Professional Documents

Culture Documents

Textured Whey Protein

Textured Whey Protein

Uploaded by

Zahid Mahmood0 ratings0% found this document useful (0 votes)

8 views14 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views14 pagesTextured Whey Protein

Textured Whey Protein

Uploaded by

Zahid MahmoodCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 14

eagasc

Aaaracwiruxeaxe Foor Daxmoraore Avmonry

Physical Properties of Textured Whey Protein Il. Bulk Density, Water Binding Capacity and

Protein Solubility

Author(s): J. J. Tuohy

Source: Irish Journal of Food Science and Technology, Vol. 4. No. 2 (1980), pp. 111-123

Published by: TEAGASC-Agriculture and Food Development Authority

Stable URL: htip:/wwwjstor.org/stable/25S58004

Accessed: 16/06/2014 06:39

‘Your use ofthe JSTOR archive indicates your acceptance of the Terms & Conditions of Use, available at

up: www jtor orgpagelinfo/abou/poicie/erms ip

JSTOR isa not-for-profit service that helps scholars, researchers, and students discover, use, and build upon a wide range of

content in a trsted digital archive. We use information technology and tools to increase productivity and facilitate new forms

of scholarship, For more information about JSTOR, please contact support @ijstor.org,

TEAGASC-Agriculture and Food Development Authority is collaborating with JSTOR to digitize, preserve and

extend access to Irish Journal of Food Science and Technology

hupwww jtor org

‘This content doloaed fom 91-2929 4908 Mn, 16 2014 063912 AM.

‘Ale sje o JSTOR Terns aod Condions

Id. SetTeebwol 4:1

3, 1980

PHYSICAL PROPERTIES OF TEXTURED WHEY PROTEIN I

BULK DENSITY, WATER BINDING CAPACITY AND PROTEL

‘SOLUBILITY

J.d. Tuohy

‘An Foras Talimis, Moorepark Research Centre, Fermoy, Co. Cork

ABSTRACT

The influence of dope pH, prten/dry matter coment, csea/totat protein ratio and acrovave

ination ime onthe bulk density, mater banding capaci and solble protein content of misromsve

Textured whey protein (LWP) was determined. The bulk dens, water binding capacity and soluble

protcin conten of microwave textured soy protein (TSP) ad the water binding capacity of Tresze died

Bet were also measured

“The bulk ange of T.W.P. ange from 0.138 to 0.639 simi but on average was between 0.2 and 0.4

g/ml compared with » minimum of 0.56 for TS. The water abworption capacky of TWP. ranged

from 40% 10 3585 (By weight) and values of 219% and 164% wer found for Irene dried beet round

and TSP. tespecvely. The soluble protein content of TWP. ranged from 11.2% t0 34.9% and the

INTRODUCTION

The consumption of texted vegetable protein (T.V.P.) products lus expanded

rapidly in recent years, It has been estimated that 5,539 million kg of textured soy

protein will be used annually in the U.S. by the year 2,000 (1). The largest single

usage of T.V.P. products has been as red meat extenders and the main class of

products used are those produced by expansion processes, principally thermoplastic

extrusion, Similar type products have been manufactured from milk protein by

‘thermoplastic extrusion (2), microwave expansion (3) and other expansion processes

45,6).

{In addition to imparting a desirable texture, textured protein meat extenders

contribute to the nutritional value and improve the functional properties of

processed meat products. Incorporation of textured whey protein has been shown to

reduce water and fat losses in sausages on cooking (7).

The physical appearance of textured protein meat extenders is not important per

se but ultrasteucture and density (which is related to ultrastructure) of T.V.P. do

correlate significantly with other physical properties (8). The bulk density of

m

12 1R.J, PD, SCL TECHNOL, VOL. 4, NO. 2, 1980

commercial T.V.P. products usually lies in the range 0.22 to 0.64 g/ml (9). The

range in bulk density values arises from the use of different expansion texturisation

processes and diverse processing conditions (10). Cumming et af (8) found that by

fnereasing the extruder barrel temperature the density (g/ce) of T.V.P. could be

reduced.

TTP products are nnrmally rehydrated pring to uce and commonly ahsarh ?

to 3.4 times their own dry weight of water (11). The time required for T.V.P. to

attain an equilibrium moisture content is inversely related to temperature but

commercial users rehydrate T.V.P. in ice water to reduce the possibility of

microbial growth (12). The amount of water absorbed by T.V-P. is a function of

extrusion temperature. A rise in extrusion temperature from 120 to 190°C increased

TP. water absorption from 90 to 200% by weight according to Cumming et a! (8).

Chiang and Sternberg (13) developed a water retention capacity test for stored

soybean fibres while les and Elson (14) using the Instron Universal Testing Machine,

devised a procedure for measuring the juiciness of rehydrated and cooked T.V.P.

produets,

A definitive characteristic of T.V.P. products is that they are insoluble in water

and retain cheir structural integrity when rehydrated. A number of empirical tests

for quantitatively measuring structural integrity were reported by Breene (15).

Burgess and Stanley (16) measured the protein solubility of T.V.P. in a range of

protein extraction solutions in an attempt to elucidate the mechanism responsible

for texturisation of soy protein by thermoplastic extrusion. Cumming et al (17)

found that the more highly texturised the sample the less soluble it became and

found extruded soy flour contained only 27% as much water soluble protein as

‘unprocessed soy flour. They also found that the various soy proteins were not

affected equally by the heat processing involved in thermoplastic extrusion.

‘A earlier publication (18) described the influence of dope composition on the

texture of textured whey protein (TWP) produced by microwave expansion. This

paper examines the effect of process parameters on the bulk density, water binding

capacity and the water soluble protein content of T.W.P.

MATERIALS AND METHODS

Materials

Textured whey protein was produced by microwave expansion as outlined by

Burgess, Downey and Tuohy (7) and described in an earlier paper (18). The dopes

‘were standardised at 66% total solids content, 60% protein/dry matter content and

were taken to have a casein/total protein ratio of zero. The dope pH was the pH of

the reconstituted whey protein concentrates, which ranged from 4.70 to 6.25, but in

later experiments the dopes were standardised at pH 7. The dopes were irradiated

for 150 sec. The dope pH, protein dry matter content and easein/total protein ratio

were independently adjusted For the appropriate experiments,

‘TUOMY: PHYSICAL PROPERTIES OF TEXTURED WHEY PROTEIN II us

‘To determine the influence of irradiation time the dopes were irradiated for 60,

90, 120, 150, 180, 240 and 270 sec.

Textured soy protein (T.S.P.) was produced by the microwave expansion

procedure of Waggle (19). One hundred grams of soy flour was mixed with 175g of

water to form a 36% total solids content dope.

Fresh beef round (semi-membranosus, semi-tendenosus muscles) was purchased

locally and freeze dried. The freeze dried product contained 77% protein, 14% fat,

3 ash, $8 moisture and 1% carbohydrate.

Bulk density

T.W.P. volume was measured by displacement of rape seed (2) and divided by its

weight to calculate its bulk density (g/ml). The average of triplicate determinations

of T.W.P. volume was taken and each treatment was replicated three times,

Water binding capacity

a) Water absorption capacity: Blocks of T.W.P. were weighed, rehydrated for 20

‘min in water at room temperature, removed and left stand for § min to allow

surface water drain off. The rehydrated T.W.P. was then reweighed and the

increase in weight was expressed as a percentage of the original T.W.P. weight

Each treatment was replicated three times.

'b) Water retention capacity: This was measured by the procedure of Chiang and

‘Sternberg (13). Twenty gram amounts of T.W.P. were blended with 100 ml of

water in a Waring blender and the slurry filtered through 100 micron nylon mesh

into a 100 ml graduated cylinder. The volume of water retained after 30 min

filtration time, expressed as a percentage of the volume of water added (100 ml),

was taken as the water retention capacity. The test was performed in duplicate,

6) Juiciness index: The procedure of lles and Elson (14) was used. Weighed cubes of

rehydrated T.W.P. were compressed between two pre-weighed filter papers on

the Instron Universal Testing Machine by a plate attached to the crosshead

pressing against a fixed base plate. The filter papers were re-weighed and the

Increase in weight expressed as a percentage of the original weight of the cube.

Samples were compressed at forees of 10, 20, 30, 40 and 0 kgs. Three replicates

of each sample were tested.

Water soluble protein

‘The procedure of Burgess and Stanley (16) was followed except that distilled water

was used rather than buffer. The T.W.P. was ground to a fine powder with a

laboratory hammer mill and extracted at a sample/water ratio of 1:50 for 30 min at

440°C in a shaking water bath. The T.W.P. and the filtrate, obtained by passing the

slurry through Whatman No. 41 filter paper, were analysed for protein by the

‘macro-Kjeldahl technique. The protein in the filtrate was expressed as a percentage

Of the protein in Ig of powder. Soluble protein does not distinguish between true

soluble protein and protein present as a colloidal suspension.

us IR. FD, SCL, TECHNOL, VOL. 4, NO. 2, 1980

RESULTS AND DISCUSSION

Bulk density

Expansion and heat-setting of the whey protein dopes occurred during the first 90

sec of microwave inadiation. T.W.P. volume reached 2 maximum after 90 sec

Inradiation of 175 ml (Fig. 1) and decreased considerably with further irradiation to

145 ml at 240 sec. This reduction in volume paralleled the reduction in moisture

content which occurs simultaneously (2). The bulk density of the T.W.P. was not

significantly affected by the irradiation time, going from 0.41 g/ml at 60 sec to 0.39

g/ml at 240 sec. The bulk density remained constant because the weight loss

resulting from dehydration compensated for the decrease in volume.

‘Dope pH is the main factor affecting expansion of whey protein dopes and T.W.P.

bulk density decreased linearly fram 0.64 g/ml, when the dope was at pH}, 10 0.14

g/ml when the dope was at pH 8 (Fig. 2). At pH 9 insufficient or incomplete

crosslinking occurred during the heat-stting stage (subsequent to expansion) and

the greatly expanded T.W.P. contracted in volume when it was removed from the

oven, yielding a final bulk density of 0.51 g/l

‘The results of Fig. 4c show that the protein/dry matter content of the dope in the

range 45 to 60% had litle effect on expansion. Bulk density values ranged from 0.26

{0.0.30 g/m! but increased to 0.34 g/ml at 65% protein/dry matter content.

‘The dope casein/total protein ratio also had very little effect on expansion up to

40% and bulk density values ranged from 0.24 to 0.26 g/ml. There was a decrease in

bulk density at the 50% casein total protein level to 0.20 g/ml (Fig Sc).

Microwave T.W.P. has a more expanded porous structure than microwave

textured soy protein having a bulk density under normal operating conditions

eg

2 i

é a

ae poo 2

ba .

5

=e 70

Irradiotion Time (see. }

Fig. 1: Influence of microwave irradiation time (sec) on the bulk density (g/ml) of

TWP (@—9), TSP. (AA) and the volume (ml) of T.W.P. (@-—-®)

‘TUOHY: PHYSICAL PROPERTIES OF TEXTURED WHEY PROTEIN It us

@

Baik ensty fol

ame

Foo

2

=

ie

g

3 0

3

i

2 0

3 aa

©

|

Soluble Protein (or total

H

Fig. 2: Influence of dope pH on (a) the bulk density g/ml), (b) the water absorption

capacity (% by weight, mean and 95% confidence limits) and (¢} soluble protein

content (% of total protein} of T.W.P.

16 1R.J, FD. SCITECHNOL., VOL. 4, NO. 2, 1980

eas 7

3 5

a

{syBjominy] Ayzodo> uouchosqy 1210,

Gromsor Water Gamo: Dry Matter

lrradiation Time (sec)

Fig. 3: The effect of microwave irradiation time (sec) on the water absorption

capacity of TWP. (i) % by weight (0——e), (i) grams moisturelgram dry matter

fo—o).

between 0.2 and 0.4 g/ml compared with 0.5 to 0.7 g/ml for microwave T.S.P. (Fig.

1). This range corresponds well with the range 0.22 to 0.64 g/ml quoted by Hayes

and Tewey (9) for commercial T.V.P. products.

Water binding capacity

‘The water absorption capacity of T.W.P. is directly influenced by irradiation time

(Fig. 3) and increased from 72% by weight after 60 sec 10 358% after 240 sec. When

‘water absorption capacity is expressed on a dry matter basis 1.04 e water/g T.W.P.

dry matter was absorbed after 60 sec compared with 3.73 g water/g D.M. after 240

sev. Thus water absorption is «ruly a function of irradiation time, independently of

‘moisture content. Cumming er al (8) found that the increase in water uptake of

extruded T.V.P. with increasing process temperature correlated (P<0.01) with

‘changes in T.V.P. density. They concluded that the increase in water uptake was

largely a result of the change in density and implied from this that the more sponge-

like the structure (ie. the greater the bulk density) the more water is absorbed. The

bulk density of T.W-P. changed very litle as a Tunction of irradiation time and

therefore was not significantly correlated with T.W.P. water absorption capacity.

‘The water absorption capacity of T.W.P. is highly dependent on the pH of the

dope from which itis produced. The water absorption capacity of T.W.P. reached a

maximum at pH 7 of 178% (Fig 2b) and fell off to a minimum on the acd side of pH

3 of 40M and on the alkaline side at pH 9 of 34%, Between pH 3 and 7 there was @

very significant (p<0.01) kegative correlation between T.W.P. water absorption

capacity and bulk density. At pH 8 case hardening of the T.W.P. appeared to

depress water absorption and at pH 9 the contraction in volume and case hardening

TUOHY: PHYSICAL PROPERTIES OF TEXTURED WHEY PROTED

uw

@)

Y

Woter Absorption Capacity [weight]

Protein | Dry Matter Content (7)

Soluble Pctein (drt)

|

Frotin] Ory Mater Content

©)

fj

mee)

2

Bulk Deni

Prot Dry Mater Content (1)

Fig. 4: Influence of dope protein/dry matter content on (a) the water absorption

capacity (% by weight, —mean and 95% confidence limits) (b) the soluble protein

‘content (% of total protein) and (c) the bulk density (g/ml) of T.W.P.

ns |R.J. FD, SCL TECHNOL, VOL. 4, NO. 2, 1980,

of the T.W.P. further reduced water absorption. Between pH 3 and 9 the overall

regression coefficient between water absorption capacity and T.W.P. bulk density

was only —0.46.

‘The water absorption capacity of T.W.P. decreased from 197% to 389% by weight

‘when the protein/dry matter content of the dope was increased between SO and 75%

(Fig. 4a). This mav be due to more extensive crosslinking at high protein/drv matter

ratios resulting in case hardening of the T.W.P. blocks.

‘The casein/total protein ratio of the dope did not significantly affect the water

absorption capacity of T.W.P. up to the 40% level but at the SOM level the water

absorption fell 10 63% (Fig. Sa). The very low water absorption capacity at the 50%

casein,/total protein ratio coincides with a high soluble protein content (34%) and a

low bulk density (0.20 g/ml). The water absorption capacity af T.W.P. is greatly

influenced by changes in dope composition and operating conditions. For this

reason, because the dope pH was not the same in all experiments, the range of

values found tended to vary a lot from experiment to experiment.

‘At approximately 10% moisture content the water absorption capacity of

T.W.P., 322%, was considerably greater than that of microwave textured soy

protein, at 164%, and even greater than that of freeze dried beef round (5%

moisture) at 219%. In contrast the freeze dried beef had a higher water retention

capacity (71%) than the microwave textured soy protein (61%) and the T.W.P.

(560%) respectively (Fig. 6). Thus, although more water can be absorbed by TWP. its

‘capacity to retain this moisture, when its texture is broken down by comminution is

not as good as that of freeze dried beef or T.S.P. Similarly, 38.6% by weight of

water was exuded when rehydrated TMP. wis compressed by 50 kg force

compared with 24% from rehydrated T.S.P. and 13% from rehydrated freeze dried

beef round (Fig. 7). This isin agreement with the findings of les and Elson (14) that

water taken up by T.V.P. is less firmly bound that water in meat cooked under the

same conditions

Protein solubility

‘The principal change occurring during microwave expansion of protein dopes is the

conversion of the protein microstructure from its native form 0 a water insoluble

form, where it has a texture similar to meat. Failure to crosslink a critical amount of

the protein, as exemplified by microwave heating of casein dopes (2) means that a

textured product cannot be obtained, Protein is rapidly denatured during microwave

expansion and the final T.W.P. soluble protein level (after 240 sec) of 17.6% was

approached after 90 sec (Fig. 8). radiating the dope for longer than 90 sec did not

significantly decrease the T.W.P. soluble protein content, suggesting that protein

‘rosslinking and heat-setting had been completed by that time.

‘The soluble protein content of T.W.P. was at a minimum when it was produced

from dope at pH 4, of 14% ang at its maximum when the dope was pH 6, of 25%

ig. 2c). The minimum soluble protein content at pH4 is consistent with the

isoelectrie point of the whey proteins (20).

‘TUOHY: PHYSICAL PROPERTIES OF TEXTURED WHEY PROTEIN It u9

3

g

@

3

Woter Absorption Capoxity| weight

i

rs

Casein {Total Protein (2)

owe 3030 doo

Cazein Total Protein C1)

©)

oN

2

fa)

Bulk Density

2

ps

Cove al Protein Rt (2)

Fig, 5: The effect of dope casein total protein ratio on (a) the water absorption

capacity (% weight, —mean and 95% confidence limits), (b) the soluble protein

‘content (% of (otal protein) and (c) the buik density (g/ml) of T.W.P.

120 AR. J. FD, SCL TECHNOL, VOL. 4, NO.2, 1980,

‘Wolter Retention Capacity

Filtration Time (min)

Fig, 6: Water retention capacity, (*), of T.W.P. (@—8), TS.P, (AAJ and freeze dried

beef round (°—0} versus filtration time.

‘The soluble protein content of T.W.P. decreased linearly from 219% to 11% when

the protcin/dry matter content of the dope was inereased between 50 and 75% (Fig.

5b). The increase in concentration of the reactants presumably led to more complete

crosslinking.

‘The substitution of casein for whey protein in the dope resulted in elevated soluble

protein levels in the T.W.P. The soluble protein content increased from 24.5% to

34.9% between the zero and S0M% casein total protein levels, The increase in soluble

protein content probably arises because the caseins are heat stable proteins and are

not denatured by the heat treatment encountered in the microwave expansion

process,

The water soluble protein content of T,W.P. ranged from 11 to 28%» of total

protein and on average was about 22%. A lower value of approximately 7% was

found for microwave textured soy protein, which compares favourably with the

value of 8.3% obtained by Burgess and Stanley (16) for extruded T.V.P. The

average water soluble protein content of T.W.P. corresponds roughly to the heat-

stable proteose-peptone plus macropeptide nitrogen fraction of the cheese whey

protein (20). The high soluble protein content of T.W.P. may result from failure to

insolubilise the proteose-peptone and macropeptide by the microwave expansion

process. This would also account for the variation observed during this work in

soluble protein content of T.W.P. made from different batches of whey protein

concentrate on the basis of lactitional variations in the proteose peptone/serum

protein ratio.

‘TUOHY: PHYSICAL PROPERTIES OF TEXTURED WHEY PROTEIN If mm

None of the three physical properties was significantly correlated with objective

‘measurements of texture, published in an earlier paper (18), over the pH range 49.

‘At a specific dope pH when the protein/dry matter content or the casein/total

protein ratio were varied, the bulk density and soluble protein content of the T.W.P.

‘were highly correlated (positively and negatively respectively) with the Minnesota

Texture Method (M.T.M.), compression-shear-extrusion force (Table 1). The

compression-shear extrusion force has already been shown to be highly correlated

with the other M.T.M. texture parameters. (3). A critical soluble protein content

‘must therefore exist above which the texture of the product is considered unsuitable

{or classification as a textured product. For T.W.P. this is somewhat greater than

35% soluble protein.

Force Applied {ko}

Fig 7: The juiciness index (% molsture loss) of TW.P. (@—®), TS.P. (4) and freeze

dried beef round (O—) versus applied force (Kg).

Soluble Protein (or total

609th hosts aks ata

Irradiation Time (see)

Fig. 8: The influence of microwave iradiation rime (sec) on the soluble protein content

(%of total protein Jof T.W.P. (© —*) and TSP, (4—A).

i IR J. FD. SCL. TECHNOL, VOL. 4,NO. 2, 1980,

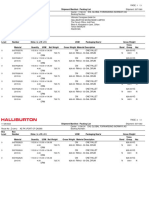

‘Table 1: Correlation between the physical properties and texture of T.W.P. at

fixed pH

Costin

Physical peopenty M-T.M. texture parameter of Significance

creation

“se lorae nme sty eee

Water-soluble protein CCompresion-shear-extusion as p< 0.005

‘omen, tore oe

Water absorption c

(@)Proten/dry mater Compresionshear-exiruson —099 p

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Marine Certificate of Insurance: (Schedule)Document3 pagesMarine Certificate of Insurance: (Schedule)Zahid MahmoodNo ratings yet

- Classification Light White Oil FarolDocument6 pagesClassification Light White Oil FarolZahid MahmoodNo ratings yet

- Purchase InvoiceDocument1 pagePurchase InvoiceZahid MahmoodNo ratings yet

- K 2019 Inter China Chemical Co. Ltd. Product k2019.2628724 DgpNofvxQJiWOZYU9m8I5gDocument1 pageK 2019 Inter China Chemical Co. Ltd. Product k2019.2628724 DgpNofvxQJiWOZYU9m8I5gZahid MahmoodNo ratings yet

- Safty DataDocument8 pagesSafty DataZahid MahmoodNo ratings yet

- Shipment Manifest / Packing ListDocument3 pagesShipment Manifest / Packing ListZahid MahmoodNo ratings yet

- LitratureDocument1 pageLitratureZahid MahmoodNo ratings yet

- Avb - 6b30e9 Baf091 037900 Aa9556 B7FFCC 7efeaeDocument2 pagesAvb - 6b30e9 Baf091 037900 Aa9556 B7FFCC 7efeaeZahid MahmoodNo ratings yet

- Certificate of AnalysisDocument1 pageCertificate of AnalysisZahid MahmoodNo ratings yet

- Alfa IndustrialDocument8 pagesAlfa IndustrialZahid MahmoodNo ratings yet

- Public Notice No. 11 Aliminium Composite PanelDocument5 pagesPublic Notice No. 11 Aliminium Composite PanelZahid MahmoodNo ratings yet

- Safety Data Sheet: Section 1: Identification of The Substance/mixture and of The Company/undertakingDocument7 pagesSafety Data Sheet: Section 1: Identification of The Substance/mixture and of The Company/undertakingZahid MahmoodNo ratings yet

- Acetoacetanilide - WikipediaDocument3 pagesAcetoacetanilide - WikipediaZahid MahmoodNo ratings yet

- Mycotoxin BinderDocument4 pagesMycotoxin BinderZahid MahmoodNo ratings yet

- ECICS Consultation: Search For Chemical Substance InformationDocument1 pageECICS Consultation: Search For Chemical Substance InformationZahid MahmoodNo ratings yet