Professional Documents

Culture Documents

Avance Automático Fresadora

Avance Automático Fresadora

Uploaded by

DavidOliva0 ratings0% found this document useful (0 votes)

55 views20 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

55 views20 pagesAvance Automático Fresadora

Avance Automático Fresadora

Uploaded by

DavidOlivaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 20

a> YER Bee wim RAs

POWER TABLE FEED InsTHlLéTion® OPERATION MANUAL

48 (INDEX)

eR BSR @ aN RTE BR

CAUTION BEFORE INSTALLATION TROUBLE SOLUTION

EIDE OBRTS

INSTALLATION OUTSIDE DIMENSION

ote FAR 88 Pi 1 HE HS EH BR

OPERATION ACCESSORIES & PARTS LIST

TR ES HENS ott RE

MAINTENANCE SPECIFICATION

ORE NE FA AUS EF RM

PLEASE READ THE OPERATION MANUAL BEFORE USE.

CHALLE NORE

KEEP THE MANUAL AND INSTALLATION DIRECTIONS AFTER PERUSAL.

@ 5) t BSIR (CAUTION BEFORE INSTALLATION) ~y

nena

© REMB DRA 2 BRR > AAS (POWER TABLE FEED) MAT RWBR >

RRBEBE HA Ree)

@ Please be sure the power is off before installation, Even the power table feed not

connected to the power. To avoid the accident caused during installation.

e ABER ABAC 110V 50/60Hz.2 BR » SARC BORD BRAG SE -

ASTHRRES- HRSRBRER > JH 2018 18 188 WS HAR)

@ This Power table feed has AC 110V 50/ 60Hz circuit. Please be sure the input power is

compliance with the power table feed. If the input power at user's place is not AC 110V

/60Hz, please Prepare the transformer. (To avoid burn down to the wires & circuit board

Caused by the wrong power supply).

OPRAH BE BG 1D OTST RBM ANAR » GEER AR PEER ME SI + ARESER

FEBU ISIS SLIM ES BA SI)

@ Except the consumable parts or maintenance parts, do not disassembly the power table

feed. To avoid any injury to operator and damage to machine caused by the wrong

assembly, omission, wrong connection and short circuit.

[ @ BEDS (INSTALLATION) 1

X@8-22 GABA (AVAILABLE FOR TABLE TRAVEL)

eng

LRA LA TOF OER OF (OM) LTPARRRRAER >

2. BRAG EE 2B EMA (MEXP 1. 0-4pcs) > MRSS MRE FALE o

@ INSTALLATION

1. Disassembly handle fix screws, handle (hand wheel), parallel socket key and dial from

the milling machine.

2. Loosen fix screws (M6xP1.0 - 4 pcs) from fix stand. Gently knock fix stand in order to take

out the fix stand from the axis screw.

ozktene—

1 BLASER BEBE

2. EXE ELH AMY O53 9 HH (2pcs) 5B Ht »

3, REX BEE + UMA FB EMRE (MEXP 1. 0-Apcs) BAB ©

4. HOXIG PUEDE EARAE HEIR

5, HOSEA SEAM AA TE EE EMO RRA » See eR RR OKO EE

FDS 7* Fa SRABMR Hh (ME XP 1. 0X25-2pe8) @49E «

@ INSTALL THE POWER TABLE FEED (FIG.1)

4.Move worktable to the left end.

2.Push the spring pin (5 - 2 pes) into X-axis fix stand for positioning.

3.Install X-axis fix stand, tighten up with fix screws (M6 x P1 .0-4 pes).

4,To set X-axis bushing onto the axis screw and push bushing to the end. : ;

5.To set power table feed at the right position & align with spring spin, set X-axis bushing &

gently knock in. Surface attach to the X-axis fix stand. Then tighten up with inner hex socket

screw (M6 xp1.0 25 - 2 pes).

@ ot AEH) 18 + RARE

1. ASV ABR DOB (26, 2X O16, 2)HE EORAR + MAA ALE ARO. 25135

2. ARAB BE LA SE 47 HB BA AE + BSR EA BB BB (7 28) ©

BGR RRS ORR WCE ENS BERD (RMD —) 16 BIE BIE” EB EMR

BEARD (A) 2. 0-2. nm P0361 AOBR AY E+ HB ABPRIE HE a Lt °

4, EEA RODR ADR (43, 4x 033, 4) JIN 55K ABO. 252 2H» MABE RARE BE ©

5. BE RAR BA A A ABR E(O. 5-0. 75mm) » AS 7R EE Lt HE BB PSB

BM So BFMMR TEAL °

6. HESS HRRAEBBE >

7. BEF GUM) WEBER >

8 BHLFRRRSSSCWMNECRAM UARERMBHHSSTIA S5

BRL BORSA AT SMSC AMRTE AB MI~OFM BBP IAL °

@INSTALL THE DRIVING SET & BACKLASH ADJUSTMENT (FIG.1\ FIG.2)

1.To add shim (26.2 x 16.2) onto axis screw. It is suggested to use 0.25t - 3pcs at

beginning.

2.To set parallel key into key way of axis screw, align with the key way, to set the bevel

gear (72T)

3.Disassembly the lower gear housing, hold power table feed shaft center(refer to FiG.11),

push bevel gearto the end, and check the backlash. (FIG.2 A) To add few shims (2.0 ~

2.2mm) for proper backlash.

4.To set the shim (43.4 x 33.4). Itis suggested to use 0.25t - 2 pcs, and then set the

dial.

5.To check backlash (0.5 ~ 0.75mm) between dial and surface of power table feed. If it's

not in the range, please repeat the procedures step 4 to step 5 until the proper backlash

is obtained.

6.To lock fix ring and dial.

7.To set handle (or hand wheel), tighten fix nut.

8.Rotate the handle few times and check whether itis interfere to power table feed. Also

check whether the gear rotated smoothly. If any noise of gear mash, it shows the

backlash checked in step 3 is not correct. Please repeat the procedures from step 3 to

step 8 until gear rotating is smoothly.

i

I#eee 1) 8 2 BB SMALL SHIM

WORK TABLE (©26.2x 016.2)

~ B08 (7208)

/" BEVEL GEAR

SEAR LARGE SHIM

\\(o43.4 033.4)

“Xe Bee

X-AXIS FIX STAND

| p RMB Be

| DIAL

#50!)

7f HANDLE |

C |

8 | |

AXIS SCREW | AS >|

38 38 $4 SPRING PIN. | go |

(©5x25)-2 pes | pat | } g

Ix RING As

Fi Rw~ \—R #4 SCREW BARING {(-

‘SOCKET PARALLEL KEY (M6XP1.0x25)-2 pcs }

Xt |

X-AXIS BUSHING ane

i128

POWER TABLE FEED

eae

GEAR COVER

2.0-2. 2 mm

jae NY

ABRS MMI +

MUST HAS BACKLASH MORE THAN 2mm

A ‘

eo LEM AR

1. #440 BRB BA 4B 8 SK (MB XP 1. 25-2pcs) ©

2. DLP MSMR th (MB XP 1. 25X35) BRET REM ESS—) AKRSWAR

ST RBUE

3. HERRHEOREOE: HOASLASEMBH 2 BABE

@ INSTALL THE LIMIT SWITCH (FIG.3)

1. Tighten limit switch unit. (M8 x P1.25 - 2pes)

2.According to the distance required, to set stop block & stop set in position with screw

(M8 XP1.25 x35).

3.Arrange and sort the cable. Be sure to keep the maximum travel distance for worktable

movement.

ik Vr

STOP BLOCK-2 pcs

ee. SS

‘STOP SET-2 pes

K

i

(M8 x P1.25 x35)-2 pes

(M8xP1.25)-2 pes

‘MAG CABLE

Ya-80%(@3EFR (AVAILABLE FOR CROSS TRAVEL)

enim rx

1. RRR LIF PBF SERB FSS \ HTPARRRRAES

2. SPA B BER SB EMMMEXP1.0-3 pcs)» MRRABER -

@PREPARATION

1.Disassembly handle fix nut, handle (hand wheel), parallel socket key and dial from

milling machine.

2.Loosen fix screws (M6 XP1.0-3 pcs) from fix stand. Take out fix stand from axis screw.

eoRKRECSED

1. HEY Oh BE BS #8 BBB PARI

2. PRES EE + LAM AIK 2 BE MR ith(M6 xP1.0-3 pcs) SE ©

3. YMA BE LR EI RAR >

4. HOES ERE LG AB RMB SVMS EB AA MR RHMEXP1O

25-2 pcs)#4 SE ©

@INSTALL THE POWER TABLE FEED (FIG.4)

{Move cross table to the column end.

2.Install Y-axis fix stand, tighten up with fx screws (M6P1.0- 3 pcs).

3.To set Y-axis bushing onto axis screw and push bushing back. i ,

4-To set power table feed at the right position and align with spring spin, set Y-axis bushin

& gently knock in. Surface attach to Y-axis fix stand. Then tighten up with inner hex Socket

screw (M6 XP1.0x25-2 pcs)

OR RAH Mt BRO (DRHBAT DAR 2 EE) °

2. FS“) ABR ED BB (26. 2x O16. 2) EMR + AMFTEAAN. 251 3A

3. EERMZRMOWATT ERM HERES AME BAM (728) -

4. RRS ZaRB HELCSHO RE+ HERKNE wesehea

PORK SL BA DADA) RY2. 0-2. Qnm > SAE LM PVA BM 3 45 gw» ns

VERB E + GAMRR TER AL °

5. BEAM (043. 4x 033, 4) RATER. 251 2H» MELROSE

6. ABR MRA AC BRR (0. 5-0. 75mm) > SANE it BB Pass ow eS 5

SR BAMRRYERAL >

LStS2E > SRRAERBE

8. RLF OS GRRBRSGTRERRA® - LFS) Rt SeRe-

9. BHF RBRESSSURAERARE - UARERSHSZSTE 85

AR 2BMRS SMART RA ER ASM: BAPIBAL -

@ INSTALL THE DRIVING SETS & BACKLASH ADJUSTMENT (FIG.4\FIG.5)

1. Tighten up extension shaft with axis screw. To align with the direction of key way of

extension shaft, drill a through hole «4.0 at the screw, then set into spring pin (4 x 14)

(Ifnecessary, can cut the length of extension shaft)

2.To add shims (©26.2 X ©16.2) onto the axis screw. Itis Suggested to use 0.25t - 3pcs

at beginning.

3.To set parallel key into the key way of extension shaft, align with the key way, to set the

bevel gear (72T).

4.Disassembly the lower gear cover, holding the power table feed Shaft center (refer to

FIG.11), push bevel gear to the end, and check backlash. (FIG.5A), to add few shims

(2.0- 2.2mm) for proper backlash. If it's notin the range, please Tepeat the

procedures step 2, step 3 & step 4 until proper backlash is obtained.

5.To set the shim (43.4 x 33.4). Itis suggested to use 0.25t-2 Pcs, then to set the

dial.

6.To check backlash (0.5 ~ 0.75mm) between dial and surface of power table feed. Ifit's

not in the range, please repeat the procedures step 5 & Step 6 until proper backlash is

obtained.

7.To lock fix ring and dial.

8.To set handle washer < If necessary > / handle (or hand wheel), tighten fix nut.

9.Rotate the handle few times, to check whether itis interfere with Power table feed. Also

check whether the gear rotate smoothly. Ifany noise from gear mash, it shows the

backlash checked in step 4 is not correct. Please repeat the Procedures from step 4 to

step 9 until gear rotating is smoothly.

2A AF 2 BB

‘SMALL SHIM (©26.2x ©16.2)

/ Yi Re

we Y-AXIS EXTENSION SHAFT

SPRING PIN(@4x 14)

17m

// SOCKET PARALLEL KEY(3x3x25)

ie B72)

BEVEL GEAR

S

ROAR BB

LARGE SHIM( 043.4 x 33.4)

sie

AXIS SCREW

Years

Y-AXIS FIX STAND

se sR AK SET SCREW

(M6XP1.0)-3 pes erne

& FIXNUT.

Y-AXIS BUSHING

#R th SCREW

(M6x?1.0%25)-2 pes

381888

POWER TABLE FEED

eSe

GEAR COVER:

_é

AN \

2.0-2.2mm

0.5~0.75mm

Y\ ‘

© BBS ROPE Lt

MUST HAS SAFETY BACKLASH

MORE THAN 2mm

A

ORE HR BS RAT

1 BSSBEERV AGE RES 75 cbt EA MIL BL (MBXP 1. 25 + BLFTRIEZO0m) ©

2. (RUDI DAR (MBXP 1, 25X 15-2pcs) BSB ARA DSO tT IO Osa .

3. FARE C00 Bee vag aS ONIT IS» RIE ISM ZAI ALR MR ONE =

{MRR + ET RTGS MTF (WOXP 1. 0» WFRE 5mm) «

4. HOF 223 5 1798 HR + GRRL SLAR At (WE XP 1. 0X 25-4pcs) BASE ES EAR VERE

(233 72 1098 EBB — AB) .

5, ASR (MB XP 1, 25x30) -2pcsMASERE HH AE MTA GE —) » HB HORS BI

RSCWuilE -

C ERRAE OBESE BOMB TH HZBABA

@INSTALL THE LIMIT SWITCH (FIG.6)

1.On the center position of cross table , to drill 2 holes (M8 x P1.25, tapping depth 20mm).

2.Refer to drawing, tighten limit switch with screw (M8 x P1.25 15-2 pcs), please apply

extra bracket (not supplied ) if necessary.

3.According to travel of cross table, to decide the position of aluminum track, also the height

Of limit switch. To drill 4 holes (M6 X 4P1.0, tapping depth 25mm) on knee.

4.By using screws (M6 x P1.0 25-4 pes), tighten two aluminum tracks onto the knee of

milling machine. (Two aluminum tracks must be aligned to each other)

5.According to the distance Tequired, to set stop block & stop set in position with screws

(M8 x P1.25 x 30-2 pes)

6.Arrange and sort the cable. Be sure to keep the maximum travel distance for cross table

movement.

Yikes = 3] tee

CROSS TABLE| [WORK TABLE

zea ae DN 2 SigaRROA NH

‘apply extra bracket

ipplied) ifnecessary.

eins mes) necessary

ALUMINUM TRACK Rk SCREW

(M8xP1.25 x30) -2 pes

Rms

CABLE 9

$8 4 SCRE

" SCR

(M8XP1.25% 15) -2 pes _ face a) Apes

STOP BLOCK

eae.

‘STOP SET

Zé$- FSF (AVAILABLE FOR KNEE TRAVEL)

one (3 -

ARR ERTES REHM SN RMSE I °

2, POR ABE ZB ERAN WEXP1. 0-3pcs) » TRAGER «

@PREPARATION

1. Disassembly handle fix screws, handle (hand wheel), parallel socket key and dial from

the milling machine.

2.Loosen fix screws (M6 x P1.0-3 pcs) from fix stand, Take out fix stand from axis screw.

1. GZ BEBE Do

2. REMBES : ABM ARF 2B EMH (ME XP |. 0- 3pos) HSE °

3. OZHO SE RAS BPR 20 BISA SEB A ©

4. AGEN SARE ATER IE >» NOIR + LAPTHT(ME XP 1. 0X25-2pcs) 9 Ah BH °

@INSTALL THE POWER TABLE FEED (FIG.7)

1.Move knee to the lowest position.

2.Install Z-axis fix stand, tighten up fix screws (M6 X P1.0- 3 pcs).

3.To set Z-axis extension shaft onto Z-axis screw, until the bearing is pressed.

4.To set power table feed onto extension shaft and close to fix stand. And tighten up with

inner hex socket screws (M6 x P1.0 x 25-2 pes)

OLE SHAtREARMBE

1. ABZRGOR EB (O31. OX O22. 2)B LMR » BIE AI. 2513F ©

2. ERE Rh 2 BPA EATER 4X 4x25) HERR E/ASBR

BB (72) ©

IA RRA ZBRS BESSY ORE+ KERHIE weoeHe

BAR B MEL (BDA RY. 0-2. mmSRB MBP GBM 2 35K

* DOZER BPIMPR ERE ALE

4. BEABRBB (043. 4x 033. 4) > FP ARO. 25t 2A RRBERRA

BR

5. RERRASS RRS 2MRRY (0. 5-0. 75mm) SRELOEA BBB

\ 55+ BARR ERAL >

6. ALGER BRRAEROE

LBLEFSHS BAAACF SHLE RASSHRS LARSR

SHOSLSLR SABUZEMRSRMARSMWZGRALE ABB3-7

SR BFP

8. 2 (<@B/\>B) PT AT AFL, OOPS HE RAG > TELAT AY SR SE BA (OSX 30) HABE =

@ INSTALL THE DRIVING SETS & BACKLASH ADJUSTMENT (FIG.7/ FIG. 8)

1.To add Z shim (31.0 X 22.2) onto extension shaft. Itis suggested to use 0.25t - 3 pcs |

at beginning.

2.To set parallel key (44 X25) into key way of extension shaft, align with the key way, to

set the bevel gear (72T).

3.Disassembly the lower gear cover, holding the power table feed shaft center (refer to

fig. 11), push bevel gear to the end, and check backlash. (FIG. 8A ), to add few shims (2.0

- 2.2mm) for proper backlash. Ifit's not in the range, please repeat the procedures step! |

, step 2 & step 3 until proper backlash is obtained.

4.To set the shim (043.4 x 33.4). Itis suggested that to use 0.25t- 2 pcs, then to set the

dial.

5.To check backlash (0.5 - 0.75mm) between the dial and surface of power table feed Ifit's

not in the range, please repeat procedures step 4 & 5 until the proper backlash is obtained

6.To lock fix ring and dial.

on Rie Rt |

|

|

|

7.To set handle (or hand wheel), tighten the dial. Rotate handle few times, to check whether

itis interfere with power table feed. Also check whether the gear rotate smoothly. If there

any noise from gear mash, it shows the backlash in step 3is not correct. Please repeat the

Procedures from step 3 to step 7 until gear rotating is smoothly.

8.Drill a through hole (5) at position as FIG.8 B, then set with spring pin (5 x 30).

77 SOR DB

JERKS SHIM(O31 x 22.2)

/ ~ Tie BRB (7 208)

Z-AXIS BEVEL GEAR

ARO BB

SHIM (LARGE)(D43.4x 33.4)

RRR A DIAL

oze

FIXRING

eFBHE

CLUTCH

NS ~

26 G Ee

Z-AXIS FIXSTAND

s8tk SCREW is

(Mex t.0}-3 pos oo SPRING PIN(@5x30)

Sipe ~

‘SOCKET PARALLEL KEY(43<4 25) ~~

N

Z-Axis EXTENSION SHAE Sa

SEQ Heres screw

RON (M8xPL.0x25)2908

aaa

GEAR COVER

O22 5 SIR FAD

1. GRO SS BS PET ETE BS HAM FL (MB XP 1. 25» KF RIE2Omm) ©

2. 1h FA Bid OR fh (MBP 1. 25% 15-2pcs) BH SHE DRA RA » 0) $209 88 G47 0B EAR «

LAKECHOARRRIFMOTE REBRZE NIE Bit aus

BBS ZHRSL(MOXP 1.0» RE25mm)

4. AGATA ZS > DUAR AH(MEXP 1. 0X 25-2pcs) SRA REAR LL » BOSE 1 DO

GER>

5. DAMR (EXP 1. 25%30-2pcs) A BIBS L FMEA REE BKECA

BGTRES Ge -

6. RERRAS OSES LS BYR BL eH) 2 BABA

@ INSTALL THE LIMIT SWITCH (FIG. 9)

1.0n the position of knee ( close to column ), drill 2 holes (M 8 x P1.25, tapping depth 20mm).

2. Tighten the limit switch with screw (M 8 x P1.25 x 15-2 pcs).

3.Refer to FIG.9, according to the travel of knee upward & downward, to decide the position

of aluminum track, also the height of limit switch. To drill 4 holes (M 6 x P1.0, tapping depth

25mm) on column.

4.By using screw (M6 x P1.0 x 25-2 pcs), tighten the two aluminum tracks onto the column

of milling machine. (Two aluminum tacks must be aligned), please apply extra bracket (not

supplied ) if necessary.

5.According the distance required, to set the stop block & stop set in position with screw

(M8 x P1.25 x 30 - 2 pes).

6.Arrange and sort cable. Be sure to keep the maximum travel distance for knee movement.

KS AIRES OS

loss apply extra bracket

please apply e 3

EuUtss|

(not supplide )ifnecessary. oLUMN

Ee

KNEE| sR SCREW

(M8 XP1.25 x 15)-2 pes

SRR EST NS

ply extra bracket

(not supplide jif necessary. |

Bah

Rik SCREW STOP BLOCK

(M6xP1.0%25)-4 pes

Ee

STOP SET

ik SCREW:

(waxes 255302908

| XIYIZ 38 FR (AVAILABLE FOR TABLE / CROSS / KNEE TRAVEL)

eR REE

KAMMEEAIIOV 50/O0H2R AB SREBKRLZERAAN CHAO

‘8 AB 28 OB 1 110V 50/60HZ75 OE A >

1, BEIGE 110V 50/60Hz-2 3 Hit MER BD OY ©

KER RARE 2 RMR RK MEOH R ARMORY -

SAT USMERRERAMZL >

le ee or el aa le

@ POWER CONNECTING .

3X This power table feed has AC 110V 50/60Hz circuit. Please be sure input power is

compliance with the power table feed.

\finput power at user's place is not AC 110V 50/60Hz, please prepare the transformer.

1.Just simply connect to 110V 50/60Hz AC power.

>XPlease avoid cable track explore in the circumstance with high temperature, high humidity

or any sharp pieces around.

@1R SSE 5S :

1. SEDPORS ME" EED" » RANSOM O" ZI MS ReAIE"0"

211 °

2. FT BESS RBHRACON) » RASHES" az CaS): SRS IER

3. ELHOPEAA/ASETD RELERGEDRM: SLSERSL

+ EAR RMB DHE ©

@ CHECKING & CONFIRMING

1.Set "jog switch” at "FEED" position, "speed adjust knob” slight away from "0" position

“feed knob" at "0" position.

2.Turn on"ON" switch. Turn "feed knob" to left (or right), to check whether the movement

is at normal status.

3.During worktable travels left / right, press left limit switch button (or right limit switch button)

, to check whether it is stop at normal status, loosen and then repeat the operation.

@{& FBSL88 OPERATION (FIG.10) 1

OD AMM R BRERA

1, BRRBABABIZON + LIROFF ONG SAM SWAT

2. BABA RAH 21S RR NSH EBR SRARBAREREE-

QROKERDTR LRSVAM DMEM BRE RR HT

TEES

@POWER SUPPLY SWITCH AND RESET SWITCH

1. The right side of power switch is "ON". The left side is OFF. The red light will shown when

press "ON".

2.The red round button on right side is "reset switch",

When machine is overload. "reset button" will jump up to cut off the power. The operator

must reduce cutting load, then press "reset switch". The machine can be operated again.

Olé DBR RIB

1, BRRHK’ WHER AMAA AES » SBMS Ai ©

2. PALE Zi ARE ITA DRUM eG) BED ROE

UNE FS RRS (AML A ce

‘@ FEED KNOB AND RAPID BUTTON

1.After power is "ON", turn “feed knob". Turn left for left side feeding,

The butonin the middle is *rapld button"

2.The button in the middle is "rapid button". The tool travel rapidly to left side (right) if kept

pressing the button. The power table feed will back to norma speed when Massie button.

turn right for right side

OR FS 2

LER LTR ARR + BIE DAN ZR eB0 (LL) ~9 (RRR) ©

@ SPEED ADJUST KNOB

1.The speed can be adjusted according to operator's requirement. The speed range is 0 to 9.

(stop to highest speed)

ot R588

1 TE Ref RE REL ZE" FEED" 21 ABET TM NEBOS 7» REI"O" Vt» ROM

MEARESMH WEA AAMCNARZUBRSRM °

@ JOG SWITCH

1.Normally, "jog switch" should be at "FEED" position. For jog movement, just switch to "0"

position. Kept holding the switch, don't release the switch until it travels to the position

required.

FER: PPI SL (ERS » SIS Re HS HEM HERES "0" (OFF) Z fz

Bo Bast RRMA FEED" Ze

Note: To stop jog operating, must turn "FEED KNOB" to "0"

(OFF) position. Then move "JOG SWITCH" to "FEED"

position.

XERU DMMB D SELMA SRMAR SAISASmMBRH

tEe

>XBe sure to follow the procedure required for jog operation. To avoid any damage caused

by the wrong operation.

‘SPEED-ADJUST See ce || _—s}sp8a88

JOG SWITCH

BRS

‘SPEED ADJUST KNOB

_- 80808

FEEDKNOB

—~ RREIRA

RAPID BUTTON

RRR

ON/OFF SWITCH

3 0 SF BE

RESET SWITCH

Cee San)

[ ‘RB 8 ME 1 MAINTENANCE

eaten insnmnsncenensnnncnenncionnenee

OGM MARR:

S45 AT MGRRRS—_RRRSRLORRESLS |! MAGTRAOB

B CHATERDBM >

@MAINTENANCE FOR GEAR LUBRICATION (FIG. 11) . ,

In every 6 months, open the gear cover, and check if lubrication for spiral gear is

Sufficient. Itis suggested to take graphite type lubrication, do not use silicon type

lubrication.

eCSMBRRS:

SRO CRB W107) > BVESLER! SREME ABRAM -

BAS ROK:

1. $7 BB 6S 6 BS od S35 3 BE A AE 9D BARE) ©

2, SRBECH-4038 + GRAPE RSS / WENA (RM RM A/ BMD / FAT

A) OS S/W A OR He B/E AED AL HERA ©

3. FRBRRRASARRARESWREFEO -

RHRRAR SCARAB RR KRAVIS

BBE AIS RAT BAK °

@CHECKING FOR GEAR WEAR OUT (FIG. 11)

To check the gear shape of spiral gear (made of plastic 107T) is wore out. If gear wore

out badly, please replace a new gear. The procedure to replace the gear at follows:

1.Open the gear cover (press the edge of hooks on both sides, and pull down.)

2.Loosen C type ring, sequentially take out washer / Adapter disk set (Occlusion soft set /

Adapter disk) / Pin / abrasive washer / Gear yoke set (spiral gear /Yoke set) / thrust bearing.

3.Disassembly Gear yoke set, replace spiral gear, then install it back by sequentially.

Occlusion soft set and surface of Yoke set must be kept clean, can not attached with oil.

If there are any oil, please clean it by volatile solvent, do not clean by water.

enMBERE -

SLE RTMRMA RERMASCRR SRE Smo RTO BAEK

FASE -

@CHECKING FOR CARBON BRUSH WEAR OUT (FIG. 12)

In every 6 months, open carbon brush cap, to check brush is wore out. If the length of

brush is less than 5mm, the brush must be replace immediately. (2 sets at the front &

back).

SMR BAM

1 08 AE.

GEAR YOKE SET

wm

YOKE SET

RED

MOTOR SHAFT

™ 18 8H

sorRA GEAR FEED SHAFT CENTER

Ib HH

THRUST BEARING

288

TARASINE-RESISTING WASHER

Baie

ADAPTER DISK SET

72e

FLAT WASHER

oes

GEAR COVER

Sm hy aa

ADAPTER DISK

BEE

‘CARBON BRUSH CAP

‘BR

CARBON BRUSH

Fe

NOT LESS THAN 5mm.

rer eer ””—“i‘_O—

eee

38 & (Condition)

4% (Checking)

3458 (Solution)

QRETEDR :

Bue EST HE °

ON/OFF lightis not

ON, power table feed

1. BRERLS RR ?

1. Check the power is not

plugon.

oH HEIDI °

‘eCheck power connecting & plug

2. BHR S Sie BONY

Mme

2.ONIOFF switch at ON position.

og 2 IR BARBIE EON 11

GI GIB 2S)

‘Press the switch to ON position.

(Red light is ON)

ON/OFF lightis ON,

start feed knob, but

power table feed is

is not working. A a a

3. GRRMRSSHES? |PRENIDAZRA Biz

(BbEAR) Taegan BRAD

#6) °

3,Reset switch i jump up. To reduce tool oad, press reset

switch , restart the power table feed.

1. St EBBRSE GE" FEED "GY | oF ie 8S He AHI "0" (OFF) ED

tit? Cre ENON AR WSN FEED"

ee se {iH BSW RDERE ©

Bue » ffB_|4.checkjog switch at*FEED" | @Turn feed knob to "0" OFF position.

SEAS 8 AMDT © position? Jog switch to *FEED" position,

restart the power table feed again.

2. REBERALRSSE'0"

Oe ?

Ong 2S 18 8 IRIS HAR

HARB ALL e

operation, the power

table feed loosing or

sliding.

not working 2.Speed adjust knob at "0" ‘Turn the speed adjust knob clockwise

position? direction until the required speed

achieved.

LFMSSR RAR ES | eR SBE 2 2

OMAEEORERED | Paneer

1.Open gear cover, check the Clutch wore out, to replace yokeset

motor shaft & gear shaft not i

gaenue , niet gear shaft not and occlusion soft set (FIG. 11)

ERATE ° 2 7eeae ‘REGS: |eHASS -(B+-)

After few years

2.Open gear cover and check

whether gear shape is wore

out.

@Replace gear. (FIG. 11)

3. KRAZSCBETR ?

GOH Bonn)

3.Carbon brush wore out.

(Less than 5mm.)

Olle F BBR B

aen. Fal oS

@Open the carbon brush cap and replace

two carbon brushes.

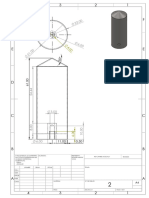

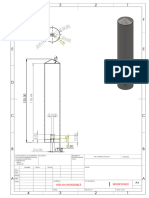

[ook Ya (OUTSIDE DIMENSION)

rs

Gs

MARK-Yi8/706

FOR-Y AXIS/Z AXIS

187.0

Oli HEIL IB BHR (ACCESSORIES & PARTS LIST) _

@ ACCESSORIES SPECIAL FOR X-AXIS a -________

28) OBS E cy) OF 8

X-AXIS FIX STAND NI HANDLE WASHER:

am (7208) 30)

BEVEL GEAR 3. HA -2pes

‘STOP BLOCK

\ »\ e i -,

; \ ore ay $8 sropser™

FIXRING J

\ RR em “@

— TV PAAR HR ALAR AH SOCKET SCREW

9 BR 28 BB(SMALL SHIM) (M8xP1.25 x 35)-2 pes

(26.2X ©16.2X0.251)-6pe8 ~~

)\ Bi 32 BB (SMALL SHIM) nave SOCKET SCREW

& vex2x 16.2X0.1t)-2pcs, pes

eon Se San SPRING PIN

(26.2x ©16.2x1.01)-3pc8 ane

~ 7 fi Pi 82 BB(LARGE SHIM )

(43.4 x ©33.4x0.25t)-4pes #830 CABLE CLAMP.

(1148)-4 pes

@ ACCESSORIES SPECIAL FOR Y-AXIS

6) he RE FS

EXTENSION SHAFT 68) YA 9B EAA -2pes

Y-AXIS BUSHING STOP BLOCK

a

@) FE L482 pes.

/ ‘STOP SET

“$8

‘SOCKET Five i

34) i

“AXIS FIX STAND ftv PF asHer

Behe e (7208)

BEVEL GEAR

orm,

FIX anes

GO ak AUNNUN TRACK

FS soannes ‘SOCKET SCREW

PI.2

\ RBBB M2 BBSMALL SHIM) sawn SEATS

(26.2 ©16.20.25t)-6 pes TY A AL te SOCKET SCREW

SNORE ARKSMALL SHIM) (M8xP1.25 x 16)-2 pos

(©26.2x ©16.2X0.11)-2pes 75 $3 77 t BR tt SOCKET SCREW

“Jf BB(SMALL SHIM) (MOXPIOX 28) pos

(26.2 016.2%1.00}-3pes 305K I SPRING PIN

2° DRAB BBILARGE SHIM) {QAR 0)-1000

(©43.4x 33.4X0.25t)-4 pes BD on CABLE CLAMP

(1/48)-1 pes

@ ACCESSORIES SPECIAL Z-AXIS

moze

Z-AXIS FIX STAND

206 RE FR

GOZBESS suner HetuF pes

we @ ‘STOP BLOCK

8 (249-2908

Ca OH STOP SET

‘SOCKET PARALLEL KEY

BBA (7208)

Se

enn

9

(Y tom ztaxaaine “Na

QnEzar

Q

FES te-2pcs:

ALUMINUM TRACK

7% BAR HARE AR fk SOCKET SCREW

Y (orx 072.2x0.26-4pe¢ H_EPrzsx30)2pes

Jf PR BB(SMALL SHIM) TY SS BCR RARUR BH SOCKET SCREW

(31 x ©222X0.11-2 p08 (MBX P1.25%16)-2 pos

|G PR 8 BB(SMALL SHIM) nN SOCKET SCREW

(©31X ©22.2x1.01)-2 pes Qe ieee

SESE SPRING PIN

(©5x30)-1 pes

#830 CABLE CLAMP

(1148)-1 pos

ASRS e

(643.4% 33.4%0.251)-4 pos

TAT

BUT

38

TECHNICA PARTS) SSS

eet

tae.

ca

sages

sera

‘25

HEE

1

wa fost] em | wx lexis) ee

MODEL | TYPE] VOLTAGE AMPERES] RPM.

i ea

‘APF-500| X.¥.Z |110V50/60Hz| 2.8amp | 155 | 136 | 0-210

APF-750| X.¥.Z |140V 50l60Hz} 3.0amp | 175 | 152 | 0-210

APF-960] X12 |110V50160H2| 34amp | 195 | 170 | 0-180

sta AIR DB)

‘Website : www.t-onemachining. en. alibaba.com

E-mail : joycechen.chp@ble-machiningparts.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Planos 3.0Document22 pagesPlanos 3.0DavidOlivaNo ratings yet

- Planos 4.0Document19 pagesPlanos 4.0DavidOlivaNo ratings yet

- Parametros Centro de Maquinados KITAMURA My Center-4 Fanuc 6MDocument15 pagesParametros Centro de Maquinados KITAMURA My Center-4 Fanuc 6MDavidOliva100% (1)

- Parametros Centro de Maquinados WEBBMATIC VMC5020 Fanuc Series O-MDocument16 pagesParametros Centro de Maquinados WEBBMATIC VMC5020 Fanuc Series O-MDavidOlivaNo ratings yet

- Linear-618 Parts ManualDocument17 pagesLinear-618 Parts ManualDavidOlivaNo ratings yet

- Manual Taladro Radial TITANIUMDocument44 pagesManual Taladro Radial TITANIUMDavidOlivaNo ratings yet

- Manual Sierra Horizontal W.F. WellsDocument43 pagesManual Sierra Horizontal W.F. WellsDavidOlivaNo ratings yet