Professional Documents

Culture Documents

Spindle Belt Replacement

Uploaded by

AshCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spindle Belt Replacement

Uploaded by

AshCopyright:

Available Formats

SPINDLE BELTS REPLACEMENT AUTO HI/LOW CHAPTER 3 - MAINTENANCE

If the machine is losing pressure and the oil level keeps dropping, the following

conditions may exist:

• the O-ring that seals the ball screw cross tubes is leaking;

• there is a hole in one of the lines.

3. 7 SPINDLE BELTS REPLACEMENT A UTO HI/LOW

The spindle drive belts are Goodyear 315K10 . Goodyear manufactures the belts to

Fadal specification. When replacing the spindle belts use only the belts from Fadal.

The belts supplied by Fadal are sized.

The following steps are for replacing the belts on the auto HI/LOW spindle.

a. Verify that the VMC is aligned with the cold start indicators.

b. Power off the VMC and lock out the main disconnect.

c. Disconnect the air supply from the VMC.

d. Cut all the wire ties holding the air lines and wires in place.

e. Disconnect the air lines going to the Orientation Arm Cylinder and Drawbar

Cylinder.

f. Remove six each of the 1/4" hex bolts holding the Drawbar Cylinder assembly.

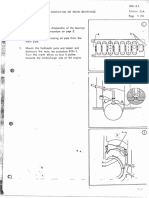

See FIG 3 - 2.

g. Remove the Drawbar Cylinder assembly.

FIG 3-2 REMOVING TOOL OUT CYLINDER

h. Remove three each of the 3/8" socket head cap screws holding the Orientation

Bridge assembly.

i. Remove the Orientation Bridge assembly and front belt guide,

j. Loosen the motor plate cable tensioner completely, if equipped with one.

k. Remove the Core Cover located on the bottom of the head.

1. Remove both of the 1/2" bolts to the rear belt guide, as well as the left 1/2"

Spindle motor bolt.

..\corelvp\typeset\maint94\maint.cnp 3-5 March 1995

CHAPTER 3 - MAINTENANCE MANUAL BELT RANGE CHANGE

m. Swing the spindle motor forward and remove the rear belt guide from the left

side (see FIG 3 - 3).

FIG 3-3 REMOVING REAR BELT GUIDE

n. Remove the 2 spindle drive belts.

o. Replace the 2 spindle drive belts. Reassemble using the previous steps in

reverse order,

p. Adjust the motor plate cable tensioner, if equipped with one.

3.8 MANUAL BELT RANGE CHANGE

a. Verify that the VMC is aligned with the cold start indicators.

b. Power off the VMC and lock out the main disconnect.

c. Disconnect the air supply from the VMC.

d. Remove four each of the 1/4" cap bolts on the Head Cover and remove the Head

Cover

e. Loosen two each of the 1/2" hex bolts to the Spindle motor.

f. Swing the Spindle motor forward.

g. Move the belt to the other position.

h. Mount a Mag base with indicator on the head and touch off the top-front edge of

the spindle pulley,

i. Set zerd while there is NO belt tension, then push back on the Spindle motor

until about .0005" of deflection is seen on the indicator,

j. Tighten two each of the 1/2" hex bolts to the Spindle motor,

k. Verify that the reading has not changed.,v

Note: If the belt tension is TOO tight, then vibration will appear at the tool tip, and a

poor finish may result.

over.

1. Reinstall the Head Cover. •

.

! •

.

March 1995 3-6 ,,V:orelvp\typeset\maint94\maintcnp

SPINDLE BEL T REPLACEMENT MANUAL BEL T DRIVE CHAPTER 3 - MAINTENANCE

3.9 SPINDLE BELT REPLACEMENT MANUAL BELT DRIVE

a. Verify that the VMC is aligned with the cold start indicators.

b. Power off the VMC and lock out the main disconnect.

c. Disconnect the air supply from the VMC.

d. Remove four each of the 1/4" cap bolts on the Head Cover and remove the Head

Cover

e. Disconnect the 1 /4" air lines from the Drawbar Cylinder assembly and the

Orientation Bridge assembly.

f. Remove six each of the 1 /4" hex bolts to the Drawbar Cylinder assembly.

g. Remove the Drawbar Cylinder assembly.

h. Remove three each of the 3/8" cap bolts to the Orientation Bridge assembly.

i. Loosen two each of the 1/2" hex bolts to the Spindle motor.

j. Swing the Spindle motor forward.

k. Remove the Spindle drive belt.

1. Install the new Spindle drive belt.

m. Mount a Mag base with indicator on the head and touch off the top-front edge of

the spindle pulley.

n. Set zero while there is NO belt tension, then push back on the Spindle motor

until about .0005" of deflection is seen on the indicator,

o. Tighten two each of the 1/2" hex bolts to the Spindle motor,

p. Verify that the reading has not changed.

Note: If the belt tension is TOO tight, then vibration will appear at the tool tip, and a

poor finish may result.

q. Reassemble using the previous steps in reverse order.

,.VDorelvp\typese1\maint94\maint.chp 3-7

You might also like

- CGen GY6 50cc Service Manual PDFDocument199 pagesCGen GY6 50cc Service Manual PDFSharkykzn0% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- 1977 Jeep-1977 TSBDocument126 pages1977 Jeep-1977 TSBperzaklieNo ratings yet

- Mazda m4-121g EngineDocument31 pagesMazda m4-121g EngineKevine Khaled89% (9)

- Mazda Fe y f2Document27 pagesMazda Fe y f2Nicolás CastroNo ratings yet

- KA350 Pilot Checklist PN-73 PDFDocument142 pagesKA350 Pilot Checklist PN-73 PDFCarlos Anderez100% (13)

- Epa07 Mbe 900 Workshop Manual (Ddc-Svc-Man-0034)Document155 pagesEpa07 Mbe 900 Workshop Manual (Ddc-Svc-Man-0034)Jose Amador Guardado100% (3)

- Aa80e EngDocument772 pagesAa80e EngMarco MeloncelliNo ratings yet

- Profession Jokes - DoctorsDocument10 pagesProfession Jokes - DoctorssagararlaNo ratings yet

- Toyota Celica GT L4 1.8L 1ZZ FEDocument21 pagesToyota Celica GT L4 1.8L 1ZZ FEWolfgang WilliamsNo ratings yet

- FM 4 Fluid Kinematics CompleteDocument48 pagesFM 4 Fluid Kinematics Completeالياس يونس مرغلانيNo ratings yet

- Aberrant - Core BookDocument292 pagesAberrant - Core BookRodrigo Hky100% (7)

- 2100103-Tilt CylindersDocument17 pages2100103-Tilt CylindersFrancisco DiazNo ratings yet

- Manual Operation XQ114-6BDocument33 pagesManual Operation XQ114-6BrogerNo ratings yet

- Toyota Truck Sienna FWD V6 3.3L 3MZ FE 2005.PDF Versión 1Document12 pagesToyota Truck Sienna FWD V6 3.3L 3MZ FE 2005.PDF Versión 1FranciscoNo ratings yet

- Aronne Armanini (Auth.) - Principles of River Hydraulics-Springer International Publishing (2018)Document230 pagesAronne Armanini (Auth.) - Principles of River Hydraulics-Springer International Publishing (2018)Matija LozicNo ratings yet

- Process Flow ChartDocument4 pagesProcess Flow Chartchacko chiramalNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Install Gear Driven Lower LiftersDocument15 pagesInstall Gear Driven Lower LiftersAnonymous WaC9PaQmr100% (1)

- Band 2 eDocument58 pagesBand 2 eIonaş Claudia Ramona100% (1)

- Starting motor operation and maintenance guideDocument155 pagesStarting motor operation and maintenance guideElzo FreitasNo ratings yet

- Snow Thrower Operator's ManualDocument32 pagesSnow Thrower Operator's ManualDavid Weisenberger100% (1)

- Major Project ReportDocument49 pagesMajor Project ReportMohini BhartiNo ratings yet

- Ensemble Marin OscillantDocument4 pagesEnsemble Marin OscillantRobson CarlosNo ratings yet

- timing-belt-replacement-2008-audi-a4-20tdiDocument2 pagestiming-belt-replacement-2008-audi-a4-20tdiJustinas RackauskasNo ratings yet

- 1953 Lucas Dynamos E3L E3LM E3NDocument7 pages1953 Lucas Dynamos E3L E3LM E3NedelapolloNo ratings yet

- Tilt CylinderDocument7 pagesTilt Cylinderluis tocoraNo ratings yet

- Engine Overhaul: EngineremovalDocument11 pagesEngine Overhaul: EngineremovalRinso PietersmaNo ratings yet

- Hercus 260 Lathe Maintenance ManualDocument24 pagesHercus 260 Lathe Maintenance ManualNewNo ratings yet

- Main Bearing 'B & W'Document5 pagesMain Bearing 'B & W'aliakbar tavafiNo ratings yet

- Reciprocator Compact Single and MultiheadDocument14 pagesReciprocator Compact Single and MultiheadjoecentroneNo ratings yet

- Dixon ZTR 428-429 Technical DataDocument10 pagesDixon ZTR 428-429 Technical DatatecsbrainNo ratings yet

- Ducati 1198-1098-848 Aluminum Servo Plate KitDocument7 pagesDucati 1198-1098-848 Aluminum Servo Plate KitgvenetisNo ratings yet

- Service Manual: VCR Mechanism UnitDocument34 pagesService Manual: VCR Mechanism UnitcobrabrNo ratings yet

- Ford 2.0L 4-Cylinder Timing Belt ReplacementDocument4 pagesFord 2.0L 4-Cylinder Timing Belt ReplacementJuan Carlos Nuñez CastilloNo ratings yet

- 07 1955 CAD-SteeringDocument9 pages07 1955 CAD-SteeringLuis Fernando ZampieriNo ratings yet

- W R H Main Manual PDFDocument14 pagesW R H Main Manual PDFjaikolangaraparambilNo ratings yet

- Instruction Manual G-550: Vertex Standard Co., Ltd. Vertex StandardDocument12 pagesInstruction Manual G-550: Vertex Standard Co., Ltd. Vertex Standardsdelpi5146No ratings yet

- Toyota Truck Highlander 2WD V6-3.0L (1MZ-FE) 2002: Timing Belt: Service and RepairDocument6 pagesToyota Truck Highlander 2WD V6-3.0L (1MZ-FE) 2002: Timing Belt: Service and RepairROSA GIMENEZNo ratings yet

- Removing and Installing Camshafts and Camshaft Adjuster - Cylinder Head (Left Side)Document7 pagesRemoving and Installing Camshafts and Camshaft Adjuster - Cylinder Head (Left Side)Julien VasilevNo ratings yet

- Tiger Heated GripsDocument9 pagesTiger Heated Gripschampion11311No ratings yet

- Engine Disassembly GuideDocument44 pagesEngine Disassembly GuideMoto TOWNo ratings yet

- 1989 Garden Way Tomahawk Chipper Technical Manual WMDocument12 pages1989 Garden Way Tomahawk Chipper Technical Manual WMgodiboNo ratings yet

- KHT5500 Power Tong ManualDocument46 pagesKHT5500 Power Tong ManualSon DDarrellNo ratings yet

- Removal & Installation: Engine Cylinder Head Assembly - Service Information - HR VDocument13 pagesRemoval & Installation: Engine Cylinder Head Assembly - Service Information - HR VkavindaNo ratings yet

- BMW Paddle Instalação e AtivaçãoDocument32 pagesBMW Paddle Instalação e AtivaçãoNicolas MNo ratings yet

- Philips N2213-00-15 SMDocument13 pagesPhilips N2213-00-15 SMFranco DurantNo ratings yet

- BALEROSDocument17 pagesBALEROSjulio cesarNo ratings yet

- Transmission and Torque Converter Hyster H360-620B Repair ManualDocument58 pagesTransmission and Torque Converter Hyster H360-620B Repair ManualArmando OrtaNo ratings yet

- Removing and Installing Camshafts and Camshaft Adjuster - Cylinder Head (Right Side)Document7 pagesRemoving and Installing Camshafts and Camshaft Adjuster - Cylinder Head (Right Side)Julien VasilevNo ratings yet

- DIXO1993 USen 304Document8 pagesDIXO1993 USen 304Per RenlundNo ratings yet

- foxboro_13a_13h_15A_mi(1)Document18 pagesfoxboro_13a_13h_15A_mi(1)Mostshar MoatmnNo ratings yet

- Manual de Instalação WarnerDocument8 pagesManual de Instalação WarnerЭлектроника EletroeletrônicaNo ratings yet

- Toyota Yaris: Instruction ManualDocument21 pagesToyota Yaris: Instruction ManualruswidNo ratings yet

- Camry Solara SLEV6Document13 pagesCamry Solara SLEV6arturmikieNo ratings yet

- Culata Motor 3406Document3 pagesCulata Motor 3406Julio GuillenNo ratings yet

- E-LOCKER Installation ManualDocument17 pagesE-LOCKER Installation ManualpacoramirezdjNo ratings yet

- Toyota Camry LE Sedan V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairDocument14 pagesToyota Camry LE Sedan V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairEutério SilvaNo ratings yet

- A600L Twin Hose ReelDocument19 pagesA600L Twin Hose ReelSusantoNo ratings yet

- TTR125 150BigBore Update2Document4 pagesTTR125 150BigBore Update2eddielindermannNo ratings yet

- Cylinder Repair ProceduresDocument20 pagesCylinder Repair ProceduresMonserrat Hernández SánchezNo ratings yet

- Volvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi Sez.8-9Document35 pagesVolvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi Sez.8-9Luciano LiuzziNo ratings yet

- Bifurcated Fan OM ManualDocument10 pagesBifurcated Fan OM ManualYana AzaharNo ratings yet

- Sci Mop Bombas Espuma Cgp80 - ChemguardDocument13 pagesSci Mop Bombas Espuma Cgp80 - Chemguarddiuska13No ratings yet

- Toyota Truck RAV4 2WD L4-2.0L (1AZ-FE) 2002: Timing Chain: Service and RepairDocument15 pagesToyota Truck RAV4 2WD L4-2.0L (1AZ-FE) 2002: Timing Chain: Service and RepairyosnielNo ratings yet

- Steering Wheel and ColumnDocument28 pagesSteering Wheel and ColumnBenz Aio Calachua AraujoNo ratings yet

- Camry Solara SEV6Document13 pagesCamry Solara SEV6arturmikieNo ratings yet

- 11 1963 CH-ClutchDocument3 pages11 1963 CH-ClutchJose LaproviteraNo ratings yet

- Math10 Q2 Mod24 WritingtheEquationofaCircleandDeterminingtheCenterandRadiusofaCircle V3-1Document19 pagesMath10 Q2 Mod24 WritingtheEquationofaCircleandDeterminingtheCenterandRadiusofaCircle V3-1Bridget SaladagaNo ratings yet

- Sehr I Time 2012 DelhiDocument1 pageSehr I Time 2012 DelhiVaibhav VermaNo ratings yet

- ME 251 Lecture 1Document20 pagesME 251 Lecture 1Seth AnkamahNo ratings yet

- Module 6 PDFDocument10 pagesModule 6 PDFTazbir AntuNo ratings yet

- A 3-Channel Monopulse Tracking Receiver System Using Commercial Off-The-Shelf EquipmentDocument9 pagesA 3-Channel Monopulse Tracking Receiver System Using Commercial Off-The-Shelf EquipmentJean-Hubert DelassaleNo ratings yet

- Four Course Meal Plan and BudgetDocument5 pagesFour Course Meal Plan and BudgetPemphoNo ratings yet

- Bai Tap Tieng Anh Lop 8 Unit 7 Environmental Protection Global SuccessDocument8 pagesBai Tap Tieng Anh Lop 8 Unit 7 Environmental Protection Global Successngtrmm1No ratings yet

- Epidemiology and Etiology of Peptic Ulcer DiseaseDocument5 pagesEpidemiology and Etiology of Peptic Ulcer DiseaseDeepali Mahajan ChaudhariNo ratings yet

- Sentron: Reliable - From ExperienceDocument16 pagesSentron: Reliable - From ExperiencehaydarNo ratings yet

- 1.trijang Rinpoche Bio CompleteDocument265 pages1.trijang Rinpoche Bio CompleteDhamma_Storehouse100% (1)

- Coastal Wall FinalDocument8 pagesCoastal Wall Finalapi-508287240No ratings yet

- The Girls Center: 2023 Workout CalendarDocument17 pagesThe Girls Center: 2023 Workout Calendark4270621No ratings yet

- Topics On Operator InequalitiesDocument29 pagesTopics On Operator Inequalitiesfrigyik100% (1)

- Equity ValuationDocument18 pagesEquity ValuationAbhishek NagpalNo ratings yet

- Lam Sendz MmsDocument8 pagesLam Sendz MmsVíc AltamarNo ratings yet

- Teaching Plan: Objectives Identified Problems/Concerns Activities Evaluation Student Nurse Client/Family MemberDocument5 pagesTeaching Plan: Objectives Identified Problems/Concerns Activities Evaluation Student Nurse Client/Family MemberRaine SarmientoNo ratings yet

- Liquid Gold Petroleum's Performance and SuccessesDocument2 pagesLiquid Gold Petroleum's Performance and SuccessesShubham DawleNo ratings yet

- Cengel FTFS 6e ISM CH 13Document83 pagesCengel FTFS 6e ISM CH 13Duck FernandoNo ratings yet

- Differences Between Circuit Switching and Packet SwitchingDocument7 pagesDifferences Between Circuit Switching and Packet Switchingdebs icapsNo ratings yet

- Swiss ReDocument9 pagesSwiss ReTuxedo1982No ratings yet

- TestDocument3 pagesTestIonescu Cristina-LucianaNo ratings yet