Professional Documents

Culture Documents

Oil Seal Service Bulletin

Uploaded by

jisuuuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oil Seal Service Bulletin

Uploaded by

jisuuuCopyright:

Available Formats

Service Bulletin

Bulletin No. 2019-10R1

Circulate to: Sales Manager Accounting Service Manager Technician Parts Manager

Upper Crankshaft Oil Seal Inspection/Repair—V‑8 200–300 and

V‑6 175–225

NOTICE

Revised November 2019. This bulletin supersedes the previous bulletin number 2019‑10 September 2019.

This bulletin was revised to allow the replacement of parts that have been contaminated with oil due to an upper crankshaft oil

seal leak. These parts include the flywheel on a V‑8 200–300 and rubber alternator mounts on a V‑6 175–225.

Models Affected

Models Covered Serial Number Or Year

V‑8 200–300 and V‑6 175–225 FourStroke 2B576232–2B639806

V‑8 250R, V‑8 300R/300R HD 1E080311–1E080817

Scope

Worldwide

Situation

Mercury Marine has identified that some outboards within the above listed serial number range may have been assembled with

a defective upper crankshaft seal. All outboards within the listed serial range should be inspected for signs of oil leakage at the

top of the powerhead, coming from the upper crankshaft seal. Leaking oil seals should be replaced as outlined in this service

bulletin.

Inspection (of Outboard in Service or Customer Owned)

1. Remove the top cowl from the engine.

2. Tilt the outboard up to a comfortable angle to access the top of the engine from the boat or a standing position.

! WARNING

Performing service or maintenance without first disconnecting the battery can cause product damage, personal injury, or

death due to fire, explosion, electrical shock, or unexpected engine starting. Always disconnect the battery cables from the

battery before maintaining, servicing, installing, or removing engine or drive components.

! CAUTION

Disconnecting or connecting the battery cables in the incorrect order can cause injury from electrical shock or can damage

the electrical system. Always disconnect the negative (‑) battery cable first and connect it last.

3. Starting with the negative lead, disconnect both battery cables.

4. Remove the cold air intake assembly. Refer to Section 3A ‑ Induction System of the appropriate service manual.

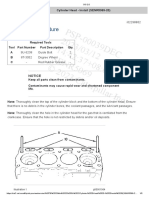

5. Looking between the spokes of the flywheel, inspect the top of the engine around the upper crankshaft seal for signs of oil

leakage.

THE INFORMATION IN THIS DOCUMENT IS CONFIDENTIAL AND PROTECTED BY COPYRIGHT AND IS THE PROPERTY OF MERCURY MARINE.

This document is provided for the sole and exclusive use of the original recipient as prescribed by Mercury Marine and may not be distributed or copied, digitally or

otherwise, without the prior written consent of Mercury Marine.

2019-10R1 NOVEMBER 2019 © 2019 Mercury Marine Page 1 / 10

Upper Crankshaft Oil Seal Inspection/Repair—V-8 200–300 and V-6 175–225

6. If no oil leakage is observed, reinstall the cold air intake assembly and reassemble the outboard. Refer to the Assembly

section of this bulletin.

7. If an oil leak is observed, proceed to the following Repair procedure.

a b a - Flywheel spokes

b - Upper crankshaft seal area on top of engine

69370

Repair

NOTE: If the alternator belt has been contaminated with engine oil, it should be cut off with a tin snips and replaced.

1. Remove the alternator belt and alternator. Refer to Section 2B ‑ Charging and Ignition System in the appropriate service

manual.

2. Remove the flywheel. Refer to Section 2A ‑ Ignition in the appropriate service manual.

IMPORTANT: If more than a few drops of oil are present on the rubber alternator mounts, they must be replaced and not

reused.

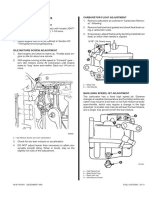

3. V‑6 175‑225 only: Inspect the six rubber alternator mounts for signs of oil. If there are more than a few drops of oil on

them, replace them as follows:

a. Remove the two hex flange head screws (one per bracket) that secure the port and starboard alternator brackets to

the engine. Be certain to retain the eight washers. Remove the brackets.

b. Use a screwdriver to work the rubber mounts out of the brackets. Rock the screwdriver back and forth until the mount

is free of the bracket.

a a- Bracket (port shown, starboard similar)

b- Rubber mount

c- Screwdriver

b d- Rock back and forth to work the rubber mount free

c

d

70117

c. Clean any oil from the brackets and washers.

THE INFORMATION IN THIS DOCUMENT IS CONFIDENTIAL AND PROTECTED BY COPYRIGHT AND IS THE PROPERTY OF MERCURY MARINE.

This document is provided for the sole and exclusive use of the original recipient as prescribed by Mercury Marine and may not be distributed or copied, digitally or

otherwise, without the prior written consent of Mercury Marine.

Page 2 / 10 © 2019 Mercury Marine NOVEMBER 2019 2019-10R1

Upper Crankshaft Oil Seal Inspection/Repair—V-8 200–300 and V-6 175–225

d. Apply soapy water to six new rubber alternator mounts and slide them into the port and starboard alternator brackets.

a - Rubber alternator mounts (3 per bracket, 6 total), shown partially

installed

a b - Alternator bracket (port shown, starboard similar)

b

70116

e. Use the eight washers and two hex flange head screws to install the port and starboard alternator brackets onto the

engine. Ensure that the ground wire is attached to the starboard alternator bracket. Refer to the following illustration

for proper stack‑up.

a- Hex flange head screw (2)

a b b- Ground wire

c- Washer (8)

c d- Starboard alternator bracket (with mounts installed)

e- Port alternator bracket (with mounts installed)

c

e d

c

c

c

70113

f. Tighten the two hex flange head screws to the specified torque.

Description Nm lb‑in. lb‑ft

Hex flange head screws (2) 30 – 22.1

IMPORTANT: If more than a few drops of oil are present on the bottom of the V‑8 flywheel, the flywheel must be replaced

and must not be reused, as some of the oil has likely migrated to the rubber damper through the four holes on the

underside of the flywheel.

THE INFORMATION IN THIS DOCUMENT IS CONFIDENTIAL AND PROTECTED BY COPYRIGHT AND IS THE PROPERTY OF MERCURY MARINE.

This document is provided for the sole and exclusive use of the original recipient as prescribed by Mercury Marine and may not be distributed or copied, digitally or

otherwise, without the prior written consent of Mercury Marine.

2019-10R1 NOVEMBER 2019 © 2019 Mercury Marine Page 3 / 10

Upper Crankshaft Oil Seal Inspection/Repair—V-8 200–300 and V-6 175–225

4. V‑8 200‑300 only: Inspect the underside of the flywheel for signs of oil. If there are more than a few drops of oil present,

discard the flywheel.

a a - Underside of the V‑8 flywheel

b b - Four holes that are open to the rubber damper

b

70126

5. Remove the retaining ring securing the upper crankshaft seal.

a - Retaining ring

a b - Upper crankshaft seal

69362

THE INFORMATION IN THIS DOCUMENT IS CONFIDENTIAL AND PROTECTED BY COPYRIGHT AND IS THE PROPERTY OF MERCURY MARINE.

This document is provided for the sole and exclusive use of the original recipient as prescribed by Mercury Marine and may not be distributed or copied, digitally or

otherwise, without the prior written consent of Mercury Marine.

Page 4 / 10 © 2019 Mercury Marine NOVEMBER 2019 2019-10R1

Upper Crankshaft Oil Seal Inspection/Repair—V-8 200–300 and V-6 175–225

6. Use a center punch or an awl to mark a drilling location at the mid‑point between the inside diameter and outside diameter

of the oil seal.

a

c

69363

a - Center punch

b - Center punch location (cross‑section view of seal)

c - Metal casing of seal

IMPORTANT: Be careful when drilling the seal. Keep the drill bit perpendicular to the seal surface and do not allow the bit

to walk from the center punch mark location. Stop drilling as soon as the bit breaks through the metal casing of the seal.

Failure to follow these precautions could damage either the crankshaft or the cylinder block seal bore.

7. Apply a small amount of grease to the drill bit and drill a small pilot hole through the upper crankshaft seal. Be careful to

stop drilling as soon as the bit breaks through the metal casing of the seal.

a - Drill bit, pilot hole

b - Upper crankshaft seal

69366

8. Use a vacuum to clean off all of the metal and rubber chips.

9. Install a sheet metal screw into the pilot hole, one to two turns to secure the seal.

THE INFORMATION IN THIS DOCUMENT IS CONFIDENTIAL AND PROTECTED BY COPYRIGHT AND IS THE PROPERTY OF MERCURY MARINE.

This document is provided for the sole and exclusive use of the original recipient as prescribed by Mercury Marine and may not be distributed or copied, digitally or

otherwise, without the prior written consent of Mercury Marine.

2019-10R1 NOVEMBER 2019 © 2019 Mercury Marine Page 5 / 10

Upper Crankshaft Oil Seal Inspection/Repair—V-8 200–300 and V-6 175–225

10. Using a needle nose pliers, lever and remove the seal from the cylinder block/crankshaft.

a - Sheet metal screw

c b - Upper crankshaft seal

c - Needle nose pliers

69367

11. Lubricate the inside lip of the new crankshaft seal with Engine Coupler Spline Grease.

Tube Ref No. Description Where Used Part No.

Engine Coupler Spline

91 Inside lip of the crankshaft seal 8M0071842

Grease

12. If removed, install the seal spacer into position. The spacer can be installed on either side of the seal to move the seal lip

location if the crankshaft has a groove caused by the seal.

13. Carefully slide a new seal over the end of the crankshaft and into the cylinder block.

a - Spacer

a b b - Crankshaft seal

66399

14. Use a short length of 90 mm (3.5 in.) outside diameter PVC pipe to press/tap the crankshaft seal into the cylinder block.

Properly installed, the top of the seal (or spacer if installed on top of the seal) should be positioned just below the retaining

ring groove in the seal bore of the cylinder block.

THE INFORMATION IN THIS DOCUMENT IS CONFIDENTIAL AND PROTECTED BY COPYRIGHT AND IS THE PROPERTY OF MERCURY MARINE.

This document is provided for the sole and exclusive use of the original recipient as prescribed by Mercury Marine and may not be distributed or copied, digitally or

otherwise, without the prior written consent of Mercury Marine.

Page 6 / 10 © 2019 Mercury Marine NOVEMBER 2019 2019-10R1

Upper Crankshaft Oil Seal Inspection/Repair—V-8 200–300 and V-6 175–225

15. Install the retaining ring over the crankshaft seal and into the retaining groove in the seal bore of the cylinder block.

69368

a - 90 mm (3.5 in.) outside diameter PVC pipe

b - Retaining ring

16. Install the flywheel. Refer to Section 2A ‑ Ignition in the appropriate service manual.

17. Install the alternator and alternator belt. Refer to Section 2B – Charging and Ignition System in the appropriate service

manual.

Assembly

1. Install the cold air intake assembly. Refer to Section 3A ‑ Induction System in the appropriate service manual.

2. Install the top cowl.

! CAUTION

Disconnecting or connecting the battery cables in the incorrect order can cause injury from electrical shock or can damage

the electrical system. Always disconnect the negative (‑) battery cable first and connect it last.

3. Starting with the positive lead, connect both battery cables.

Owner Notification

A letter will be sent to registered owners of potentially affected outboards. The letter will advise the owner to either inspect the

outboard or take it to any Mercury Marine authorized dealer for inspection or repair. Visit MercNET, contact Mercury Marine

customer service, or your regional service center to determine whether repairs on a specific outboard within the affected serial

number range has been completed. As a Mercury Marine dealer, you should contact known affected customers to advise them

of this recall and assist with the inspection and if needed, schedule an appointment for the repair. A copy of the customer letter

is included with this service bulletin for your reference.

THE INFORMATION IN THIS DOCUMENT IS CONFIDENTIAL AND PROTECTED BY COPYRIGHT AND IS THE PROPERTY OF MERCURY MARINE.

This document is provided for the sole and exclusive use of the original recipient as prescribed by Mercury Marine and may not be distributed or copied, digitally or

otherwise, without the prior written consent of Mercury Marine.

2019-10R1 NOVEMBER 2019 © 2019 Mercury Marine Page 7 / 10

Upper Crankshaft Oil Seal Inspection/Repair—V-8 200–300 and V-6 175–225

Improved Seal Identification—Factory

Outboards produced with the improved current production upper crankshaft oil seal (serial number 2B639806 and above) are

identified with a green paint mark on the port side of the cylinder block bedplate near the upper crankshaft seal location.

69501

Rework Identification—Dealer

After completing the upper crankshaft inspection or repair instructions in this bulletin, apply a white paint mark on the oil filter

manifold.

69479

THE INFORMATION IN THIS DOCUMENT IS CONFIDENTIAL AND PROTECTED BY COPYRIGHT AND IS THE PROPERTY OF MERCURY MARINE.

This document is provided for the sole and exclusive use of the original recipient as prescribed by Mercury Marine and may not be distributed or copied, digitally or

otherwise, without the prior written consent of Mercury Marine.

Page 8 / 10 © 2019 Mercury Marine NOVEMBER 2019 2019-10R1

Upper Crankshaft Oil Seal Inspection/Repair—V-8 200–300 and V-6 175–225

Outboards in Dealer Inventory

All outboards in dealer inventory within the affected serial number range must have the upper crankshaft oil seal replaced prior

to customer delivery. Seal replacement is required for new unsold outboards, regardless of whether an oil leak is discovered.

Apply a white paint mark on the oil filter manifold to indicate that the upper crankshaft oil seal has been replaced.

69479

Parts Required

Qty. Description Part Number

1 Upper crankshaft seal 8M0162050

1 Alternator belt (if required) 8M0142251

1 V‑8 200–300 only – Flywheel (if required) 8M0142245

6 V‑6 175–225 only – Alternator rubber mount (if required) 8M0142676

Warranty

Mercury Marine will credit the dealer for the cost of parts and labor. Complete a warranty claim, listing:

Repair

• Labor: 1.0 hours

• Warranty flat rate code: SB10

• Part code: 410

• Fail code: 00

• Qty. 1 P/N 8M0162050 – Upper crankshaft seal

• Qty. 1 P/N 8M0142251 – Alternator belt (if required)

V‑8 200–300 Only:

• Qty. 1 P/N 8M0142245 – Flywheel (if required)

V‑6 175–225 Only:

• Qty. 6 P/N 8M0142676 – Alternator rubber mount (if required)

• Labor: 0.2 hours (if rubber mounts were replaced)

THE INFORMATION IN THIS DOCUMENT IS CONFIDENTIAL AND PROTECTED BY COPYRIGHT AND IS THE PROPERTY OF MERCURY MARINE.

This document is provided for the sole and exclusive use of the original recipient as prescribed by Mercury Marine and may not be distributed or copied, digitally or

otherwise, without the prior written consent of Mercury Marine.

2019-10R1 NOVEMBER 2019 © 2019 Mercury Marine Page 9 / 10

Upper Crankshaft Oil Seal Inspection/Repair—V-8 200–300 and V-6 175–225

• Warranty flat rate code: SB02 (if rubber mounts were replaced)

Inspection Only—Customer‑Owned Outboards

• Labor: 0.3 hours

• Warranty flat rate code: SB03

• Part code: 410

• Fail code: 00

Dealer Parts Inventory

Submit a Parts and Accessories warranty claim, and return any p/n 26‑8M0142379 upper crankshaft seals in dealer inventory.

Claims Submission

United States and Canada: Complete/process the claim via MercNET or return a warranty claim form.

Outside the United States and Canada: Follow the instructions issued by the Marine Power International office or by an

authorized Marine Power distributor.

THE INFORMATION IN THIS DOCUMENT IS CONFIDENTIAL AND PROTECTED BY COPYRIGHT AND IS THE PROPERTY OF MERCURY MARINE.

This document is provided for the sole and exclusive use of the original recipient as prescribed by Mercury Marine and may not be distributed or copied, digitally or

otherwise, without the prior written consent of Mercury Marine.

Page 10 / 10 © 2019 Mercury Marine NOVEMBER 2019 2019-10R1

Dear Customer,

Our records indicate you are the registered owner of a Mercury Marine product that is the subject of a

fix campaign.

What You Need to Know:

Mercury Marine has identified that your outboard(s) may develop an oil leak at the upper crankshaft

seal. Your outboard(s) should be inspected for signs of oil on top of the powerhead.

What You Should Do:

You can remove the top cowl and inspect the upper powerhead area for signs of oil. If you would rather

not inspect the outboard yourself, bring your outboard to an authorized Mercury Marine dealer. If no

signs of an oil leak are detected, no further action is required. If signs of an oil leak are detected, contact

your authorized Mercury Marine outboard dealer to schedule a service appointment. When scheduling

your service appointment, be sure to mention Mercury Outboard Service Bulletin 2019-10.

Mercury Marine’s Commitment to You:

We have provided instructions to Mercury authorized dealers for this service. This service will be

performed at no charge to you. We sincerely appreciate your business and regret any inconvenience this

may cause you.

If you have questions or if you no longer own this engine, please contact Mercury Marine Customer

Service:

U.S., Canada …………………………………………920 929 5040

Australia, Pacific …………………………… …….+ 61 3 9791 5822

Europe, Middle East, Africa .…………………+ 32 87 32 32 11

Mexico, Central America, Caribbean,

South America ……………………………………. + 1 954 744 3500

Asia, Singapore …………………………………….+ 65 6805 8100

You might also like

- Wire Abrasion Service BulletinDocument7 pagesWire Abrasion Service BulletinjisuuuNo ratings yet

- MAN B&W Diesel A/S: Service LetterDocument8 pagesMAN B&W Diesel A/S: Service LetterKaushalKishoreNo ratings yet

- TP CSL A-2019Document9 pagesTP CSL A-2019turboshaftNo ratings yet

- Carga SuspensionesDocument17 pagesCarga SuspensionesHeriberto ColqueNo ratings yet

- Cylinder Head - Inspect: Shutdown SIS Previous ScreenDocument3 pagesCylinder Head - Inspect: Shutdown SIS Previous ScreenbejoythomasNo ratings yet

- 206-19-42 July 2019Document9 pages206-19-42 July 2019turboshaftNo ratings yet

- CSB19-01A Fuel (Primer) Diverter Valve AssemblyDocument12 pagesCSB19-01A Fuel (Primer) Diverter Valve AssemblyFranco PugaNo ratings yet

- 3-7L MerCruiser All Service BulletinsDocument83 pages3-7L MerCruiser All Service BulletinsGerrit DekkerNo ratings yet

- ON A/C FSN 551-600: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSN - FSNDocument7 pagesON A/C FSN 551-600: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSN - FSNEdson CarvalhoNo ratings yet

- 407-19-23 July 2019Document9 pages407-19-23 July 2019turboshaftNo ratings yet

- Rolls - Royce Engine - Inspection/Check: M250 - C20 Series Operation and MaintenanceDocument36 pagesRolls - Royce Engine - Inspection/Check: M250 - C20 Series Operation and MaintenanceFranny Alexandra Tamayo RiocampoNo ratings yet

- 212 Asb 08 130Document7 pages212 Asb 08 130Walberto PachecoNo ratings yet

- Sioux 7192 PDFDocument22 pagesSioux 7192 PDFJeff LetcherNo ratings yet

- 1/10 2WD On-Road Nitro Racer: Downloaded From Manuals Search EngineDocument12 pages1/10 2WD On-Road Nitro Racer: Downloaded From Manuals Search EngineJosep MªNo ratings yet

- TrimDocument9 pagesTrimOlegs GrNo ratings yet

- Rolls Royce m250 c20r Series Operation and Maintenance 720000 5Document32 pagesRolls Royce m250 c20r Series Operation and Maintenance 720000 5Antonio AmbrosoneNo ratings yet

- Cylinder Head Gasket - Installation (08 - 2013 - ) (Cylinder Head Assembly) - Toyota Sienna 3.5ltsDocument8 pagesCylinder Head Gasket - Installation (08 - 2013 - ) (Cylinder Head Assembly) - Toyota Sienna 3.5ltsFran SanchezNo ratings yet

- CC200 - CC400 CRIMPER Operators ManualDocument15 pagesCC200 - CC400 CRIMPER Operators ManualPTCNo ratings yet

- P10C-D201 Especificaciones Model CDocument9 pagesP10C-D201 Especificaciones Model CWilliam ValenciaNo ratings yet

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 72-60-00Document62 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 72-60-00anony8103No ratings yet

- MC-10165512-0001 Subaru Forester FB25 RECALLDocument8 pagesMC-10165512-0001 Subaru Forester FB25 RECALLFelipe TeareNo ratings yet

- Cyl Head c4Document5 pagesCyl Head c4lilikNo ratings yet

- Cylinder Head - Install: Desarmado y ArmadoDocument35 pagesCylinder Head - Install: Desarmado y ArmadoCésar Pérez100% (1)

- John Deere PowerTech 2.9L Diesel Engine Diagnostic Service Repair Technical Manual (CTM125)Document16 pagesJohn Deere PowerTech 2.9L Diesel Engine Diagnostic Service Repair Technical Manual (CTM125)laopaodunNo ratings yet

- Hydraulic BrakesDocument65 pagesHydraulic BrakesGeo AdmNo ratings yet

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 72-50-00Document40 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 72-50-00anony8103No ratings yet

- Cylinder Head - InstallDocument4 pagesCylinder Head - InstallGeorge GuerreroNo ratings yet

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 73-20-01Document6 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 73-20-01anony81030% (1)

- TCM Torque SB96 7DDocument14 pagesTCM Torque SB96 7DИван КоньковNo ratings yet

- Osn 407-19-23Document22 pagesOsn 407-19-23ferbmdNo ratings yet

- IMSB 5th Wheel KH KS KD KPM 001 0617 Rev2 PDFDocument10 pagesIMSB 5th Wheel KH KS KD KPM 001 0617 Rev2 PDFAsep WahyudyNo ratings yet

- Hydraulic RAM Installation Service Handbook Is-2533Document13 pagesHydraulic RAM Installation Service Handbook Is-2533Arnie SaysonNo ratings yet

- Installation and Parts Manual: FOR D8R Series Ii TractorsDocument11 pagesInstallation and Parts Manual: FOR D8R Series Ii TractorsAbdalla gibrilNo ratings yet

- Carbur 50 CV 2t MercDocument7 pagesCarbur 50 CV 2t MercJon BondNo ratings yet

- Rcrit 14V647 9581Document43 pagesRcrit 14V647 9581Eko PurwantoNo ratings yet

- Service Bulletin: Engine Wiring Harness Chafing - 200/225/250/275 VeradoDocument4 pagesService Bulletin: Engine Wiring Harness Chafing - 200/225/250/275 VeradoJason WilliamNo ratings yet

- Duratec 16v tTI-VCTDocument40 pagesDuratec 16v tTI-VCTStarsky UrblejoNo ratings yet

- AMM August 2020 12-13-79-610-003-C - Oil Tank DrainingDocument5 pagesAMM August 2020 12-13-79-610-003-C - Oil Tank DrainingIrfan05No ratings yet

- VSP 267Document11 pagesVSP 267JS VivasNo ratings yet

- Cylinder Blok c4Document7 pagesCylinder Blok c4lilikNo ratings yet

- UI Bulletin 124jDocument22 pagesUI Bulletin 124jJoshNo ratings yet

- Steering Acuator Seal Replacement Instrucctions-1Document5 pagesSteering Acuator Seal Replacement Instrucctions-1userfileNo ratings yet

- Service Manual LK14M42 LT0661Document893 pagesService Manual LK14M42 LT0661KHALED ALINo ratings yet

- 1980 ET 340T 18 PagesDocument18 pages1980 ET 340T 18 PagesTony SleckNo ratings yet

- 1991 Ford Technical Service BulletinsDocument147 pages1991 Ford Technical Service Bulletinsalexander pintoNo ratings yet

- Kubota Beta MarineDocument80 pagesKubota Beta Marinecerolan100% (1)

- 73 10 01 PDFDocument6 pages73 10 01 PDFAnonymous 298xlo3uUNo ratings yet

- John Deere PowerTech 10.5L Diesel Base Engine Service Repair Technical Manual (CTM100)Document17 pagesJohn Deere PowerTech 10.5L Diesel Base Engine Service Repair Technical Manual (CTM100)laopaodunNo ratings yet

- Valve Body, Removing and Installing: Special Tools, Testers and Auxiliary Items RequiredDocument17 pagesValve Body, Removing and Installing: Special Tools, Testers and Auxiliary Items RequiredDiego GarciaNo ratings yet

- Land Rover V8: and ToolDocument56 pagesLand Rover V8: and ToolAntonio OliveiraNo ratings yet

- Trim Limit N Switch Install InstructionsDocument10 pagesTrim Limit N Switch Install InstructionsMin KangNo ratings yet

- Effluent/Grinder PumpsDocument9 pagesEffluent/Grinder PumpsmorjafNo ratings yet

- Install Cylinder HeadDocument6 pagesInstall Cylinder Headrahmat sanusiNo ratings yet

- v6 v8 Model InformationDocument25 pagesv6 v8 Model InformationjisuuuNo ratings yet

- On A/C All: Reference DesignationDocument10 pagesOn A/C All: Reference DesignationOsama MagedNo ratings yet

- Man-10-20220607-Paae058977 Update ManualDocument18 pagesMan-10-20220607-Paae058977 Update Manualrafael.eloidasilvaNo ratings yet

- Emd-Bearing Inspection and Qualification of Engine Main BearingsDocument30 pagesEmd-Bearing Inspection and Qualification of Engine Main BearingsIvanNo ratings yet

- 830Document10 pages830cleberNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Rigging Manual 2018: Printed in JapanDocument421 pagesRigging Manual 2018: Printed in JapanjisuuuNo ratings yet

- MEFI 5 Series ECM PDFDocument403 pagesMEFI 5 Series ECM PDFCheohdezNo ratings yet

- v6 v8 Model InformationDocument25 pagesv6 v8 Model InformationjisuuuNo ratings yet

- MedallionII TroubleshootDocument8 pagesMedallionII TroubleshootrfffffNo ratings yet

- Indmar MEFI4manualDocument287 pagesIndmar MEFI4manualjisuuuNo ratings yet

- L510003 PDFDocument177 pagesL510003 PDFleejoNo ratings yet

- L510003 PDFDocument177 pagesL510003 PDFleejoNo ratings yet

- Engine Mechanical - 5.7LDocument426 pagesEngine Mechanical - 5.7LjisuuuNo ratings yet

- Engine Mechanical - 5.7LDocument426 pagesEngine Mechanical - 5.7LjisuuuNo ratings yet

- Turbine Engine Design and ConstructionDocument4 pagesTurbine Engine Design and ConstructionWanda Aulia SukmaNo ratings yet

- Catálogo 155 FT HYSTERDocument574 pagesCatálogo 155 FT HYSTERWagner Dalla Bernardine75% (4)

- Pda300832en 0317 V1 - 1Document128 pagesPda300832en 0317 V1 - 1auasincNo ratings yet

- Michael M. Calistrat: Safety, Application, and Service Factors As Applied To Shaft Couplings byDocument8 pagesMichael M. Calistrat: Safety, Application, and Service Factors As Applied To Shaft Couplings byronny_fernandes363No ratings yet

- KES Parts OverviewDocument18 pagesKES Parts OverviewВенцислав ВеневNo ratings yet

- WS-01 - Flow SwitchDocument1 pageWS-01 - Flow SwitchSHARAB IMTIAZNo ratings yet

- 4JG1TPD03 Eng Parts-Catalog-20140325085404Document62 pages4JG1TPD03 Eng Parts-Catalog-20140325085404GiuseppeNo ratings yet

- Evinrude 5007525 LoResDocument369 pagesEvinrude 5007525 LoResJulie Lafrance100% (2)

- Caterpillar Planned-Maintenance PMDocument2 pagesCaterpillar Planned-Maintenance PMmaggioraNo ratings yet

- C30 Series Specs C30-SS017 Rev. C 07.02.2021Document1 pageC30 Series Specs C30-SS017 Rev. C 07.02.2021Cristian TorresNo ratings yet

- 4R44E / 4R55E / 5R55E: 4 & 5 SPEED RWD WITH LOCK UP (Full Electronic Control)Document4 pages4R44E / 4R55E / 5R55E: 4 & 5 SPEED RWD WITH LOCK UP (Full Electronic Control)krzysiek1975100% (1)

- EED203 Mid Exam Paper SolutionsDocument8 pagesEED203 Mid Exam Paper SolutionsAvinash SinghNo ratings yet

- Tabel PulleyDocument4 pagesTabel PulleyDimas D'rooyal Borooss'No ratings yet

- Caterpillar D6R Tractor (Electronic Clutch Brake) Electrical System PDFDocument2 pagesCaterpillar D6R Tractor (Electronic Clutch Brake) Electrical System PDFdothao78% (9)

- QLT M10 Part CatalogDocument109 pagesQLT M10 Part CatalogEffendiCibuburNo ratings yet

- Cambio de Resortes de LiftersDocument4 pagesCambio de Resortes de LiftershectorescallonquioneNo ratings yet

- Hartzell Propeller 2016 Price ListDocument93 pagesHartzell Propeller 2016 Price ListPeterNo ratings yet

- CTRLDocument57 pagesCTRLpbontyNo ratings yet

- F160 23 PDFDocument52 pagesF160 23 PDFДенис Черный100% (2)

- 2022 Gavsdipm - Ga7-90vsd PM Wuxi Leaflet 2935081648Document7 pages2022 Gavsdipm - Ga7-90vsd PM Wuxi Leaflet 2935081648Rio TrungNo ratings yet

- Suspension SystemDocument15 pagesSuspension Systemaashish koiralaNo ratings yet

- Rotary Screw Compressors: Online Condition Monitoring ofDocument3 pagesRotary Screw Compressors: Online Condition Monitoring offazzlieNo ratings yet

- Us 3123958 PDFDocument11 pagesUs 3123958 PDFLUIS ISAAC LEON PARONo ratings yet

- Section 12 - Compressed Air System - Group 12Document3 pagesSection 12 - Compressed Air System - Group 12Miodrag HuberNo ratings yet

- Analysis of Multi-Element Torque ConverterDocument11 pagesAnalysis of Multi-Element Torque ConverterbaharmarineNo ratings yet

- Drilling MachinesDocument37 pagesDrilling MachinesChandrakantha K33% (3)

- ATF3-3 Single-Stage Geared Fan, Five-Stage I-P Compressor,: Garrett-Airesearch (Usa)Document1 pageATF3-3 Single-Stage Geared Fan, Five-Stage I-P Compressor,: Garrett-Airesearch (Usa)ValBMSNo ratings yet

- Aice Question BankDocument3 pagesAice Question BankAnonymous bVWN51O90NNo ratings yet

- GR10-CD-F479 P.S.C.C.H.Co Comm.15.13Document33 pagesGR10-CD-F479 P.S.C.C.H.Co Comm.15.13Islam AttiaNo ratings yet

- F 416 Ex Compressed Air Motor EnglishDocument4 pagesF 416 Ex Compressed Air Motor EnglishUriel LvNo ratings yet