.02-Motori EURO I0-17 0-17 1/15/2010 8:09:26 PM

INTRODUCTION

5 1 2

6

Fig.3 - Serial number

0-18

307.W.M300.en.0.02-Motori EURO I0-18 0-18 1/15/2010 8:09:26 PM

INTRODUCTION

0.3 - IDENTIFICATION OF THE ENGINE TYPE AND SERIAL NUMBER POSITION,

EPA VERSION

For Countries that call for EPA approval, a plate is affixed to the engine showing, in addition to the Constructor, the following

information:

1. Engine type

2. Month and year of engine manufacture

3. U.S. EPA regulation number with which the engine complies

4. Engine displacement (cm³)

5. Stated power (kW)

6. Engine idling speed (n/1’)

7. Injection advance (degrees)

8. Type of fuel to use

9. Designation of the relevant group in the EP regulation (the first digit denotes the year of construction)

10. Constructor

11. Serial number

The serial number (always included between the symbols *) for these engines is punched only on the left-hand side of the crankcase,

while the identification plate is fixed to the right-hand side of the crankcase next to the starter motor.

NOTE

The injection advance value (BTDC) is also punched on the left-hand side of the crankcase, outside of the identification

data.

NOTE

The expressions RIGHT-HAND and LEFT-HAND are referred to the engine viewed from the timing side.

0-19

307.W.M300.en.0.02-Motori EURO I0-19 0-19 1/15/2010 8:09:27 PM

INTRODUCTION

6 8 4 7 5 9 3 1 2

Made by - IMPORTANT ENGINE INFORM ATION - 1000 . 6 W

For engine tuneup and adjustments :

SAME - Trasmission in neutral position :

- Accessories not operatin g

DEUTZ-FAHR - Date of manufacture :

GROUP S.p.A. - Diese l fue l

This engine conforms t o U.S. E PA regulation s

Iarge nonroad compression-ignition engines .

TREVIGLIO I TALY E PA family designatio n 1 FG XLO6 .OWO O

2, 9929 , 685 , 0/5 0

Fig.4 - Identification plate

10 1 2

11

Fig.5 - Serial number

0-20

307.W.M300.en.0.02-Motori EURO I0-20 0-20 1/15/2010 8:09:27 PM

INTRODUCTION

0.4 - IDENTIFICATION OF THE INJECTION PUMP TYPE

Tab.10

IDENTIFICATION PUMP TYPE (BOSCH) PUMP PART NUMBER (BOSCH) PUMP ASSEMBLY ORDER CODE

PLATE COLOUR

Black PFM1A 90S 2505 0 414 396 006 2.4619.280.0

Make a note of the pump type and BOSCH code marked on the

identification plate.

1

NOTE

2

If necessary, strop the paint with solvent.

NOTE

Always specify the data indicated above when 3

ordering.

0-21

307.W.M300.en.0.02-Motori EURO I0-21 0-21 1/15/2010 8:09:27 PM

INTRODUCTION

0.5 - IDENTIFICATION OF THE INJECTOR TYPE

Read the distinctive numbers on the injector nozzle representing the

end part of the BOSCH code.

Find the various injectors shown in the “Technical characteristics” and

the corresponding order codes in the table below.

Tab.11

END OF BOSCH INJECTOR NOZZLE PART NUMBER INJECTOR NOZZLE ORDER CODE INJECTOR ASSEMBLY PART

CODE (BOSCH) (1) NUMBER

1352 DLLA 150P 1352 2.4729.630.0 2.4719.640.0

0-22

307.W.M300.en.0.02-Motori EURO I0-22 0-22 1/15/2010 8:09:27 PM

INTRODUCTION

0.6 - INJECTOR TYPE IDENTIFICATION

Read the distinctive numbers on the injector nozzle representing the

final part of the BOSCH code.

Find the various injectors shown in the “Technical characteristics” and

the corresponding order codes in the table below.

Tab.12

END OF BOSCH INJECTOR NOZZLE PART NUMBER INJECTOR NOZZLE ORDER CODE INJECTOR ASSEMBLY PART

CODE (BOSCH) (1) NUMBER

2159 DLLA 150P 2159 2.4729.650.0 2.4719.650.0

0-23

307.W.M300.en.0.02-Motori EURO I0-23 0-23 1/15/2010 8:09:28 PM

INTRODUCTION

PAGE LEFT INTENTIONALLY BLANK

0-24

307.W.M300.en.0.02-Motori EURO I0-24 0-24 1/15/2010 8:09:28 PM

10 - TECHNICAL CHARACTERISTICS

307.W.M300.en.0.02-Motori EURO I10-1 10-1 1/15/2010 8:09:28 PM

TECHNICAL CHARACTERISTICS

10.1 - ENGINE

10.1.1 - Engine block technical data

2

3 1

*

5

4

Fig.6 - Engine block - cylinders

* Selection class

NOTE

Always check the cylinder class

Tab.13

POS. ITEMS TO BE CHECKED NORMAL MEAS- MAXIMUM TOLER- NOTES

UREMENT ANCE LIMIT

1 Cylinder diameter Class A 105,000 (4.1370) 105,100 -

(distance from liner 105,022 (4.1379) (4.1410)

top: A= 70 mm (2.758 Class B -

in.))

Cylinder ovality 0,020 (0.0008) Max. 0,080 -

(Max. 0.0032)

2 Protrusion from crankcase 0,020 - 0,090 - -

(0.0008 - 0.0035)

3 Lapping intersection angle 40 - 50° 40 - 50° With surface rough-

ness Ra 0.2- 0.6 μm

10-2

307.W.M300.en.0.02-Motori EURO I10-2 10-2 1/15/2010 8:09:28 PM

TECHNICAL CHARACTERISTICS

POS. ITEMS TO BE CHECKED NORMAL MEAS- MAXIMUM TOLER- NOTES

UREMENT ANCE LIMIT

4 Main bearings diameter 70,018 - 70,068 70,130 -

(2.7587 - 2.7607) (2.7631)

1st undersize (grinding) 69,768 - 69,818 69,880

(2.7488 - 2.7508) (2.7139)

2nd undersize (grinding) 69,518 - 69,568 69,650

(2.7390 - 2.7410) (2.7442)

5 Camshaft bearings diameter 55,060 - 55,090 55,180 -

(2.1694 - 2.1705) (2.1741)

Tolerance between bearing and camshaft 0,060 - 0,120 (0.0024 - 0.0047) -

Unit of measure: mm (in.)

10-3

307.W.M300.en.0.02-Motori EURO I10-3 10-3 1/15/2010 8:09:28 PM

TECHNICAL CHARACTERISTICS

10.1.2 - Crankshaft technical data (1000.3 WT E III,1000.3 WTI E III)

n°1 n°2 n°3

1

4 1 1 1

2 2 3

Fig.7 - Crankshaft - 3-cylinder version

Unit of measure: mm (in.)

Tab.14

POS. ITEMS TO BE CHECKED NORMAL MEASURE- TOLERANCE LIMIT

MENT

1 Main bearing journals diameter 69,98 - 69,96 (2.7572 69,90 (2.7541)

- 2.7564)

1st undersize (grinding) 69,73 - 69,71 (2.7474 69,65 (2.7442)

- 2.7466)

2nd undersize (grinding) 69,48 - 69,46 (2.7375 69,40 (2.7344)

- 2.7367)

Permitted taper Max. 0.030 (Max. 0.0012) 0,050 (0.002)

Out of round Max. 0.005 (Max. 0.0002) 0,050 (0.002)

2 Crankpins diameter 63,50 - 63,48 (2.5019 63,40 (2.4980)

- 2.5011)

1st undersize (grinding) 63,25 - 63,23 (2.4920 63,15 (2.4881)

- 2.4913)

2nd undersize (grinding) 63,00 - 62,98 (2.4822 62,90 (2.4783)

- 2.4814)

Permitted taper Max. 0.030 (Max. 0.0012) 0,050 (0.002)

Out of round Max. 0.005 (Max. 0.0002) 0,050 (0.002)

3 Crankshaft end float 0.105...0.300 (0.0041 0,500 (0.020)

- 0.0118)

Half thrust washers 1st assembly - -

1st oversize +0.250 (+0,01) -

2nd oversize +0,500 (+0.02) -

4 Crankshaft pulley screw tightening torque See “ENGINE ASSEMBLY”

Notes for grinding

1 Before grinding the crankshaft, check for the presence of cracks with penetrating liquids.

In the presence of cracks, even slight, the crankshaft must be rejected.

2 Grinding with the permitted undersizes does not call for regrinding of the crankpin fillets.

10-4

307.W.M300.en.0.02-Motori EURO I10-4 10-4 1/15/2010 8:09:28 PM

TECHNICAL CHARACTERISTICS

NOTE

Do not alter the existing fillet radii.

3 When grinding, the crankshaft must rotate preferably in the opposite direction to that of operation; it is however permissible for

the crankshaft to turn in the operating direction.

4 During the polishing stage the crankshaft must rotate exclusively in the operating direction.

5 The surfaces of the main journals and crankpins must be completely free of scoring (Ra=0.25 mμ).

10-5

307.W.M300.en.0.02-Motori EURO I10-5 10-5 1/15/2010 8:09:29 PM

TECHNICAL CHARACTERISTICS

10.1.3 - Crankshaft technical data (1000.4 WTI E III)

n°1

n°2 n°3 n°4

1

4 1 1 1 1

2 2

3

2 2

Fig.8 - Crankshaft - 4-cylinder version

Unit of measure: mm (in.)

Tab.15

POS. ITEMS TO BE CHECKED NORMAL MEASURE- TOLERANCE LIMIT

MENT

1 Main bearing journals diameter 69,98 - 69,96 (2.7572 69,90 (2.7541)

- 2.7564)

1st undersize (grinding) 69,73 - 69,71 (2.7474 69,65 (2.7442)

- 2.7466)

2nd undersize (grinding) 69,48 - 69,46 (2.7375 69,40 (2.7344)

- 2.7367)

Permitted taper Max. 0.030 (Max. 0.0012) 0,050 (0.002)

Out of round Max. 0.005 (Max. 0.0002) 0,050 (0.002)

2 Crankpins diameter 63,50 - 63,48 (2.5019 63,40 (2.4980)

- 2.5011)

1st undersize (grinding) 63,25 - 63,23 (2.4920 63,15 (2.4881)

- 2.4913)

2nd undersize (grinding) 63,00 - 62,98 (2.4822 62,90 (2.4783)

- 2.4814)

Permitted taper Max. 0.030 (Max. 0.0012) 0,050 (0.002)

Out of round Max. 0.005 (Max. 0.0002) 0,050 (0.002)

3 Crankshaft end float 0.105...0.300 (0.0041... 0.500 (0.020)

0.0118)

Half thrust washers 1st assembly - -

1st oversize +0,250 (+0.01) -

2nd oversize +0,500 (+0.02) -

4 Crankshaft pulley screw tightening torque See “ENGINE ASSEMBLY”

Notes for grinding

1 Before grinding the crankshaft, check for cracks with penetrating liquids.

In the presence of cracks, even slight, the crankshaft must be rejected.

2 Grinding with the permitted undersizes does not call for regrinding of the crankpin fillets.

10-6

307.W.M300.en.0.02-Motori EURO I10-6 10-6 1/15/2010 8:09:29 PM

TECHNICAL CHARACTERISTICS

NOTE

Do not alter the existing fillet radii.

3 When grinding, the crankshaft must rotate preferably in the opposite direction to that of operation; it is however permissible for

the crankshaft to turn in the operating direction.

4 During the polishing stage the crankshaft must rotate exclusively in the operating direction.

5 The surfaces of the main journals and crankpins must be completely free of scoring (Ra=0.25 mμ).

10-7

307.W.M300.en.0.02-Motori EURO I10-7 10-7 1/15/2010 8:09:29 PM

TECHNICAL CHARACTERISTICS

10.1.4 - Piston technical data - Piston rings (1000.3 WT E III)

TOP

1

2

TOP

3

5

4

H1

** 2-3-4

*

20

Fig.9 - 3-cyinder WT pistons

Tab.16

POS. ITEMS TO BE CHECKED NORMAL MEASUREMENT TOLERANCE NOTES

LIMIT

1 Piston external Class A H= 104,890 (4.1326) 104,680 -

diameter (Position 104,902 (4.1331) (4.1244)

from edge: H = 9 H1 = 104,765 (4.1277) 104,600

mm (0.3546 in.) 104,777 (4.1282) (4.1212)

H1 = 58.3 mm

Class B H= 104,900 (4.1330) 104,680

(2.297 in.)

104,912 (4.1335) (4.1244)

H1 = 104,630 (4.1224) 104,600

104,642 (4.1228) (4.1212)

10-8

307.W.M300.en.0.02-Motori EURO I10-8 10-8 1/15/2010 8:09:29 PM

TECHNICAL CHARACTERISTICS

POS. ITEMS TO BE CHECKED NORMAL MEASUREMENT TOLERANCE NOTES

LIMIT

2-3-4 Clearance 1st ring 0.110 ... 0.145 - Chrome plated

between rings and (0.0043 ... 0.0057) and convex

piston seat 2nd ring 0.050 ... 0.082 0,150 Tapered face, 90°

(0.0020 ... 0.0032) (0.006)

Wiper ring 0,030 (0.0012) 0,150 Chromium plated

0,065 (0.0026) (0.006)

Piston rings gap 1st ring 0.40 ... 0.65 1,5 -

(0.016 ... 0.026) (0.06)

2nd ring 0.40 ... 0.65 1,5

(0.016 ... 0.026) (0.06)

Wiper ring 0.30 ... 0.60 1,5

(0.012 ... 0.024) (0.06)

5 Gudgeon pin outside diameter 34.99 ... 34.984 34,960 -

(1.3786 ... 1.3784) (1.3774)

Gudgeon pin bore diameter 35,012 (1.3795) 35,020

35,006 (1.3792) (1.3798)

Unit of measure: mm (in.)

10-9

307.W.M300.en.0.02-Motori EURO I10-9 10-9 1/15/2010 8:09:29 PM

TECHNICAL CHARACTERISTICS

10.1.5 - Technical data for pistons - Piston rings (1000.3 WTI E III,1000.4 WTI E III)

TOP

1

2

TOP

3

5

4

H1

** 2-3-4

*

20

Fig.10 - 3-cyinder WT pistons

Tab.17

POS. ITEMS TO BE CHECKED NORMAL MEASUREMENT TOLERANCE NOTES

LIMIT

1 Piston external Class A H= 104,890 (4.1326) 104,680 -

diameter (Position 104,902 (4.1331) (4.1244)

from edge: H = 9 H1 = 104,765 (4.1277) 104,600

mm (0.3546 in.) 104,777 (4.1282) (4.1212)

H1 = 58.3 mm

Class B H= 104,900 (4.1330) 104,680

(2.297 in.)

104,912 (4.1335) (4.1244)

H1 = 104,630 (4.1224) 104,600

104,642 (4.1228) (4.1212)

10-10

307.W.M300.en.0.02-Motori EURO I10-10 10-10 1/15/2010 8:09:29 PM

TECHNICAL CHARACTERISTICS

POS. ITEMS TO BE CHECKED NORMAL MEASUREMENT TOLERANCE NOTES

LIMIT

2-3-4 Clearance 1st ring 0.110 ... 0.145 - Chrome plated

between rings and (0.0043 ... 0.0057) and convex

piston seat 2nd ring 0.050 ... 0.082 0,150 Tapered face, 90°

(0.0020 ... 0.0032) (0.006)

Wiper ring 0,030 (0.0012) 0,150 Chromium plated

0,065 (0.0026) (0.006)

Piston rings gap 1st ring 0.40 ... 0.65 1,5 -

(0.016 ... 0.026) (0.06)

2nd ring 0.40 ... 0.65 1,5

(0.016 ... 0.026) (0.06)

Wiper ring 0.30 ... 0.60 1,5

(0.012 ... 0.024) (0.06)

5 Gudgeon pin outside diameter 34.99 ... 34.984 34,960 -

(1.3786 ... 1.3784) (1.3774)

Gudgeon pin bore diameter 35,012 (1.3795) 35,020

35,006 (1.3792) (1.3798)

Unit of measure: mm (in.)

10-11

307.W.M300.en.0.02-Motori EURO I10-11 10-11 1/15/2010 8:09:29 PM

TECHNICAL CHARACTERISTICS

10.1.6 - Connecting rod technical data

1 124,4 20°

2 4

Fig.11 - Connecting rods for pistons

Unit of measure: mm (in.)

Tab.18

POS. ITEMS TO BE CHECKED NORMAL MEASUREMENT TOLERANCE LIMIT

1 Bush inside diameter 35,015 (1.3796) 35,060

35,025 (1.3800) (1.3814)

2 Connecting rod bush inside 63,535 (2.5033) 63,620

diameter 65,575 (2.5836) (2.5066)

1st undersize (grinding) 63,285 (2.49349) 63,370

63,325 (2.4950) (2.4968)

2nd undersize (grinding) 63,035 (2.4836) 63,120

63,075 (2.4851) (2.4870)

3 Connecting rod axes parallelism - Max. 0,05

(measured at 142,4 mm from con (Max. 0.0020)

rod axis)

4 Difference between diameters in - Max. 0,1

segment A of screws (Max. 0.004)

5 Weight difference between all - Max. 20 g

connecting rods

10-12

307.W.M300.en.0.02-Motori EURO I10-12 10-12 1/15/2010 8:09:30 PM

TECHNICAL CHARACTERISTICS

10.1.7 - Camshaft technical data - static advance of 11° (1000.3 WT E III)

2 1 1 1 1

n°1 n°2 n°3

Fig.12 - 3-cylinder

NOTE

The presence of part “A” indicates a static advance of 11°

Unit of measure: mm (in.)

Tab.19

POS. ITEMS TO BE CHECKED NORMAL MEASUREMENT MAXIMUM TOLERANCE LIMIT

1 Camshaft bearings 54,970 - 55,000 55,950

(2.1658 - 2.1670) (2.2044)

2 End float 0,08 - 0,206 Max. 0,25

(0.0032 - 0.0081) (Max. 0.001)

10-13

307.W.M300.en.0.02-Motori EURO I10-13 10-13 1/15/2010 8:09:30 PM

TECHNICAL CHARACTERISTICS

10.1.8 - Camshaft technical data - static advance of 12° (1000.3 WTI E III,1000.4 WTI E

III)

2 1 1 1 1

n°1 n°2 n°3

Fig.13 - 3-cylinder

2 1 1 1 1 1

n°1 n°2 n°3 n°4

Fig.14 - 4-cylinder

Unit of measure: mm (in.)

Tab.20

POS. ITEMS TO BE CHECKED NORMAL MEASUREMENT MAXIMUM TOLERANCE LIMIT

1 Camshaft bearing journal 54,970 - 55,000 55,950

(2.1658 - 2.1670) (2.2044)

2 End float 0,08 - 0,206 Max. 0,25

(0.0032 - 0.0081) (Max. 0.001)

10-14

307.W.M300.en.0.02-Motori EURO I10-14 10-14 1/15/2010 8:09:30 PM

TECHNICAL CHARACTERISTICS

10.1.9 - Timing gears technical data

5 6

4 2

Fig.15 - Timing gears

NOTE

Apply Loctite 542 to part A.

Unit of measure: mm (in.)

Tab.21

POS. ITEMS TO BE CHECKED NORMAL MEAS- TOLERANCE LIMIT NOTES

UREMENT

1 Intermediate gear bush inside diameter 40,025 (1.5770) 40,125 -

40,064 (1.5785) (1.581)

2 Intermediate gear support shaft outside 39,975 (1.5750) 39,950 -

diameter 40,000 (1.5760) (1.574)

3 Intermediate gear end float 0,13 - 0,53 Max. 0,80 -

(0.0051 - 0.0208) (Max. 0.0315)

4 Backlash between teeth of crankshaft gear 0.05...0.10 Max. 0,10 -

- intermediate gear (0.0019...0.0039) (Max. 0.0039)

5 Backlash between teeth of intermediate gear 0.05...0.10 Max. 0,10 -

and camshaft gear (0.0019...0.0039) (Max. 0.0039)

10-15

307.W.M300.en.0.02-Motori EURO I10-15 10-15 1/15/2010 8:09:30 PM

TECHNICAL CHARACTERISTICS

POS. ITEMS TO BE CHECKED NORMAL MEAS- TOLERANCE LIMIT NOTES

UREMENT

6 Intermediate gear Base Red dot for backlash

of 0.05...0.10

(0.0019...0.0039)

1st oversize Yellow dot for backlash

of 0.11...0.13

(0.0043...0.0051)

2nd oversize Green dot for backlash above

0.13 (0.0051)

10-16

307.W.M300.en.0.02-Motori EURO I10-16 10-16 1/15/2010 8:09:30 PM

TECHNICAL CHARACTERISTICS

10.1.10 - Counter-rotating weights technical data (1000.4 WTI E III)

Counter-rotating weights

45 45

1 1

Gears backlash

Unit of measure: mm (in.)

Tab.22

POS. ITEMS TO BE CHECKED NORMAL MEASUREMENT TOLERANCE LIMIT

1 Bushes inside diameter 26.050...26.075 26,150

Shafts outside diameter (45 mm) 25.087...26.000 -

2 Counter-rotating weights end float 0.10...0.43 -

3 Gear backlash 0.10...0.20 0,20

10-17

307.W.M300.en.0.02-Motori EURO I10-17 10-17 1/15/2010 8:09:30 PM

TECHNICAL CHARACTERISTICS

10.1.11 - Technical data and dimensions of valves - valve springs (1000.3 WT E III)

Valve - valve spring

4

2

3

DANGER

The spring should be positioned so that the end with the more tightly-packed coils is contact with the cylinder head.

NOTE

The identification mark is shown in yellow under the valve crown

Unit of measure: mm (in.)

10-18

307.W.M300.en.0.02-Motori EURO I10-18 10-18 1/15/2010 8:09:31 PM

TECHNICAL CHARACTERISTICS

Tab.23

POS. ITEMS TO BE CHECKED NORMAL MEAS- TOLERANCE LIMIT NOTES

UREMENT

1 Stem diameter Intake 8,972 (0.3535) - Renew when the

8,958 (0.3527) valve stem to guide

Exhaust 8.972 (0.3532) - clearance exceeds

8,987 (0.3540) 0.1 mm (0.004 in.)

2 Valve diameter Intake 39.3 ... 39.5 - -

(1.547 ... 1.555)

Exhaust 43.9 ... 44.1 -

(1.728 ... 1.736)

3 Valve angle Intake 91° 15’±15’ - -

Exhaust 140° 30’±141°

4 Free spring length Intake - - -

Exhaust -

Inclination Intake - - No deviation from

Exhaust - perpendicular permit-

ted

10-19

307.W.M300.en.0.02-Motori EURO I10-19 10-19 1/15/2010 8:09:31 PM

TECHNICAL CHARACTERISTICS

10.1.12 - Technical data and dimensions of valves - valve springs (1000.3 WTI E III)

Valve - valve spring

4

2

3

DANGER

The spring should be positioned so that the end with the more tightly-packed coils is contact with the cylinder head.

Unit of measure: mm (in.)

Tab.24

POS. ITEMS TO BE CHECKED NORMAL MEAS- TOLERANCE LIMIT NOTES

UREMENT

1 Stem diameter Intake 8,972 (0.3535) - Renew when the

8,958 (0.3527) valve stem to guide

Exhaust 8.972 (0.3532) - clearance exceeds

8,987 (0.3540) 0.1 mm (0.004 in.)

2 Valve diameter Intake 39.3 ... 39.5 - -

(1.547 ... 1.555)

Exhaust 43.9 ... 44.1 -

(1.728 ... 1.736)

10-20

307.W.M300.en.0.02-Motori EURO I10-20 10-20 1/15/2010 8:09:31 PM

TECHNICAL CHARACTERISTICS

POS. ITEMS TO BE CHECKED NORMAL MEAS- TOLERANCE LIMIT NOTES

UREMENT

3 Valve angle Intake 91° 15’±15’ - -

Exhaust 140° 30’±141°

4 Free spring length Intake - - -

Exhaust -

Inclination Intake - - No deviation from

Exhaust - perpendicular permit-

ted

10-21

307.W.M300.en.0.02-Motori EURO I10-21 10-21 1/15/2010 8:09:31 PM

TECHNICAL CHARACTERISTICS

10.1.13 - Technical data and dimensions of valves - valve springs (1000.4 WTI E III)

Valve - valve spring

4

2

3

DANGER

The spring should be positioned so that the end with the more tightly-packed coils is contact with the cylinder head.

NOTE

The identification mark is shown in yellow under the valve crown

Unit of measure: mm (in.)

10-22

307.W.M300.en.0.02-Motori EURO I10-22 10-22 1/15/2010 8:09:31 PM

TECHNICAL CHARACTERISTICS

Tab.25

POS. ITEMS TO BE CHECKED NORMAL MEAS- TOLERANCE LIMIT NOTES

UREMENT

1 Stem diameter Intake 8,972 (0.3535) - Renew when the

8,958 (0.3527) valve stem to guide

Exhaust 8.972 (0.3532) - clearance exceeds

8,987 (0.3540) 0.1 mm (0.004 in.)

2 Valve diameter Intake 39.3 ... 39.5 - -

(1.547 ... 1.555)

Exhaust 43.9 ... 44.1 -

(1.728 ... 1.736)

3 Valve angle Intake 91° 15’±15’ - -

Exhaust 140° 30’±141°

4 Free spring length Intake - - -

Exhaust -

Inclination Intake - - No deviation from

Exhaust - perpendicular permit-

ted

10-23

307.W.M300.en.0.02-Motori EURO I10-23 10-23 1/15/2010 8:09:31 PM

TECHNICAL CHARACTERISTICS

10.1.14 - Technical data and dimensions of cylinder heads - valve guide - valve seats

(1000.3 WT E III)

Fig.16 - Heads - valve guide - valve seats

Unit of measure: mm (in.)

Tab.26

POS. ITEMS TO BE CHECKED NORMAL MEAS- TOLERANCE LIMIT NOTES

UREMENT

1 Valves recess Intake 0.7-1.3 1,8 -

(0.028 - 0.051) (0.0709)

Exhaust 0.9-1.5 2,0

(0.035 - 0.060) (0.0788)

2 Valve seats angle Intake 120° - -

Exhaust 90° -

3 Width of valve contact Intake 2,10 - -

area with seat (0.083)

Exhaust 2,21 -

(0.087)

4 Valve guides inside diameter 9,025 (0.364) - Renew when the

9,040 (0.356) valve stem to guide

clearance exceeds

0.1 mm (0.004 in.)

10-24

307.W.M300.en.0.02-Motori EURO I10-24 10-24 1/15/2010 8:09:31 PM

TECHNICAL CHARACTERISTICS

POS. ITEMS TO BE CHECKED NORMAL MEAS- TOLERANCE LIMIT NOTES

UREMENT

5 Protrusion of valve Intake 14,3 - 14,7 - -

guides from spring Exhaust (0.563 - 0.579)

locating surface

6 Injector nozzle guide length 19,28 - 19,18 - -

(0.760 - 0.752)

7 Injector nozzle guide bore 7,3 - 7,4 - -

(0.288 - 0.292)

8 Copper bushes bore 17,9 - 18 - -

(0.705 - 0.709)

9 Injector protrusion 2,383 - 3,095 - -

(0.094 - 0.122)

10-25

307.W.M300.en.0.02-Motori EURO I10-25 10-25 1/15/2010 8:09:32 PM

TECHNICAL CHARACTERISTICS

10.1.15 - Technical data and dimensions of cylinder heads - valve guide - valve seats

(1000.3 WTI E III,1000.4 WTI E III)

Fig.17 - Heads - valve guide - valve seats

● A = Washer “A” (drwng. n° 2.1499.224.0) is located between the injector and the copper bush.

Unit of measure: mm (in.)

Tab.27

POS. ITEMS TO BE CHECKED NORMAL MEAS- TOLERANCE LIMIT NOTES

UREMENT

1 Valves recess Intake 0.7-1.3 1,8 -

(0.028 - 0.051) (0.0709)

Exhaust 0.9-1.5 2,0

(0.035 - 0.060) (0.0788)

2 Valve seats angle Intake 120° - -

Exhaust 90° -

3 Width of valve contact Intake 2,10 - -

area with seat (0.083)

Exhaust 2,21 -

(0.087)

10-26

307.W.M300.en.0.02-Motori EURO I10-26 10-26 1/15/2010 8:09:32 PM

TECHNICAL CHARACTERISTICS

POS. ITEMS TO BE CHECKED NORMAL MEAS- TOLERANCE LIMIT NOTES

UREMENT

4 Valve guides inside diameter 9,025 (0.364) - Renew when the

9,040 (0.356) valve stem to guide

clearance exceeds

0.1 mm (0.004 in.)

5 Protrusion of valve Intake 14,3 - 14,7 - -

guides from spring Exhaust (0.563 - 0.579)

locating surface

6 Injector nozzle guide length 19,28 - 19,18 - -

(0.760 - 0.752)

7 Injector nozzle guide bore 7,3 - 7,4 - -

(0.288 - 0.292)

8 Copper bush bore 17,9 - 18 - -

(0.705 - 0.709)

9 Injector protrusion 1,844 - 2,734 - -

2,65 (-0.267; +0.445)

10-27

307.W.M300.en.0.02-Motori EURO I10-27 10-27 1/15/2010 8:09:32 PM

TECHNICAL CHARACTERISTICS

10.1.16 - Technical data and dimensions of rocker arms - rocker shafts - tappets

3

2

1

Fig.18 - Rocker arms - rocker shafts - tappets

Unit of measure: mm (in.)

Tab.28

POS. ITEMS TO BE CHECKED NORMAL MEASURE- TOLERANCE LIMIT NOTES

MENT

1 Rocker arm bush inside 19,015 (0.749) - Renew when the rocker

diameter 19,025 (0.746) shaft clearance exceeds

0.08 mm (0.0031 in.)

2 Intake valve clearances 0,20 (0.008) - -

0,25 (0.001)

Exhaust valve clearances 0,15 (0.006) - -

0,25 (0.001)

3 Diameter of rocker shafts 19...18.987 - -

(0.749 - 0.748)

4 Tappets outside diameter 15,984 (0.630) - -

15.966 (0,629)

5 Flexure of pushrods - Max. 0,3 -

(Max. 0.012)

10-28

307.W.M300.en.0.02-Motori EURO I10-28 10-28 1/15/2010 8:09:32 PM

TECHNICAL CHARACTERISTICS

10.1.17 - Engine injector technical data (1000.3 WT E III)

Injector type: P/N 2.4719.620.0

Calibration pressure: 180 ... 188 bar (2610.5 ... 2726.5 psi)

Max. injection pressure: 1200 bar (17403 psi)

Injector nozzle: P/N 2.4729.630.0, end of Bosch code 1352

Injector nozzle holder: type D.17 - P/N 2.4719.590.0

10-29

307.W.M300.en.0.02-Motori EURO I10-29 10-29 1/15/2010 8:09:32 PM

TECHNICAL CHARACTERISTICS

10.1.18 - Engine injectors technical data (1000.3 WTI E III,1000.4 WTI E III)

Injector type: P/N 2.4719.650.0

Injector type: P/N 2.4719.650.0

Calibration pressure: 180 ... 188 bar (2610.5 ... 2726.5 psi)

Max. injection pressure: 1200 bar (17403 psi)

Injector nozzle: P/N 2.4729.650.0

Injector nozzle holder: P/N 2.4719.650.0; end of Bosch code 2159

10-30

307.W.M300.en.0.02-Motori EURO I10-30 10-30 1/15/2010 8:09:32 PM

TECHNICAL CHARACTERISTICS

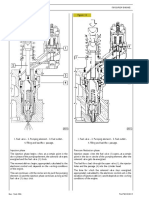

10.1.19 - Hydraulic tappets diagram

Fig.19

Diagram showing hydraulic tappets operated

10-31

307.W.M300.en.0.02-Motori EURO I10-31 10-31 1/15/2010 8:09:32 PM

TECHNICAL CHARACTERISTICS

Fig.20

Diagram showing hydraulic tappets diagram not operated

10-32

307.W.M300.en.0.02-Motori EURO I10-32 10-32 1/15/2010 8:09:35 PM

20 - METHOD OF INTERVENTION

307.W.M300.en.0.02-Motori EURO I20-1 20-1 1/15/2010 8:09:38 PM

METHOD OF INTERVENTION

20.1 - B0 - ENGINE

20.1.1 - Operations prior to removal

1 During disassembly remove from the engine:

● Disconnect the accelerator and engine stop cables of the mechanical governor, the fuel supply and return pipes;

● starter motor;

● cooling fan and relative belt;

● alternator, oil filters and auxiliary PTO, if present;

● air conditioning compressor, if present, and relative drivebelt;

● trailer air braking compressor, if present;

● clutch;

● flywheel;

● engine mounting flange.

Removal of blow-by assembly

1 DANGER 15 15

The blow-by unit is one of the solutions adopted;

for other models the solution may be different,

but the operations to be performed are identical.

Loosen the clamps and disconnect oil recovery pipes (15).

NOTE

Renew the oil seal on reassembly.

2 Remove nuts (16) and remove blow-by assembly (17) complete

with pipes.

17

16

20-2

307.W.M300.en.0.02-Motori EURO I20-2 20-2 1/15/2010 8:09:38 PM

METHOD OF INTERVENTION

3 Loosen screws with washer (18) and remove filler (19).

18 19

18

4 Remove union (20).

21

NOTE

21

Renew oil seal (21) on reassembly.

20 21

20-3

307.W.M300.en.0.02-Motori EURO I20-3 20-3 1/15/2010 8:09:38 PM

METHOD OF INTERVENTION

20.1.2 - Checking engine block

1 Mount main bearing caps complete with main bearing shells or main bearings on the block.

NOTE

Position the main bearing caps and main bearing shells according to the punched numbers and the marks

executed on disassembly.

Fix the main bearing caps with the screws.

Screws: 92 Nm (67.8 lb.ft.)

2 Check the main bearings diameter and out of round with an

internal dial gauge.

NOTE

Make a note of the values read for each main

bearing and renew the bearing if the diameters

exceed the tolerance limits specified in

“TECHNICAL DATA AND DIMENSIONS”.

NOTE

The main bearings must be replaced with

undersize main bearings whenever the crankshaft

is reground.

3 Check the crankshaft main bearings diameter with an internal

dial gauge.

NOTE

If the bearings exceed the permissible tolerance

values specified in “TECHNICAL DATA AND

DIMENSIONS” they must be replaced, and the

new bearings must be bored after assembly.

NOTE

To facilitate removal of the worn main bearings

and boring of the new main bearings, remove the

plug on the flywheel side. When this procedure

has been carried out, refit a new plug smeared

with sealant.

Plug: Loctite 554

20-4

307.W.M300.en.0.02-Motori EURO I20-4 20-4 1/15/2010 8:09:39 PM

METHOD OF INTERVENTION

20.1.3 - Crankshaft

1 Position a dial gauge on a magnetic stand “A” and preload the

gauge by about 3 mm (0.118 in.) on the head of crankshaft A

(1). Using lever “B”, pry the crankshaft axially in one of the two

directions; set the dial gauge to zero and move the crankshaft in

the opposite direction to check if the end float reading is within

the permissible range of values. If the end float is not within the 1

specified limits, replace the thrust washers with oversize versions

(see “Technical data checks”).

2 Remove the screws and remove connecting rod caps (2)

complete with main bearing shells (3). 2

NOTE

Label the main bearing shells and connecting

rod for the following dimensional check.

3

NOTE

Note the connecting rod cap and relative

connecting rod are marked with punched

numbers facing the injection pumps side.

NOTE

Mark the assembly position of each connecting

rod. Do not switch positions unless a general

overhaul is to be carried out.

3 Remove the screws and remove central main bearings (4) 2

complete with the main bearing shells. 2

NOTE

1

Label the main bearing shells and main bearings

1

for the following dimensional check. 4

A

NOTE

Note that the central main bearings have the

same numerical punch marking shown on the

engine block and that orientation is defined by

the smaller diameter spot facings “A” facing the

injection pump side.

20-5

307.W.M300.en.0.02-Motori EURO I20-5 20-5 1/15/2010 8:09:40 PM

METHOD OF INTERVENTION

4 Remove the screws and remove front main bearing (5) complete

with main bearing shell (6).

5

6

NOTE

Label the main bearing shell and front main

bearing for the following dimensional check.

NOTE

When removing the bearing remove also the

triangular seals and be sure to renew them at the

time of reassembly.

5 Remove the screws and remove rear main bearing (7) complete

7A

with main bearing shell and crankshaft half thrust washers (8).

NOTE

8

Label the main bearing shell and rear main

bearing for the following dimensional check.

NOTE

Note the direction of installation of the half thrust

washers, the oil grooves of which must face the

crankshaft are installed.

NOTE

When removing the bearing remove also the

triangular seals and be sure to renew them at the

time of reassembly.

6 Attach crankshaft (1) to a hoist with soft belt and lift it clear of

the engine.

1

20-6

307.W.M300.en.0.02-Motori EURO I20-6 20-6 1/15/2010 8:09:41 PM

METHOD OF INTERVENTION

7 Remove lower half thrust washers (9) and main bearing shells

(10).

NOTE 10

Label the positions of the main bearing shells for

the following dimensional check.

8 Remove tappets (11) from the block.

NOTES

Carefully check that the contact surface of each 11 11

tappet with the cam is perfectly smooth. Renew

any tappets showing signs of a pitted or rough

surface.

9 Remove nut (12) and remove washer jets (13) and relative

14

seals.

NOTE

Only if necessary: remove union (14). 12

13

Installing crankshaft

1 Position main bearing shells (7), with the lubrication hole, in block

(6) with the lubrication hole. 8

NOTE

Take care to align the tabs of the shells (7) in

6

their locations in the block (6).

7

2 Position the two lower half thrust washers (8).

20-7

307.W.M300.en.0.02-Motori EURO I20-7 20-7 1/15/2010 8:09:41 PM

METHOD OF INTERVENTION

NOTE

The oil grooves must be facing outwards.

NOTE

To hold the half thrust washers in place, smear grease on their seats.

3 Lubricate main bearings (7) and half thrust washers (8) liberally

and fit crankshaft (9).

9

Main bearings and half thrust washers: Engine oil

4 Lubricate crankshaft (9) liberally and fit central main bearing

shells and main bearings (10).

Crankshaft: Engine oil 10

1

NOTE 1

9

Carefully check correct orientation of main A

bearings (10); smaller diameter spot facing “A”

must be on the injection pump side. The main

bearings are numbered and must be fitted

according to the punch markings on the block.

5 Fit the upper half thrust washers (8) and triangular gaskets (12)

11

for the lateral seals, in the rear main bearing (11).

12

NOTE

Smear grease on the half thrust washers and

gaskets to hold them in position; apply grease

also to the exterior surface of the gaskets. 8 A

Equip the engine block with two installation guide plates “A”

(thickness. 0.3 mm (0.012 in) made of soft metal, and install the

rear bearing.

20-8

307.W.M300.en.0.02-Motori EURO I20-8 20-8 1/15/2010 8:09:43 PM

METHOD OF INTERVENTION

6 Fix rear main bearing (11) with the screws tightened manually

to hold the position; remove guide plates “A” by pulling them 11

sideways with respect to the gasket.

A

7 Install the front main bearing (13) by means of the same

procedure utilised for the rear main bearing. 12

A 13

8 Tighten the 5 screws (14) of main bearings (15) to the 1st torque

stage with a torque wrench.

Screws: 1st stage = 10 Nm (7.4 lb.ft.)

15 14

Using a torque wrench, tighten the main bearing screws to the

specified pre-torque value.

Screws pre-torque: 40 Nm (29.5 lb.ft.) 15

DANGER

Before proceeding, check that end float is within

tolerance limits given in “Technical data and

dimensions (For the procedures, see “Removing

the crankshaft”).

9 Using the same torque wrench and angular tightening protractor

T17 (code 5.9030.640.0), tighten main bearing screws (11) and

(13).

T17

Screws: Angle-tighten through 55°±1°

Check that the crankshaft rotates freely with no points of

stiffness.

11

20-9

307.W.M300.en.0.02-Motori EURO I20-9 20-9 1/15/2010 8:09:44 PM

METHOD OF INTERVENTION

10 Trim off the protruding part of the triangular gaskets (12) for

lateral sealing of the front and rear main bearings. Ensure that 12

the gasket protrusion is no more than 0.2 mm (0.008 in.).

12

11 Fit bearing half-shells (19) in connecting rods (18).

NOTE

Take care to align the tabs of bearing half-shells

(19) in their locations in connecting rod (18). 19

Lubricate the bearing half-shells and engage the connecting rods

on the crankshaft.

18

● Bearing half-shells: Engine oil.

F0012200

NOTE

Take care to install the connecting rods the right

way round; the side marked with the punched

number must face the injection pump side.

12 Lubricate the crankshaft and fit the big-end bearing caps (20)

complete with half shells.

Hand tighten the screws of the big-end bearing caps (20). 20

20

F001 1270

13 Using a torque wrench, tighten screws (21) of the big-end bearing

caps (20) to Stage 1 torque.

● Screws: 10 Nm (7.4 lb.ft.)

Still with a torque wrench, tighten screws (21) to Stage 2 torque.

20

● Screws pre-torque: 30 Nm (22.1 lb.ft.) 21

21

F001 1280

20-10

307.W.M300.en.0.02-Motori EURO I20-10 20-10 1/15/2010 8:09:45 PM

METHOD OF INTERVENTION

14 Using the same torque wrench and angular tightening protractor

T17 (code 5.9030.640.0), fully tighten connecting rod screws

T17

(21).

● Screws: Angle-tighten through 90±1°

Check that the crankshaft rotates freely with no points of 21

stiffness. 21

NOTE

Check during crankshaft rotation that the cooling

oil spray is perfectly aligned with the hole of the F001 1291

piston chamber.

20-11

307.W.M300.en.0.02-Motori EURO I20-11 20-11 1/15/2010 8:09:46 PM

METHOD OF INTERVENTION

20.1.4 - Crankshaft checks

1 Check the diameter of the main bearing journals and crankpins

with the micrometer gauge.

NOTE

Check at various points and all around the

circumference to detect also taper and out of

round.

2 If dimensional and geometrical errors exceed the tolerances

specified in “TECHNICAL DATA AND DIMENSIONS” (even on

a single crankpin or main journal), grind the entire crankshaft,

reducing the diameters of the main journals and crankpins to one

of the possible undersize diameters indicated.

NOTE

If the crankshaft is reground, the main bearings

and crank bushes must be replaced.

3 Only if necessary

Using puller T12 (P/N 5.9030.008.4/10) to remove timing gear (1)

1 T12

from the crankshaft.

Heat the new gear on a thermostatic hotplate to approx. 100°C

and fit it to the crankshaft, making sure that it is located fully

home against the thrust washer.

NOTE

Check the condition of the key.

4 6-cylinder version

If necessary, renew the lubrication oil pump drive gear.

2 T12

Using puller T12 (P/N 5.9030.008.4/10), remove oil pump drive

gear (2).

NOTE

Remove sealant residues from the crankshaft.

20-12

307.W.M300.en.0.02-Motori EURO I20-12 20-12 1/15/2010 8:09:46 PM

METHOD OF INTERVENTION

5 Heat the new gear on a thermostatic hotplate to a temperature A 2 3

approx. 100°C above the crankshaft temperature. 3

Apply sealant to the area of the crankshaft that will receive the

gear. 2

Crankshaft: Loctite 648

Fit gear (2) on crankshaft (3) at distance “A” from crankshaft

thrust surface (3).

NOTE

A = 0.2...0.5 mm (0.079...0.197 in.).

6 After cooling the gear, remove excess sealant and check that

lateral oscillation of the gear does not exceed 0.1 mm (0.004 in.)

at a the height of the 116 mm diameter (4.56 in.).

NOTE

If lateral oscillation exceeds 0.1 mm (0.004

in.), use a punch made of soft metal (copper,

aluminium, brass) to return the gear to within

tolerance.

20-13

307.W.M300.en.0.02-Motori EURO I20-13 20-13 1/15/2010 8:09:47 PM

METHOD OF INTERVENTION

20.1.5 - Flywheel checks

1 The checks relative to the flywheel are as follows:

● Visual inspection of ring gear conditions.

● Check radial runout (post-assembly check).

● Check face runout (post-assembly check).

2 If the ring gear is damaged, remove it using a puller.

NOTE

Tap the ring gear all the way around until

removing it.

NOTE

Note the direction of assembly of the ring

gear; The bevelled side of the teeth must face

outwards.

3 Clean the seat with care, heat the new ring gear on a thermostatic

hotplate to approx. 100°C and then fit it to the flywheel, making

sure that it is fully seated.

4 After having fitted the flywheel to the crankshaft and tightened

down the retaining bolts, use a dial gauge with magnetic stand to

check the radial and face runout.

NOTE

The max. permissible error is 0.10 mm (0.004

in.).

NOTE

For the tightening torque, see “ENGINE

ASSEMBLY”.

20-14

307.W.M300.en.0.02-Motori EURO I20-14 20-14 1/15/2010 8:09:47 PM

METHOD OF INTERVENTION

20.1.6 - Renewal of crankshaft rear oil seal

1 Remove rear oil seal (2) from crankcase (1) using a punch.

NOTE

Note which way round the oil seal is installed and

2

note the position.

DANGER 1

On first fitting, oil seal (2) is fitted fully into the

location in the crankcase. At each replacement,

oil seal (2) must be installed with displacement

towards the exterior of 2.5 mm (0.098 in.).

2 Tab.29

A B C

ORIGINAL 1st OVERHAUL 2nd OVERHAUL

A B C

X= 0 mm (0 in.) X= 2.5 mm (0.098 X= 5 mm (0.197 in.)

in.)

X X X

3 Using a press and suitable tool, install new oil seal (2) on

crankcase (1) in the position determined by the overhaul.

20-15

307.W.M300.en.0.02-Motori EURO I20-15 20-15 1/15/2010 8:09:49 PM

METHOD OF INTERVENTION

20.1.7 - Pistons and cylinder liners

Disassembly

1 Using a plastic drift and mallet, free and remove cylinder liner (1)

and pistons and connecting rods at the same time.

2 Remove piston-connecting rod assembly (2) from the lower part

of cylinder liner (1).

Remove O-rings (3) from cylinder liner (1). 1

2

NOTE

3

Renew the O-rings on reassembly.

3 Remove circlip (5) from piston (4).

Withdraw pin (6) and remove connecting rod (7).

7

NOTE

5 4

Note the arrow on the piston crown is opposite to 6

the number on the connecting rod.

4 Using piston ring pliers, remove first and second rings (8) and (9)

from piston (4). 8

NOTE

Note that the word TOP is inscribed on the upper

face of the piston rings.

8

9

20-16

307.W.M300.en.0.02-Motori EURO I20-16 20-16 1/15/2010 8:09:49 PM

METHOD OF INTERVENTION

5 Remove wiper ring (10).

10

6 Remove spring (11) of wiper ring (10).

11

Installation

1 Position O-rings (2) on perfectly clean and degreased cylinder

liner (1).

1

DANGER

The O-rings are specially treated and once

removed from their packaging, they must not be

exposed to the air for more than 48 hours.

2

NOTE

Do not lubricate O-rings (2).

2 Using piston ring pliers, fit rings (4) and (5) on piston (3) .

3 4

DANGER

The upper rings must be installed with the word

TOP towards the piston crown.

4

5

20-17