Professional Documents

Culture Documents

Ameri-King AK-950R Installation/Operation Manual

Ameri-King AK-950R Installation/Operation Manual

Uploaded by

Minivation100%(1)100% found this document useful (1 vote)

159 views18 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

159 views18 pagesAmeri-King AK-950R Installation/Operation Manual

Ameri-King AK-950R Installation/Operation Manual

Uploaded by

MinivationCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 18

Document No.: IM-950

INSTALLATION & OPERATION MANUAL

for

P/N AK-950R- ()

REMOTE RELAY ASSEMBLY

Per TSO-C129a, RTCA DO-208 and DO-160¢ Requirements

AMERI - KING CORPORATION

17881 Sampson Lane

Huntington Beach, CA 92648

Tel: (714) 842-8555

Fax: (714) 842-4235

Email: sales@ameri-king.com

Website: www.ameri-king.com

20

2.2

2.24

2.2.2

2.2.3

2.2.4

2.2.8

23

24

244

24.2

INSTALLATION AND OPERATION MANUAL, MODEL AK.060

‘OP6 / NAV SWITCHING & ANNUNCIATOR PANEL

‘TABLE OF CONTENTS

Table of Contents

Technical Characteristics

Interface

Equipment

Major Components ....

Accessories supplied

eaavave

SECTION It

INSTALLATION AND TEST

Unpacking and Inspecting Equipment

Mechanical Installation

Equipment Location

Cooling... :

Additional Annunciations

Additional Relays...

Routing of Cables

10

Electrical Installation n

Post InsteleGoni lest) cece te ttm (06)

Pre Installation Tests... 15

Operating Instructions... 15

34

3.2

44

42

43

INSTALLATION AND OPERATION MANUAL. MODEL AK.960

‘OPS / NAV SWITCHING & ANMUNCIATOR PANEL

‘TABLE OF CONTENTS (CONT'D)

SECTION I

OPERATION

General 16

Operation .. 16

SECTION IV

WARRANTY AND SERVICE

Limited Warranty .... 7

Repair Service : 19

Factory Comprehensive Test Service 19

LIST OF FIGURES

Outline Drawing esses 4

Schematic Pinout for Connector .. 12

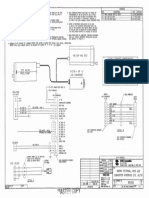

Electrical Schematic Diagram . 14

‘APPENDIX A

Environmental Qualification form RTCA / D0160C

ai

12

INSTALLATION AND OPERATION MANUAL, MUDEL AKU

(GPS | NAV SWITCHING & ANMUNCIATOR PANEL

SECTION 1

GENERAL INFORMATION

SCOPE

This manual contains information necessary for the

installation, test. and operation of the model AK-950R,

Remote Relay Assembly, for GPS / NAV Switching,

manufactured by Ameri - King Corporation, California, U.S.A.

DESCRIPTION

The Ameri-King AK-950-R is a FAA TSO'd approved Remote

Relay Assembly. It is designed to provide Switching Function,

for HSI / CDI Data Inputs, between NAV {VOR) Receiver and

the Approached certified GPS Receiver.

‘The Assembly consisted of 24 Poles built-in Relays to simplify

installation of the Switching Function, All Relays have Gold

plated Contacts and are Nitrogen filled for high Reliability

‘The AK-950-R consisted of 2 Sub-groups of A and B.

‘Sub-group A includes 20 Poles Switching; a Failure Detection

Pole built in; and an ILS Auto Override (to reverse to NC (NAV)

position upon ILS Frequency is tuned in}.

‘Sub-group B includes 2 Poles Switching,

Each Sub-group is controlled independently.

Protection includes Input Power Reverse Polarity, Power

Transient. All Relay Coils are protected against EMI and

Transient Switching.

Refer to figure 1-1 for Outline Drawing for all Series for all

Models’ Remote Relay Assembly.

WNSIALLAIIUN ANU UPEHATIUN MANUAL, MUUEL AR sou

‘OPS | NAV SWITCHING & ANNUNCIATOR PANEL

FIGURE 1

OVERALL DIMENSIONS

(OUTLINE ORAWING

AK-9508 7

Remote Relay Assembly:

INSTALLATION AND OPERATION MANUAL, MODEL AK.960 INSTALLATION AND OPERATION MANUAL, MODEL AK.960

Crs nav awrronna & ARMCITOR Pant ‘ore NAV SHTTCHING 8 ANMUNCIATOR PAREL

1.3. TECHNICAL CHARACTERISTICS ENVIRONMENTAL TEST SPECIFICATIONS:

SPECIFICATIONS: SHARACTERISTICS: * RICA DO-208 ANDI

SO COMPLIANCE: 180 - ¢128a * RTCA DO-160C ENV. CAT.: C1AC/XXXSKXXSXXXXBXB,

PHYSICAL CHARACTERISTICS: ‘+ TEMP. AND ALTITUDE: Category A2 & D1

* MOUNTING size Rack Mounted, Low Temperature -20 deg. C Operating:

‘AND WEIGHT: 2.7°W x 3.30°L x 1.25°H -8B deg. C.Storagi

0.2 tbs High Temperature: +70 deg. © Operating:

+85 deg. C Stor

ett tated + TEMP. VARIATION: Category C

+ powER INPUT: (10.0 - 32.2) vee 2.deg. C minimum per minute

* HuMurTy: Category A

95% RH, 50 hours operating

* RELAY TyP%

~ No. of available Poles: 24 Poles, Double throws * sHock: 6G, 11 +/ 2 msec, operational

~ Switching Current / 18G, 11 +/2 msec, crash safety

Voltage 2 Amp / 220 Vade maximum * VIBRATION: Coes Mana

~ Carrying Current / .

Voltage: 2 Amp / 220 Vde maximum MAGNETIC EFFECT: Category A

= Contact Resistance: 60 mill - ohm max Less then 0.3 m

~ Contact Material: Gold overlay * POWER INPUT: Category 8

= Switching Tim (1 = 2) mill - seconds Normal Operating: (10.0 - 16.1) Vde

+ Insulation Resistance: 1,000 mega - ohm @ 500 Vde (20.0- 30.3) vae

= Life Expectancy: 100 milion mechanical operations ‘Abnormal Operating:(11,0 -16.1) Vde

.2 milion electrical operations @30V: (22.0 - 32.2) Vae

~ Coil Resistance 2880 Ohm @ 24 Vas; 7

1028 Ohm @ 12 Vac. VOLTAGE SPIKE: Category B

* AUDIO EREO. CONDUCTED

‘SUSCEPTIBILITY: Category 8

* INDUCED sIGNA\

‘SUSCEPTIBILITY: Category A

* RE SUSCEPTIBILITY: Category T

* EMISSION OF RF ENERGY: Category A.

6

INSTALLATION AND OPERATION MANUAL, MODEL AK.060

(OPS | WAV SWITCHING & ANNUNCIATOR PANEL

14 INTERFACE 1s

1.4.1 INTERFACE FOR MODEL AK-950R - ( ):

+14/28 voc: Receives + 14/28 Vdc Input Power.

(Pin 78)

RELAY COIL (-ve)

{SUB GROUP A)

(Poles #1 thru #20)

Recei

95 DC Power Ground.

6 a ground logic input

for Sub Group A Relays

(Poles #1 thru #20)

(Pin 62) (Alternate Ground Input)

(NAV @ N.C. Position) / (GPS @ N.O. Pos

RELAY FAILURE Provides a ground logic output,

DETECTION (N.C.) all Relay Contacts, of

(Poles #1 thru #20) Relay Poles #1 thru #20,

(Pin 67) are in N.C. (NAV) Positions

(Alternate Ground Output)

16

RELAY FAILURE Provides a ground logic output,

DETECTION (N.O.) to verify all Relay Contacts, of

(Poles #1 thru #20) Relay Poles #1 thru #20,

(Pin 71) are in N.O. (GPS) Positions

(Alternate Ground Output) WwW

174

IAV Recei Receives an ILS ground logic input

ILS ENERGIZE: from the NAV receiver. In

(Pin 63) this configuration, all the Relay Poles

(ILS Auto 41 thru #20, will reverse to N.C, (NAV) mode,

Override) regardless Sub Group A Coil (-vel position.

‘The Sub Group A Relays are de-energized

automatically,

RELAY COIL (-ve} Receives a ground logic input

{SUB GROUP B) for Sub Group B Relays

(Poles #21 and #22) (Poles #21 and #22)

(Pin 7)

(Alternate Ground Input)

INAV @ N.C. Position) (GPS @ N.O. Position)

Page 7

INSTALLATION AND OPERATION MANUAL, MODEL AK-#60

(OPS | NAV SWITCHING & ANMUNCIATOR PANEL

EQUIPMENT LIMITATIONS

‘The AK-95OR series Relay Assembly contains specific dash

numbers, to be used with various Number of Poles. The

installer must ensure, the correct number of poles required, for

the GPS receiver Interface Requirement.

The condition and tests required for TSO approval of this

article are minimum performance standards. It is the

responsibility of those desiring to install this article either on

or within a specific type or class of aircraft to determine that

the aircraft installation conditions are within the TSO standards.

‘The article may be installed only if further evaluation by the

applicant documents an acceptable installation and is approved

by the Administrator.

NOTE: Anytime the AK-95OR is disconnected or removed from

the aircraft, the HSI / CDI will be inoperative in both NAV (VOR)

and GPS.

MAJOR COMPONENTS.

‘The system is comprised of one major component, the

‘AK-950R, Remote Relay Assembly.

ACCESSORIES SUPPLIED

INSTALLATION KIT:

PART NO. DESCRIPTION

9500001 P1, Mating Connector Kit.

High Density D Subminiature Conn.

Plug, 78 Female Crimped Pins, with

Backshell and Thumbscrews.

PIN 162X11989X & FK22SLOS

Conec Corporation)

P/N ODD78F00000 & FC8122D

(Positronic Industry Inc.)

9500002 Optional Pre-fabricated Cable Assembly

with MIL-SPEC shielded Cable, including:

MIL-W-22759/18-24-9

M27500-1-24-TG-2-T-14

M27500-1-24-1G-3-7-14

Page 8

STALLATION AND OPERATION MAMUAL, MODEL AX-200

(O78 RAV SWTTCHNEG & ANMUNCIATOR PANEL

Type of Mating Connector:

24

Hi Density D-Subminiature Connector,

78 Female Sockets Plug.

Information for Crimping Tool.

1. Hand Crimping Tool:

2. Positioner:

3. Extract/Removal Tool:

4. Vendor Sources:

M22520/2-01

Daniel P/N AFMA

Positronics P/N 9507-0-0-0

22

M22520/2-06

Daniel P/N K41

Positronics P/N 9502-3.0-0

2241

M81969/1-04

Daniel P/N 91067-1

Positronics P/N 91067-1

Daniel Manufacturing Inc.

6103 Anno ave.

Orlando, FL 32809

Tel (407) 855-6161

Fax (407) 855-6884

222

INSTALLATION AND OPERATION MANUAL, MODEL AK-960

(OPS | NAV SWITCHING & ANMUNCIATOR PANEL

SECTION It

INSTALLATION AND TEST

UNPACKING AND INSPECTING EQUIPMENT

Extreme care when unpacking the equipment. Visual inspection

of the equipment for evidence of damage incurred during

shipment. Any claim should be promtly filed with the

transportation company. Save the shippit

subtantiate the claim. Retain the container and packaging

‘material for possible future use.

MECHANICAL INSTALLATION

The AK-950R is designed with the installer in mind. All

accessories which are required for completing system

installation are provided, including Optional Pre-fabricated

Wiring Cable Assembly.

EQUIPMt 1

‘The preferable location for AK-950R is near the HSI / CDI that

will be displaying the FPS information, or Radio Equipment

Rack. The unit depth, with connector attached, must also be

taken into consideration.

‘Avoid mounting close to heater vents or other high heat

sources.

Secure the AK-95OR in place with four 4-40 x 3/8 to 1.0" flat

head philips screws.

COOLING

No direct cooling is required. As with any electronic

equipment, overall reliability may be increased if the AK-960R.

is not located near any high heat source or crowded next to

other equipment. Means of providing a gentle air flow will be

a plus.

10

223

224

225

23

INSTALLATION AND OPERATION MANUAL. MODEL AK.960

‘OPS / NAV SWITCHING & ANMUNCIATOR PANEL

ADDITIONAL ANNUNCIATIONS

Depending upon the installation and approving agency, you may

be required to provide additional NAV Source Select external

annunciators near the HSI / CDI. Spare relay contacts on the

‘AK-950R connector may be used for this purpose.

TIONAL RELAYS

‘The AK-950R contains 24 relay poles. Some installations may

Fequire more than 24 poles due to data lines, superflags, etc.

If this should occur, you may use one spare relay pole to switch

additional relays. it may be more desirable to

have all the relay switching done at a remote location, i.e.:

remote mounted equipment), one relay pole on the AK-950R

may be used for switching this bank of relays. Please note that

the maximum relay contact rating for the AK-950R is 2 ampsDC

ROUTING OF CABLE:

Care must be taken not to bundle the AK-YBUR logic and low

level signal lines with any high energy sources. Examples of

these sources include 400 Hz AC, Comm, DME, HF and

transponder transmitter coax. Always use shielded wire when

shown on the installation print. Avoid sharp bends in cabling

and routing near aircraft control cables,

ELECTRICAL INSTALLATION

Refer to figure 3-1 for Schematic Pin Out Assignment for

Connector, and figure 3-2 for Electrical Schematic Diagram.

Use at least 24 AWG wire for all connections. You MUST use

shielded wire where shown, Avoid sharp bends and routing

cable near high energy sources. Care must be taken to tie the

harness away from aircraft controls and cables. Normal

installation techniques should be applied.

"

INSTALLATION AND OPERATION MANUAL, MODEL AK: 960

(QP8 / NAV SWITCHING & ANNUNCIATOR PANEL

WOTALLATION AND OPERATION MANUAL, MODEL AK.960

CONNECTOR (OFS | AV BWITCHANa & ANMUNCIATOR PANEL,

REAR VIEW OF CONNECTOR

RELAY #18 — NC

RELAY #19 — NC

0c GROUND

RELAY #1 NO

RELAY #2 — NO

RY y= RELAY #3 ~ NO.

RtY #2 - © RELAY #4 — NO

Ruy ys - ¢ RELAY #5 ~ NO

rns RELAY #6 ~ NO

RELAY 45 - © RELAY #7 — NO

REY #6. - C RELAY #8 ~ NO

REY #7 C RELAY #9 ~ NO.

REY 4 BC RELAY #10 ~ NO.

REY #9 = C RELAY #11 = NO.

J ats p10 = c RELAY #12 ~ No

Rey ait = RELAY 413 — NO

RELAY #12 = RELAY #14 = NO.

RELAY #13 = C RELAY #15 — NO

RELAY gla = RELAY 416 ~ KO

15 FP euay fis — RELY 97 — HO

16 Fi eur pie - RELAY #18 — NO.

7 ee retary a7 RELAY 419 — NO

rs ee Peuay 421 ~ c

19 eeu ana ¢ RAY 422 = ¢

20 |P——retay 420 - € CVE} COIL RETURN FOR RELAYS (#1 thru #20)

ps ee NS AUTO OVERRIDE

22 Petar 42 — nc RELAY #20 — NC

23} eeuay 43 - HC evar 42) ~ Nc

24 Pp retay 44 = NC Betay 422 — ne

2s Pp euay 4 5 = NC fail GerecTion Fon RELAYS (#1 thu 420

26 Pp—— reuay 46 - NC Fe oS ©: Postion!

27 pew 47 - NC RELAY #21 ~ Ko

28 }——— retay 48 ~ nc EEN ered

a netarteiel = ‘AILURE DETECTION FOR RELAY (#1 thew #20)

eee 'Ground Outout @ GPS NO. Position)

31 fp reve ait ~ nc

32 Pp retay 412 - nc

33 prey 93 - Nc

34 PL reuay 414 = nc

38 Pp retar 4s - nc VE) COIL RETURN FOR RELAYS (#21 and #22)

}— eeiar 16 ~ xc #14/28 VOC POMER INPUT

eeUAY #17 — NC

FIGURE 3-10 SCHEMATIC PINOUT FOR CONNECTOR FIGURE 3-1b SCHEMATIC PINOUT FOR CONNECTOR

12. P/N AK-950-R24 13. P/NAK-950-R24

(SOFTALLATION AND OPERATION MANUAL, MODEL AK $80

are | ma ePeTCre © ARBOUROIATOR PANEL

REAR VIEW OF CONNECTOR

EIGURE 3-10

CONNECTOR

RARRRRRRRRRR

SCHEMATIC PINOUT FOR CONNECTOR

12

PIN AK-950-R12

\WSTALLATION AND OFERATION MAMUAL, MODEL AK 980

‘FS | WAV BWITCHING & ANUNCIATOR PANEL

40 | — oc cRouno

ar} — reuay # 1 ~ no

42 }— REY #2 - WO

as }— eur gs ~ no

a4 b— eeu 94 = wo

a5 }— rewy ys — no

46 }— rer 6 — no

rs ae

48 }— rer #8 ~ no

49} Reuay 49 ~ Ho

50 |-— retar #10 - wo

st }— evay #11 — No

52 [— rear #12 — wo

5

3s

56

38

3

60 Pe reiay azn -c

61 PF aeuay a2 -

62 | CVE) COW RETURN FOR RELAYS (#1 thew 412

63 [ws auro ovennine

recay #2 = Ne

Betay 422. ne

FAILURE Berection Fon RELAYS #1 thm #12

IGroung Output @ NAVN.C: Postion

ReLAr 421 ~ no

FAILURE DETECTION FOR RELAY (#1 thy

\Ground Outout @ GPS .0. Postion) (MY HI2

(VB COIL RETURN FOR RELAYS (#21 end #22)

#14/28 VOC POWER meUT

FIGURE 3-1b SCHEMATIC PINOUT FOR CONNECTOR

1a PINAK-950-R12

INSTALLATION AND OPERATION MANUAL, MODEL AK. 060

(OPS / NAV SWITCHING & ANAUNCIATOR PANEL

INSTALLATION AND OPERATION MANUAL, MODEL AK-960

CONNECTOR (PS | WAV BWAITCHINO & ARUNCIATOR PANEL

REAR VIEW OF CONNECTOR

iy DSubminture Canneclor are

(050 78, Hi Oensily 0 Subriniatare Conned RELY 9 — NO

REY 42 ~ NO

Rey #1 = REY 3 ~ NO

eeu #2 RELAY #4 ~ NO

Rear eS RELAY #5 — NO

Rua eae RELAY #6 = NO.

REY #5 - C RELAY #7 = NO

REY 6. € RELAY #8 — NO

ROY EBC

RELAY #21 =

(VE) COIL RETURN FOR RELAYS (#1 thu 48 1

RELAY 4 NC ILS AUTO OVERRIDE

REY #2 - NC

REY #3 = NC eevay 421 ~ Nc

RELAY #4 = NC Btay 422 Ne

RELAY #5 NC FAICURE DETECTION FOR RELAYS (21 tins a8 )

{Ground Output @ NAV N.C. Postion!

RELAY #6 — NC

REY #7 = NC RELAY 421 = NO

RELY #8 - NC Prtay 427 = No

FAILURE DETECTION FOR RELAY (#1 tu 8

(Ground Outout @ GPS N.0, Position}

[-— (VE) COIL RETURN FOR RELAYS (#21 and #22)

[14/28 voc Power INPUT

FIGURE 3-10 SCHEMATIC PINOUT FOR CONNECTOR

FIGURE 5=1b SCHEMATIC PINOUT FOR CONNECTOR

12 PIN AK-950-R8 JRE_3=1b

13 PIN AK-950-R8

INSTALLATION AND OPERATION MANUAL, MODEL AK-950

S| NAV SWITCHING & ANNUNCIATOR PANEL

2.4 POST INSTALLATION TEST

After completing the mechanical installation, the following Post

Installation Function Tests must be performed.

ak-950

2.4.1 PRE INSTALLATION TESTS

14/28 yoo poweR put

(Ver PoweR'FoR’ ALL cons.

8c cROUND ——y

With the AK-950R disconnected, turn on the avionics master

switch and verify that the aircraft power of 14 / 28 Vdc are

[agate orem on ‘on Connector Pin 78 (Relay Coil +Power). Using an Ohm

"acre reveato Thaw oc Poston Meter, verify that Pin 40 is aircraft ground.

2.4.2 OPERATING INSTRUCTIONS

JE Faure vetection Fon ni ;

pene ome The AK-950R is a GPS Accessory Item,

(Ground Output @ NAV N.C. Position) Refer to GPS Manufacturer's Installation Manual for complete

GPS System Operating Instructions.

| FAILURE DETECTION FOR RELAYS

(#1 thru 220).

(Ground Output @ GPS N.0. Position) No periodic mainteriance or calibration is necessary for

continued airworthiness of the AK-950R.

Le wwe cot neon

FIGURE.

S=2 ELECTRICAL SCHEMATIC DIAGRAM

P/N AK-950-R24

RELAY ONLY ASSY.

15

14

24

aK-950

241

1/28 voc PoMER wut

(Ver POWER FORALL coLs.

2 CRON —y_

ate 2402

FAILURE DETECTION FOR RELAYS.

(#1 thu #20,

(Ground Output @ NAV N.C. Position)

FAILURE DETECTION FOR RELAYS

(81 thw #20)

(Ground Output @ GPS N.O. Position)

FIGURE 3-2 ELECTRICAL SCHEMATIC DIAGRAM

P/N AK-950-R12

RELAY ONLY ASSY.

14

INSTALLATION AND OPERATION MANUAL, MODEL AK 960

POST INSTALLATION TEST

After completing the mechanical installation, the following Post

Installation Function Tests must be performed,

PRE INSTALLATION TESTS

With the AK-950R disconnected, turn on the avionics master

switch and verify that the aircraft power of 14 / 28 Vdc are

fon Connector Pin 78 (Relay Coil +Power). Using an Ohm

Meter, verify that Pin 40 is aircraft ground.

OPERATING INSTRUCTIONS

‘The AK-95OR is a GPS Accessory Item.

Refer to GPS Manufacturer's Installation Manual for complete

GPS System Operating Instructions.

No periodic mainteriance or calibration is necessary for

continued airworthiness of the AK-950R.

15

24

ak-950

244

$14/28 yoo pom mut

(1 Ver PoWeER'FOR ALL COILS

1 cRouNe —y_

Armucabte ron routs 1 TMU H8 OM.

24.2

FAILURE DETECTION FOR RELAYS.

(Fl thu #89)

(Ground Output @ NAV N.C. Position)

FAILURE DETECTION FOR RELAYS

(the ag

{Ground Output @ GPS N.0. Position)

Fon os vn aR #8

(nav @ nc Position

(crs Ono rosiTon,

FIGURE 3-2 ELECTRICAL SCHEMATIC DIAGRAM

PIN AK-950-R8

RELAY ONLY ASSY,

14

INSTALLATION AND OPERATION MANUAL, MODEL AK950

(OPS / NAV SWITCHING & ANMUNCIATOR PANEL

POST INSTALLATION TEST

After completing the mechanical installation, the following Post

Installation Function Tests must be performed

PRE INSTALLATION TESTS.

With the AK-950R disconnected, turn on the avionics master

switch and verify that the aircraft power of 14 / 28 Vde are

‘on Connector Pin 78 (Relay Coil + Power). Using an Ohm

Meter, verify that Pin 40 is aircraft ground.

OPERATING INSTRUCTIONS

‘The AK-95OR is a GPS Accessory Item,

Refer to GPS Manufacturer's Installation Manual for complete

GPS System Operating Instructions.

No periodic maintenance or calibration is necessary for

continued airworthiness of the AK-950R,

18

‘maumnoop si jo aed apy an wo wonan

igo, yy bar

'

Lege 5. Ine

tv” nq DlOD20 Dei

NOILWHOdHOO ONID -

Se

34

3.2

INSTALLATION AND OPERATION MANUAL, MODEL AK-960

SECTION I

OPERATION

GENERAL a

‘The Remote Relay Assembly, AK-950R, is a GPS Accessory Item.

It is designed to provide Switching Function, for HSI / CD! Data

Inputs, between NAV/VOR Receiver and GPS Receiver.

OPERATION

Refer to GPS Manufacturer's Installation Manual for complete

GPS System Operating Instructions.

16

INGTALLATION AND OPERATION MANUAL, MODEL AK.960

(OPS NAV SWITCHING & ANMUNCIATOR PANEL

SECTION IV

WARRANTY

LIMITED WARRANTY

All equipments manufactured by Am

against defective materials and workmanship for a period of two

years.

Any equipment found to be defective due to material and

workmanship during this limited warranty will be repaired and put

in original manufactured operating condition.

‘An option of extended third and fourth year limited warranty

become valid at the end of this second year, which will warrant

to the original owner.

This Ameri-King Corp. warranty is void unless the Warranty

Registration Card ie filled out and returned to Amor King Corp.

within 15 days after original installation.

Ameri-King Corp.'s liability under this warranty is limited to

servicing, repairing, replacing or adjusting any equipment

returned prepaid to the factory by express written or oral

authorization for that purpose and to repair or replace defective

parts thereof. Repaired equipment will be returned to the

equipment user freight pre-paid. Shipping charge will be paid one

way only by Ameri-King Corp.

Upon discovery of a condition believed to be caused by a defect

in manufacturing, Amer-King Corp, must be notified. No

equipment to be shipped to Ameri-King Corp. without prior

authorization. Any equipment returned to Ameri-King Corp.

should be accompanied by a failure report, in writing, giving full

Particulars in support of the cl

This limited warranty does not cover or apply to any of the

followings, including: misuse of the equipment; installation or

operation not in accordance with factory instructions; accidents

or negligent damage; alterations of any manner; repair by other

7

INSTALLATION AND OPERATION MANUAL. MODEL AX-960

‘OPS / WAV SWITCHING & ANNUNGIATOR PANEL

factory; changes in calibration occuring as a result of normal

Use of the equipment; the cost of labor, material, or other

expense incidental to the repair, installation, removal from the

aircraft or replacement of the equipment; damaged during

shipment or installation; any personal injuries or damage to

property resulting from the installation or the operation of the

equipment or the failure of the equipment or any part thereof, the

equipment user assumes the risks of all such injuries or damage.

In such cases, the repair will be billed at cost. An estimate will

be submitted for approval before repair is initiated,

‘Any equipment which is returned for warranty and found not to

be defective shall be charged a minimum handling and service

charge and returned C.0.0.

No warranty will be activated for Ameri-King Corp. products

Unless the installation is approved by an FAA Certified Installer

and the warranty card is completed by the supplying dealer or

upon receipt by Ameri-King Corp. of form(s) 337 or 8130-4)

THE IMPLIED WARRANTY AND ALL OTHER IMPLIED

WARRANTIES ARE HEREBY EXCLUDED. AMERI- KING CORP.

MAKES NO OTHER WARRANTY OR REPRESENTATION OF ANY

KIND WHATSOEVER EXPRESSED OR IMPLIED, AND ALL

IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

ARE HEREBY DISCLAIMED.

AMER! - KING CORP.'S MAXIMUM LIABILITY HEREUNDER IS

LIMITED TO THE PURCHASED PRICE OF THE PRODUCT. IN NO

EVENT SHALL AMERI- KING CORP. BE LIABLE FOR ANY

CONSEQUENTIAL, INDIRECT, INCIDENTAL OR SPECIAL

DAMAGES OF ANY NATURE ARISING FROM THE SALE OR USE

OF THE PRODUCT, WHETHER BASED IN CONTRACT, TORT.

STRICT LIABILITY OR OTHERWISE.

18

42

43

INSTALLATION AND DPERATION MANUAL, MODEL AK-260

(OPS / NAV SWITCHING & ANNUNCIATOR PANEL.

REPAIR SERVICE

All equipments manufactured by Ameri-King Corp. must be

repaired at the facility of Ameri-King Corp.

All the repair services shall be performed and completed within

3 days upon repairing estimate is approved by equipment user or

installation dealer.

FACTORY COMPREHENSIVE TEST SERVICE

Factory Comprehensive Test Service is available. There is a

service charge for this service. All equipments returned for

Factory Comprehensive Test Service must be sent freight

prepaid.

19

INSTALLATION AND OPERATION MANUAL, MODEL AK 960

APPENDIX. A

ENVIRONMENTAL QUALIFICATION FORM

RTCA / DOI60C

MODEL NO: AK-980 TSONO: C1298 CLASS AL

MANUFACTURER: AMER - KING CORP.

18842 BROOKHURST ST.

FOUNTAIN VALLEY, CA. $2708,

=a

‘Temp. & Altitude 40

Low temperature 45.1

High Temperature] 4.5.2 & 4.5.3

In-Flight Loss of 45.4

Cooling

4.6.1

4.6.2

Humidity

Shock

Operational

Crash Safety

Vibration

Description of Conducted Tests

Equipment tested to Categories

A2&DI

Cooling air not required

Equipment tested to Category C

Equipment tested to Category A

Equipment tested per DO-160C

Par. 7.2.1

Equipment tested without shock-

‘mounts to Categories M & N

(Table 8-1)

Equipment identified as

Category X, no test required

Equipment identified as,

Category X, no test required

INSTALLATION AND OPERATION MANUAL, MODEL AK.960

ENVIRONMENTAL QUALIFICATION (Cont'd)

Fluids Susceptibility

‘Sand and Dust

Salt Spray

Magnetic Effect

Voltage Spike

Audio Frequency

Susceptibility

Induced Signal

Suscepribilit

Radio Frequency

Susceptibility

Radio Frequency

Emissions

Lightning Induced

Transient

Susceptibi

Lightning Direct

Effects

Icing

Description of Conducted Tests

Equipment identified as

Category X, no test required

Equipment identified as

Category X, no test required

Equipment identified as,

Category X, no test required

Equipment identified as

Category X, no test required

Equipment tested to Class A

Equipment tested to Category B

Equipment tested to Category B

Equipment tested to Category B

Equipment tested to Category A

Equipment tested to Category T

Equipment tested to Category A

Equipment identified as,

Category X, no test required

Equipment identified as

Category X, no test required

Equipment identified as,

Category X, no test required

e ‘sont ena omecronsr

oes, [AIRCRAFT CERTIFICATION SERVICE

LOS ANGELES AIRCRAFT CERTIFICATION OFFICE

rociasie {3940 PARAMOUNT BOULEVARD

LAKEWOOD, CALIFORNIA 907

i

Woy 22 596

Amet-King Corporation

Mr Keith Van

18842 Brookhurt Stet

Fountain Vabey,Caoria 92708,

Dear Me Van

Anesiking Corporation,

GGPSINAV Switching nd Anrnistor Pac,

“eh Stand Orde C1298

‘Your application dated November 7, 1995, requesting the iasuance ofa Tecnica Standard Ove

(FSO) authorization n accordance with he procedural equrerens of Feder! Aviation

Regulation (FAR) Pat 2, Subpart 0. Based upon yur data ard statement of conformance

ering your aril) has ma th quirements of FAR Part 21, Subpart O an the minimum

performance standards of TSO C120 (Re FAR 21608) auhoriztion sere rane forthe

folowing

MODEL DESCRIELION

AK 9504) Seis GGPSINAV Suitehng and Anrancntor Parl

For your information. he coins an et required fr TSO approval re imum

performance standards The sricis) may be installed ono within» specific pe Cas of

tireraf ony ifurer evaluation by the userintlr documents an acceptable stalition tat i

Approved bythe Adiiator

“The quality contol procedutes contained in your quality contol manual, current on le atthe

Phoetix Manuficturing Inspection Suite Oc. and your statement that howe procedures wail

tbe applied to the manufacturer ofthe mijet aise) at the above adress. te considered

equate in acordance with FAR 2.142

_Eective this dt, your authorization to ue TSO procedures is extended to inh the subject,

smiles). You may defy the aril) wih the applicable TSO markings a resuies by

TS0CI200,

As recipient of this TSO authorization, excep! a provided in FAR 21 3(4. you re required to

report ary fale, malfunction, odfect nay product opt marae by you o out

éovtracted suppliers and which you have determined hat reed or oul est may ofthe

currence sted in FAR 21) Therepor should be cornet rally by teepne to

the Supervisor, Tehncal and Administrative Sopor Staff, ANM-103L, (310) 6275300. with

24 hours alert hasbeen detemined she fare as oceuted and flloned up witha writen

‘otice FAA Ferm 8010-4 (Malunetion or Defect Repo or eer appropriate formats

{acceptable in arsiting the egied dea As required by FAR 21 16). you must aso

‘oily the FAA when you no longer manfacture a TSO approved ace

‘This authorization pets coy to marufhtring operations at te aboveaess This office

mus be aaied in advance of any proposed acylation opecade meron whe

avating quality corral ppvosa! fs Scity

Sincere

Michael Murphy, Manage:

Technical and Adoiinative

Suppor Sia, ANMIO3L,

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- S-Tec DWG 570Document4 pagesS-Tec DWG 570MinivationNo ratings yet

- FI-2 Position Tuned Injector Nozzles ManualDocument15 pagesFI-2 Position Tuned Injector Nozzles ManualMinivation0% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- S-Tec GPSS 429 Converter Interface Wiring Pictoral For System 40/50Document1 pageS-Tec GPSS 429 Converter Interface Wiring Pictoral For System 40/50MinivationNo ratings yet

- Gables G7511 Installation Manual Rev. 0Document44 pagesGables G7511 Installation Manual Rev. 0Minivation100% (1)

- Cessna SNL94-6Document17 pagesCessna SNL94-6MinivationNo ratings yet