Professional Documents

Culture Documents

400kV Outdoor Metal Oxide Surge Arresters Without Gaps - 1517201 R5

Uploaded by

waqarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

400kV Outdoor Metal Oxide Surge Arresters Without Gaps - 1517201 R5

Uploaded by

waqarCopyright:

Available Formats

400kV Metal Oxide Surge Arresters Without Gaps 1.5.1.7.2.01-Rev.

LIST OF CONTENT FOR METAL OXIDE SURGE ARRESTERS WITHOUT GAPS

INDEX

SECTION TITLE

1. SCOPE

2. APPLICABLE STANDARDS

2.1 International Standards

2.2 DEWA Internal Specifications

2.3 Applicable Regulations/Guidelines

3. DESIGN AND CONSTRUCTION

4. COMPONENTS AND ACCESSORIES

5. OPERATIONAL REQUIREMENTS

6. INSTALLATION AND MAINTENANCE REQUIREMENTS

7. WORKSHOP TESTS

7.1 Type Tests

7.2 Routine Tests

7.3 Factory Acceptance Tests

8. COMMISSIONING REQUIREMENTS AND TESTS

8.1 General

8.2 Pre-commissioning Test Requirements

Annexure-1 Schedule of requirements

Dubai Electricity & Water Authority 1 of 5 All Rights are reserved

400kV Metal Oxide Surge Arresters Without Gaps 1.5.1.7.2.01-Rev.5

1. SCOPE

Para (1) This Specification details the requirements for Metal Oxide Surge Arresters without gaps

for system voltage rating of 400 kV.

2. APPLICABLE STANDARDS

2.1 International Standards

Para (2) Except where modified by this specification, Surge Arresters shall be designed, constructed

and tested in accordance with following International Standards.

IEC 60099-3 Surge Arresters - artificial pollution testing of surge arresters

IEC 60099-4 Metal-oxide surge arresters without gaps for a.c. systems.

IEC 60099-5 Surge Arresters - selection and application recommendations

IEC 60060-1 High Voltage Test Techniques

IEC 60815 Guide for the selection of insulators in respect of polluted

conditions.

IEC62155 Hollow pressurized and unpressurized ceramic and glass

insulators for use in electrical equipment with rated voltages

greater than 1 000 V

IEC 60071 Insulation Coordination

IEC 60270 Partial discharge measurements

ISO 9000 Series of standards

2.2 DEWA Internal Specifications

1.1.0.0.0.01. General Design Criteria

1.2.1.0.0.01. General Technical Requirements for equipment

1.3.1.0.0.01. General Quality Assurance Standards for Electrical Equipment

2.3 Applicable Regulations / Guidelines

Nil

3. DESIGN AND CONSTRUCTION

Para (3) Surge arresters shall be suitable for the maximum system voltage specified and

temporary over voltages due to earth fault of up to 1-second duration. Full protective

margin shall be obtained at a nominal discharge current of up to 20kA. Energy

requirements in kJ/kV shall be sufficient to withstand the high ambient temperatures that

exist at site.

Para (4) Other ratings and technical particulars of the surge arresters shall be as per the schedule

of requirements given in Annexure-1.

Para (5) Values for each particular project shall be confirmed by the corresponding Insulation

Coordination Study subject to DEWA approval.

Para (6) Surge arresters shall be metal oxide type for outdoor installation in air or for installation

inside gas insulated switchgear (GIS).

Para (7) Surge arresters for outdoor installation in air shall be installed in polymeric housing with

hydrophobic characteristics.

Para (8) SF6 insulated, metal enclosed, metal oxide type surge arresters shall be provided for

corresponding GIS feeders as specified. The surge arresters shall be connected to the gas

Dubai Electricity & Water Authority 2 of 5 All Rights are reserved

400kV Metal Oxide Surge Arresters Without Gaps 1.5.1.7.2.01-Rev.5

filled bus duct from the outdoor terminal bushings or transformers and shall be capable to

protect the HV equipment from lightning and switching surges. Further they shall be

designed to prevent any oscillating over-voltages during normal / abnormal switching

conditions.

Para (9) Provision shall be made to relieve the rapid build-up of internal pressure following

prolonged current flow or internal flashover, where applicable.

Para (10) All joints shall be hermetically sealed with material, which will not deteriorate under

service conditions at site.

Para (11) The internal components of arresters shall be arranged to minimize radial voltage stresses

and internal corona. Except where approved by DEWA / Engineer organic materials are

not permitted.

Para (12) Surge arresters shall be fitted with a pressure relief diaphragm that shall prevent

explosive rupturing of the housing in the event of an arrester failure and the arrester shall

have been tested according to the high and low current tests specified in IEC 60099-4.

Para (13) A rating plate in accordance with requirements of IEC 60099 shall identify each arrester.

In addition an identification mark shall be permanently inscribed on each separately

housed unit of a multi-unit arrester so that units can be replaced in the correct position in

the event of them being dismantled.

4. COMPONENTS AND ACCESSORIES

Para (14) Internal components shall be unaffected by atmospheric conditions on site.

Weatherproof housing shall be designed to allow the recording device to be read without

opening of any doors or covers.

Para (15) Surge counters and leakage current indicators shall be provided for all surge arrestors.

Para (16) Surge counters shall be designed to be operated by discharge current passed by the

arrester. Surge counters shall be designed for continuous service and shall be capable of

passing repeatedly, without distress, the maximum discharge current of the arresters.

Para (17) Leakage current indicators shall be mounted in a similar manner to the surge counter and

may be combined with the counter in a common enclosure/housing provided with a

viewing window.

5. OPERATIONAL REQUIREMENTS

Para (18) Nil.

6. INSTALLATION AND MAINTENANCE REQUIREMENTS

Para (19) The surge counter shall be connected in the main earth lead from arrester and bolted link

shall be provided so that the surge counter may be short-circuited and removed without

taking the arrester out of service.

7. WORSHOP TESTS

7.1 Type tests

Dubai Electricity & Water Authority 3 of 5 All Rights are reserved

400kV Metal Oxide Surge Arresters Without Gaps 1.5.1.7.2.01-Rev.5

Para (20) Type test reports for tests performed on identical surge arrester as per IEC 60099-4,

where applicable, shall be submitted.

Para (21) If evidence of successfully carrying out the above tests was not available, the above tests

shall be carried out on one unit in the presence of DEWA/Engineer.

Para (22) For surge arresters installed in polymeric housing the service reliability of polymeric

housing shall be demonstrated by the following type tests:

A. Full scale ageing test

B. Thermal/mechanical tests

C. Tightness test

7.2 Routine Tests

Para (23) Routine tests shall be carried out in accordance with IEC 60099-4 on all surge arresters.

Para (24) Special thermal stability tests on metal oxide element shall be performed in accordance

with IEC 60099-4.

7.3 Factory Acceptance Tests

Para (25) The acceptance tests shall be carried out on the nearest lower whole number to the cube

root of the number of arresters to be supplied. The manufacturer shall submit quality

plans in advance for DEWA’s approval. The acceptance tests shall comprise of the

following:

A. Measurement of power frequency reference voltage on the complete arrester at the

reference current measured at the bottom of the arrester.

B. Measurement of leakage current at Um/√3

C. Partial Discharge tests

D. Visual and dimensional checks on one typical unit.

E. Lightning impulse residual voltage.

8. COMMISSIONING REQUIREMENTS AND TESTS

Para (26) Detailed test procedure covering all the Site Acceptance Tests along with connection

diagrams, acceptance norms, reference standards and details of test instruments shall be

submitted well in advance for approval by DEWA.

8.1 Pre-Commissioning Test Requirements

Para (27) The pre-commissioning tests shall include:

1. Visual inspection

2. Final checks prior to issuance of clearance for energization.

Dubai Electricity & Water Authority 4 of 5 All Rights are reserved

400kV Metal Oxide Surge Arresters Without Gaps 1.5.1.7.2.01-Rev.5

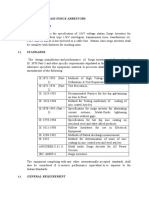

Annexure-1 Schedule of requirements

Sl. Description Unit Requirement

No.

1. Rated system voltage kV 400

2. Rated arrester voltage kV 336

3. Maximum continuous arrester operating voltage kV 264

4. Discharge class 4

5. Nominal discharge current kA 20

6. Temporary over voltage withstand capability

A. For 1s kV 390

B. For 10s kV 370

7.. Maximum residual voltage at

A. Switching impulse

1. 2 kA kV 680

2. 3 kA kV 700

7. B. Lightning impulse (8/20wave)

1. 10 kA kV 780

2. 20 kA kV 850

3. Energy absorbing capability kJ/kV 12.5

4. Insulator creepage distance mm 55mm/kV*

(*Insulator creepage distances shall be

calculated based on highest system voltage)

-oOo-

Dubai Electricity & Water Authority 5 of 5 All Rights are reserved

You might also like

- Cathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesFrom EverandCathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesRating: 4.5 out of 5 stars4.5/5 (5)

- PGCIL GIS Specification - Rev 4 (June-14)Document74 pagesPGCIL GIS Specification - Rev 4 (June-14)Travis Wood100% (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- 220kV GIS Tech Spec - TrackDocument42 pages220kV GIS Tech Spec - Trackaravind_k104100% (1)

- 66kv Lightning ArresterDocument9 pages66kv Lightning ArresterbinodeNo ratings yet

- Offshore Electrical Engineering ManualFrom EverandOffshore Electrical Engineering ManualRating: 4 out of 5 stars4/5 (9)

- 11Kv Voltage Class Surge ArrestorsDocument16 pages11Kv Voltage Class Surge ArrestorsSandip AhireNo ratings yet

- LV PanelDocument9 pagesLV PanelMuhammad Jamil ShahidNo ratings yet

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Hybrid SwitchgearDocument24 pagesHybrid SwitchgearbinodeNo ratings yet

- Ti SPC Ohe Ins 0070 FinalDocument38 pagesTi SPC Ohe Ins 0070 FinalAbhishek Pandey100% (1)

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Technical Spec. of 5 MVA PTRsDocument47 pagesTechnical Spec. of 5 MVA PTRsSubdivn EM-IINo ratings yet

- Technical Specification For Lightning ArrestorsDocument7 pagesTechnical Specification For Lightning ArrestorsAravind Reddy0% (1)

- Technical Spec. of 12.5MVA PTRDocument57 pagesTechnical Spec. of 12.5MVA PTRVilas_123No ratings yet

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- La TSDocument23 pagesLa TSanirban 007No ratings yet

- Eti Ohe 16 - 1 94Document27 pagesEti Ohe 16 - 1 94Abhishek Pandey100% (1)

- Technical Specification For Gas Insulated Metalclad 36kV Switchgear For Indoor ApplicationDocument30 pagesTechnical Specification For Gas Insulated Metalclad 36kV Switchgear For Indoor ApplicationS.M.Touhidur RahmanNo ratings yet

- Pararrayos Product Guide 2004EDocument96 pagesPararrayos Product Guide 2004ECesar RojasNo ratings yet

- 12 SwitchyardErectionRev07Document91 pages12 SwitchyardErectionRev07Rajesh Sirigirisetty SNo ratings yet

- Specification of Lightening ArrestersDocument12 pagesSpecification of Lightening ArrestersS BalasubramaniamNo ratings yet

- 2667 SpecDocument27 pages2667 SpecanuragpugaliaNo ratings yet

- PDFDocument218 pagesPDFRague MiueiNo ratings yet

- 12 TMSS 10Document19 pages12 TMSS 10Fouad AliNo ratings yet

- General Requirements For HV Hybrid SwitchgearDocument16 pagesGeneral Requirements For HV Hybrid SwitchgearSyarif KotoNo ratings yet

- Technical Specification of LT Panel (Switchboard) : To Be Found in The One-Line DiagramDocument13 pagesTechnical Specification of LT Panel (Switchboard) : To Be Found in The One-Line DiagramSharath CherryNo ratings yet

- Cathodic Protection Clarifier Specification-Jun 2010Document7 pagesCathodic Protection Clarifier Specification-Jun 2010656665665No ratings yet

- P 8-96 Disc Porcelain InsulatorsDocument14 pagesP 8-96 Disc Porcelain InsulatorsSyed Oon Haider ZaidiNo ratings yet

- Circuit Breaker SpecificationDocument60 pagesCircuit Breaker SpecificationYash YadavNo ratings yet

- Tech Specification of 33 KV 800amp Isolators With Without EB 17.06.19Document46 pagesTech Specification of 33 KV 800amp Isolators With Without EB 17.06.19SE O&M Circle Wardha WardhaNo ratings yet

- Ehv SubstationDocument91 pagesEhv Substationt_syamprasadNo ratings yet

- Tender Specs ROSOV CH 7 BDocument17 pagesTender Specs ROSOV CH 7 BShakeel AhmedNo ratings yet

- Section-7.1, 33KV GISDocument49 pagesSection-7.1, 33KV GISBRB CABLENo ratings yet

- RMU Simplified Data For Ele BookDocument25 pagesRMU Simplified Data For Ele BookY.Divakara ReddyNo ratings yet

- Specification of 11kv SF6 Insulated Ring Main UnitsDocument8 pagesSpecification of 11kv SF6 Insulated Ring Main UnitsGAGANNo ratings yet

- Msetcl 400 220kv Gis SpecDocument51 pagesMsetcl 400 220kv Gis SpecPrashanth Chandrashekar0% (1)

- 11and-22-Kv - LA 0307 Correctn FinalDocument14 pages11and-22-Kv - LA 0307 Correctn FinalSE O&M Circle Wardha WardhaNo ratings yet

- 400kV XLPE CablesDocument25 pages400kV XLPE CablespijakzkaraibowNo ratings yet

- E16406Document11 pagesE16406HOFFERNo ratings yet

- SEC 32 Outdoor Equipment (Spec)Document28 pagesSEC 32 Outdoor Equipment (Spec)Prasad MenonNo ratings yet

- 33 KV VCBDocument7 pages33 KV VCBMathur Dinesh0% (1)

- Technical Specification: Section-Series Reactor (400 KV CLASS)Document15 pagesTechnical Specification: Section-Series Reactor (400 KV CLASS)byjuvcNo ratings yet

- GD-1 FY Lot-1 2022-23 - Vol - 2 - of - 2 - Lot - 2Document605 pagesGD-1 FY Lot-1 2022-23 - Vol - 2 - of - 2 - Lot - 2Zubab PanniNo ratings yet

- 15Document24 pages15danferreiro8318No ratings yet

- GAS INSULATED SWITCHGEAR - Rev 2Document33 pagesGAS INSULATED SWITCHGEAR - Rev 2Essam AlBannaNo ratings yet

- 15 TMSS 01 R0Document12 pages15 TMSS 01 R0Khaja MoinNo ratings yet

- Section-4-Isolator MettalicsDocument21 pagesSection-4-Isolator Mettalicsthumula.rameshNo ratings yet

- IEE On-Site GuideDocument179 pagesIEE On-Site GuideMahmud Sied100% (5)

- RMU Testing and InspectionDocument3 pagesRMU Testing and Inspectionryan.chxlNo ratings yet

- Product Guide 2015EDocument111 pagesProduct Guide 2015EGerson cuyaNo ratings yet

- Switchyard ErectionDocument56 pagesSwitchyard Erectiondilleh100% (1)

- Gas Insulated SwitchgearDocument33 pagesGas Insulated SwitchgearsudhirguduruNo ratings yet

- Draft Revised ETI OHE 16 (1-94)Document25 pagesDraft Revised ETI OHE 16 (1-94)AQIBNo ratings yet

- Specification ListDocument3 pagesSpecification ListwaqarNo ratings yet

- GIS Specification 170 - 245 KV ELK14 - Rev01 - To CustomerDocument41 pagesGIS Specification 170 - 245 KV ELK14 - Rev01 - To CustomerwaqarNo ratings yet

- RigidBusbarDesign Paper vsIEEEDocument13 pagesRigidBusbarDesign Paper vsIEEEwaqarNo ratings yet

- 33 Specification P 19Document21 pages33 Specification P 19waqarNo ratings yet

- GETCO TECHNICAL SPECIFICATION OF 132, 220 & 400 KV IsolatorsDocument34 pagesGETCO TECHNICAL SPECIFICATION OF 132, 220 & 400 KV IsolatorswaqarNo ratings yet

- 32 Specification P 82 81Document22 pages32 Specification P 82 81waqarNo ratings yet

- Calculation of Cable Tray SizeDocument4 pagesCalculation of Cable Tray SizewaqarNo ratings yet

- List of Top Pakistani RecruitersDocument4 pagesList of Top Pakistani RecruiterswaqarNo ratings yet

- Compound Rates On Special Savings Certificates R 1 3Document11 pagesCompound Rates On Special Savings Certificates R 1 3waqarNo ratings yet

- Payment Schedule Jan 2023Document1 pagePayment Schedule Jan 2023waqarNo ratings yet

- Detailed Notes: "Power System Protection"Document48 pagesDetailed Notes: "Power System Protection"waqarNo ratings yet

- WAPDA Book of Financial Powers (May 2016)Document113 pagesWAPDA Book of Financial Powers (May 2016)waqar67% (3)

- Section 2 - Bid Data Sheet 2-3R2Document1 pageSection 2 - Bid Data Sheet 2-3R2waqarNo ratings yet

- Indian Telegraph Act 1885Document13 pagesIndian Telegraph Act 1885waqarNo ratings yet

- List of Malaysian Standards Prepared by MCMA SWO PDFDocument7 pagesList of Malaysian Standards Prepared by MCMA SWO PDFfisplNo ratings yet

- Digsilent Powerfactory: Technical Reference DocumentationDocument23 pagesDigsilent Powerfactory: Technical Reference DocumentationDong BachNo ratings yet

- Operation Manual JOAN LABDocument2 pagesOperation Manual JOAN LABDoménica Feijoó ChávezNo ratings yet

- Cable Splicing - Part 1: Edition IIDocument0 pagesCable Splicing - Part 1: Edition IISalman FaisalNo ratings yet

- Root Cause Analysis: Maintenance Standard ReportDocument4 pagesRoot Cause Analysis: Maintenance Standard ReportShahNo ratings yet

- Manual de Usuario Er-350ii (Nos)Document111 pagesManual de Usuario Er-350ii (Nos)W Fabricio Hernandez R100% (2)

- Surge Arrester Buyers Guide Ed5 (English) PDFDocument96 pagesSurge Arrester Buyers Guide Ed5 (English) PDFraj sekharNo ratings yet

- 3M Terminal Lugs 5637k.multimedia PDFDocument10 pages3M Terminal Lugs 5637k.multimedia PDFElsan BalucanNo ratings yet

- Installation Instructions Product-Ident: 75168: Doorboards With Soundsystem, BMW 8 Series E31Document10 pagesInstallation Instructions Product-Ident: 75168: Doorboards With Soundsystem, BMW 8 Series E31post8713No ratings yet

- Overhead Power Line Manual 111Document58 pagesOverhead Power Line Manual 111rameez_zafar6138100% (11)

- Teraohmxa 10 KV: Instruction ManualDocument60 pagesTeraohmxa 10 KV: Instruction Manualbona INSTtechnicianNo ratings yet

- Sam4s ER-380 Service ManualDocument110 pagesSam4s ER-380 Service Manualsupport-43No ratings yet

- Philips 32pfl3504d-f7 Chassis Fl9.1Document105 pagesPhilips 32pfl3504d-f7 Chassis Fl9.1Big DustyNo ratings yet

- Hydropower Engineering II Blue PrintDocument22 pagesHydropower Engineering II Blue Printgirtufa60No ratings yet

- TECO AESV AESU AESV LA Series Squirrel Cage Induction MotorDocument32 pagesTECO AESV AESU AESV LA Series Squirrel Cage Induction MotorNeo Dinastian OnssalisNo ratings yet

- Dry Gis and Transformer TerminationsDocument2 pagesDry Gis and Transformer TerminationssalvgranNo ratings yet

- Phoenix Contact 3211757 enDocument7 pagesPhoenix Contact 3211757 enDGNo ratings yet

- TM - A5msy - BR PDFDocument66 pagesTM - A5msy - BR PDFEddieNo ratings yet

- ESD ConsiderationsDocument9 pagesESD Considerationskwangjin1980No ratings yet

- Breaker Technical InspectionDocument3 pagesBreaker Technical InspectionLee Anthony SigaNo ratings yet

- Specification For Testing & CommissioningDocument7 pagesSpecification For Testing & CommissioningEric TaylorNo ratings yet

- Evaluation The High Voltage Gas Insulated Substations (GIS) Based On Flashovers in The 220 KV SwitchgearsDocument8 pagesEvaluation The High Voltage Gas Insulated Substations (GIS) Based On Flashovers in The 220 KV SwitchgearsAjay SantiNo ratings yet

- MV Cable IEC STDDocument2 pagesMV Cable IEC STDrt1973No ratings yet

- Surface Potential Decay of Low Density PolyethylenDocument6 pagesSurface Potential Decay of Low Density Polyethylenlabiod sihamNo ratings yet

- Application Charges EodbDocument78 pagesApplication Charges Eodbgurumurthy38No ratings yet

- Philippine Electronics Code - Volume 1 - IdentificationDocument4 pagesPhilippine Electronics Code - Volume 1 - IdentificationDonovan Paul Uy DoroinNo ratings yet

- Technical Spesification of MV Sectionalizer 33 KV: Ministry of Electricity Planning and Studies Office Baghdad - IraqDocument9 pagesTechnical Spesification of MV Sectionalizer 33 KV: Ministry of Electricity Planning and Studies Office Baghdad - IraqAhmed JaNo ratings yet

- Don Reed3-25070-H2 - WS58 Answers May11Document7 pagesDon Reed3-25070-H2 - WS58 Answers May11ThanThansccNo ratings yet

- 7ffce454-d793-424b-9f46-77c86e39d033Document40 pages7ffce454-d793-424b-9f46-77c86e39d033adst34No ratings yet

- Pe Oscr PVC-FRDocument3 pagesPe Oscr PVC-FRJeyhan M DonavistaNo ratings yet