Professional Documents

Culture Documents

07 - Properties of Synthetic Lightweight Aggregates For Use in Pavement Systems

07 - Properties of Synthetic Lightweight Aggregates For Use in Pavement Systems

Uploaded by

TRAN Viet CuongOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

07 - Properties of Synthetic Lightweight Aggregates For Use in Pavement Systems

07 - Properties of Synthetic Lightweight Aggregates For Use in Pavement Systems

Uploaded by

TRAN Viet CuongCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/268590566

Properties of Synthetic Lightweight Aggregates for use in Pavement Systems

Conference Paper in Geotechnical Special Publication · October 2005

DOI: 10.1061/40776(155)9

CITATIONS READS

10 424

2 authors:

Christopher W. Swan Aaron Sacks

Tufts University Manav Rachna College Of Engineering

126 PUBLICATIONS 872 CITATIONS 6 PUBLICATIONS 14 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

NSF Innovation Corps for Learning (I-Corps L) View project

Efficacy of Macroethics Education in Engineering View project

All content following this page was uploaded by Christopher W. Swan on 16 July 2019.

The user has requested enhancement of the downloaded file.

GSP 130 Advances in Pavement Engineering

Properties of Synthetic Lightweight Aggregates for use in Pavement Systems

Christopher Swan1 and Aaron Sacks2

1

Associate Professor, Dept. of Civil & Env. Eng., Tufts Univ., Medford, MA 02155,

Downloaded from ascelibrary.org by TUFTS UNIVERSITY on 10/20/14. Copyright ASCE. For personal use only; all rights reserved.

chris.swan@tufts.edu

2

Undergraduate, Dept. of Civil and Env. Eng. Tufts Univ., Medford, MA 02155,

aaron.sacks@tufts.edu

ABSTRACT

This paper presents properties of new synthetic lightweight aggregates (SLAs), made

of plastic and fly ash, and their implications for use as aggregate in pavements

systems. These aggregates are manufactured through a thermal process that combines

and co-extrudes plastic and coal fly ash. The plastic acts as a matrix material that

binds and encapsulates the fly ash particulates. In this study, index and compression

properties are presented for SLAs made with different plastic types. All aggregates

have an approximate fly ash to plastic ratio, by weight, of 80:20 and use fly ash with

carbon contents of 15% to 30%. Index properties presented for the various SLAs

include gradation, specific gravity, and water absorption capacity. A series of one-

dimensional compression tests, at moderate and elevated stresses, were performed to

compare the compression behavior of SLAs with that of traditional aggregate (sand).

The results shows that SLAs have relatively substantial elastic deformation and rates

of secondary compression but also exhibit substantial rebound upon unloading when

compared to sand. However, at elevated stresses, the rate of secondary compression

for both the SLAs and sand approach similar values, with some SLAs actually

exhibiting a slower rate of secondary compression. Overall, the compression results

show that SLAs will have advantages (e.g., lightweight, stress absorption) and

disadvantages (e.g., excessive deformation) over the use of traditional granular

materials in pavement systems.

1. INTRODUCTION

In the past few decades interest in sustainable development has prompted the

design of products that are made from recycled materials and can be recycled at the

end of their usable lives, as well as processes that do not deplete non-renewable

resources. Agencies such as the U.S. Environmental Protection Agency (EPA) and

state departments of environmental protection have enacted regulations requiring the

recycling of many types of waste and restricting the amounts of waste that can be

disposed in landfills (USEPA, 2002).

The increasing rate of waste output, combined with increasing fees for

disposal of that waste, has prompted research on ways to reuse common waste

materials in other applications. Of particular concern to civil engineers has been the

potential for the use of recycled materials in highway construction. Recycled asphalt

Copyright ASCE 2005 Advances in Pavement Engineering

Advances in Pavement Engineering

GSP 130 Advances in Pavement Engineering

concrete, Portland cement concrete, coal combustion fly ash, scrap tires, plastic,

glass, compost, blast furnace and steel slag, and other materials have been used in

highway construction with varying levels of success (Shelburne and DeGroot, 1998).

Research on an innovative aggregates made from recycled waste has been an

ongoing effort at Tufts University and the University of Massachusetts at Lowell

since 1995. Synthetic lightweight aggregates, or SLAs, are made from recycled

plastics and fly ash, two high volume components of the U.S. waste stream. The

studies to date have evaluated a number of structural and geotechnical properties of

Downloaded from ascelibrary.org by TUFTS UNIVERSITY on 10/20/14. Copyright ASCE. For personal use only; all rights reserved.

SLAs as well as many potential applications for their use in the construction industry.

1.1 Objective and Scope

The objective of this paper is to evaluate the deformation and creep behavior

of SLAs under one-dimensional compression at moderate and elevated stresses, and

to compare their behavior to that of a traditional aggregate (sand) and to the behavior

predicted by theoretical models. One-dimensional compression tests were performed

on four types of SLAs and a granitic sand using a computer-controlled testing

equipment. Index properties, including gradation, specific gravity, and water

absorption are also presented. All of the SLAs tested had an approximate fly ash to

plastic ratio of 80:20 by weight and used fly ash with carbon contents of 15% to 30%.

The following presents an overview of the raw materials used in, and the

development and manufacturing of, SLAs. The paper then presents the testing

program and results of the present study. A discussion of these results and their

relevance to pavement systems concludes the paper.

2 Recycled Materials Used in the Manufacture of SLAs

2.1 Plastics

Plastics make up a rapidly growing portion of the United States municipal

solid waste stream (MSW). In 2000, 10.7% of the US MSW was plastics, up from

0.4% in 1960. However, only 5.7% of discarded plastics were recovered (USEPA,

2002). Part of the reason for the low recovery rate of plastics is the wide range of

forms in which it occurs. Plastics recycling is also difficult because different types of

plastic cannot be mixed without compromising the quality of the recycled product.

Thermoplastics were used in the development of SLAs. The strength,

stiffness, and hardness of thermoplastics are very sensitive to temperature and

typically decrease as temperature increases. Thermoplastics are also susceptible to

creep, or strain under constant stress, due to slippage of the molecules within the

polymer (Kiggins, 2001). SLAs used in this study utilized either polystyrene (PS),

low density polyethylene (LDPE), high density polyethylene (HDPE), or a mixture of

varios plastics (MP) as outlined in Table 1. A summary of physical and mechanical

properties of PS, LDPE, and HDPE is given in Table 2.

Copyright ASCE 2005 Advances in Pavement Engineering

Advances in Pavement Engineering

GSP 130 Advances in Pavement Engineering

Table 1: Polymer Composition of Mixed Plastics (Weingram 2003)

Polymer Resin Mass Concentration, %

PET [Polyethylene Terephthalate] (Recycled bottle 30

grade)

HDPE (Recycled blow molding grade) 30

HDPE (Injection molding grade) 5

LDPE (Extrusion grade) 10

PP [Polypropylene] (Injection molding grade) 10

Downloaded from ascelibrary.org by TUFTS UNIVERSITY on 10/20/14. Copyright ASCE. For personal use only; all rights reserved.

PS (Injection molding grade) 5

HIPS [High-Impact Polystyrene] (Injection molding 10

grade)

Table 2: Properties of Plastics Used (Kiggins 2001 and Weingram 2003)

Plastic Type

Property

PS HDPE LDPE

Tensile Yield Stress (MPa) 36-52 22-31 8.3-31

Tensile Modulus (MPa) 2280-3280 1070-1090 172-283

Elongation (%) 1.2-2.5 10-1200 100-650

Flexural Modulus (MPa) 3160 770 140

Flexural Strength (MPa) 69-101 2 7

Crystalline Melting

* 128-135 102-112

Temperature (°C)

* = amorphous crystal structure (does not undergo crystalline melting)

2.2 Fly Ash

Fly ash is a by-product of thermal processes. It is formed by the solidification

of molten minerals in the gases exiting through the flue of a combustion chamber. Fly

ash particles are collected by various air pollution control techniques, such as

electrostatic precipitation, and subsequently disposed of or recycled. The vast

majority of fly ash is produced from coal combustion for electricity. More than half

of the electric power utilized in the United States is generated by coal combustion

resulting in 62 million metric tons (Mt) of fly ash in 2001 (Kalyoncu, 2001).

About one quarter of the fly ash produced in the United States is reused as an

admixture in Portland cement concrete or for flowable fill, filler in asphalt mixes,

road base material, or in waste stabilization (Holmstrom and Swan, 2001). The

remainder of the fly ash waste stream is disposed in landfills or wet impoundments.

The fly ash used in this study was obtained from a coal combustion facility in

New England. The fly ash was the resulting waste product from a beneficiation

process that separates low carbon (<6% by weight) from high carbon ash. The typical

carbon content of the fly ash ranged from 15 to 30%.

Copyright ASCE 2005 Advances in Pavement Engineering

Advances in Pavement Engineering

GSP 130 Advances in Pavement Engineering

3 Synthetic Lightweight Aggregates

3.1 Manufacturing Process

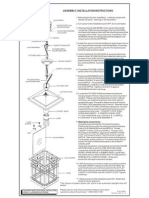

The synthetic lightweight aggregates used in this study were created by

combining fly ash and plastics though a melt blending process. The compounding

was performed at the University of Massachusetts at Lowell using a 30 mm diameter,

co-rotating intermeshing twin screw extruder (Werner Pfleiderer, Ramsey, NJ model

Downloaded from ascelibrary.org by TUFTS UNIVERSITY on 10/20/14. Copyright ASCE. For personal use only; all rights reserved.

ZSK30) at mixing temperatures between 200 and 230 °C. A schematic of the

manufacturing process is shown in Figure 1. During the mixing process, plastic

polymers are fed into the primary auger feeder and fly ash is added through a

downstream feeder to obtain the desired fly ash to plastic ratio. The mixing product is

extruded through a 6mm by 16 mm rectangular opening to form a continuous strand

that is quenched in a water bath to cool and solidify. The solid extrudate is then

granulated in a rotating knife granulator. Figure 2 shows the extrudate before and

after granulation.

SLA particles consist of fly ash bound in a plastic matrix. The particles are

dark-gray to black in color and range in texture from firm to noticeably deformable,

depending on the type of plastic used. All of the SLAs tested had fly ash to plastic

ratios of 80:20 by weight.

Downstream Fly

Thermoplastics Ash Additive Thick

Feeder Solid

Profile

Die Granulator

Cooling

Tank

Extruder

Synthetic

Lightweight

Aggregate

Figure 1 Schematic of SLA Manufacturing Process (Kashi et al 2000)

Copyright ASCE 2005 Advances in Pavement Engineering

Advances in Pavement Engineering

GSP 130 Advances in Pavement Engineering

Downloaded from ascelibrary.org by TUFTS UNIVERSITY on 10/20/14. Copyright ASCE. For personal use only; all rights reserved.

Figure 2 Extrudates before and after granulation

(from Malloy et al. 2001)

4 TESTING PROGRAM

The major component of the testing program consisted of 15 one-dimensional

compression tests on four types of SLA and a granitic sand (three tests on each

material). The materials were sieved through a U.S. Standard No. 8 sieve (2.36 mm

opening diameter) and a No. 16 sieve (1.18 mm opening diameter) with particles

passing the No. 8 yet retained on the #16 sieve used in testing. In addition, index

properties of specific gravity and water absorption were determined for each material

in general accordance with ASTM Standard specifications D 854 and C128,

respectively.

4.1 One-Dimensional Testing Procedure

Specimens were tested in a brass compression ring having an outside diameter

of 88 mm, an insider diameter of 63 mm and a height of 25 mm. A film of vacuum

grease was applied to the interior surface of the ring prior to each test and the ring

was placed on a stainless steel base plate. Test specimens were developed using an air

pluviation process where the granular material is “rained” through a series of screens

and comes to rest inside the ring. Filter paper was then placed on the develop

specimen and a circular loading plate (cap) was then placed on the specimen. The

side of the brass ring was tapped with a metal bar until the loading cap reached a level

indicating a specimen height of 19.1 mm, giving an initial specimen volume of 59.4

cm3. The base plate, brass ring, and cap are shown in Figure 3.

Copyright ASCE 2005 Advances in Pavement Engineering

Advances in Pavement Engineering

GSP 130 Advances in Pavement Engineering

Downloaded from ascelibrary.org by TUFTS UNIVERSITY on 10/20/14. Copyright ASCE. For personal use only; all rights reserved.

Figure 3 Compression Test Components (2.5-inch diameter ring)

Each material was developed so as to be initially “loose” such that it was

possible to easily attain the desired specimen volume by tapping the sides of the brass

ring. Table 3 lists the average specimen mass and corresponding average initial

porosity (no) developed for each material tested.

Table 3 Specimen Masses and Initial Porosities

Specimen Type Mass (g) Initial Porosity, no

Sand 88.18 0.45

SLA with PS 42.76 0.57

SLA with LDPE 33.26 0.63

SLA with HDPE 34.21 0.63

SLA with MP 39.55 0.58

The specimens were tested in a LoadTrac II loading device developed by

GeoComp Corporation (Boxborough, MA). The device was capable of applying and

holding specific piston loads according to a pre-programmed loading schedule while

continuously measuring specimen strain. Each test was programmed to run for a total

of 50 hours, including loading and unloading stages with piston loads of up to 4000

kg, according to the schedule presented in Table 4.

Table 4 Incremental Specimen Loading and Unloading Schedule

Increment Applied Stress Step Final Stress

Number (kPa) Maintained for

(hours)

1 0 to 1240 24

2 1240 to 12380 24

3 12380 to 1240 2

Copyright ASCE 2005 Advances in Pavement Engineering

Advances in Pavement Engineering

GSP 130 Advances in Pavement Engineering

5 TEST RESULTS

5.1 Index Properties

For purposes of testing consistency, the SLAs and sand used in this study

were constrained to a near-uniform particle size with all particles tested passed a #8

(2.36 mm opening diameter) sieve but were retained on a #16 (1.18 mm opening

diameter) sieve. Specific gravity and water absorption capacity for the aggregates are

Downloaded from ascelibrary.org by TUFTS UNIVERSITY on 10/20/14. Copyright ASCE. For personal use only; all rights reserved.

provided in Table 5 and show that the SLAs would have lower densities than the

sand. However, the SLAs would absorb more water than the sand but the amount of

water absorbed wouild still be insignificant to their overall weight.

Table 5 Index Properties of SLAs and Sand Tested (from Gaudreau, 2002)

Plastic Type Used Specific Gravity Water Absorption Capacity

ASTM D 854 (%) ASTM C128

PS 1.68 3.48

LDPE 1.53 8.14

HDPE 1.56 3.46

MP 1.60 7.49

Sand 2.7 1.60

5.2 One-Dimensional Compression

Figure 5 displays normalized porosity (n/no) versus effective stress where

normalized porosity represents the material’s instantaneous porosity during testing

divided by the material’s initial porosity at setup. Figures 6 and 7 show the secondary

consolidation, or creep, occurring at the 1240 kPa and 12380 kPa load increments,

respectively. Table 6 presents a summary of the secondary consolidation rates

calculated for each material at each load increment.

In the following figures, SLAs are identified by the type of plastic they

contain. For example, “HDPE” denotes a specimen of SLA containing HDPE.

Table 6 Secondary Consolidation Rates C for Specified Materials

Material C under 1240 kPa Load C under 12380 kPa

Load

Sand 0.002 0.087

SLA with PS 0.082 0.104

SLA with LDPE 0.163 0.097

SLA with HDPE 0.223 0.172

SLA with MP 0.208 0.136

Copyright ASCE 2005 Advances in Pavement Engineering

Advances in Pavement Engineering

GSP 130 Advances in Pavement Engineering

1

Sand

0.9 Sand (Unload)

PS

0.8

PS (Unload)

Normalized Porosity n/n 0

0.7 MP

0.6 MP (Unload)

Downloaded from ascelibrary.org by TUFTS UNIVERSITY on 10/20/14. Copyright ASCE. For personal use only; all rights reserved.

HDPE

0.5

HDPE (Unload)

0.4 LDPE

0.3 LDPE (Unload)

0.2

0.1

0

10 100 1000 10000 100000

Stress (kPa)

Figure 5 Normalized porosity versus log effective stress for specified materials

average of three tests per material

*Note: Displacements normalized so that 0 mm displacement occurs at beginning of secondary consolidation.

0.00

Sand

PS

0.10 LDPE

MP

0.20 HDPE

Displacement* (mm)

0.30

0.40

0.50

0.60

0.70

0.80

100 1000 10000 100000

Time (s)

Figure 6 Secondary consolidation of specified materials under 1240 kPa stress

average of three tests per material

Copyright ASCE 2005 Advances in Pavement Engineering

Advances in Pavement Engineering

GSP 130 Advances in Pavement Engineering

*Note: Displacements normalized so that 0 mm displacement occurs at beginning of secondary consolidation.

0.00

Sand

PS

0.10 LDPE

MP

HDPE

0.20

Displacement* (mm)

0.30

Downloaded from ascelibrary.org by TUFTS UNIVERSITY on 10/20/14. Copyright ASCE. For personal use only; all rights reserved.

0.40

0.50

0.60

0.70

10 100 1000 10000 100000

Time (s)

Figure 7 Secondary consolidation of specified materials under 12380 kPa stress

averages of three tests per material

6 DISCUSSION OF COMPRESSION RESULTS

6.1 Stress-Strain Behavior

As shown in Figure 5, the sand undergoes significantly less reduction in

volume during compression testing than do the SLAs. Comparing the SLAs’

behaviors shown in Figure 6 indicates that the PS is the stiffest SLA followed by MP,

HDPE, and LDPE. This behavior is not surprising since PS is the stiffest of the plastic

types tested in this study (refer to Table 2).

Stresses in the loading cycle where creep was allowed to occur, namely at

1240 kPa and 12380 kPa, are very noticeable. At these points, the SLAs deformed

significantly under no added stress. It is interesting to note that upon resumption of

loading, the SLA loading curves quickly recover to their original paths. This

phenomenon can be conceptualized by thinking of the creep as “aging” which

effectively overconsolidates the soil specimens. When loading is resumed, the

specimens must go through an initial “reconsolidation” stage, characterized by elastic

skeleton deformation and particle rearrangement, before reaching their “maximum

past pressures” and continuing with virgin consolidation.

The differences in sand and SLA behavior can be attributed to the deformability of

SLA particles, a char acteristic not considered for most granular materials. Where

most natural granular soils must reach a significantly high stress level before particle

deformation (i.e. breaking) begins to occur, particle deformation in SLAs begins

under low stresses along with the usual rearrangement and skeleton deformation that

occur under low stresses in natural soils.

Copyright ASCE 2005 Advances in Pavement Engineering

Advances in Pavement Engineering

GSP 130 Advances in Pavement Engineering

6.2 Secondary Compression Behavior

Under the 1240 kPa sustained stress, a wide range of compression or creep

behaviors were shown by the materials (see Figure 6). While all SLAs displayed

significant rates of secondary compression, with the HDPE-based SLA displaying the

highest, sand displayed almost zero creep deformation under the 1240 kPa stress.

However, under the 12380 kPa stress, all materials exhibit significant rates of

secondary compression (see Figure 7). Moreover, the “softer” SLAs exhibit a lower

Downloaded from ascelibrary.org by TUFTS UNIVERSITY on 10/20/14. Copyright ASCE. For personal use only; all rights reserved.

rate of compression at this stress level than at the lower stress level. As with the

overall compression behavior, the differences in secondary compression behavior

between sands and SLAs may be due to particle deformation characteristics. The

primary mechanism of creep in natural granular soils is particle rearrangement and

breakage at contact points; the contact stresses for the 1240 kPa stress were not

enough to initiate this type of failure in the sand but was sufficient for the SLAs. It

could be concluded that as the void space in the SLAs reduce to almost non-

existence, the material become stiffer and less creep susceptible. This behavior

requires more study to substantiate this conclusion.

6.3 Post-Test Observations

It is interesting to note that at the conclusion of each test, the specimen was

removed from the consolidation ring. Most of the SLA specimens had bonded into

solid “disks” during testing, and some had to be removed forcefully from the

consolidation ring. A photograph of a typical SLA specimen after testing is shown in

Figure 8. This interlocking of particles to form a “SLA cake” lead to lower than

expected recovery of strains after removal of applied stresses.

Figure 8 Typical SLA specimen after testing

7 IMPLICATIONS FOR PAVEMENT SYSTEMS

SLAs may present a number of potential advantages and disadvantages for their

use in pavement systems (i.e., subgrade to final wearing surface). As shown by the

bulk density results, the full replacement of normal aggregate with SLA could lead to

10

Copyright ASCE 2005 Advances in Pavement Engineering

Advances in Pavement Engineering

GSP 130 Advances in Pavement Engineering

a lower weight pavement system for roadways and bridges. As for use in asphalt

concrete, previous work by Hooper et al (2004) has shown that a partial substitution

of SLA as the aggregate in hot mix asphalt lead to an increase in resilient modulus

with a decrease in rutting. However, the significant compression of the SLAs could

be problematic if a stiffer pavement system is needed, such as for heavily traveled

roads or runways. In addition, the level of creep at low stress levels would indicate

that sustained loading on the pavement system could lead to pre-mature rutting of the

road surface. More research is needed to evaluate the effects of SLAs in actual

Downloaded from ascelibrary.org by TUFTS UNIVERSITY on 10/20/14. Copyright ASCE. For personal use only; all rights reserved.

pavement system.

8 CONCLUSIONS AND RECOMMENDATIONS

8.1 Conclusions

One-dimensional compression tests were carried out on four types of synthetic

lightweight aggregate, each containing fly ash and plastic in an 80:20 ratio, and a

granitic sand. Conclusions that may be drawn from the results are as follows.

1. SLAs undergo a much greater reduction in volume than natural sand under

applied stress.

2. SLAs absorb stress through plastic particle deformation over the entire

range of applied stresses, whereas natural sand absorbs low stresses

through elastic skeleton deformation and particle rearrangement and high

stresses through crushing at particle contact points.

3. Because of particle interlock and bonding, SLA particles rebound

minimally after undergoing high stresses.

4. SLAs exhibit significant amounts of creep under both low and high

sustained stresses. Sand exhibits significant creep only under high

sustained stresses.

8.2 Recommendations

Future testing should focus on duplicating the tests described herein at higher

stress levels. This will allow the investigation of the sand and SLAs as they approach

zero porosity. Additionally, tests similar tests should be carried out for mixtures of

SLA and natural soils to see if partial substitution of SLAs for normal aggregates in

pavement systems is possible. Finally, similar testing should be carried out on SLAs

with fly ash to plastic ratios other than 80:20 so that the effects of changing the fly

ash content may be observed.

11

Copyright ASCE 2005 Advances in Pavement Engineering

Advances in Pavement Engineering

GSP 130 Advances in Pavement Engineering

REFERENCES

American Society for Testing Materials (1994). Annual book of ASTM Standards,

Vol. 8. Soil and Rock, pp. 530-550. Philadelphia: ASTM.

Cook, Glenn J. (2000). “Physical and Mechanical Properties of Composite

Lightweight Aggregates,” Thesis submitted to Tufts University in partial fulfillment

of the requirements of Master of Science from the Department of Civil and

Downloaded from ascelibrary.org by TUFTS UNIVERSITY on 10/20/14. Copyright ASCE. For personal use only; all rights reserved.

Environmental Engineering, 109p.

Gaudreau, Jade A. (2002). “Stress-Strain-Strength Behavior of Synthetic Lightweight

Aggregates in Triaxial Compression,” Thesis submitted to Tufts University in partial

fulfillment of the requirements of Master of Science from the Department of Civil

and Environmental Engineering, 136p.

Hooper, Fredick; Mallick, Rajib; O’Brien, Sean; and Kashi, Mohsen (2004).

“Evaluation of Use of Synthetic Lightweight Aggregate (SLA) in Hot Mix Asphalt”,

83rd Transportation Research Board Annual Meeting, Washington DC, January 11-15,

2004.

Kalyoncu, Rustu S. (2001). “Coal Combustion Products”. United States Geological

Survey, 2001 Minerals Yearbook, 11p.

Kiggins, Michael L. (2001). “Synthetic (Fly Ash/Plastic) Lightweight Aggregates in

Concrete,” Thesis submitted to Tufts University in partial fulfillment of the

requirements of Master of Science from the Department of Civil and Environmental

Engineering, 298p.

Malloy, R., Swan, C. W., and Kashi, M. G. (2001). “High Carbon Fly Ash/Mixed

Thermoplastic Aggregates for Use in Lightweight Concrete,” Society of Plastics

Engineers Annunal Conference.

Shelburne, W., and DeGroot, D. (1998). “The Use of Waste and Recycled Materials

in Highway Construction”, Civil Engineering Practice – Journal of the Boston

Society of Civil Engineers Section/ASCE, Vol. 13, No. 1, pp. 5-16.

United States Environmental Protection Agency (2002). “Municipal Solid Wastes in

the United States: 2000 Facts and Figures”. Office of Solid Waste and Emergency

Response (5305W), EPA 530-R-02-001, 165p.

Weingram, Joshua A. (2003). “Shrinkage and Durability of Concrete Containing Fly

Ash/Mixed Plastic Aggregates,” Thesis submitted to Tufts University in partial

fulfillment of the requirements of Master of Science from the Department of Civil

and Environmental Engineering, 127p.

12

Copyright ASCE 2005 Advances in Pavement Engineering

View publication stats Advances in Pavement Engineering

You might also like

- Proposal For The Crestwood Plaza Redevelopment Area by UrbanStreet - Crestwood, MODocument52 pagesProposal For The Crestwood Plaza Redevelopment Area by UrbanStreet - Crestwood, MOnextSTL.comNo ratings yet

- 3 7 RD Design Report TemplateDocument2 pages3 7 RD Design Report TemplateDaramola AyotopeNo ratings yet

- Highrise InformationDocument59 pagesHighrise InformationNupur BhadraNo ratings yet

- Reinforced ConcreteDocument12 pagesReinforced ConcreteluckywaysNo ratings yet

- Ajeas Joint FlexibilityDocument7 pagesAjeas Joint FlexibilitycatullusNo ratings yet

- Review of Methodologies For Composite Material Modelling Incorporating FailureDocument17 pagesReview of Methodologies For Composite Material Modelling Incorporating FailureSCRIBDNo ratings yet

- Admixtures For ConcreteDocument4 pagesAdmixtures For ConcreteRm1262No ratings yet

- Compacted Earth FillDocument8 pagesCompacted Earth FillTwin Wayne100% (1)

- Modeling of The Mass Transfer Rates of Metal IonsDocument27 pagesModeling of The Mass Transfer Rates of Metal Ionslorenna1514No ratings yet

- 1 s2.0 S0950061823008139 MainDocument22 pages1 s2.0 S0950061823008139 MainrayanelmpNo ratings yet

- Seismic Behavior of Steel Reinforced Concrete Beam-Columns and FramesDocument10 pagesSeismic Behavior of Steel Reinforced Concrete Beam-Columns and Framesanon_47684961No ratings yet

- By Carlos Guedes Spares, A. M. ASCE and Tore H. Soreide: J. Struct. Eng. 1983.109:451-467Document17 pagesBy Carlos Guedes Spares, A. M. ASCE and Tore H. Soreide: J. Struct. Eng. 1983.109:451-467Saul Max Huayta AguilarNo ratings yet

- Materials: Influence of Alkali Treatment On The Microstructure and Mechanical Properties of Coir and Abaca FibersDocument20 pagesMaterials: Influence of Alkali Treatment On The Microstructure and Mechanical Properties of Coir and Abaca FibersUNITED CADDNo ratings yet

- Failure Mechanisms in FRC 2Document18 pagesFailure Mechanisms in FRC 2Quang Huy PhạmNo ratings yet

- (Asce) 1532-3641 (2002) 2 3Document22 pages(Asce) 1532-3641 (2002) 2 3ABHINAV KUMARNo ratings yet

- Modulos Resilient in Granulas Soils PDFDocument25 pagesModulos Resilient in Granulas Soils PDFLuisRodrigoPerezPintoNo ratings yet

- (25) تابع الى (1) Buehler - Optimization of compositeDocument8 pages(25) تابع الى (1) Buehler - Optimization of compositeali aliNo ratings yet

- Volume Fraction in CompositesDocument11 pagesVolume Fraction in Compositeschetan_thakur4278No ratings yet

- A Material Model For Flexural Crack Simulation in Reinforced Concrete Elements Using ABAQUS - Wahalathantri2011Document7 pagesA Material Model For Flexural Crack Simulation in Reinforced Concrete Elements Using ABAQUS - Wahalathantri2011marcilio1986No ratings yet

- Effects of Humidity On Shear Behavior of Bamboo: Theoretical and Applied Mechanics Letters November 2015Document9 pagesEffects of Humidity On Shear Behavior of Bamboo: Theoretical and Applied Mechanics Letters November 2015MochamadAliHaidarNo ratings yet

- Pastas Minerales 1Document11 pagesPastas Minerales 1Voca FistNo ratings yet

- Factors Affecting The Interlayer Shear Strength of Laboratory and Field SamplesDocument11 pagesFactors Affecting The Interlayer Shear Strength of Laboratory and Field SamplesRohith ReddyNo ratings yet

- Chute Flow As A Means of Segregation CharacterizationDocument15 pagesChute Flow As A Means of Segregation CharacterizationPrashant GuptaNo ratings yet

- Cellulose Nanomaterials Review - ChemSocRev 2011Document54 pagesCellulose Nanomaterials Review - ChemSocRev 2011Ismael Gracia GNo ratings yet

- Advances in Flexible CompositesDocument14 pagesAdvances in Flexible CompositesHanzla ZubairNo ratings yet

- 2010-Semi-Rigid ConnectionsDocument12 pages2010-Semi-Rigid ConnectionsVanessa OlivoNo ratings yet

- Disturbed State Concept As Unified Cons - 2016 - Journal of Rock Mechanics and GDocument17 pagesDisturbed State Concept As Unified Cons - 2016 - Journal of Rock Mechanics and GNicolás Andrés Bastián MonarcaNo ratings yet

- Computational Materials Science: Guangji Xu, Hao WangDocument9 pagesComputational Materials Science: Guangji Xu, Hao Wangchristofer kevinNo ratings yet

- Model Prediction of Rutting in Asphalt Concrete by D. V. Ramsamooj P.E., J. Ramadan/ and G. S. Lin, 3 P.EDocument9 pagesModel Prediction of Rutting in Asphalt Concrete by D. V. Ramsamooj P.E., J. Ramadan/ and G. S. Lin, 3 P.EdedyNo ratings yet

- A Review On Exploring The Behavior of Multi-Layer Composite Structures Under Dynamic LoadingDocument9 pagesA Review On Exploring The Behavior of Multi-Layer Composite Structures Under Dynamic LoadingRafael ZanettiNo ratings yet

- 1 s2.0 S0167844218302234 MainDocument8 pages1 s2.0 S0167844218302234 MainSudeep SAHOONo ratings yet

- 1 s2.0 S2238785419319714 MainDocument18 pages1 s2.0 S2238785419319714 MainRio ArrayNo ratings yet

- Review Papers Fatigue Behavior of Fiber-Reinforced Polymer Composites-A ReviewDocument8 pagesReview Papers Fatigue Behavior of Fiber-Reinforced Polymer Composites-A ReviewNeelkant PatilNo ratings yet

- Experimental and Statistical Investigation On Synergistic - 2023 - DevelopmentsDocument13 pagesExperimental and Statistical Investigation On Synergistic - 2023 - DevelopmentsHany RagabNo ratings yet

- Seismic Response Study of Degraded Viscous Damping Systems For Tall Buildings in ChinaDocument13 pagesSeismic Response Study of Degraded Viscous Damping Systems For Tall Buildings in ChinaErika MartínezNo ratings yet

- Sci p360 SecureDocument15 pagesSci p360 SecureOktayNo ratings yet

- Basic Expr Charaof Polymer CompositesDocument28 pagesBasic Expr Charaof Polymer Compositeswdrrrw6xnkNo ratings yet

- Punetha 2019Document31 pagesPunetha 2019B RAMUNo ratings yet

- Ajeas Joint FlexibilityDocument7 pagesAjeas Joint Flexibilityding liuNo ratings yet

- Comparison of Life Cycle Carbon Footprints of Steel and Concrete Pressure PipesDocument11 pagesComparison of Life Cycle Carbon Footprints of Steel and Concrete Pressure PipesAndresNo ratings yet

- Temperature-Accelerated Strength Development in Stabilized Marine Soils As Road Construction MaterialsDocument13 pagesTemperature-Accelerated Strength Development in Stabilized Marine Soils As Road Construction MaterialsHocine HocineNo ratings yet

- Fatigue Properties of Asphalt Materials at Low In-Service TemperaturesDocument8 pagesFatigue Properties of Asphalt Materials at Low In-Service TemperaturesKarim BenyoucefNo ratings yet

- Methodology Joint FlexDocument7 pagesMethodology Joint FlexAdilhakimin AnwarNo ratings yet

- Função de DistribuiçãoDocument7 pagesFunção de DistribuiçãoLeonan CostaNo ratings yet

- Saha2018 PDFDocument11 pagesSaha2018 PDFAnand SolomonNo ratings yet

- Crack Influence and Fatigue Life Assessment in RaiDocument12 pagesCrack Influence and Fatigue Life Assessment in Railatifa boussaliaNo ratings yet

- Synthetic Evolution of Colloidal Metal Halide Perovskite NanocrystalsDocument20 pagesSynthetic Evolution of Colloidal Metal Halide Perovskite NanocrystalsAdrianoDSNo ratings yet

- ConferencepreceedingsDocument18 pagesConferencepreceedingssaza rayNo ratings yet

- Optimization of Sisal Fiber, Glass Fiber and Alumina - Based Hybrid Composite For Flexural Strength Using Taguchi TechniqueDocument12 pagesOptimization of Sisal Fiber, Glass Fiber and Alumina - Based Hybrid Composite For Flexural Strength Using Taguchi TechniqueIJRASETPublicationsNo ratings yet

- Introduction !!Document6 pagesIntroduction !!atef.selmi01No ratings yet

- Re 1Document21 pagesRe 1Shirin OthmanNo ratings yet

- A Comprehensive Review On Drop Weight Impact Characteristics of BastDocument9 pagesA Comprehensive Review On Drop Weight Impact Characteristics of BastKhaled GammoudiNo ratings yet

- IRJAES V2N2P313Y17 Aaaaaaaaaaaaaaaaaa PDFDocument5 pagesIRJAES V2N2P313Y17 Aaaaaaaaaaaaaaaaaa PDFYogesh ShindeNo ratings yet

- An Evaluation of The Environmental Burdens of Present and Alternative Materials Used For Electricity TransmissionDocument13 pagesAn Evaluation of The Environmental Burdens of Present and Alternative Materials Used For Electricity TransmissionVishal AryaNo ratings yet

- Modeling, Analysis, and Behavior of Load-Carrying Precast Concrete Sandwich PanelsDocument13 pagesModeling, Analysis, and Behavior of Load-Carrying Precast Concrete Sandwich PanelsAristotle MedinaNo ratings yet

- Factores de LewisDocument25 pagesFactores de LewisRuiz ManuelNo ratings yet

- Formation of Silicone Elastomer Networks Films With Gradients in ModulusDocument12 pagesFormation of Silicone Elastomer Networks Films With Gradients in Modulustoyito20No ratings yet

- Apply For Canada Scholarships ListDocument13 pagesApply For Canada Scholarships ListMD.SABBIROJJAMAN PAYELNo ratings yet

- IAC-2019 Paper Zimmermann JDocument9 pagesIAC-2019 Paper Zimmermann JAbbasnejad ShahramNo ratings yet

- Sandeep2011 - Thermo-Mechanical Correlations To Erosion Performance of Short Carbon FibreDocument9 pagesSandeep2011 - Thermo-Mechanical Correlations To Erosion Performance of Short Carbon FibreAnkushNo ratings yet

- A Study of Dynamic PullDocument8 pagesA Study of Dynamic PullHEMANTH KUMAR CNo ratings yet

- Liu Et Al. 2023 - Ialcce2023Document9 pagesLiu Et Al. 2023 - Ialcce2023mohamed magdiNo ratings yet

- Seismic Performance and Global Ductility of Reinforced Concrete Frames With CFRP Laminates Retrofitted JointsDocument15 pagesSeismic Performance and Global Ductility of Reinforced Concrete Frames With CFRP Laminates Retrofitted Jointsdewa made adityaNo ratings yet

- Wang Et Al 2019 Quantitative Adjustment To The Molecular Energy Parameter in The Lake Thomas Theory of Polymer FractureDocument6 pagesWang Et Al 2019 Quantitative Adjustment To The Molecular Energy Parameter in The Lake Thomas Theory of Polymer FracturelizixicNo ratings yet

- Study of Materials Properties Made of Steel, Stainless Steel, Aluminium, and Concrete While Applying The Total Load To The GeometryDocument4 pagesStudy of Materials Properties Made of Steel, Stainless Steel, Aluminium, and Concrete While Applying The Total Load To The GeometryResearch ParkNo ratings yet

- DL HB Needs Analysis QuestionnaireDocument3 pagesDL HB Needs Analysis QuestionnaireNadya BerlianNo ratings yet

- TECS Water Cooled ChillerDocument8 pagesTECS Water Cooled Chillerntt_121987No ratings yet

- Cooling Tower Fan 301 Sr. DS Installation Manual 2006.12Document8 pagesCooling Tower Fan 301 Sr. DS Installation Manual 2006.12Krishna BadheNo ratings yet

- Resume of Deepak KR BhartiDocument2 pagesResume of Deepak KR BhartiNitin SharmaNo ratings yet

- Technical Note 2016 TN 01 Transmission of Column Loads Through SlabsDocument6 pagesTechnical Note 2016 TN 01 Transmission of Column Loads Through SlabsZuzar PitolwalaNo ratings yet

- MVTPL Kurnool Wind FarmDocument263 pagesMVTPL Kurnool Wind Farmsurya chandraNo ratings yet

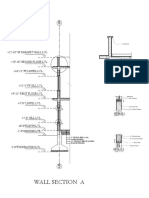

- Wall SectionDocument1 pageWall SectionSusma DotelNo ratings yet

- Greenstar CDi Classic Combi ErP Operating InstructionsDocument24 pagesGreenstar CDi Classic Combi ErP Operating InstructionsMaysam BagheriNo ratings yet

- Book 3 - 5. Revi̇zyonDocument129 pagesBook 3 - 5. Revi̇zyonsinan erogluNo ratings yet

- Gea Denco PDF 54 MBDocument72 pagesGea Denco PDF 54 MBcobs80No ratings yet

- Introduction To Different Civil Engineering SpecializationDocument6 pagesIntroduction To Different Civil Engineering SpecializationJay GrijaldoNo ratings yet

- Unit IiiDocument180 pagesUnit IiiNisarga JNo ratings yet

- TimberDocument80 pagesTimberYooganNo ratings yet

- 6 Great Benefits of Using Carbon Steel Pipe: In, byDocument3 pages6 Great Benefits of Using Carbon Steel Pipe: In, byMarnel Roy MayorNo ratings yet

- Fatigue Capacity of Plain Concrete Under Fatigue Loading With Constant Confined StressDocument17 pagesFatigue Capacity of Plain Concrete Under Fatigue Loading With Constant Confined StressVicente Bergamini PugliaNo ratings yet

- A B C D E: Parts Book 零件样本Document29 pagesA B C D E: Parts Book 零件样本Kalim KamNo ratings yet

- SFL GAU 300 3.5 Mánometro SecoDocument1 pageSFL GAU 300 3.5 Mánometro Secoadministración camelotNo ratings yet

- SKF Composite Plain Bearings - 11004 EN - TCM - 12-107917 PDFDocument60 pagesSKF Composite Plain Bearings - 11004 EN - TCM - 12-107917 PDFAnonymous 1qAH6CKCNo ratings yet

- QS PM CoursesDocument4 pagesQS PM CoursesBRGRNo ratings yet

- Plumbing & FireproDocument9 pagesPlumbing & FireproJonathan Quilang ObienaNo ratings yet

- Tubing and Fittings Quick Reference (Metric and Inch) - WebDocument9 pagesTubing and Fittings Quick Reference (Metric and Inch) - WebRajkumar MudaliarNo ratings yet

- Cts Spare Stock - Kasi Sales - 31!12!19.Document7 pagesCts Spare Stock - Kasi Sales - 31!12!19.saptarshi halderNo ratings yet

- Ansys 20, 22,23.012.2014 AnDocument12 pagesAnsys 20, 22,23.012.2014 AnM.Saravana Kumar..M.ENo ratings yet

- Is Hc1909flDocument1 pageIs Hc1909fldayshift5No ratings yet