Professional Documents

Culture Documents

J 1365-2842 2002 00830 X

Uploaded by

Kumar NiwalikarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

J 1365-2842 2002 00830 X

Uploaded by

Kumar NiwalikarCopyright:

Available Formats

Journal of Oral Rehabilitation 2002 29; 263267

An investigation into the transverse and impact strength of `high strength' denture base acrylic resins

D . C . J A G G E R * , R . G . J A G G E R , S . M . A L L E N & A . H A R R I S O N *

*Department of Oral and Dental

Science, Division of Restorative Dentistry (Prosthodontics), Bristol Dental School and Hospital, Bristol and Department of Adult Dental Health, Dental School, University of Wales, Cardiff, UK

SUMMARY

A range of materials, often marketed as high strength resins is available. These materials are often expensive options to conventional heat-cured acrylic resin. The aim of this study was to investigate transverse and impact strength of ve `high strength' acrylic resin denture base materials. A conventional heat-cured acrylic resin was used as a control. Specimens were prepared as specied in the International Standard Organization (ISO 1567: 1988) and British standards for the Testing of Denture Base Resins (BS 2487: 1989) and the British Standard Specication for Orthodontic resins (BS 6747: 1987) for transverse bend and impact testing. The impact strength was measured using a Zwick

pendulum impact tester and the transverse bend strength measured using a Lloyds Instruments testing machine. The results showed that Metrocryl Hi, Luctitone 199 and N.D.S. Hi all had an impact strength which was signicantly higher than the control. For the modulus of rupture, there was a signicant difference between Sledgehammer and the other groups. There was no signicant difference between the other groups and the control. For the modulus of elasticity, Sledgehammer produced the highest value followed by the control. The remaining four materials had a modulus of elasticity less than the control.

Introduction

The material most commonly used in the construction of dentures is poly (methyl methacrylate), however this material it is not without limitations, particularly in terms of exural and impact strength. Attempts to improve the mechanical properties of poly (methyl methacrylate) have taken the researcher through many avenues and the reinforcement of denture base materials has been reviewed (Jagger et al., 1999). Alternative materials to poly (methyl methacrylate) have been introduced only later to be withdrawn (Mutlu et al., 1989). Over the years various types of bres or beads, such as carbon (Bowman & Manley, 1984; Ekstrand et al., 1987), polyethylene (Clarke et al., 1992; Ladizesky et al., 1994), glass (Solnit, 1991; Vallittu, 1996), aramid (Grave et al., 1985; Berrong et al., 1990) and poly (methyl methacrylate) (Jagger & Harrison, 1999; Jagger et al., 2000) have

2002 Blackwell Science Ltd

been added to acrylic resin in an attempt to improve its mechanical properties. Metal inserts in the form of wires, meshes and plates have been incorporated into dentures in an attempt to reinforce areas potentially vulnerable to fracture (Vallittu & Lassila, 1992; Polyzois, 1995). The chemical modication of acrylic resin through the incorporation of rubber in the form of butadiene styrene has been successful in terms of improving the impact strength (Rodford, 1990; Rodford & Braden, 1992). However, the incorporation of rubber has not been entirely successful in that it can have detrimental effects on the modulus of elasticity and hence the rigidity of the denture base. A wide range of materials, often marketed as high strength resins is available. These materials are often expensive options to conventional heat-cured acrylic resin. The aim of this study was to investigate transverse and impact strength of a selection of `high strength'

263

264

D . C . J A G G E R et al.

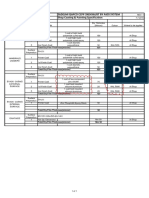

Table 1. Materials used in the investigation together with the manufacturer Material Metrocryl High Luctitone 199 Sledgehammer Enigma Hi-base N.D.S. Hi Trevalon (control) Manufacturer Metrodent, Hudderseld, UK Dentsply, Weybridge, UK Bracon, Etchingham, UK Schottlander, Letchworth, UK Mobildent, St Annes, UK Dentsply, Weybridge, UK Material Metrocryl Hi Luctitone 199 N.D.S. Hi Enigma Hi-base Sledgehammer Trevalon Number of specimens 10 9 10 9 9 10 Mean (kJ m2) 1145 1058 913 773 740 494 s.d. 234 203 103 163 220 329 Table 2. Impact fracture energies (kJ m2) of denture base acrylic resins. Zwick notched Charpy test. Specimens tested in air at 20 2 C

acrylic resin denture base materials. A conventional heat-cured acrylic resin was used as a control.

Materials and method

The materials used in the investigation are presented in Table 1. A series of polymerized blanks was produced by mixing the appropriate amount of polymer with monomer according to the manufacturers' instructions. The mix was allowed to reach the dough stage prior to loading into a gypsum mould in a dental ask. Moulds were prepared by investing master Perspex* blanks in gypsum. Following a trial closure, the plate specimens were cured in a thermostatically controlled water bath for 7 h at 70 C and 3 h at 100 C. The asks were allowed to bench cool before opening. The cured plates were carefully removed from the mould, the excess ash was removed and the specimens nished using a Kemet polishing machine with wet, self-adhesive. waterproof silicon carbide paper discs of 203 mm diameter, 320 and 600 A grit size. Each plate was of sufcient size to be cut into four specimens using a band saw. The specimens were then returned to the polishing machine and carefully nished to the dimensions of 64 10 25 mm for the transverse bend tests and 50 6 4 mm for the impact tests, as specied in the International Standard Organization (ISO 1567: 1988) and British standards for the Testing of Denture Base Resins (BS 2487: 1989) and the British Standard Specication for Orthodontic Resins (BS 6747: 1987). A tolerance of 003 mm was accepted. Ten specimens were prepared for each percentage group and stored in a water bath at 37 2 C until fully saturated. The impact specimens were taken from the water bath and stored in air for 1 h prior to testing.

*ICI, Welwyn Garden City, UK. Kemet, Maidstone, Kent, UK.

A one-way analysis of variance demonstrated that there was a signicant difference between some groups P < 0001. A Scheffe test was performed and the vertical tie bars in the table indicate values, which are not signicantly different between one another.

Impact test For the impact tests on each specimen, a v-notch was cut to a depth of 08 mm leaving an effective depth under the notch of 32 mm. This was carried out with a Zwick notch cutter (Model 5000) and a notch broach 69D. The impact strength was measured using a Zwick pendulum impact tester (Model 5102). Impact tests were undertaken in air at 20 2 C. Transverse bend test The transverse bend test used the three-point loading method (British Standard Specication For Denture Base Polymers 2487: 1989) with a cross-head speed of 5 mm min1. A Lloyds Instruments testing machine (Model L2000R) was used. Specimens were tested in a water bath at 37 C to simulate oral conditions. Moduli of rupture, moduli of elasticity and peak load were recorded.

Results

The results of the impact tests are presented in Table 2 and the results of the transverse bend tests are presented in Tables 35. The results in Tables 35 were subjected to statistical analysis using a one-way analysis of variance and where appropriate the Scheffe test.

Zwick Testing Machines Ltd, Leominster, Hereford, UK. Lloyds Instruments plc, Southampton, UK.

2002 Blackwell Science Ltd, Journal of Oral Rehabilitation 29; 263267

HIGH STRENGTH DENTURE BASE ACRYLIC RESINS

Table 3. Modulus of rupture (MPa). Transverse strength of acrylic resin denture base materials. (Test cross-head speed 5 mm min1, tested in water at 37 C) Number of specimens 10 10 6 10 9 7 Modulus of rupture (mean Mpa) 7735 6291 6174 6144 6144 6166 Table 5. Peak load (N). Transverse strength of acrylic resin denture base materials. (Test cross-head speed 5 mm min1, tested in water at 37 C) Number of specimens 10 10 9 7 6 10 Peak load (N) 6572 5258 5233 5169 5133 5097

265

Material Sledgehammer Trevalon N.D.S. Hi Enigma Hi-base Luctitone 199 Metrocryl Hi

s.d. 449 700 319 450 361 123

Material Sledgehammer Trevalon Luctitone 199 Metrocryl Hi N.D.S. Hi Enigma Hi base

s.d. 467 606 300 110 304 507

A one-way analysis of variance demonstrated that there was a signicant difference between Sledgehammer and the other groups P < 0001. A Scheffe test was performed and the vertical tie bars in the table indicate values, which are not signicantly different between one another.

A one-way analysis of variance demonstrated that there was a signicant difference between Sledgehammer and the other groups P < 0001. A Scheffe test was performed and the vertical tie bars in the table indicate values which are not signicantly different between one another.

Table 4. Modulus of elasticity (MPa). Transverse strength of acrylic resin denture base materials. (Test cross-head speed 5 mm min1, tested in water at 37 C) Number of specimens 10 10 6 10 7 9 Modulus of elasticity (mean MPa) 19995 17370 15283 15082 14891 1465

`high strength' denture base acrylic resins with a conventional heat-cured acrylic resin. Impact test In all the impacts tests, the specimens broke with a sharp fracture. This type of fracture is typical of brittle fracture behaviour characterized by a lack of distortion of the broken parts. Impact energy values satised the requirements of the British Standard Specication for orthodontic resins BS 6747: 1987 although it should be noted that these are auto-polymerizing resins. The results demonstrated that there were signicant differences between some materials. There was no signicant difference between Enigma Hi-base (773 kJ m2) and Sledgehammer** (740 kJ m2) compared with the control (494 kJ m2). The impact fracture energies ranged from 1145 kJ m2 for the highest value recorded for Metrodent Hi to 494 kJ m2 for the conventional heat-cured acrylic resin Trevalon. Metrocryl Hi, Luctitone 199 and N.D.S. Hi had an impact strength which was signicantly higher than the control. An improvement in the impact strength of the `high strength' acrylic resins was expected. This result should be reected in a reduction in the clinical failure of dentures through impact fracture manufactured from

Schottlander, Letchworth, UK. **Bracon, Etchingham, UK. Metrodent, Hudderseld, UK. Dentsply, Weybridge, UK. Mobildent, St Annes, UK.

Material Sledgehammer Trevalon N.D.S. Hi Enigma Hi-base Metrocryl Hi Luctitone 199

s.d. 983 398 921 1401 913 1003

A one-way analysis of variance demonstrated that there was a signicant difference between some groups P < 0001. A Scheffe test was performed and the vertical tie bars in the table indicate values which are not signicantly different between one another.

Discussion

The fracture of acrylic resin dentures remains an unresolved problem and failure is probably because of a multiplicity of factors rather than the intrinsic properties of the denture base material. Various attempts have been made to overcome the problems associated with the fracture of acrylic resin dentures. One approach is the development of denture base materials marketed as high strength in comparison with conventional heat-cured acrylic resin. This study compared the impact and transverse strengths of ve

2002 Blackwell Science Ltd, Journal of Oral Rehabilitation 29; 263267

266

D . C . J A G G E R et al.

these materials. It is not possible to discuss the mechanisms of reinforcement of the individual acrylic resins as most manufacturers of denture base materials are reluctant to reveal the exact constituents of the products, or the mechanisms of reinforcement used. The development of high impact strength denture base acrylic resin and the mechanisms of reinforcement has been discussed in more general terms (Rodford & Braden, 1992). The mechanism of reinforcement described was acrylate terminated butadiene styrene copolymers (Macromers) of relatively low molecular weight and narrow molecular range together with nonacrylate terminated block copolymers. The results of this study are in agreement with Murphy et al. (1982) in an investigation of some mechanical properties of three denture base materials, a conventional heat-cured acrylic resin, a rubber reinforced heat-cured acrylic resin and an injection moulded, rubber-reinforced acrylic resin. They reported a considerable improvement in the impact strength for the rubber-reinforced polymers. However, in contrast, Johnston et al. (1981), in an investigation of the exural fatigue of 10 commonly used denture base acrylic resins which included a `high strength' acrylic resin, reported that the `high impact' acrylic resins as a category did not exhibit superior results compared with other resins. Transverse bend test The transverse (exural strength) of a material is a measure of stiffness and resistance to fracture. Flexural strength tests were undertaken as these were considered relevant to the loading characteristics of a denture base in a clinical situation. A number of studies (Regli & Kydd, 1953; Swoop & Kydd, 1966) have established that dentures in service undergo only small deformations and Ladizesky et al. (1993) reported that exural modulus should be measured at similar small deformations. In addition when deections are small the calculated exural modulus may be regarded as Young's (elastic) modulus of the material. The machine chosen for the tests, the Lloyd's Instrument Materials Testing Machine is routinely used and widely accepted. The tests were carried out according to BS 2487: 1989 such that the results were directly comparable with previous studies. The International Standard Organization (ISO 1567) (1988) and the British Standard specication 1989 (BS 2487) for denture base resins have specied transverse deformation limits which are from 1 to 25 mm for a force of 15 35 N and 25 mm for a force of 1550 N. The average breaking force of acrylic resin should not be less than 55 N. In this respect, only Sledgehammer satised the requirement. There were no signicant differences between the other materials tested. The lowest recorded peak load was for Enigma (5097 N). Stafford et al. (1980) compared the properties of a range of high impact polymers with conventional acrylic resin denture base materials. They demonstrated that some unreinforced conventional acrylic resin materials had a higher fatigue life value compared with the reinforced acrylic resins but demonstrated a large scatter. In the present study, for the modulus of rupture, a one-way analysis of variance demonstrated a signicant difference between Sledgehammer and the other groups. There was no signicant difference between the other groups and the control. An increase in the modulus of elasticity is associated with an increase in the rigidity of the denture base material. Sledgehammer produced the highest value of 1999 MPa, followed by Trevalon. The remaining four materials had a modulus of elasticity less than the conventional heat-cured control. The reduction in the modulus of elasticity may be a reection of the type of reinforcement, for example the incorporation of rubber.

Conclusions

Metrocryl Hi, Luctitone 199 and N.D.S. Hi all had an impact strength which was signicantly higher than the conventional heat-cured acrylic resin control material. For the modulus of rupture, there was a signicant difference between Sledgehammer and the other groups. There was no signicant difference between the other groups and the control. For the modulus of elasticity, Sledgehammer produced the highest value followed by the control. The remaining four materials had a modulus of elasticity less than the control.

References

BERRONG , I.M., WEED , R.M. & YOUNG , J.M. (1990) Fracture resistance of Kevlar-reinforced poly (methyl methacrylate) resin: a preliminary study. International Journal of Prosthodontics, 3, 391. BOWMAN , A.J. & MANLEY , T.R. (1984) The elimination of breakages in upper dentures by reinforcement with carbon bre. British Dental Journal, 156, 87.

2002 Blackwell Science Ltd, Journal of Oral Rehabilitation 29; 263267

HIGH STRENGTH DENTURE BASE ACRYLIC RESINS

BRITISH STANDARD SPECIFICATION FOR DENTURE BASE POLYMERS . BS 2487 (1989) British Standards Institution. London, UK. BRITISH STANDARD SPECIFICATION FOR ORTHODONTIC RESINS . BS 6747 (1987) British Standards Institution. London, UK. CLARKE , D.A., LADIZESKY , N.H. & CHOW , T.W. (1992) Acrylic resins reinforced with highly drawn linear polyethylene woven bres. Construction of upper denture bases. Australian Dental Journal, 37, 394. EKSTRAND , K., RUYTER , I.E. & WELLENDORF , H. (1987) Carbon/ graphite bre reinforced poly (methylmethacrylate): properties under dry and wet conditions. Journal of Biomedical Materials Research, 21, 1065. GRAVE , A.M.H., CHANDLER , H.D. & WOLFAARDT , J.F. (1985) Denture base acrylic reinforced with high modulus bre. Dental Materials, 1, 185. INTERNATIONAL STANDARD ORGANISATION (ISO) 1567 (1988) Specications for Denture Base Polymers. ISO, Geneva, Switzerland. JAGGER , D.C. & HARRISON , A. (1999) The effect of chopped poly (methyl methacrylate) bres on some properties of acrylic resin denture base material. Journal of Oral Rehabilitation, 12, 542. JAGGER , D.C., HARRISON , A. & AL -MARZOUG , K. (2001) The effect of the addition of poly (methyl methacrylate) beads on some properties of acrylic resin. International Journal of Prosthodontics 13, 378. JAGGER , D.C., HARRISON , A. & JANDT , K. (1999) The reinforcement of dentures. A review. Journal of Oral Rehabilitation, 26, 185. JOHNSTON , E.P., NICHOLLAS , J.I. & SMITH , D.E. (1981) Flexure fatigue of 10 commonly used denture bare resins. Journal of Prosthetic Dentistry, 46, 478. LADIZESKY , N.H., CHEN , Y.Y., CHOW , T.W. & WARD , I.M. (1993) Acrylic reinforced with chopped high performance polyethylene bres-properties and denture construction. Dental Materials, 9, 128. LADIZESKY , N.H., CHOW , T.W. & CHENG , Y.Y. (1994) Denture base reinforcement using woven polyethylene ber. International Journal of Prosthodontics, 7, 307. MURPHY , W.M., BATES , J.F., HUGGETT , R. & BRIGHT , R. (1982) A comparative study of three denture base materials. British Dental Journal, 152, 273. MUTLU , G., HARRISON , A. & HUGGETT , R. (1989) A history of denture base materials. Quintessence Dental Technology Yearbook, 145. POLYZOIS , G.L. (1995) Reinforcement of denture acrylic resin. The effect of metal inserts and denture resin type on fracture resistance. European Journal of Prosthodontics and Restorative Dentistry, 3, 275. REGLI , C.P. & KYDD , W.L. (1953) A preliminary study of the lateral deformation of metal base dentures in relation to plastic base dentures. Journal of Prosthetic Dentistry, 3, 326. RODFORD , R.A. (1990) Further development and evaluation of high-impact-strength denture base materials. Journal of Dentistry, 18, 151. RODFORD , R.A. & BRADEN , M. (1992) Further observations on the high impact strength denture base materials. Biomaterials, 13, 726. SOLNIT , G.S. (1991) The effect of methyl methacrylate reinforcement with silane-treated and untreated glass bers. Journal of Prosthetic Dentistry, 66, 310. STAFFORD , G.D., BATES , J.F., HUGGETT , R. & HANDLEY , R.W. (1980) A review of the properties of some denture base polymers. Journal of Dentistry, 8, 292. SWOOP , C.C. & KYDD , W.L. (1966) The effect of cusp form and occlusal surface area on denture base deformation. Journal of Prosthetic Dentistry, 16, 34. VALLITTU , P.K. (1996) Comparison of in vitro fatigue resistance of acrylic resin partial denture reinforced with continuous glass bres or metal wire. Journal of Prosthodontics, 5, 115. VALLITTU , P.K. & LASSILA , V.P. (1992) Effect of metal strengthener's surface roughness on fracture resistance of acrylic denture base material. Journal of Oral Rehabilitation, 19, 385.

Correspondence: Dr D.C. Jagger, Restorative Dentistry, Bristol Dental School, Lower Maudlin Street, Bristol BS1 2LY, UK. E-mail: d.c.jagger@ bris.ac.uk

267

2002 Blackwell Science Ltd, Journal of Oral Rehabilitation 29; 263267

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Gannon - Primary Firm Secant Pile Concrete Specification - April 2016Document11 pagesGannon - Primary Firm Secant Pile Concrete Specification - April 2016muhammad ismailNo ratings yet

- Engineering Data Book-Spirax Sarco (2009) PDFDocument187 pagesEngineering Data Book-Spirax Sarco (2009) PDFVILLANUEVA_DANIEL2064100% (1)

- Chiller Installation InstructionsDocument36 pagesChiller Installation InstructionsIsaias Ramirez100% (1)

- Glass Fibre Reinforced Products PDFDocument16 pagesGlass Fibre Reinforced Products PDFRaghNo ratings yet

- WMS Concrete Repair WorkDocument8 pagesWMS Concrete Repair WorkRepl microsoft, PuneNo ratings yet

- Cladding FixationDocument38 pagesCladding FixationArun Chandra Babu100% (1)

- Technical Manual Schoeck Isokorb (5185) 2016-02-10Document158 pagesTechnical Manual Schoeck Isokorb (5185) 2016-02-10ing urbanNo ratings yet

- YORK YAEP PC145GB (50Hz) - 0304.1126592716Document24 pagesYORK YAEP PC145GB (50Hz) - 0304.1126592716Phúc Tiết75% (16)

- List Din STD For PipeDocument11 pagesList Din STD For PipeybazyariNo ratings yet

- Stonclad GS Stonkote GS4 Guide Spec - en - USDocument8 pagesStonclad GS Stonkote GS4 Guide Spec - en - USAriel MarínNo ratings yet

- Tamcrete CR: Description Technical DataDocument2 pagesTamcrete CR: Description Technical DataCesar MarquesNo ratings yet

- Cswip 3 (1) .1 Bridge Examination QuestionDocument3 pagesCswip 3 (1) .1 Bridge Examination QuestionbassamNo ratings yet

- Structural Steel Design: DR - Mu'taz K.M Ass - Prof. in Civil EngineeringDocument12 pagesStructural Steel Design: DR - Mu'taz K.M Ass - Prof. in Civil EngineeringAhmed Pshtiwan AhmedNo ratings yet

- Column NotesDocument62 pagesColumn NotesAnno AlNo ratings yet

- Rar 803: Architectural Structures Module-1 Analysis and Design of Roof Trusses (Steel) PART-1Document6 pagesRar 803: Architectural Structures Module-1 Analysis and Design of Roof Trusses (Steel) PART-1AshutoshNo ratings yet

- Temporary Refuge - FPSO AccommodationDocument10 pagesTemporary Refuge - FPSO Accommodationcxb07164No ratings yet

- Lubricación Por Modelo PDFDocument3 pagesLubricación Por Modelo PDFMatias Alfredo Contreras KöbrichNo ratings yet

- SEONGWHA NewCatalog (Published On 1408)Document214 pagesSEONGWHA NewCatalog (Published On 1408)Miguel0% (1)

- O Ring GuideDocument4 pagesO Ring GuidesadiqkhattakNo ratings yet

- RS2544 RS2622 RS2644 RS2666 RS2777 Model:: SAMSUNG Home Appliance ServiceDocument66 pagesRS2544 RS2622 RS2644 RS2666 RS2777 Model:: SAMSUNG Home Appliance ServicemarcoantoniopolovillNo ratings yet

- SK95, Such As It Is Commonly Used in Bars, Sheet, Plates, Steel Coils, Steel Pipes, Forged and OtherDocument3 pagesSK95, Such As It Is Commonly Used in Bars, Sheet, Plates, Steel Coils, Steel Pipes, Forged and OtherFortune FireNo ratings yet

- Industrial 2-Electrode Conductivity Cells With Rapid Temperature ResponseDocument8 pagesIndustrial 2-Electrode Conductivity Cells With Rapid Temperature ResponseHernan Humberto Castañeda MendozaNo ratings yet

- SMT Oven No1Document5 pagesSMT Oven No1eduardoquijadaNo ratings yet

- B.Tech. Mechanical Engg. (SEMESTER-VII) : Subject:Tribology (030050715)Document8 pagesB.Tech. Mechanical Engg. (SEMESTER-VII) : Subject:Tribology (030050715)Palak NaikNo ratings yet

- Analytical Studies On Flanged Shearwall Under Lateral Loading Using AnsysDocument17 pagesAnalytical Studies On Flanged Shearwall Under Lateral Loading Using AnsysBajrang GuptaNo ratings yet

- TribologyDocument8 pagesTribologyKamal ChaitanyaNo ratings yet

- Jawalakhel Handicraft Center Pvt. LTD.: Structural Analysis and Design ReportDocument32 pagesJawalakhel Handicraft Center Pvt. LTD.: Structural Analysis and Design ReportSandip BudhathokiNo ratings yet

- Stack Painting SpecsDocument1 pageStack Painting SpecsAmer Y KNo ratings yet

- A2 Historia de Freyssinet ACI CI Octubre 2013 PDFDocument117 pagesA2 Historia de Freyssinet ACI CI Octubre 2013 PDFJancarlo Mendoza MartínezNo ratings yet

- Avantguard Frost and Sullivan Pis 750Document2 pagesAvantguard Frost and Sullivan Pis 750Alberyt099No ratings yet