Professional Documents

Culture Documents

Polysure PP RM30CR

Uploaded by

yansyafOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polysure PP RM30CR

Uploaded by

yansyafCopyright:

Available Formats

Provisional Technical Datasheet

RM30CR Polysure PP Random Copolymer Injection Molding

Product Characteristics:

Polysure RM30CR is a Polypropylene Random Copolymer, produced by latest Spheripol – II Technology &

primarily suitable for Injection Molding & ISBM processes. RM30CR is a clarified grade & contains antistatic agent

to reduce static charge build up on products. This grade offers excellent clarity, superior stiffness, low cycle time

and reduced specific energy consumptions to enhance sustainability.

Recommended Applications:

High clarity containers, Laboratory products, ISBM bottles, TWIM, Medical applications

Typical Properties:

Sr. No. Property Test Method Unit Value*

1 Melt Flow Index (230°C & 2.16 kg) ASTM D1238 g/10 min 30

2 Tensile Strength at Yield, Type I Specimen ASTM D638 MPa 29

3 Tensile Elongation at Yield, Type I Specimen (50 mm / min) % 10

4 Flexural Modulus (1% Secant) ASTM D790A MPa 1000

5 Notched Izod Impact Strength (23°C) ASTM D256A J/m 50

6 Vicat Softening Point (10 N) ASTM D1525 °C 130

7 Heat Deflection Temperature (0.455 MPa) ASTM D648 °C 85

*All the mechanical properties are tested on Injection molded Test Specimen, prepared in accordance with ASTM D4101

Processing Guidelines:

• Barrel Temperature : 190 - 230°C

• Mold Temperature : 30 - 40°C

Storage & Handling:

Bags should be stored in dry & dust free environment at temperature below 50°C and Prevent from direct exposure

to sunlight & heat to avoid quality deterioration.

Regulatory Requirements:

RM30CR to be manufactured complying the requirements specified in IS 10910 on “Specification for

Polypropylene & its Copolymers for safe use in contact with Foodstuff, Pharmaceutical & Drinking water”.

Furthermore, the Additives added in this grade formulation compiles to the “Positive list of constituents for

Polypropylene, Polyethylene and their Copolymers for its safe use in contact with Foodstuffs & Pharmaceuticals'

as laid down under IS 16738:2018. In general, the additives & constituents used in the grade are in line with

requirement laid down under FDA: CFR Title 21,177.1520, Olefin Polymers.

Updated as of May 2021

Disclaimer: The information & data presented herein are typical values & should not be considered as specification and may be used as guideline only. HMEL does not undertake any

responsibility for any outcome or results from the adoption or replication of the above-mentioned data & information there on for possible use for various applications. HMEL reserves the

right to change the information & data without any prior notice or information. The user will solely be responsible for any process/product usage.

HPCL-Mittal Energy Limited (HMEL), INOX Tower, Plot No.17, Sector-16A, Noida – 201301 (U.P), India. Tel: 0120-4634500. Corporate Site: www.hmel.in

You might also like

- Summary - Corporate Finance Beck DeMarzoDocument54 pagesSummary - Corporate Finance Beck DeMarzoAlejandra100% (2)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Polysure PP RB02CRDocument1 pagePolysure PP RB02CRPiyush A JoshiNo ratings yet

- TDS B0155DDocument1 pageTDS B0155DtechnopackishvarlalNo ratings yet

- M12RR PDFDocument1 pageM12RR PDFJordan Rock100% (1)

- Impact Copolymer: For Injection Moulded ProductsDocument1 pageImpact Copolymer: For Injection Moulded ProductsarthymanicNo ratings yet

- Opal - Hdpe - 4Document2 pagesOpal - Hdpe - 4Piyush A JoshiNo ratings yet

- Linear Low Density Polyethylene Injection MoldingDocument2 pagesLinear Low Density Polyethylene Injection MoldingakshayNo ratings yet

- PDS M365Document2 pagesPDS M365prabhunmayNo ratings yet

- High Density Polyethylene Injection MoldingDocument2 pagesHigh Density Polyethylene Injection MoldingQuality teamNo ratings yet

- Polypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- Re H200MKDocument1 pageRe H200MKnisargpatel766No ratings yet

- Polypropylene Homo Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Homo Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- Im B120MADocument1 pageIm B120MAPrashant MalikNo ratings yet

- Ra R120MKDocument1 pageRa R120MKyansyafNo ratings yet

- HD M5306 PDFDocument2 pagesHD M5306 PDFmohamed1303No ratings yet

- F03RRDocument1 pageF03RRPiyush A JoshiNo ratings yet

- P O L Y P R O P Y L E N E: Reliance Industries LimitedDocument1 pageP O L Y P R O P Y L E N E: Reliance Industries LimitedSiddheshNo ratings yet

- Polypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

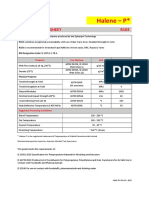

- Halene - P: Technical Data Sheet F103Document1 pageHalene - P: Technical Data Sheet F103Dharmendrasinh ZalaNo ratings yet

- R03RRDocument1 pageR03RRPiyush A JoshiNo ratings yet

- Haldia Petrochemicals PP Packing CoverDocument1 pageHaldia Petrochemicals PP Packing CoverAnand Kumar MunirajuNo ratings yet

- Impact Copolymer: For Injection Moulded ProductsDocument1 pageImpact Copolymer: For Injection Moulded ProductsSanjay SharmaNo ratings yet

- Y35GRDocument1 pageY35GRPiyush A JoshiNo ratings yet

- Polypropylene Random Co Polymer Injection Molding & ISBM: Provisional Technical DatasheetDocument2 pagesPolypropylene Random Co Polymer Injection Molding & ISBM: Provisional Technical DatasheetMohit MohataNo ratings yet

- Polypropylene Impact Co Polymer Injection MoldingDocument2 pagesPolypropylene Impact Co Polymer Injection MoldingMohit MohataNo ratings yet

- Y25GRDocument1 pageY25GRPiyush A JoshiNo ratings yet

- Polypropylene Homo Polymer BOPP Films: Provisional Technical DatasheetDocument2 pagesPolypropylene Homo Polymer BOPP Films: Provisional Technical DatasheetMohit MohataNo ratings yet

- Halene - P: Technical Data Sheet F110Document1 pageHalene - P: Technical Data Sheet F110Dharmendrasinh ZalaNo ratings yet

- 3 Property R3450 EngDocument1 page3 Property R3450 EngMohit MohataNo ratings yet

- Halene - P: Technical Data Sheet B200Document1 pageHalene - P: Technical Data Sheet B200Dharmendrasinh ZalaNo ratings yet

- PP Homo k1111 DatasheetDocument1 pagePP Homo k1111 Datasheethamdany danyNo ratings yet

- Film Grades LL F2001SDocument2 pagesFilm Grades LL F2001SKool LeisureNo ratings yet

- Sé Etec: ApplicationsDocument1 pageSé Etec: ApplicationsMohit MohataNo ratings yet

- b325.b328 Polimaxx 3340HDocument1 pageb325.b328 Polimaxx 3340HdianaNo ratings yet

- 3 Property H7900 EngDocument1 page3 Property H7900 EngMohit MohataNo ratings yet

- Séetec: ApplicationsDocument1 pageSéetec: ApplicationsAdonis BasilioNo ratings yet

- 3 Property H1501 EngDocument1 page3 Property H1501 EngMohit MohataNo ratings yet

- Sabic 37MK10Document2 pagesSabic 37MK10Chu ChuNo ratings yet

- SABIC® HDPE - M200056 - Global - Technical - Data - SheetDocument2 pagesSABIC® HDPE - M200056 - Global - Technical - Data - SheetAhmed Elgazar100% (1)

- Haldia PP Raffia - R103 DatasheetDocument2 pagesHaldia PP Raffia - R103 DatasheetNarender RawatNo ratings yet

- Linear Low Density Polyethylene: Provisional Technical DatasheetDocument2 pagesLinear Low Density Polyethylene: Provisional Technical DatasheetMohit MohataNo ratings yet

- Halene - P: Technical Data Sheet B202SDocument1 pageHalene - P: Technical Data Sheet B202SDharmendrasinh ZalaNo ratings yet

- Halene - H : Technical Data SheetDocument1 pageHalene - H : Technical Data SheetIshah KaziNo ratings yet

- Polypropylene (PP) : DescriptionDocument1 pagePolypropylene (PP) : DescriptionBanupriya BalasubramanianNo ratings yet

- Ube Nylon 5034bDocument1 pageUbe Nylon 5034bDiegoTierradentroNo ratings yet

- Hdpe Me8000 (En)Document1 pageHdpe Me8000 (En)Judith Casstañeda AgurtoNo ratings yet

- UPP TDS EP241N+ (Trial) EnglishDocument1 pageUPP TDS EP241N+ (Trial) EnglishRula SiuNo ratings yet

- F2001ADocument2 pagesF2001APratik GaikwadNo ratings yet

- Polimaxx 1102K Product Data Sheet 1 1Document1 pagePolimaxx 1102K Product Data Sheet 1 1Kaleb Rido ManurungNo ratings yet

- Polimaxx 1102K Product Data Sheet 1 1Document1 pagePolimaxx 1102K Product Data Sheet 1 1Kaleb Rido ManurungNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- H030SGDocument2 pagesH030SGLaxman AhirNo ratings yet

- Ficha Tecnica Polipropileno Moplen Ep300l (J440)Document1 pageFicha Tecnica Polipropileno Moplen Ep300l (J440)Carlos SiuNo ratings yet

- TDS ASTM LM915 Eng 210923Document2 pagesTDS ASTM LM915 Eng 210923PrashaNo ratings yet

- Upp Tds Ep548s EnglishDocument1 pageUpp Tds Ep548s EnglishRula SiuNo ratings yet

- Sabic® Ldpe Hp0322Nn: Low Density PolyethyleneDocument2 pagesSabic® Ldpe Hp0322Nn: Low Density PolyethyleneGabriela Lopez MunozNo ratings yet

- SABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFDocument2 pagesSABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFvishal mehtaNo ratings yet

- Ra R120MKDocument1 pageRa R120MKyansyafNo ratings yet

- AREC LS-US2 DatasheetDocument4 pagesAREC LS-US2 DatasheetyansyafNo ratings yet

- Crystal/Oscillator: PF Epaper Memory LCD TFT OledDocument1 pageCrystal/Oscillator: PF Epaper Memory LCD TFT OledyansyafNo ratings yet

- NVIDIA Intelligent Video Analytics Platform Infographic PosterDocument1 pageNVIDIA Intelligent Video Analytics Platform Infographic PosteryansyafNo ratings yet

- CityPulse IoTWeek2014 Payam PDFDocument13 pagesCityPulse IoTWeek2014 Payam PDFyansyafNo ratings yet

- SENSIT Data Collector Datasheet Nedap v4.1Document2 pagesSENSIT Data Collector Datasheet Nedap v4.1yansyafNo ratings yet

- G 20 Summit 2023Document7 pagesG 20 Summit 2023harshantil74No ratings yet

- Jose C. Guico For Petitioner. Wilfredo Cortez For Private RespondentsDocument5 pagesJose C. Guico For Petitioner. Wilfredo Cortez For Private Respondentsmichelle m. templadoNo ratings yet

- Direct Shear Test ResultDocument7 pagesDirect Shear Test ResultDeepak Kr GuptaNo ratings yet

- Talento Vs Escalada Jr.Document20 pagesTalento Vs Escalada Jr.Terry FordNo ratings yet

- Ag 180ao MMM 000Document294 pagesAg 180ao MMM 000sergey62No ratings yet

- Stacks HWDocument3 pagesStacks HWSarah PachapureNo ratings yet

- Binary-to-BCD Converter: Basic IdeaDocument5 pagesBinary-to-BCD Converter: Basic IdeaNguyễn LongNo ratings yet

- Mysore Master Plan Vol 2Document100 pagesMysore Master Plan Vol 2shahimabdu50% (2)

- Course No: FMPE-358 Course Title: Farm Machinery and Equipment-I Credits: 2 (1+1) Semester:-V TheoryDocument38 pagesCourse No: FMPE-358 Course Title: Farm Machinery and Equipment-I Credits: 2 (1+1) Semester:-V TheoryMrunali GaikwadNo ratings yet

- POV 6 Build For CloudDocument1 pagePOV 6 Build For Cloudsriram tennetiNo ratings yet

- AdvtDocument5 pagesAdvtMohd KazimNo ratings yet

- Rapport Annuel 2020 2021 EnglishDocument29 pagesRapport Annuel 2020 2021 EnglishOusseynou NdiayeNo ratings yet

- HF 40 - EspecificaçõesDocument1 pageHF 40 - EspecificaçõesVenicio AchermanNo ratings yet

- Practice Test 1Document6 pagesPractice Test 1Glenn XyzzyllyzzyxNo ratings yet

- Resume SparkDocument4 pagesResume SparkleninbabusNo ratings yet

- Trial9 Ora 17055 Inform Answer Close Query - TRCDocument76 pagesTrial9 Ora 17055 Inform Answer Close Query - TRCManoj MohapatraNo ratings yet

- Haier Oven ManualDocument206 pagesHaier Oven ManualAmar KonathalaNo ratings yet

- Invoice Template in Excel FormatDocument12 pagesInvoice Template in Excel FormatNirmal GhoshNo ratings yet

- E DLetterDocument4 pagesE DLetterDhruba Kumar SethiNo ratings yet

- List of Cases For Quiz No 4 With DigestDocument11 pagesList of Cases For Quiz No 4 With DigestDawn JessaNo ratings yet

- Banking Financial Institutions - SyllabusDocument8 pagesBanking Financial Institutions - SyllabusLove RosalunaNo ratings yet

- Project Management For Managers My Notes 1Document27 pagesProject Management For Managers My Notes 1DaisyNo ratings yet

- Electrochimica Acta 50 (2005) 4174-4181Document8 pagesElectrochimica Acta 50 (2005) 4174-4181Dulce BaezaNo ratings yet

- CA-Inter Advanced Accounting VOL.3Document156 pagesCA-Inter Advanced Accounting VOL.3salaarbhai2322No ratings yet

- HTML BackgroundsDocument5 pagesHTML Backgroundsrc.david.florendoNo ratings yet

- Coiltools Roll On CT Connector PsDocument3 pagesCoiltools Roll On CT Connector Psoswaldo58No ratings yet

- Republic vs. Valencia CcvcccbjbtyrxcDocument2 pagesRepublic vs. Valencia CcvcccbjbtyrxcMonikka100% (1)

- 64 LawDocument2 pages64 LawJay TiwariNo ratings yet

- Doc. No. - Page No. - Book No. - Series of 2014Document2 pagesDoc. No. - Page No. - Book No. - Series of 2014mgllacunaNo ratings yet