Professional Documents

Culture Documents

JIndal GI Pipe-Catalogue2022

Uploaded by

LalitMohanSenapati0 ratings0% found this document useful (0 votes)

131 views24 pagesgi items

Original Title

JIndal GI Pipe-catalogue2022

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentgi items

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

131 views24 pagesJIndal GI Pipe-Catalogue2022

Uploaded by

LalitMohanSenapatigi items

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 24

Galvanized Tubes & Pipes | MS Black Tubes & Pipes | Hollow Seclions | Line Pipe (API Tubes) | Swaged Poles

Be mwa Vp s

a

Kul

PINAR

\ D3 oT TSS

x i Oh HAY [\) ROIS:

a Aa eth NAVAS TF IR

mI i ae RING Ya TRS Sus

LO c

< NX

is

WH

Y

Lie

IT XI 7

xi, afte " IVASAIRS MS ~

es es my LAR Ay OS

wh, are RA NSS is SRS

rc 4 ee LIRR OF xm

Xt ATs si Oo 3 PS

IS SL

mK

About Us:

Jindal Industries Pvt. Limited, HISAR, is one of the reputed industrial house, and a part of the

JINDALS, who have proved their unerring might in steel sector and reckoned with high esteem in the

pipe manufacturing industry.

Set up in the year 1980, JINDALHISSAR plant is the most advanced state-of-the-art facility equipped

with Modern Manufacturing Machineries. Besides having all the plants under one roof--from Rolling

Milling, Welding to Galvanizing the plant has a fully functional in-house maintenance Workshop

and Laboratory Testing facility. The plant is well equipped to manufacture best Quality MS Black and

Galvanized Pipes & Tubes in the range

of 15mm to 300mm as per National and

International standards besides other

variants.

In the Past five years the company has

experienced manifold growth due to our

relentless endeavour to maintain higher

standards of Quality and service to our

worthy Customers.

1RAdE,

Alt

NY

HISSAR

Steel Hollow Sections

(Square, Rectangular and Circular) for Structural Purpose

JINDALHISSAR, products have earned the reputation of impeccable Quality and total Reliability. The name has

become synonyms with the best in Stes! Hollow Sections and Tubes. Manufactured in its state-ofthe art

manufacturing plant, the Hollow Sections are regarded best for their excellent quality and reliability. Having BIS

certification and backed by our reputed Brand name our Hollow Sections offer most comprehensive range in SHS

25 x 25mm to 220 x 220mm and RHS 50x 25mm to 200 x 100mm.

Hollow sections are supplied to clients nationwide for a variety of applications including mechanical engineering

for example, manufacturing of booms. frames and other vehicle components, especially for applications where

high strength combined with excellent usability is needed. With high torsion rigidily and compressive strength,

these hollow sections are comparably more efficient than conventional steel sections. The excellent distribution of

material around the axis of the square

and rectangular stee! hollow sections

cllows for remarkable strength qualities

cond thus offers decisive advantages in ‘a =

its applications. The smooth and h

uniform profile of he section minimizes j @ a

corrosion and facilitates easy, onsite =

fabrication to significantly enhance the j

aesthetics of structures. A higher | il @)

strength to weight ration credits these ~ An =

sections with nearly 20% reduction in a

the use of steel @ isa}

Es

| ee

‘Adhering to the stringent Quality Standards has always been our motto. Whatever the circumstances may

we always remain stubborn as far as Quality is concerned. Itis our Quality that makes us Unique. To check Qual

ct every stage of production Jindal Industries has its own set of strict procedure in compliance with International

Standards. Various Accreditations and Certifications are testimony to our commitment to Quality and Service.

(Ourin-house Testing facilities are considered best in the industry.

Certification

MANAGEMENT S¥STEN MANAGEMENTSYSTEM MANAGEMENT SYSTEM

cetricare CeRTFICATE ceevtcare

ee. itmoes = CE APISL

Inspection Agencies

D6sKD Mares @ SES.

@ wr)

DMRC

Product Range

Black Pipes - _¥"[15mm NB) to 12"(300mm NB} to various National & International Standards.

Galvanised Pipes. - _%"{15mm NB} fo 12"(300mm NB) to various National & International Standards

API (Line Pipes) - 80mm to 300mm API Pipes upto Grade X70

Hollow Sections -_Reclangular & Square from 25mm x 25mm to 250mm x 250mm, Black & GI

Poles - Swaged Tubular Poles from 410 SP 1 to 410 SP 66

Grades

‘Conforming To Stringent Specifications

a) Indian Standards

i) 18:12391 - For Ordinary Use In Water, Gas, Air Lines & Fire Fighting

ii) 15:3589 —_- Grade Fe330 & 410 For Water, Gas & Sewage Purpose

iii) 18:4270 Grade Fe 410, Steel Tubes For Water Wells (Casing Pipes)

i) 18-1161 + Grade Yst 210, 240, 310 & 355 For Structural Purpose

vw 18:3601 = Steel Tubes For Mechanical & General Engineering

vi) 15:9295 = Grade Yst 210, 240 & 310 for Idlers & Conveyors

vii] IS/SO:3183, = Grade Yst 210 & 240 For Use In Oil & Notural Gos Industries

vill) IS:2713 | ~ Swaged type steel Tubular Poles 410 SP 1 to 410 SP 72.

ix) 18:4923 | RHS & SHS, Grade Yst 210, 240, 310 & 355 For Structural Purpose

b) International Standards

1) British

i) BS:1387 _- For Ordinary Use In Water, Gos Lines Cen eee

ii) BS:1775 - for Mechanical, Structural & General Engineering

eSTiestay it

iil) BS:1189) _- Tubes For Metal Scaffolding ting unit

iv) BS:534 - For Water, Gas & Sewage ERW Pipe Mills

vy} BS:6363 —_- Structural Tubes, Round Square & Rectangular Shape panels

2) American

Eddy Current Testing

i) ASTMAS3 — - For Ordinary Use In Water, Gas & Air Lines with

Ul Certification ee

ii) ASTM A120 - For Ordinary Use In Agriculture & Air Lines

iii) ASTMA795__ - For Fire Protection Use With UI Cerification

iM ASTM A 500, ~ Structural Tubes Round, Square & Rectangular Shape

vy) APISL ~ For Oil & Gos Conveying At High Pressure Nene TH

Meee Lis

cera Us

3) European

i) EN 102241 For Use In Water, Gas & Air Flow

ii) EN 10255. For Water, Gas & Air Flow With Ce Cerification

4) Japanese cea

i) JIS G3452__- For Use In Water, Gas & Air Flow

rN TEL

Berens

Power Plant

SS a eC

Oil & Gas Transportation

General Engineering

Agriculture & Irrigation

Concealed Piping

Cold Storage

Fire Fighting System

Construction Scaffolding

Water Lines

Structural Purposes

GALVANISED & BLACK PIPES FOR’ WATER, GAS & AIR

TECHNICAL DATA OF BLACK & GALVANISED PIPES,

‘SPECIFICATION IS:1239(PART-1):2004 - DIN 2440, DIN 2441

(EQUIVALENT BS:1387:1990/EN-10255:2004*/DIN EN 10240 : 1998)

ih = = 095 1052 0.96

Medion 710 718 26 12 1.21 82% 122 820 Tolerances

Hey 210 218 3210144 674145690

20 Uh 764 769 23° «19 198 725 «199 719325 39

8) Thickness

LighTuber + + Notlimied

Modim 265 273 26 12 156 641 157 697 8%

Heay 265 279 32 10 187 535 188 532 Medium & Heavy Tubes

25° ligt «= «93.2 938 «6-26 ©«12—«1.98_ 50S 200 500 39S Ab 1 Cod

Medium 932 942 32 10 241 415 249 412 ee

Heay 399942 40 «82.93 341 2.95 09 Light Series

32 sigh 419 425-26) 122.54 394 2.57 389 49 51—(Single Tube: + 10% /- 8%

Maedim (420429 32 10 410 322 319 319 aa

Hey 420 42.9 40 & 379 264 982 262 1OTonnes Minimum: 47.5%, 5%

40 | ligt 478 484-29 11-323 310 3.27 908 | 56S

Medium 47.8 488 32 10 356 281 960 278

Heay 479 488 40-8 487 229 AAl 207

‘Medium & Heavy Series

Single Tobe: = 10%

50 Light 59.6 602 29 11 408 245 4.15 241 68° 60-—_‘ForQuaniiesperloodof

Medium 597 608 36 9 503 199 S10 196 VOTonnes Minimom: 47.5%

Heay 597 608 45 7 619 161 626 160 een

65) ight 75.2) 76.09 3.2 TO 5:74 4759/59) 117291) BA) [GPT] Nomal sem + 0.03

Medion 752 766 26 9 642 156 654 153 Rondo engh 4107 Mrs

Heoy 753766 4S 7793126 805 124 (r osspctecty Customer

% gh 879 687 92 10 67219 699 US 9B 75) HyroTet

Medium 88.0 895 40 8 836 120 853 117 Each pipe le ested for look

Heavy 88.0 89.5 4.8 6 9.90 101 10.10 96 etal

100 [le 1190" [1199/96 197975) Ten /1000 1005124997) 4) endcndion

him 131 1150. 457 1220. #21250. 60 romero

fem 1311150, 54-5 1450 491480 68 EESEED eon

125 Vadim 1305 1408 48° 6 1590 63 1640 6115195 SieceWrotNNaE

Hom 1985408 5451790 56 1840) 54 SASPIRCUSTONERSPCHICATON

150 Waden 1699 1655 48 6 1090 59 1950 51 178 95

Heavy 163.9 166.5 5.4 5 2130 47 21.90 46

“This specication confos to CE Mark conetted by Det Norse Veritas 13315:2018.CEIND.DNV

JINOALHISSAR MANUFACTURES PIPE SIZE 1 Srim NB fo 150mm NB, BOTH BLACK & Gi, BIS LICENCE NO. CM/L- 0458956

ERW STEEL TUBES FOR WATER

& SEWAGE PURPOSE

CONFORMING TO IS: 3589 : 2001

Grade Fe 330 and Fe 410/ EN 10224

OUTSIDE WALL Wweigur

(8, Silt mci ee, ams

so me 40 ae

8a

se uo

7 855

OUISDE DIETER OF 8 2075%

ovaty Mo

THceNess 10%

7

Unies cihor specified, longh

axe in Single Random longhh of 4 0 7 Mt

WEIGHT : Moss por Track Lod of 275%

10 Tons or above

PHYSICAL PROPERTIES

GRADE YS. (MIN) TS. (MIN) _%Elongaton (MIN)

Fo3s0 195 330 20

Foalo 235 410 18

Now

Thate are prslecrad OD & Thickness, her Sizes nol inckidad

‘may be suplied os per Customer Specification

JINDAL-HISSAR MANUFACTURES PIPE SIZE 150mm NB

10 300mm NB, BOTH BLACK & Gi,

BIS LICENCE No. CML - 9402267

ERW STEEL TUBES FOR

WATER WELLS CONFORMING

TO IS: 4270 : 2001

PLAIN END CASING PIPES

OUTSIDE Walt

Ne Weis

ft | POSE PaCS hey MON

too Has |S 14a 74

54 las 6

vs | ais [S 168 ey

54 181 55

71 235 4

so 1683S 201350

54 2168

71 282 35

vs | 1937 (5A 2501 4

64 296 3

8 366

200 (219, 5478465

67 36 30

8 4600

250 | 278 71 46572

8 s2a 19

Cee 15

0a] SST 8

8 3 16

0 7A 4

TOLERANCES:

‘OUTSIDE DIAMETER OF PPE 218

— Wit

ty

My

Unlas char spac anh 1; lip yl

‘an Sng Rendomangh ak 127 Mr all

“WEIGHT : Siala Taba 10% 8% vy

yy My My

PHYSICAL PROPERTIES ae

GRADE YS. {rin TS. fin) Elongation PIN) Mf

rmonufocurad of par Custer reciramant.

oinnGanies

10:300mm NB, BOTH BLACK & GI, Uy

ee YY

Slotirg of ppas con be done ae pars

STEEL TUBES FOR STRUCTURAL PURPOSES a

TECHNICAL DATA OF BLACK & GALVANISED PIPES

SPECIFICATION IS:1161: 2014

on —— 1397 on a

26 120 239 48 1597 “3

32 143 699 54 17.89 56

20 269 23 1.40 74 so 1651 45 17.82 56

26 156 eal 48 1898 53

32 1.87 525 54 21.27 a7

2 a7 26 199 503 59 23.20 as

32 241 41s 63 24.67 41

40 293 aa so 168.3 4s tate 55

22 42d 26 2.55 392 48 19.5 52

a2 2.09 324 54 21.69 4

40 379 264 6a 25.17 40

0 483 29 2.25 308 75 1987 4a 22.36 4s

32 356 281 54 25.08 40

40 437 29 59 2749 7

so | 603 29 al 249 6a 29.12 a4

a6 503 199 80 36.64 a

45 619 162 200 | 219.1 48 2537 9

6 7B 29 5.24 191 56 29.49 a4

36 6.48 155 59 31.02 2

4s 795 126 6a 33.08 20

eo | 89 32 676 ae 80 4165 24

40 838 ne 100 5157 1°

48 9.96 100 250 | 278 59 38.86 26

9 | 1016 36 870 ns 63 Aad 24

40 963 lo 80 52.28 9

48 146 7 10.0 64.86 15

yoo | 1143 36 983 102 300 | 93239 63 49.34 20

45 v9 cA 80 6232 16

54 450 a 10.0 77A\ 13

LINDALHISSAR MANUFACTURES PIPE SIZE |Srmm NB to 300mm NB, 830TH SLACK & Gl, 85 CENCE NO, CM/- 0641038

Over 48.3 mim = 41% yst-210 330

Thickness = 10% (For All Sizes) yst-240 240 410 7

Weight Single Tubes: + 10% 10 Ton los: +75 % yst-310 310 450 “

Yst-355 355 490 10

STEEL TUBES FOR MECHANICAL AND GENERAL

ENGINEERING PURPOSES

TECHNICAL DATA OF BLACK & GALVANISED PIPES SPECIFICATION 1S:3601: 2006

1s 21a 18

0.866 1155 90 1016 36 870 ns

20 0.952 1os3 40 9.63 104

26 1.20 833 50 1190 84

32 143 699 too | 1143 32 377 14

40 171 585 36 98a 102

2 269 Le Mu 901 45 122 82

20 123 813 5A 45 9

23 1.40 74 63 168 60

26 156 641 1251397 36 121 83

32 a7 535 40 laa 75

40 2.26 442 45 150 o

2s | 337 20 156 64) 50 166 60

23 178 562 5A 179 56

26 199 503 63 207 48

32 241 ais 130 165.1 45 78 56

40 293 34) 5.0 197 51

4s 3.24 309 54 212 a

2 ad 23 227 44) 63 248 0

26 255 392 1301689 40 162 a2

32 3.09 324 45 182 55

36 3.44 291 50 20.1 50

40 379 264 5.4 217 4

0 483 2a 261 383 63 252

26 293 34) 7. 20.2 35

29 3.25 308 7s 1937 48 22.36 5

a2 3 281 5.4 25.08 0

a6 397 252 59 2739 7

40 437 29 63 29.12 4

50 603 23 3.29 80 36.64 7

26 370 200 | 219.1 45 23,82 2

29 an 243 50 26.04 38

32 451 222 56 29.48 a

36 5.03 199 63 33.06 30

40 555 180 80 4165 24

4s 619 162 10.0 5157 19

6s 76 26 524 191 20 wa 50 33.00 30

29 575 174 63 41.04 24

32 6.44 155 7. 46.60 21

36 7 1 10.0 64.90 15

45 795 126 a9 56 44.00 23

50 a7 na

60 | (889 29 615 163

32 676 v4

40 ee ng

50 103 7

JINDALHISSAR MANUFACTURES PPE AS PER IS 3601 SIZE 1mm

NB to 300mm NB, BIS UCENCE NO CM/L-95985 16WI 210 WT 240 wi2I0 210 2 20

wr24o 240 10 15

wrsi0 310 08 10

ERW STEEL TUBES FOR IDLERS FOR BELT 4)

CONVEYORS

TECHNICAL DATA OF PIPES SPECIFICATION AS PER 1:9295 - 1983 DIMENSIONS & NOMINAL MASSES

paneer TMERNESS ea kfm cancer MERE Naa kom

fr) Oo) fon) ~

635 3.45 5.39 1683 450 18.20

450 655 485 19355

%. 3.65 652 5.40 21.69

450 7.95 630 25.17

889 405 ear 1937 5.40 25.10

485 100s 6.30 29.12

630 12.83 7.10 3267

1016 4.05 974 219. 5.40 22.50

4.85 1157 430 33.08

6.30 Maat 710 97.12

143 450 129

5.40 1450 TOLERANCES.

6.30 1678

1397 450 15.00 ee

485 16.13 Ovbide Diomoter 08%

5.40 17.89 vay Bolow 168.3mm OD 0.5mm

430 2073 Ovaity Above 168.3mm OD 1.0mm

es Lass 700 Thickness 10%

485 19.17

5.40 2127 mss mss

630 Bra Weight Ka/Mis Single Tube 10%

For Trek toad of 10 Tons 275%

LINDALHISSAR Manufacires Pipe Size from 63.5mm 0 219. mm OD,

Both Block & Gi Licence No, CM/L 9200109912

LiL

Ls if A

anufacturing Process

The process vilses the latest technology and modern

‘equipments for producing high Guality ERW Pipes

it Preparations

HR Colis are slited to predetermined widths for

each size of pipe and thickness. Slitted coll is

uncoiled at the entry of ERW mill and the ends are

sheared and welded one after another to make it

single endless strip.

2. Forming

Sted coil are initially formed into 'U' shape and

then into a cylindrical shape with open edges

using a series of forming rolls.

3. Welding

The open edges are heated to the required

temperature through high frequency low vollage

high current ond press welded by forge rolls

making perfect and strong buttweld without filler

materials.

4, Debeading

Weld flash on top and ins

outthrough carbide tools.

(if need) is trimmed

- Seam Annealing

Whenever required, welding portion and heat

affected zone is put to normalising with medi

frequency normaliser and then cooled down in air

cooling bed.

. Sizing & Cutting

After water quenching, slight reduction is applied

to pipes with sizing rolls to give them desired

accurate outside diameter.

Pipes are cut to required lengths by flying cut off

disc/saw cutter.

. Facing and Bevelling

The pipe ends are faced and bevelled by the end

facer.

All the processes are continuous with auto

arrangements. These plain ended tubes go for

further processing as per the customer need like

galvanizing, threading, black varnishing etc.

pes are bundled in desired number of

ieces as per customer's requirement and packed

properly to ensure freshness till delivery.

SHEAR WELDER STAMPING

ROLL UNDER

- GROUND

= LOOPER

=

LE I f i

UNIT. TESTER, |

(CUT OFF MACHINE

1 Univeral Testing Machines 100 Ton

2 [Non Desrctive Test

2. Eddy Curren Teting Machine

, Automatic Utrasonic Testing For Pipe Weld & Body

3 Hydro Tasting Mochine

4 Vickers Micro Hordes Tote

5 Digial Uraton tickets Gouge

6 Mandrls ond Fishes

7 Hydeaul Press

8 Bonding Mochine

° Impoc Tesing Machine (200)

10 Borosope

" Speco Analyar

2 Metlorgical Mirscope

13 DWT Machine

For mola esting (mechanical properties)

For onlin flow deticton on wai & HAZ.

Detection of deac in tes and welding

High Pressre Teng up 450hg/em

For hocking microhardness on weld eat alfced zone ond mail

For checking hickres& pipes.

For wading root bod io.

For laening ond weld duct txt

Fer pipe bond es.

Fer Inpect et

For nena Vial npecon

For Chamical Analyse

Micostuctre Sid of Stel

To determine hacture duct of ie Pipe

SCARFING UNIT

EJECTING TABLE. HyoROsranic

TESTER

ROP CUTTER

FACER & FLATTENING

WEIGHING MACHINE _ VARNISHING

VISUAL INSPECTION

FORMING UNIT WELDING SEAM

UNIT, ANNEALER =e

‘GAWANZING

THREADING

a PHYSICAL TESTING

[ HOGA

reste! we

WeLDNG FUME. MeRO

MARKING ROOT BEND | NING ANALYSIS.

BUNDLING:

SWAGED TYPE STEEL TUBULAR POLES AS PER IS:2713 (PART I!)-1980-410 SP-MPA

inl eal 10 2

0

us v8

6

Nika) NOK) NK N Kal NG

ea0qre6) 91243) Texe{I 1245127) 72580)

zaanig Voo}112) 1240026) 15101154 94166)

2seci6s) 1013) ses) 7e0(18) tore)

Vera{17q) 1520135) 941A) NISOHIIT) 82764)

e000) 981(10 TTe0(11) TadONI7) 74576)

23woiai} 118{120) 1330138) 16200165) 87389)

sowoiig) s4aq157) 74077) 211018) 1400145)

4058S 750 125 090 625 450 150 150 1997ABS 1149065 99.9325 103 4430172) 3280;335) 150}168) SOBA zz50;25) 4B)

059 750 125 090 625 450 150 150 1997540 1143065 99.70.25 110 SToO;2—) s620;%6% 810}185) ZO4OROB) ZA80;5%) 160065)

"

FL ih hh ml) i) tm)

1 al

{Aase1 700125 0:20 575 400 180 150 1140.65 889x025 761025 62

{A0St3 700125 030 575 400 150150 114.540 @892485 76,1025 BS

ASR 780 125 0:90 625 450 180 150 1A%265 089x025 761025 67

‘A0st5 750 125 0:20 625 450 150 150 1142450 889 AOS 76.10.25 79

AOSt7 780 125 0:30 625 450 180 150 1997450 11AR0.65 a99025, 97

4AlOSP.10 8.00 150 030 650 450 175 175 1145348 889.325 7611125 70 2240} ed{l6s) BOHB2) Foe] 14112) 52015)

{AlG5e11 8.00 150 050 650 450 175 175 11436450 889 AOS 76.1125 83 2730078] 199097) 97IFH) TORENT) 320135) 618163)

{)0SR12 800 150 020 650 450.175 175 ViA3SA0 €B99485 761x325 47 319025) 227021) 119115) 1270190) IS501ISe) 72574)

AGSPIa 800/150 00 650 450 175 175 1997450 11432465 899x225 101 4160}424 29501) 14EONSI} T67E{I7—) 202008) 1 18R{120

0814 600 150 0:90 650 450 175 175 1997485 VIAI450 9.90.25 111 a44oUsD) 9140; ISeOIL6I| 17708) 2160229 1280131)

‘MSPS 8.00 150 090 650 450 175 175 1397540 11434450 99.91825 109 49HOKOR) 47056 174771 T9E0RION) 2390) 1280(140)

{s0SR16 850 150 030 700 500175 175 ViARa6S 889x125 761225 75 2OH0;213) VAXIST) 7457S) KU|S| T02mI04 47244)

‘MOSPI7 850 150 030 7.00 500 175 175 11436450 (889 AOS 74.1K825 89 2520057 I7918—] _BBBfPl) LoleOs) /250128) | SiO)

{M018 650 150 0:20 7.00 500 175 175 11A3SA0 689x485 76.10.25 104 Z#S0;01) zI0N2I4 OSoLIO7| 11807120) 1420;I48) Sea)

‘Al0sP19 6.50 150 050 700 S00 175 175 13e7%450 114385 9991475 109 seAKa9R) 2790778) 134035) 15401157) Taco) 96119)

-AlosP20 8.50 150 090 7.00 500 175 175 I297WkAS 1142065 87.925 11S SI1041% 2910297 14sOI40) 14SE{68) 2000204) 1010{103)

‘105621 850 150 090 700 500 175 175 1397540 11436450 899x825 129 asao.sa} 2028) T6264) TelOIeS) 2210025) 1120{15)

1)0S922 £50 150 020 760 500 175 175 165x450 1997450 1149365 14) S450]55e) 367005) pRd}197) 2I8ORRA 2450: 173176)

‘Alos°23 8.50 150 030 7.00 00 175 175 14S Aas 1SP7—ASO TiA4sAS 148 sedc|oe) 150428) 2060712) 2880058) 2e4OR) Y820{84)

0824 650 150 0:90 7.00 500 175 175 \65.1a540 1997450 1049365 158 G4SOK5H) 4s80467) 2004 2579269) B140;29) 1970201)

‘05°25 9.00 150 090 750 500 200 209 T1465 '98930.25 761x925 78 I94q9m I98ONAN) GB6PC) 7757) | UTINS) 33904

1108926 900 150 030 750 500 260 200 V1A4SO GBP A405 7611225 92 24003) 16701170) aRUlES) 9416) T140{116) 4024)

0527 9.00 150 020 7.50 500 200 200 114.540 8 ABS 76.1025 108 2750) 19519 ooqta) 230084) 46147)

4105928 900 150 090 7.50 500 200 200 12974450 1143045 @99%125 119 3590065) 7540750) 400148) 1740017) 74576)

‘4105729 9.00 150 050 750 500 200 200 Ise 7AaS TiAsaAS aP9KI75 125 se20R%q} 2728277) 1350138) 1530158) TesO9N) BIA]

-Al0SP20 9.00 150 020 7.50 500 200 200 129%540 11426450 879425 199 422040 299005) 1500159) 16mC(172 2050207) 82>)

‘05°91 900 150 090 750 500 2.00 200 145.1450 T397%450 114.045 147 S07OISI7) 60067) YRODIeM| ZORORG7) 2AsORS) 1240{199)

1108992 900 150 0:20 750 500 260 200 6S IxABS 1997450 114.365 154 S4IO]5S4) BBS0:99) 9RO}197) 2INORAN|. 2eMOR6A) 143146)

‘AlosP33 9100 180 030 750 S00 200 200 14S e540 13P7WASO TIASBAS 164 so0O\2) A27ONSH) 2I3ORIN 2Al0R48) 2P1ORH 1s40{157)

|

T

|

k=

GL

ne

1

Weight: () 5% on lot basis & {} 7.5% on individual Pole

Straightness: The finished pole shall not out of skraightness by more than 1/600 af Ist length

SWAGED TYPE STEEL TUBULAR POLES AS PER IS:2713 (PART Il)-1980-410 SP-MPA

i a i se

678 8 Ca

2

13

fr) ih LI) toh ho) tomtom) ter) Kal (KS) Nh ONKGh ONG) Nal Nl

{10824 950 1.80 040 770 S00 25 225 1397450 1143450 B9.9K25 122 I6ROR7H] 25E0R26H) 128031) T4SOI4H) 1768) 7ASI7e)

410895 950 180 060 770 500 225 225 1997485 1143450 8994125 129 3850] 27407261) 1990142) 1S50N5H) 190,92) 724}C)

108P36 950 180 060 770 S00 225 225 1997540 1144450 89.91.25 137 a2e0436) 2040919) 15201155) I7I0]174) 2oeD~I2) 89)

AlOSPI7 950 180 060 770 $00 225 225 165.450 199ZASO 114.2248 152 51501525) 2660079) 1820186) 2040210) 2500255) 1200129)

0899 950.180 040 225 225 165.1685 13976480 1148.65 160 S5I0}62] 3910999 1960700) 2210125) 2480/73) 137040)

4108029 950 140 060 225 225 165.1540 13970450 114333.65 170 copo}21} 4370441) 2140170) 2430;248) 2960107) 1480151

110SP40 1009 1.80 0.60 240 240 19974880 11434480 B9.9K.25 128 SaHO;4H) 24I0;246) I2IO{123) Iasol3e) 1480]68) 056

410841 10.00 1.80 060 240 240 12970685 11434450 999%3.25 195 36201370) 25807263) 1280S!) 1450]148) 174080) 637165)

‘i0se42 1000 1.80 060 240 240 19974540, 11434450 @99%0.25 144 3690407] 7820209) TAIO{AR 14001169) I94OIF—| 716%

410SP43 10.00 1480 060 820 620 240 240 165.450 1997450 114.4245 160. 4B10H9E) 241048) 171174) 1929) 22202) 10801108)

J0SF44 1000 1.80 0.40 820 520 240 240 165.184 85 19973450 1140.65 148 5150125) 640072) T820:18) 2040210) 2sOO;55) 1120114)

{4105P45 1000 180 060 820 520 240 240 155 n5.40 1997450 11431045 178 S6POSEE| co4EUT2) 2020206) 2280792) 1200472

‘10sr46 1009 1.80 060 240 240 193 7AkS 165.10 80 1995d-80 208 72IOY39} si29s22) 2540:261) 2a80;204 tase

410847 1000 1.80 060 240 240 193745 40 165.1n4 $0 13972450 221 7910807) 56201573) 2800%286) 31701323 38401972) 199003

0849 1000 180 0.40 240 240 19374590 165.1 80 13973450 233 8620179] 61201624) 20601012) 34501352) A190}, 217025),

410sp49 1190 1480 060 270 270 19974650 11434450 @99%3.25 140 3000808) 2130;217) 10701109) 1200]12) 144045) 41214

4108950 1100 1.80 060 270 270 199 7akas 11434480 99.9%325 147 S2iOI327, aa0Rs) I\4n{16) T2aq{31} 154059) 4144

410851 11.00 1.80 060 270 270 12974540 1143x450 899%3.25 164 352060) 2510256) 12401128) T4I0;144) 1720175) OK)

05752 11.00 180 0.60 270 270 145.1450) 19974450 11430. 175 4280439) 30109907) TSIO{15@ 1700117} 2060RI0) | 72674

410SP53 11,00 1480 060 920 40 270 270 166.m4AS 1997450 114.245 182 ASSOH64) 223029) 1620165) 1820[86) 2220226) 765178)

JOSP54 11,00 180 040 920 540 270 270 145.18540 19974450 1140.65 194 SCIOTO] 257064 I78E{182) 2O10;209) 24404H| 8189)

{41QSPSS 11.00 180 060 920 540 270 270 \9A7x4RS 165 HA50 12976450 227 SI7OKSE| 453C462) 2260081) 2550760) 21001816) 1270110)

410SPS6 11.00 180 040 920 $40 270 270 I9B5AO 14S HAAS I9P7MA50 241 OPIS} 4e2OKOR) 248053) 27ORES) sAodIAN 1370(40)

{A1OSPS7 11.09 1480 060 920 $40 270 270 1947590 165 nkAS 1297040 256 7420777 S410S52) 2710276) IOSO]TT) 710978) 14705)

{4105°58 1200 200 060 1000 580 3,10 310 1651450 19974450 114.5065 266 JB60|HH) 27407261) 196041) TS5ONSH) 198092) 5991S)

410SP59 1200 200 060 1000 $80 2,10 310 165 m4AS 1997450 11435245 297 4160424) 2950901) 1480151) 1670170) 20207206) S698)

{410540 1200 200 040 1000 $80 3.10 3.10 16514540 13974450 114.245 208 4soOH4R| 227099) 1AIOT48) T24NIeH) 2240028) 57061)

410881 1200 200 060 1000 540 9,10 310 19874485 145 1450 12970450 245 582054) 4140472) 20700711) 29907208) 2290709] 951177

410P42 1200 200 060 1000 580 3.10 310 19275.40 165 AAS 12976450 259 6OPOKSA| 4S40U6H) 2270091) 2560R6I) 3119917) TorOLO3)

{410SP43 1200 200 060 1000 $80 2.10 3:10 1927590 165.mkAS 19PZM450 277 SPLOY IO) 47404) 2470252) 27OREA 2390045) 1090111

{410544 1200 200 060 1000 580 9.10 310 219 KAAS 19974AA 145.0450 292 7AVOFEM) 5920542) 266027) I000!KOH) 640971) T44OAC)

‘41QSPAS 1200 200 060 1000 580 310 310 219.540 1997485 165.150 319 859OKE71] 6OEEHTE) 20N00R a4TORAB) 4150429] 1eI0N6H

410SP46 1200 200 0.60 1000 $80 2.10 3.10 219.4590 1997AAS 146.150 229 PEO]PTA) KI7ESEO) 2190025) I5PORE) Asso HAS) 1680/65)

LINDALHISSAR MANUFACTURES POLES AS PER IS 2715 SIZE 410SP1 TO 4105.66, ICENCE NO CM/1 9908605

CIRCUMFERENTIAL WELD ‘Oukide Dioner of | length afin

Tolerances: Thickness Tolerance up to +/- 10%

Length: of any section +/- 40mm overall length of pole «/-25 mm

peers Sater ube leit tuner 2)

ao REaey a a

DIMENSIONS AND PROPERTIES OF SQUARE

SECTIONS (SHS) AS PER 1S:4923-2017

Meer fia fet) Rd of Goon fn Rado Goon ev Rad of Graton ow

20

274 2158382811751 3.85 22526262

5025-260 -3.46 2711016336 71099 08267 5.268 3.21

sO 25 320 4133.24 62 380 168 096 445304 143.73

50-25 400495 3883.19 4231430925259. 429

60 40260476 373 22-76 1209 2.19189 759 6059.96 7.07

60 402.905.2512 247413. 2.17 5882S 8581028 7.78

60 403.604.3598 28.90 15.23 2.13155 9.63762 12.169.15

60 4050747602 «33.30 1743-20811 11,10 87214321075

6 33260470369 5.15 843231 .8h 762 SMB 5.9K

6 3290 S.19, | 407 27.33 9.12229 ad ze 5.531059 a9

66 3360628498) 31.87 (1052-225 1.29 966 GAT 7.66

6633S 758 | 5.95 36.64 193-220 «125 MN. 7.28 17794

8 02.60 5.80455 «44.58 15.7328 «1.65 118A 7871463 9.01

8 02.90 6A 5.035087 17.11 «282.612.7256 16.07 8.88

8 403.207.0150 54.94 18.4) 2.80 1.621374 9.21 17.46 10.72

8040-40055 71479 «2149-275 159 16.20 10742091127

9 48 = 3.20854 6719861 93.28 © 3401.97 1387 25.85 15.91

9 | 48 © 4001047822, 11754 99.82 -3.35 1942449 16.90 4.21 19.14

36 484.80 9.66 4455 3.30 1.90 2799 18.56 46,13 22.08

100 50 320 8937.01 9795 355-206-2246 15.18 2820 17.97

loo 50340995 7.81 4156 352 204 24701663 91.20 ‘19.19

Too 504501217955 4887 3.47 200 29.32*19.55 37.55 23.00

Too 505.40 14.28 11.21 5509 342 196 33,36 -2204 «43.34 26.43.

120 | 60 320 108s ast 6794 429-250-3331 22.65 41.50 25.63,

120 603601211 —-9.50 7h76 427 248 3679 24.92 46,06 28.40

120 60 | 450 1487 11.67 eea7 422 24d 4408 29.62 55.82 24.90

26 34012 9.67 434 2.35 98.13 25.84 47.71 29.42

1220 61450 15.14 11.88 429° 249 4572-3075 $7.85 35.56

26 5.40 1401 424 5260 35.09 67.29 41.22

M5 824.80 2028 15.92 5.23, 7657 5573 9493 63.93,

us 825402260 17.74 520 3 2426 6112 70.66

7292-480 23831870 620 382 10664 75.41 85.61

72 26.59 101247 61737911773 82.99 94.86

200 2.95 1199.64 723 42411996 82.15 91.70

200 28.36 1459.16 71741914592 9.98 2.09

200 39.43 1703.17 7.12 414 17032-11538 213.25 131.49

41 with a minimum of 5mm

210%

Individual Lngih + 10%, 8%

(On bt of 10 tonnes = 7.5%

Squore ze

Rodi of Comer: Outside 43 Max. Wher is the thickness of he eecton

8 of Comer 90"

ysi210 330 210 2 20

ysi240 10 240 10 15

ys1310 450 310 8 10

‘ys 955 490) 355 8 10

ra

25

25

32

2

2

22

38

38

38

38

40

40

40

40

495

295

495

495

6

60

60

60

60

72

n

20

80

80

os

%

25

25

2

2

2

2

38

38

38

38

40

40

40

4

495

495

495

95

Sssgsasssss

ois

915

os

a

28

32

20

26

32

40

20

26

32

40

26

29)

32

40

26

29

32

40

26

29

32

40

45

32

40

48

a2

40

49

36

45

5a

40

50

60

4s

48

5A

$0

48

54

60

49

50

60

70

80

40

50

60

70

1a

174

216

253

23

2.88

342

407

278

351

419

5.03

372

409

445

5.35

470

519

5.65

687

5.80

6ai

112

136

1.69

198

1.80

226

269

319)

218

275

3.29

3.95

292

321

349

420

3.69

407

446

539

455

5.03

550

67)

743

671

322

9.66

751

1.28

148

172

1.89

3.36

402

454

5.02

5.88

7.3

318

9.26

8.45

an

972

Nor

1.91

1837

1974

22.94

31.33

3421

96.94

4355

47.20

66.32

79.02

90.30

271

11.04

12951

156.48

187.56

215.66

226.34

271.08

3114s

972.86

398.28

48255

499.78

63436

700.07

76293

80778

982.07

1145.84

1299.36

1442.89

2639.06

3237.9

3813.19

4365.39

0.94

092,

0.89

0.86

121

18

1s

um

1s

1a

1.40

136

151

149

148

1d

1.90

1

187

Las

239

2ai

20

2.26

223

279

275

27

an

3.07

3.03

3.56

3.52

3.48

3.89

aed

379

Ade

440

438

435

516

5.13

5.10

593

5.89

5.84

579

574

379

874

7

865,

i

1.38

151

2.10

251

2.83

ala

3.10

376

430

487

42

456

486

554

6.83

742

797

927

lose

M40

1231

1452

1573

1842

2195

25.08

23.18

y76

32.38

34.20

41,00

4744

45.27

5422

6229

45.70

69.30

76.22

82.78

96.11

106.07

115.40

107,70

130.94

152.78

173.25

192.39

239.91

294.35

346.65

396.85

a

176

198

254

an

359

4

370

457

534

622

5.12

558

6.00

701

816

893

967

1146

1294

13.56

1473

17.64

19.31

21.80

2632

30.48

2729

3207

39.09

40.24

4879

5676

53.30 :

6459

75.09

7732

81a)

90.54

98.95

11268

125.01

136.97

124.86

152.97

179.87

205.57

730.09

275.46

309.72

402.16

462.81

Technical Data Sheet- Pipe to API 5L 46th Edition / IS/ISO:3183-2019

(ut Side Diameter Telronce Body —_‘Specied OD. + 0.00750 (0.75%),

nd From 88.9 mm OD fo 166.3 mm OD Speciiod OD +).60 mm, -0.40 mm

From 219.1 mn OD mmo 323.9 mm OD Speciiod OD 10,0050 {+0.5%)

Thickness Toleronces thicknoss «5.00 men $0.5 mm

thickness 25.00 mm to 15 mm 10%

Weigh Tolronces ‘Speciol PE pipes (Single Tobe] +10%, -5%

For other pipes (Single Tbe) +10% 3.5%

oto 20 Ton 175%

PHYSICAL PROPERTIES

La10/A 210 335

245 /8 2s as 2a 450, as 455

\a90pKaa 290 415 290 195 ais 655

ts20/46 320 435 320 525 435 655

\s60/K52 360 480 360 530 480 760 As per Table 6 (<) 47)

\s90/%56 390 490 390 545 490 760 ARTS.

u1s/x60 as 520 41s 565 520 760

uso/n6s 450 535 450 600 535 760

4s5/x70 485 570 485 635 570 760

Chemical Properties

WIo/A 022 0.90 0.03 003

1245/8 0.26 120 0.03 0.03 022 1.20 0025 0015 045

1290/x2 026 130 0.03 003 022 1.30 0025 0015 045

1320/x46 0.26 1.40 0.03 003 Now <0.06% 0.22 1.30 0.025 0015 0.45 ‘As per Table 5 footnotes

1260/X52 0.26 1.40 0.03 003 NbiVeh <0.15% 0.22 1.40 0.025 0015 O45 4,6, 9, hand lof A215

L390 /x56 0.26 1.40 0.03 003 APSE 022 1.40 0025 0015 045

LAI5/X60 026 1.40 0.03 0.03 0.12 1.60 0025 0015 04s

LUSO/K65 026 1.45 0.03 003 0.12 1.60 0025 0015 04s

Uuss/X70 026 1.65 0.03 0.03 0.12 170 0025 0015 04s

LINDALHISSAR MANUFACTURES PPE AS PER API SL SIZE 8Omm NB lo 300m NB, APLSLLICENCE NO, $L1163

JINDALHISSAR MANUFACTURES PIPE AS PER 15/ISO 3189 SIZE 80mm NB to 300mm NB, 15/ISO 3183 LICENCE NO CM/L 9586509

i 1)

Technical Data Sheet- Pipe to API 5L 46th Edition / IS/ISO:3183-2019

El

nn Be

Bl ewatecue ele bales]

869 440 1272 1484 1757 1939 2181 2343 2514 2726 2938 1483 870 1329 1850 2294 253.1 2847 3085 5282 3559 3006

089 490 TaR@ 1419 1917 2115 2979 2577 2749 2974 3205 1489. 950 145.1 149. 7505 776A 109 9960 9504 3686 4189

B89 640 Tas0 2159 2555 2820 3172 497 2657 2965 407.4 219.1 480 $63. 457 972 1073 1207 1907 1991 1508 1626

889 710 2059 2195 2695 3128 3519 9812 4057 4999 474) 219.1 $20 610 712 1053 162 1907 1416 1507 1604 1761

889 760 7197 2564 2035 3348 3767 4001 4349 A709 S075 219.1 540 457 766 1194 1251 1408 1525 1629 1740 1697

1143 (440 989 1154 1266 1508 1676 1898 1955 2120 2285 219.1 700 82.1 958 T4I8 T5KA 1760 1906 2029 2200 247.1

1143 |'$20 1169 1264 1615 1782 2005 2172 2911 2506 2701 219.1 820 962 1122 46: 1602 2061 2233 2976 2577 2777

1143 $60 1259 1469 1729 1919 2159 2339 2489 2699 2908 219.1 70 1021 119. 1762 1944 2187 2969 2521 2724 2947

1149600 1949 1574 166.3 7056 2313 2506 2666 2691 3116 219.1 950 1115 1900 924 7129 7998 2507 7753 2985 3217

114370 1897 1863 2205 2493 2797 2965 15S 4421 2688 721-400 452 527 BBA 975 I0R7 1189 1265 1971 7A

1143 790 1777 2073 2453 2707 3046 9299 951.1 2607 4103 272.1 $20 489 57.1 $57 1057 189 1288 1970 1486 1601

1143860 1954 7256 267.1 2947 3915 3592 3627 AAA G7 731/540 527 615 TORT TIDB 1290 1387 1476 1600 1724

41a 480 673 1019 1206 199.1 1497 1622 1726 187.1 2017 79) -7.10 4B 780 1907 1449 1423 1758 167.1 2029 2186

41a 660 120.1 140.1 1658 1830 2058 2230 2973 2679 2779 7B) 87D B19 955 1402 1768 I989 215A 2292 2486 2679

41a 7.10 1292 1507 1784 1968 2214 2999 2552 2768 2989 272.1 9:90 7S 1021 1712 18RD 2126 2203 245.1 2657 206A

14ia 790 497 1677 1985 2190 246A 2659 2640 9079 3519 3989 (44d 949 M07 689 754 B48 919 978 1060 1142

41a 980 1728 2014 2086 2603 2963 9209 2415 709 99.1 «2289 20 41a 4B 807 BPI 1002 1086 1155 1253 1350

1463 400 6 055 N64 1209 1418 150 1696 1764 9299 540 MAA 518 869 $59 1079 1169 124A 1949 1454

1683 460 723 855 1265 1996 187.1 1702 1611 1964 2116 9239 7.10 $63 657 102 121.6 1968 1482 1977 1710 1043

W483 520 79k 927 1971 1513 1702 1844 1962 2127 2099 BBY 790 627 73.1 1224 1953 1523 1649 1755 1909 2051

1682 640/977 1140 1687 1662 2005 2269 2415 2618 2802 2029 870 670 80S 1361 490 1677 1816 1933 2006 259

Waa 710 1OR4 1245 1479 7045 2194 2517 2679 2905 1120 2229 950 754 860 47S 1627 1891 1983 211.1 2289 2467

Technical Specification of Pipes conforming to aaa A53 Grade A&B

213 © 277 rr pe sie plo od Inldng BNO 20 dn

287 * 2 169 a as Mge sue ON 3D bg 1%

1 25 ma 0 398250 4 46 Be)

1 2 22 ” a6 aa? a3 °

2 0 3 © a9) sae 159 wa Caen

2 6s 730 0 516 843 v2 v2 (os por ASTM 8-90)

2 0 89 © sai) as v2 Ka er

4 wo) a3 © 602) 1607) aa 152 Mao Zine coatg og

5 ws la ra 55 2177S 14 ‘50 g/m2 79 pops}

‘ 1501683 Pi 7% 05 23

0 20 7a » 35417558 68 ‘Mechanical Properties

10 20 “0 927 7b 99 vemesinth Soe

2 300) mag) 20 635971 as 7 Bs el

m1 a Bo) oe a long Min. As par ASTAASS

2 mag © on 797 79 92

Chemical Properties ( Max %)

‘—Srnie_||_e_|_twe_]|_ru_|_s_][_evu_|_no_|_eva_[_was_|_ve_

2 030 1300s mess oe ou 01s 008

INDALHISSAR MANUFACTURES APE AS PE ASTM ASS S

14" fe 12", BOTH BIACK & Gl, UL USTEDICENCE NO. 3PPPA

Technical alse of el ves erie cuterring teva to BS EN Eee

Zid 218 210 218 210 26 121 122 217 7.0 23 198 109 217 210 10? 214 210 20-0947 0956

37/1 42/393 40 299 295 342 999 22 241 249/240 303 29 220 277 40 992 29 270 272 998992 26 198 200

489 Wh 498 W79 40 437 44\ 488 47932 356 940 496 478 29 975 979 M86 W78 29 324 379 4B4 478 29 929927

603 2 G8 597 45 619 626 608 S97 26 509 5.10 607 S06 32 451 458 607 $96 22 447 456 602 596 29 408 415

751 2% 764 753 45 793 G05 756 753 36 642 654 740 752 42 575 587 753 752 32 573 585 760752 92 571 583

889 2 695 820 50 102 105 875 M80 40 026 59 487 O79 12 676 69 EPA B79 26 755 772 B7 O79 22 472 689

143-4 11501121 $4 145 148 11501191 45 122 125 11991190 26 969 101 11491130 40 108 111 11991190 36 975 100)

1997S M0B1985 $4 179 Te4 08 1985 $0 166 17) 4081985 45 150 155

1451 6 16651699 54 213 719 16551609 50 198 204 16651699 45 178 184

Tolerances ‘Chemical Properties ‘Mechanical Properties Galvanizing Test

(Moxie) Yel ress 195 N/mm Win}

(0D As pr above ble 1. Zine eating 255 in

Coben = 020% ee ‘dpe et pl 603 mm 0)

Telos Margorese = 140% 20 8iMin} ‘ ™e

TOR ocr Masai] Fhtphors : 00K or tpt incdig 603 mn OO

‘eB (fori BL2 Ser phar = 030% ee

Bending

Bending rods: 30

Flonening Test:

1 ate plo 75% of OD fr wel et wel

ot 2t3 Ook,

2 an plo 6% of OD for row ma

Weigh

SOA MBSAE AACA SPA C2SSRERUE SHOR ACCA 3)520)6cLNOEN!

Our Esteemed Customers

BAS © EZ

‘METRO IndianOil

fi repro Ye ,DLFéas oA. 9 Oil India Limited ETSI

aa

Q

@® Oo ~J JINDAL SAW LTD. —ISSL_

snpa. TOTAL PIPE SOLUTIONS

©

v

a OA

o Bharat Coking Coal Lid ¥

We vouras LimrreD

i

19

Seas STERLING & WILSON. a |OMAXE|

Sean LINZ Turning dreams into reality

Yau icrar

oy JJM (HP)

aM (MP)

JJM. 8K)

Our Marketing Network

Haryana

307, 3rd Floor, MGF Metropolis Mall,

Near MG Road Metro Station, Gurvgram - 122001

up.

102, PIE 7th Miles, Gini Border,

PO. Chikamberpur, (Ghaziabod) U.P.

Ph: +91-120-4134289. M:9810162296

Punjab

Vill. Kumbh, Amloh Road, Mandi Gobindgarh (P8.)

Ph: +91-1765:242908, 242907. M9256301486

Telangana

43-104-108/17/203, 2nd Floor, Anjaish Complex,

Hil Sreet, Ranigunj, Secundrabad ~ 500003, Telangona

8008249707

Kernataka

164, Ist Floor, dth Cross Road, KS. Garden,

Lal Bagh Road, Bangalore - 560027

Ph: 080.41554473, M8050072302

Tamil Nadu

334, Poonamallee farms, color homes,

Soprenchri village, Patiabiram, Chennai 600072

Mob. 7496952374

Chandigarh

SCO 827, Top Floor, NAC Kelka Read,

Manimajra, Chandigarh

Ph: 01723938570, M9876871980

Rajasthan

Office No. F1, Shop No. 11 & 12, First Floor,

Exin, Sharma Colony, Swei Form, Nandpur Road,

Sodala, Jaipur'302019 (Rajasthan)

Mob. 9261620007

Maharashtra

1148, Vardhman Chambers, Near HDFC Bank,

Sec-17, Vashi, Navi Mumba-400705

M- 9920887727

TRADE,

You might also like

- Treatment Technologies: Presented byDocument32 pagesTreatment Technologies: Presented bySunghava UpadhayaNo ratings yet

- Unplasticized PVC Pipes For Water Supplies - Specification: Indian StandardDocument34 pagesUnplasticized PVC Pipes For Water Supplies - Specification: Indian Standardarchana100% (1)

- Rubber Seal DimensionDocument1 pageRubber Seal DimensionLalitMohanSenapatiNo ratings yet

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyNo ratings yet

- Is 4984 2016Document24 pagesIs 4984 2016LalitMohanSenapatiNo ratings yet

- Is 4984 2016Document24 pagesIs 4984 2016LalitMohanSenapatiNo ratings yet

- Rubber Seal Dimension PDFDocument1 pageRubber Seal Dimension PDFLalitMohanSenapatiNo ratings yet

- 50 - Draft Final EIA and EMP Pahari Sewerage and STP PDFDocument100 pages50 - Draft Final EIA and EMP Pahari Sewerage and STP PDFLalitMohanSenapatiNo ratings yet

- MBBR C0661521 PDFDocument7 pagesMBBR C0661521 PDFLalitMohanSenapatiNo ratings yet

- Cured-In-Place Pipe (CIPP)Document3 pagesCured-In-Place Pipe (CIPP)LalitMohanSenapatiNo ratings yet

- TGM - Comman Municipal Sold Waste Management - 160910 - NK PDFDocument232 pagesTGM - Comman Municipal Sold Waste Management - 160910 - NK PDFLalitMohanSenapatiNo ratings yet

- Water Supply Hand BookDocument102 pagesWater Supply Hand Booksrekha11100% (8)

- Is 5312 1 2004Document13 pagesIs 5312 1 2004kprasad_56900No ratings yet

- 50 - Draft Final EIA and EMP Pahari Sewerage and STP PDFDocument100 pages50 - Draft Final EIA and EMP Pahari Sewerage and STP PDFLalitMohanSenapatiNo ratings yet

- Handbook On Sewage and Swerage Treatment PlantsDocument45 pagesHandbook On Sewage and Swerage Treatment PlantsFredy MasukaNo ratings yet

- SWM & SanitationDocument24 pagesSWM & Sanitationchannel_partners5979No ratings yet

- Toolkit of SWM - JnnurmDocument49 pagesToolkit of SWM - JnnurmVishal DuggalNo ratings yet

- SP6-Steel Hand BookDocument209 pagesSP6-Steel Hand BookAmit87% (15)

- Ar-2006 (6 3 07)Document271 pagesAr-2006 (6 3 07)gsr_svsNo ratings yet

- M7L7 PDFDocument8 pagesM7L7 PDFRANJINI02VNo ratings yet

- 2.5 Technical Specifications For Hydro Mechanical WorksDocument62 pages2.5 Technical Specifications For Hydro Mechanical WorksAbhishek PandeyNo ratings yet

- Volume 2 Building Works Ss R 2012Document262 pagesVolume 2 Building Works Ss R 2012bbaplNo ratings yet

- 54 CE Bodhi 2015 PDFDocument165 pages54 CE Bodhi 2015 PDFSpectrumNo ratings yet

- Laying of DWC PipesDocument56 pagesLaying of DWC Pipessatyam50% (2)

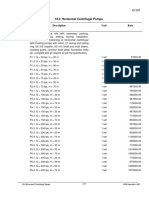

- 18.0 Horizontal Centrifugal Pumps: Code No Description Unit RateDocument1 page18.0 Horizontal Centrifugal Pumps: Code No Description Unit RateLalitMohanSenapatiNo ratings yet

- DECAST CPP Installation Manual 2016.02.10 PDFDocument60 pagesDECAST CPP Installation Manual 2016.02.10 PDFLalitMohanSenapatiNo ratings yet

- Code No Description Unit Rate RS.: Basic Rates 0.1 LabourDocument24 pagesCode No Description Unit Rate RS.: Basic Rates 0.1 LabourLalitMohanSenapatiNo ratings yet

- Is 784 2001Document39 pagesIs 784 2001Parul MathurNo ratings yet

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)