Professional Documents

Culture Documents

MANF386 Labsafety

MANF386 Labsafety

Uploaded by

Jack DanielsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MANF386 Labsafety

MANF386 Labsafety

Uploaded by

Jack DanielsCopyright:

Available Formats

Distributing/conveyor station

1 General requirements for operating the devices

The laboratory or the classroom must be equipped with the following devices:

x An emergency-off device must be provided.

– At least one emergency-off device must be located within, and one outside the laboratory or

the classroom.

x The laboratory or classroom must be secured so that the operating voltage and compressed air supply

cannot be activated by any unauthorised persons, for example by means of:

– A key switch

– A lockable on-off valve

x The laboratory or classroom must be protected by residual current devices (RCDs).

– Type B residual current circuit breakers with a residual current rating of ≤ 30 mA

x The laboratory or classroom must be protected by overcurrent protection devices.

– Fuses or circuit breakers

x The laboratory or classroom must be overseen by a supervisor.

– A supervisor is a qualified electrician or a person who has received appropriate instruction,

has knowledge of the respective safety requirements and safety regulations and

whose training has been documented accordingly.

x No damaged or defective devices may be used.

– Damaged devices must be barred from further use and removed from the laboratory or classroom.

General requirements for safe operation of the devices:

x Do not lay cables over hot surfaces.

– Hot surfaces are identified with a corresponding warning symbol.

x Maximum permissible current loads for cables and devices must not be exceeded.

– Always compare the current ratings of the device, the cable and the fuse.

– In the event that these are not the same, use a separate upstream fuse in order to

provide appropriate overcurrent protection.

x Devices with an earth terminal must always be grounded.

– If an earth connection (green-yellow laboratory socket) is available, it must always be

connected to protective earth. Protective earth must always be connected first (before voltage),

and must always be disconnected last (after voltage).

x If not otherwise specified in the technical data, the device is not equipped with an integrated fuse.

© Festo Didactic 8034662 25

Distributing/conveyor station

2 Pictograms

This document and the hardware described include warnings concerning possible hazards which may arise if

the system is used incorrectly. The following pictograms are used:

Warning

Non-observance of this pictogram may result in serious personal injury or damage

to property.

3 Use for intended purpose

The stations of the Modular Production System may only be used:

x For their intended purpose in teaching and training applications

x When their safety functions are in flawless condition

The stations are designed in accordance with the latest technology as well as recognised safety rules.

However, life and limb of the user and third parties may be endangered, and the components may be

impaired if they are used incorrectly.

The learning system from Festo Didactic has been developed and produced exclusively for training and

continuing vocational education in the field of automation technology. The training company and/or trainers

must ensure that all trainees observe the safety precautions described in this workbook.

Festo Didactic hereby excludes any and all liability for damages suffered by trainees, the training company

and/or any third parties, which occur during use of the equipment sets in situations which serve any

purpose other than training and/or vocational education, unless such damages have been caused by Festo

Didactic due to malicious intent or gross negligence.

26 © Festo Didactic 8034662

Distributing/conveyor station

4 For your safety

4.1 Important information

Fundamental prerequisites for safe use and trouble-free operation of the MPS include knowledge of basic

safety precautions and safety regulations. This manual includes the most important instructions for safe use

of the MPS .

In particular, the safety precautions must be adhered to by all persons who work with the MPS .

Beyond this, all pertinent accident prevention rules and regulations, which are applicable at the respective

location of use, must be adhered to.

4.2 Obligations of the operating company

The operating company undertakes to allow only those persons to work with the MPS who:

x Are familiar with the basic regulations regarding work safety and accident prevention and have been

instructed in the use of the MPS

x Have read and understood the chapter concerning safety and the warnings in this manual

Personnel should be tested at regular intervals for safety-conscious work habits.

4.3 Obligations of the trainees

All persons who have been entrusted to work with the MPS undertake to complete the following steps

before beginning work:

x Read the chapter concerning safety and the warnings in this manual

x Familiarise themselves with the basic regulations regarding work safety and accident prevention

4.4 Dangers associated with the modular production system

The MPS is laid out in accordance with the latest technology, as well as recognised safety rules.

Nevertheless, life and limb of the user and third parties may be endangered, and the machine or other

property may be damaged during its use.

© Festo Didactic 8034662 27

Distributing/conveyor station

The MPS may only be used:

x For its intended purpose

x When its safety functions are in flawless condition

Malfunctions which may impair safety must be eliminated immediately!

4.5 Working safely

General information

x Trainees may only work with the circuits under the supervision of a trainer.

x Electrical devices (e.g. power supply units, compressors and hydraulic power units) may only be

operated in training rooms which are equipped with residual current devices (RCDs).

x Observe the specifications included in the technical data for the individual components, and in

particular all safety instructions!

x Malfunctions which may impair safety must not be generated in the training environment, and must be

eliminated immediately.

x Wear personal protective equipment (safety goggles, safety shoes) when working on circuits.

Mechanical safety

x Switch off the power supply!

– Switch off the working as well as the control power before working on the circuit.

– Only reach into the setup when it’s at a complete standstill.

– Observe possible overruning of the drives.

x Mount all of the components securely onto the slotted profile plate.

x Make sure that limit switches are not actuated from the front.

x Risk of injury during troubleshooting!

Use a tool to actuate the limit switches, for example a screwdriver.

x Set all components up so that activation of switches and disconnectors is not made difficult.

x Follow to the instructions regarding positioning of the components.

28 © Festo Didactic 8034662

Distributing/conveyor station

Electrical safety

x Disconnect from all sources of electrical power!

– Switch off the power supply before working on the circuit.

– Please note that electrical energy may be stored in individual components.

Further information on this issue is available in the data sheets and operating

instructions included with the respective components.

x Use extra-low voltage only: max. 24 V DC.

x Establishing and disconnecting electrical connections

– Electrical connections may only be established in the absence of voltage.

– Electrical connections may only be disconnected in the absence of voltage.

x Maximum permissible current loads for cables and devices must not be exceeded.

– Always compare the current ratings of the device, the cable and the fuse.

– In the event that these are not the same, use a separate upstream fuse in order to

provide appropriate overcurrent protection.

x Use only connecting cables with safety plugs for electrical connections.

x When laying connecting cables, make sure they are not kinked or pinched.

x Do not lay cables over hot surfaces.

– Hot surfaces are identified with a corresponding warning symbol.

x Make sure that connecting cables are not subjected to continuous tensile loads.

x Devices with an earth terminal must always be grounded.

– If an earth connection (green-yellow laboratory socket) is available, it must always be

connected to protective earth. Protective earth must always be connected first (before voltage),

and must always be disconnected last (after voltage).

– Some devices have a high leakage current. These devices must be additionally grounded

with a protective earth conductor.

x The device is not equipped with an integrated fuse unless specified otherwise in the technical data.

x Always pull on the plug when disconnecting connecting cables; never pull the cable.

© Festo Didactic 8034662 29

Distributing/conveyor station

Pneumatic safety

x Depressurise the system!

– Switch off the compressed air supply before working on the circuit.

– Check the system with pressure measuring instruments to make sure that the entire circuit

is pressure-free.

– Please note that energy may be stored in pressure reservoirs.

Further information on this issue is available in the data sheets and operating

instructions included with the respective components.

x Do not exceed the maximum permissible pressure of 600 kPa (6 bar).

x Do not switch on the compressed air until all tubing connections have been completed and secured.

x Do not disconnect tubing while under pressure.

x Do not attempt to connect tubing or push-in connectors with your hands or fingers.

x Risk of injury when switching compressed air on!

Cylinders may advance and retract automatically.

x Risk of accident due to advancing cylinders!

– Always position pneumatic cylinders so that the piston’s working space is unobstructed

over the entire stroke range.

– Make sure that the piston rod cannot collide with any rigid components of the setup.

x Risk of accident due to tubing slipping off!

– Use shortest possible tubing connections.

– In the event that tubing slips off:

Switch off the compressed air supply immediately.

x Pneumatic circuit setup:

Connect the devices with plastic tubing with an outside diameter of 4 or 6 mm. Push the tubing into the

push-in connector as far as it will go.

x Switch off the compressed air supply before dismantling the circuit.

x Dismantling the pneumatic circuit

Press the blue release ring down so that the tubing can be pulled out.

x Noise due to escaping compressed air

– Noise caused by escaping compressed air may damage your hearing. Reduce noise

by using silencers, or wear hearing protection if noise cannot be avoided.

– All of the exhaust ports of the components included in the equipment set are equipped

with silencers. Do not remove these silencers.

30 © Festo Didactic 8034662

You might also like

- Calculation ReferenceDocument220 pagesCalculation Referencekhudhayer1970100% (1)

- ManualDocument202 pagesManualSri Sai100% (1)

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Instron MerlinDocument76 pagesInstron Merlinjsidev100% (4)

- 02 - RelaySimTest AppNote Line Distance Protection 2017 ENUDocument24 pages02 - RelaySimTest AppNote Line Distance Protection 2017 ENUJ100% (1)

- Viavi PSD90 1C Operating ManualDocument44 pagesViavi PSD90 1C Operating ManualJuan RiosNo ratings yet

- PSD90-1C Operation ManualDocument41 pagesPSD90-1C Operation ManualmglemNo ratings yet

- M47-16781-EN RevF - Impact TestingDocument48 pagesM47-16781-EN RevF - Impact TestingIvy LiNo ratings yet

- Instron 5569 Load Frame ManualDocument122 pagesInstron 5569 Load Frame ManualMat HarzickNo ratings yet

- Iso 10012-2Document1 pageIso 10012-2JavierSeimanNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- TP 601MV PDFDocument80 pagesTP 601MV PDFGORDNo ratings yet

- Publication Blum 2018 19 PDFDocument742 pagesPublication Blum 2018 19 PDFNikola TrnavacNo ratings yet

- ISO 27001-2022 Transition BookDocument20 pagesISO 27001-2022 Transition BookzghibNo ratings yet

- TSX07 Manual PDFDocument474 pagesTSX07 Manual PDFHubert Vásquez CuevaNo ratings yet

- ESSENCE TheFace Modeling and TexturingDocument41 pagesESSENCE TheFace Modeling and Texturingcatio0000% (1)

- AEL6 Series Smart Electric Linear Actuators For DN15 To DN100 Control Valves-Installation Maintenance ManualDocument28 pagesAEL6 Series Smart Electric Linear Actuators For DN15 To DN100 Control Valves-Installation Maintenance ManualNguyen Xuan QuangNo ratings yet

- EL5600 Linear ActuatorsDocument28 pagesEL5600 Linear ActuatorsBurthun ReeazeNo ratings yet

- SMP100 Simple Media Platform Manual enDocument143 pagesSMP100 Simple Media Platform Manual enVíctor MayaNo ratings yet

- FX3U 64DP Profibus Master User ManualDocument130 pagesFX3U 64DP Profibus Master User ManualflaviobnNo ratings yet

- XPSMCMCP0802x: Instruction Sheet (Original Language)Document20 pagesXPSMCMCP0802x: Instruction Sheet (Original Language)Said AzaouiNo ratings yet

- TP-502 (E)Document62 pagesTP-502 (E)Koffi Olivier N'kounouNo ratings yet

- Someks Manual GL1000 CompleteOperatorsManual enDocument135 pagesSomeks Manual GL1000 CompleteOperatorsManual endmitriy.astakhovNo ratings yet

- Atv320 Atex Manual en Nve41307 01Document21 pagesAtv320 Atex Manual en Nve41307 01nto_ntoNo ratings yet

- Ppis 9Document5 pagesPpis 9Fadilah Bint AbdulakeemNo ratings yet

- Iitri Manual m26 14150 en - RevaDocument34 pagesIitri Manual m26 14150 en - RevaHajdukNo ratings yet

- Simple Media Platform User Manual v1.05-n en 20150316Document132 pagesSimple Media Platform User Manual v1.05-n en 20150316gianniM0No ratings yet

- Mc236 Shortform Guide V5140 1Document138 pagesMc236 Shortform Guide V5140 1Mosisa DugoNo ratings yet

- Ingersoll Rand System Automation VX Accessory Box Installation ManualDocument12 pagesIngersoll Rand System Automation VX Accessory Box Installation ManualMike DavidNo ratings yet

- Tippingpoint: Eurasian Economic CommissionDocument14 pagesTippingpoint: Eurasian Economic Commissionyony alejandro laraNo ratings yet

- P521 - en M - C63Document503 pagesP521 - en M - C63Rajiv Selvaraj100% (1)

- Truyen Thong Modbus FX3U PDFDocument130 pagesTruyen Thong Modbus FX3U PDFBố TáoNo ratings yet

- MANY0702A.GB - Technical Manual Metacentre DX BoxDocument31 pagesMANY0702A.GB - Technical Manual Metacentre DX Boxmiguel angel vanegas medinaNo ratings yet

- TP 202Document60 pagesTP 202Enker enkerNo ratings yet

- Manual Pendulo de Ensaio de Impacto - S NIP - em InglêsDocument62 pagesManual Pendulo de Ensaio de Impacto - S NIP - em InglêsOsmaire RubimNo ratings yet

- 2 Health and SafetyDocument3 pages2 Health and SafetytonyNo ratings yet

- Instron 5565 Materials Testing Frame M10-14190-EN (RevA) PDFDocument236 pagesInstron 5565 Materials Testing Frame M10-14190-EN (RevA) PDFLuiz VieiraNo ratings yet

- 6800 Single Column Table Model Operator GuideDocument126 pages6800 Single Column Table Model Operator GuideJacob Gutierrez GarciaNo ratings yet

- Acoposinverter X64 Acoposinverter P64New: Migration ManualDocument36 pagesAcoposinverter X64 Acoposinverter P64New: Migration ManualMarekNo ratings yet

- 650V 123 Installation Manual HA467649U002Document101 pages650V 123 Installation Manual HA467649U002vdalsheroqNo ratings yet

- Ha 465492Document170 pagesHa 465492Gabriel Leite Dos SantosNo ratings yet

- p521 en M A83Document522 pagesp521 en M A83psesltd2003No ratings yet

- 3360 Dual Column Table Frames Operator GuideDocument60 pages3360 Dual Column Table Frames Operator GuideMohamed ShabanNo ratings yet

- 690+ Series AC Drive: Frame G, H & JDocument148 pages690+ Series AC Drive: Frame G, H & JDanilo CarvalhoNo ratings yet

- Many0915a.gb X-Iri Operators Manual 80445596 enDocument81 pagesMany0915a.gb X-Iri Operators Manual 80445596 enBen Schumacher100% (1)

- ATV630 Single Phase S7B Application Note en EAV64364 01Document22 pagesATV630 Single Phase S7B Application Note en EAV64364 01unedo parhusipNo ratings yet

- SINAMICS G130 DVDT Filter en-USDocument40 pagesSINAMICS G130 DVDT Filter en-USSergio PastellettoNo ratings yet

- 3340 Single Column Table Frames Operator GuideDocument60 pages3340 Single Column Table Frames Operator GuideMohamed ShabanNo ratings yet

- Bluehill Test Development ManualDocument58 pagesBluehill Test Development ManualNarcisDanielPetreaNo ratings yet

- Instruction Manual: Types 3ah3 and 3ahc Vacuum Circuit Breaker Operator Modules 4.16 KV To 38 KVDocument56 pagesInstruction Manual: Types 3ah3 and 3ahc Vacuum Circuit Breaker Operator Modules 4.16 KV To 38 KVGary MokNo ratings yet

- 42 0410 0828 94517 SnapshotDocument92 pages42 0410 0828 94517 Snapshotgronci5410No ratings yet

- Atv600 Atv900 Atex Manual Nve42416 01Document27 pagesAtv600 Atv900 Atex Manual Nve42416 01Jan KowalskiNo ratings yet

- P521 en M C31Document450 pagesP521 en M C31Sarah BreckenridgeNo ratings yet

- Fronius IG2000Document92 pagesFronius IG2000Jimmy F HernandezNo ratings yet

- 512C ManualDocument37 pages512C Manualcs.makeNo ratings yet

- Operators Guide 598X - M10-16249-EN Rev. EDocument58 pagesOperators Guide 598X - M10-16249-EN Rev. EIvy LiNo ratings yet

- MPR 5000 - Ct-Ctless Personalization Module - Us - SZ Version PDFDocument24 pagesMPR 5000 - Ct-Ctless Personalization Module - Us - SZ Version PDFGon PhamNo ratings yet

- Areva Relay Micom 225 Manual PDFDocument370 pagesAreva Relay Micom 225 Manual PDFk v reddy100% (1)

- HBehJsSb (Knick Safety Instructions)Document100 pagesHBehJsSb (Knick Safety Instructions)junNo ratings yet

- 3600 ServiceDocument250 pages3600 ServiceSean CallowayNo ratings yet

- Product 26304 Management PDFDocument146 pagesProduct 26304 Management PDFCutui MariusNo ratings yet

- Microinverter User Manual: (Model: MI-1000/MI-1200)Document20 pagesMicroinverter User Manual: (Model: MI-1000/MI-1200)Ueslei BarrosoNo ratings yet

- MANY0703A.gb - Technical Manual Metacentre CX BoxDocument62 pagesMANY0703A.gb - Technical Manual Metacentre CX Boxmiguel angel vanegas medinaNo ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- IKO BearingsDocument172 pagesIKO BearingsNathan SheatherNo ratings yet

- Tracking Progress ExerciseDocument4 pagesTracking Progress ExerciseCowly ChinetseuNo ratings yet

- I AM SpecificationsDocument8 pagesI AM SpecificationsLaura VelandiaNo ratings yet

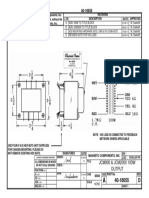

- Transformador JCM900 40-18055Document1 pageTransformador JCM900 40-18055dario_fernNo ratings yet

- Solution Manual of Walter EndersDocument147 pagesSolution Manual of Walter EndersIbrahim Yakubu HaliNo ratings yet

- HLASM R4 Share PresentationDocument20 pagesHLASM R4 Share Presentationgborja8881331No ratings yet

- Attributes Assessing The Quality of Microservices Automatically Decomposed From Monolithic ApplicationsDocument10 pagesAttributes Assessing The Quality of Microservices Automatically Decomposed From Monolithic ApplicationsNelson FabianNo ratings yet

- Gartner Agile EADocument10 pagesGartner Agile EAShahriar khanNo ratings yet

- Comparison of Microprocessor, Microcontroller, Pic and Arm ProcessorsDocument1 pageComparison of Microprocessor, Microcontroller, Pic and Arm ProcessorsSasi BalajiNo ratings yet

- Salinan Dari Personal Trainer CV by SlidesgoDocument56 pagesSalinan Dari Personal Trainer CV by SlidesgoMeitaprima DhaniNo ratings yet

- 2018 Gifts Catalogue PDFDocument263 pages2018 Gifts Catalogue PDFGiovanni RossiNo ratings yet

- ComColor FT5430 LeafletDocument2 pagesComColor FT5430 LeafletBaptiste JamesonNo ratings yet

- Lab 1 - Azure For The Data EngineerDocument5 pagesLab 1 - Azure For The Data EngineerMangesh AbnaveNo ratings yet

- Oracle Applications - Query To Get Payment Method For Supplier and Supplier SitesDocument3 pagesOracle Applications - Query To Get Payment Method For Supplier and Supplier SitesNikhil PatilNo ratings yet

- Sitrans Accessories Modem and SIPROM T For Sitrans TH100/TH200/TR200/TF200/TFDocument48 pagesSitrans Accessories Modem and SIPROM T For Sitrans TH100/TH200/TR200/TF200/TFRoger RiveroNo ratings yet

- Division, Multiplication, Substraction, Decimal, Fraction, GCF and LCM Word Problems and SolutionsDocument5 pagesDivision, Multiplication, Substraction, Decimal, Fraction, GCF and LCM Word Problems and SolutionsYam MuhiNo ratings yet

- Clevo d900k Sager np9750 PDFDocument96 pagesClevo d900k Sager np9750 PDFSelmar CavalcantiNo ratings yet

- SvlogDocument5 pagesSvlogMateus batistaNo ratings yet

- Universiti Teknologi Mara Final Examination: Confidential CS/DEC 2019/CSC580Document5 pagesUniversiti Teknologi Mara Final Examination: Confidential CS/DEC 2019/CSC580ainNo ratings yet

- AX M1 5000VA 24V ManualDocument52 pagesAX M1 5000VA 24V Manualalexandru juncuNo ratings yet

- Software Obsolescence - Complicating The Part and Technology ObsolescenceDocument4 pagesSoftware Obsolescence - Complicating The Part and Technology ObsolescenceSoltan AmelNo ratings yet

- MetNum Thread - Sabrina Aziz Aulia - 4111421048Document3 pagesMetNum Thread - Sabrina Aziz Aulia - 4111421048sabrinaazizauliaNo ratings yet

- The Master and Margarita 2005 TV Series DVDrip Rus With Eng Sub (Download Torrent) - TPBDocument3 pagesThe Master and Margarita 2005 TV Series DVDrip Rus With Eng Sub (Download Torrent) - TPBVictor O. KrausskopfNo ratings yet

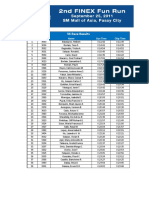

- Finex 2011 ResultDocument50 pagesFinex 2011 ResultConjo BalagnasNo ratings yet

- Ge Fanuc Automation: Powermotion™ ProductsDocument105 pagesGe Fanuc Automation: Powermotion™ ProductsHoang Nam NguyenNo ratings yet

- 06 - CT050-3-2 Web HCI, Web Usability, Page and Site Design - SlidesDocument42 pages06 - CT050-3-2 Web HCI, Web Usability, Page and Site Design - SlidesMOHAMAD FIRDAUS BIN CHE ABDUL RANINo ratings yet