Professional Documents

Culture Documents

Sika WS

Uploaded by

aristo onanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sika WS

Uploaded by

aristo onanCopyright:

Available Formats

Metal

®

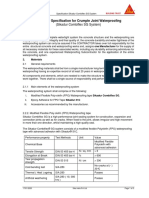

Sikasil WS-305 WS-605 S

Components one-part one-part

Weatherseal

Curing system neutral neutral

Skin forming time

(23°C/50% rel. humidity) [min] ~20 ~25

Permanently elastic range [ °C] – 40 to +150 – 40 to +150

Double glazing

Shore A hardness 1

~20 ~20

Tensile strength 2 [N/mm2 ] ~0.50 ~0.45

Modulus at 100%

elongation 2 [N/mm2 ] ~0.30 ~0.27

1) ISO 868, 2) ISO 8339-A. These figures are intended as a guide and should not be used in preparing specifica-

tions. For technical information about the products, please ask for the latest respective data sheets.

Weatherseal, double glazing/metal, joint width: depth = 2:1

18

Telecom Center Munich, Germany; Kiessler + Partner

Sikasil® WS Weatherseals –

effective Protection against the Elements

Perfect Appearance - UV and weathering resistance specimens of the project material at one Weathersealing of bolted Water/Vapour Proofing Standards and Guidelines

- Improved impermeability to air and of Sika’s Facade Competence Centres. Glass Facades Membranes

The quality and optical appearance of a driving rain Because of the requirements for the

curtain wall are critically dependent on - Very good movement absorption Individual Colour Scheme To ensure the correct choice of a sealant Connections of the glass facade to the sealant, standards for weatherseals are

appropriate weather sealing. The individual in bolted glass facades, Sika recommends concrete structure can be too wide for significantly different from those for

elements are ultimately subject to extreme Dimensioning of For weatherseals and natural stone seal- checking the design and statics. This is wet sealing. For sound water proofing structural glazing applications.

movements due to temperature changes, weatherproofing Joints ants, Sika offers project-specific colour necessary to ascertain whether the sealant Sika offers sophisticated vapour control

moisture (in the case of concrete), shrink- matching services. In addition to the wide only serves as a highly elastic weatherseal membrane systems (see page 30). ISO 11600

age of construction materials (wood, In general range of standard colours, Sika also offers or whether it also acts as a structure- ISO 11600 is the world’s first standard

concrete), sound, wind and vibrations, - The joint edges must run parallel to a individual special colours on request. stiffening element, in which case it must Weatherproofing Gaskets to combine the classification of widely

which may affect the joints and depth of twice the joint width, but at Please note that special colours are sub- also be taken into account in the static different sealant grades and their tests.

adjacent elements. least 30 mm. This gives the backing ject to special delivery conditions such calculations. On request, our Facade UV-resistant silicone rubber gaskets are However, national standards, such as

material sufficient grip as minimum order quantities and delivery Competence Centres carry out individual suitable for use as structural glazing ASTM C 920 and DIN 18545 are also

The joints between the elements may be - For most sealants, the joint width must be times. Your Sika sales manager will be calculations and tests for each project. weatherseals. All gaskets (particularly important, not only because of local prac-

effectively sealed with preformed gaskets at least 4 times the expected joint move- pleased to give you further details. non-silicones such as EPDM) have to be tices, but also because of specific char-

or alternatively with UV and weather resist- ment, which results from 25% movement Sikasil® WS-305 individually tested for compatibility accord- acteristics such as the abrasion test

ant silicone sealants. Sikasil® WS sili- capability - Ready-to-use one-part sealant ing to ASTM C 1087 or EOTA ETAG (DIN 18545) or early movement capability

cone sealants preserve the quality and - The optimal ratio of joint width to depth is - Neutral curing No. 002. (DIN 18540).

perfect optical appearance of the facade in 2:1 (see Fig. top right) - UV and weathering resistant

the long term, thanks to their outstanding - Highly flexible

advantages: Project-specific Adhesion Tests

Sikasil® WS-605 S

For weather-tight sealing of a curtain wall, - Ready-to-use one-part sealant

it is essential to ensure optimum adhesion - Neutral curing

of the sealant to the surfaces. Before the - Non-staining on glass and metal surfaces

sealant is used, it should therefore be - UV and weathering resistant

individually tested for perfect adhesion to - Highly flexible

24 | 25

You might also like

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- Joint Sealants For Curtain Wall WaterproofingDocument5 pagesJoint Sealants For Curtain Wall WaterproofingMAJ1980100% (1)

- Sikalastic®-560 GCC Co-Elastic TechnologyDocument1 pageSikalastic®-560 GCC Co-Elastic Technologybassem muhannaNo ratings yet

- Sikaflex - 11 FCDocument4 pagesSikaflex - 11 FCSahanNo ratings yet

- E 1605 SikaCor 255 277Document5 pagesE 1605 SikaCor 255 277manoj_sitecNo ratings yet

- Tds OTTOCOLL M 500 42 - 28gb PDFDocument4 pagesTds OTTOCOLL M 500 42 - 28gb PDFJoeNo ratings yet

- Expansion Joint Waterproofing Specs - SD Combiflex SG v2Document5 pagesExpansion Joint Waterproofing Specs - SD Combiflex SG v2VIJAYTECH CONSULTANTS PVT. LTD.No ratings yet

- Sikaflex 252 TDSDocument3 pagesSikaflex 252 TDSxingobuilderNo ratings yet

- Dow Corning 991 Product InfoDocument4 pagesDow Corning 991 Product InfocurlyjockeyNo ratings yet

- SikaHyflex 250 FacadeDocument4 pagesSikaHyflex 250 FacadeNoelMeziel Canimo CabilesNo ratings yet

- Analysis of The Significance of Changes in The Num PDFDocument23 pagesAnalysis of The Significance of Changes in The Num PDFNhà Quê Ra TỉnhNo ratings yet

- Sikaflex® PRO-3 WF: Product Data SheetDocument4 pagesSikaflex® PRO-3 WF: Product Data Sheetsugiarto budiNo ratings yet

- Myk Aso Joint Tape 2000 Ver 2Document2 pagesMyk Aso Joint Tape 2000 Ver 2Devinder SokhiNo ratings yet

- Particular Specifications For Expanssion Joint Waterproofing - Sikadur CombiflexDocument5 pagesParticular Specifications For Expanssion Joint Waterproofing - Sikadur CombiflexEIL DORCNo ratings yet

- Butyl Tapes, Mastic Tapes, Adhesives & SealantsDocument35 pagesButyl Tapes, Mastic Tapes, Adhesives & SealantsNikhil MathewNo ratings yet

- Tehnički List - KIMITECH 550+Document3 pagesTehnički List - KIMITECH 550+MARKO MATUHANo ratings yet

- Sika® Carbodur® S: Product Data SheetDocument4 pagesSika® Carbodur® S: Product Data Sheetrikki nijigenNo ratings yet

- Sikagrout 215 M Pds enDocument3 pagesSikagrout 215 M Pds enfikryh_2No ratings yet

- SikaWrap 231 C PDS PDFDocument4 pagesSikaWrap 231 C PDS PDFMohit KohliNo ratings yet

- Fosroc Dekguard E2000: (Also Known As Nitocote FBC)Document4 pagesFosroc Dekguard E2000: (Also Known As Nitocote FBC)Tejinder KumarNo ratings yet

- Sikagrout 215 M - Pds en PDFDocument3 pagesSikagrout 215 M - Pds en PDFPrabowo SandiNo ratings yet

- Sikagrout 215 M Pds enDocument3 pagesSikagrout 215 M Pds enAdiprabowo WicaksonoNo ratings yet

- Sikaflex - 11 FCDocument3 pagesSikaflex - 11 FCNirwanKasbiyNo ratings yet

- Wacker WN - Weatherseal NeutralDocument4 pagesWacker WN - Weatherseal NeutralMohammad SaadehNo ratings yet

- Ottocoll® M 500: The Water-Resistant Premium Hybrid Adhesive/sealantDocument4 pagesOttocoll® M 500: The Water-Resistant Premium Hybrid Adhesive/sealantJoeNo ratings yet

- Sikahyflex 220 Window - Pds en PDFDocument4 pagesSikahyflex 220 Window - Pds en PDFKaya EmanuelNo ratings yet

- Sika Waterbars 2011-10-1Document5 pagesSika Waterbars 2011-10-1ShamaNo ratings yet

- Sikawrap - 430 G/25: Woven Glass Fiber Fabric For Structural StrengtheningDocument4 pagesSikawrap - 430 G/25: Woven Glass Fiber Fabric For Structural StrengtheningCretu Cezar CatalinNo ratings yet

- HereShield TDSDocument5 pagesHereShield TDSMahdi BagheriNo ratings yet

- Sika RaingardDocument3 pagesSika RaingardSubuk T. RathodNo ratings yet

- TDS - Sika Grout 100 (G) Ed.2Document3 pagesTDS - Sika Grout 100 (G) Ed.2Himanshu ThakurNo ratings yet

- Ipd Pds Sikalastomer 95 UsDocument2 pagesIpd Pds Sikalastomer 95 Usernest manNo ratings yet

- Dekguard E2000Document4 pagesDekguard E2000m.elsanee.cubicNo ratings yet

- Scs2000 Silpruf: Ge SiliconesDocument8 pagesScs2000 Silpruf: Ge SiliconesThiagoAgNo ratings yet

- Silicona Estructural TremcoDocument2 pagesSilicona Estructural Tremcoabu.qckumyangNo ratings yet

- Fosroc Dekguard AC: Constructive SolutionsDocument4 pagesFosroc Dekguard AC: Constructive SolutionsVJ QatarNo ratings yet

- Dekguard E2000 UAEDocument4 pagesDekguard E2000 UAEJanardhana ReddiNo ratings yet

- CoronaShield® P 8001 SemiConductive Varnish Von RollDocument3 pagesCoronaShield® P 8001 SemiConductive Varnish Von Rollyeprem82No ratings yet

- Premier Coatings SeaShield Series 2000HDDocument6 pagesPremier Coatings SeaShield Series 2000HDfakmiloNo ratings yet

- STEICOfix en IDocument2 pagesSTEICOfix en IEmil DoreNo ratings yet

- Glo Brochure Sikagard 555 W ElasticDocument4 pagesGlo Brochure Sikagard 555 W ElasticYasndra AbeygunewardhaneNo ratings yet

- Silicone Sealants: High Performance SealantDocument4 pagesSilicone Sealants: High Performance SealantParamdeep SinghNo ratings yet

- 3M™ Tapes For Solar Panel Fabrication PDFDocument8 pages3M™ Tapes For Solar Panel Fabrication PDFchipulinoNo ratings yet

- Sikaflex® PRO-3: Product Data SheetDocument4 pagesSikaflex® PRO-3: Product Data SheetArrow LazarusNo ratings yet

- SdadsadasDocument3 pagesSdadsadasTwink Arcane 9No ratings yet

- Sikagrout FM - Pds en PDFDocument3 pagesSikagrout FM - Pds en PDFANDI SETIAWANNo ratings yet

- Sikaflex® Construction: Product Data SheetDocument4 pagesSikaflex® Construction: Product Data SheetFritz NatividadNo ratings yet

- Acrylic WaterProofing Liquide TDSDocument3 pagesAcrylic WaterProofing Liquide TDSMohamed MagdiNo ratings yet

- STEICOfix en IDocument2 pagesSTEICOfix en IClaudiu BaditaNo ratings yet

- Tekasil Universal TD - V2 - GB - 06 20Document2 pagesTekasil Universal TD - V2 - GB - 06 20Fateh AzwiNo ratings yet

- Sikasil PoolDocument3 pagesSikasil PoolA GlaumNo ratings yet

- Sika Hydrotite CJDocument3 pagesSika Hydrotite CJGB career CouncilNo ratings yet

- Design Components For Structural GlazingDocument8 pagesDesign Components For Structural GlazingnonspodNo ratings yet

- Sikalastic - 614: Single Component, Polyurethane, Liquid Waterproofing MembraneDocument7 pagesSikalastic - 614: Single Component, Polyurethane, Liquid Waterproofing MembraneANDRE AURELLIONo ratings yet

- 6 2 1 6 1 Polyflex PDFDocument2 pages6 2 1 6 1 Polyflex PDFFourier MakambioNo ratings yet

- Bitumag BM Seal 1000C TDSDocument2 pagesBitumag BM Seal 1000C TDSvinoth kumar SanthanamNo ratings yet

- Sikagrout 214 11 Pds enDocument3 pagesSikagrout 214 11 Pds ensalma karimahNo ratings yet

- Tehnički List - KIMITECH BS ST 200Document2 pagesTehnički List - KIMITECH BS ST 200MARKO MATUHANo ratings yet

- Self-healing Ceramic Matrix Composites: A MonographFrom EverandSelf-healing Ceramic Matrix Composites: A MonographNo ratings yet

- Solved Problems: Single Degree Free VibrationDocument14 pagesSolved Problems: Single Degree Free Vibrationprem adhikariNo ratings yet

- Arch MLCDocument471 pagesArch MLCJoseNo ratings yet

- ٣. المنقذ (١٠٠ سؤال)Document44 pages٣. المنقذ (١٠٠ سؤال)ايمان عبد الشافىNo ratings yet

- Lovol - Fl936-Dhbo6g0131Document140 pagesLovol - Fl936-Dhbo6g0131LuzioNetoNo ratings yet

- Physics1ist Year Practical FilDocument27 pagesPhysics1ist Year Practical FilManish GoyalNo ratings yet

- Your Paragraph TextDocument11 pagesYour Paragraph TextTalha AamirNo ratings yet

- Essay On Education in IndiaDocument6 pagesEssay On Education in IndiaSümît DãsNo ratings yet

- Torque SpecsDocument21 pagesTorque SpecssaturnayalaNo ratings yet

- Module Bar PTX1.6 PDFDocument8 pagesModule Bar PTX1.6 PDFkumelachewbirre22No ratings yet

- اسئلة الهيئة السعودية- تمريضDocument39 pagesاسئلة الهيئة السعودية- تمريضlolo trabNo ratings yet

- First Quarter Examination in PracticalDocument2 pagesFirst Quarter Examination in PracticalMark Anthony B. AquinoNo ratings yet

- Biosash Order Form Latest - 2019-9281576348996003Document3 pagesBiosash Order Form Latest - 2019-9281576348996003Amer Suhail ShareefNo ratings yet

- Vertical Immersion Pump VTP-BBFDocument23 pagesVertical Immersion Pump VTP-BBFmourinho2No ratings yet

- Special Theory of RelativityDocument16 pagesSpecial Theory of RelativityBrigita SteffyNo ratings yet

- Faster and Cheaper - How Ride-Sourcing Fills A Gap in Low-Income Los Angeles NeighborhoodsDocument29 pagesFaster and Cheaper - How Ride-Sourcing Fills A Gap in Low-Income Los Angeles NeighborhoodsSam StecklowNo ratings yet

- Lighting Control: Dimmerpacks ProdigiDocument1 pageLighting Control: Dimmerpacks Prodigiwcma570% (1)

- PfroDocument4 pagesPfrobe3pNo ratings yet

- UNIT 2 - LESSON 1 - Overview To Qualitative ResearchDocument31 pagesUNIT 2 - LESSON 1 - Overview To Qualitative ResearchmikkaellaNo ratings yet

- CV Achmad AgusDocument11 pagesCV Achmad AgusWoori ConsultingNo ratings yet

- Essay 1 DraftDocument1 pageEssay 1 Draftgdx3100% (3)

- ISTH v50 Porto Rico 2006 Trabalho Filme Morango OFSDocument169 pagesISTH v50 Porto Rico 2006 Trabalho Filme Morango OFSAlexandra MamedeNo ratings yet

- Acr Oss The Line ContactorsDocument2 pagesAcr Oss The Line ContactorshmavisNo ratings yet

- Affordable HousingDocument12 pagesAffordable HousingTenzin KesangNo ratings yet

- Cut Pieces: From Flat Plates, Strips and Coil Stock. A. Shearing B. Bend Allowance C. Forming Dies D. Spring BackDocument100 pagesCut Pieces: From Flat Plates, Strips and Coil Stock. A. Shearing B. Bend Allowance C. Forming Dies D. Spring BackJade DigNo ratings yet

- MIS 310 - Syllabus 1.0Document12 pagesMIS 310 - Syllabus 1.0jackNo ratings yet

- SDKFZ 251 Mittlere SchutzenpanzerwagenDocument108 pagesSDKFZ 251 Mittlere SchutzenpanzerwagenPeterD'Rock WithJason D'Argonaut83% (6)

- 2022 Grade 10 Study GuideDocument85 pages2022 Grade 10 Study Guideeskaykhan11No ratings yet

- Instruction Manual: El SaadDocument184 pagesInstruction Manual: El SaadElias Rabbat100% (1)

- Project Report On Working-CapitalDocument74 pagesProject Report On Working-Capitalravikant2105100% (1)