Professional Documents

Culture Documents

Element06DNEMNov 19 01

Uploaded by

Danilo AugustoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Element06DNEMNov 19 01

Uploaded by

Danilo AugustoCopyright:

Available Formats

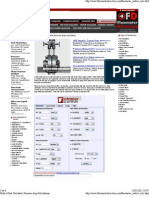

HP06DH Element

HP06DH Series

Interchanges for Hycon/Hydac

0060D/0110D/0140D pressure series

Hy-Pro G6 Dualglass

High Performance Filter Elements

Performance

Temperature: -45f to 225f, -43c to 107c (buna)

-20f to 250f, -29c to 120c (viton)

Element collapse 3000 psid (210 bar)

Interchange

Hydac/Hycon Hy-Pro

0060D003BH3HC HP06DHL4-3MB

Media 0060D003BHHC HP06DHL4-3MB

G6 media pleat pack features our latest 0060D005BH HP06DHL4-6MSB

generation of graded density glass media that 0060D005BH3HC HP06DHL4-6MB

delivers required cleanliness while optimizing 0060D005BHHC HP06DHL4-6MB

dirt capacity. 0060D010BH HP06DHL4-12MSB

0060D010BH3HC HP06DHL4-12MB

Dynamic Filter Efficiency 0060D010BHHC HP06DHL4-12MB

DFE rated elements perform true to rating even 0060D020BH3HC HP06DHL4-25MB

under demanding variable flow and vibration 0060D020BHHC HP06DHL4-25MB

conditions. Today’s industrial and mobile 0110D003BH3HC HP06DHL7-3MB

0110D003BHHC HP06DHL7-3MB

hydraulic circuits require elements that deliver

0110D005BH3HC HP06DHL7-6MB

specified cleanliness under all circumstances. 0110D005BHHC HP06DHL7-6MB

Wire mesh supports the media to ensure against 0110D010BH3HC HP06DHL7-12MB

cyclical flow fatigue, temperature, and chemical 0110D010BHHC HP06DHL7-12MB

resistance failures possible in filters with 0110D020BH3HC HP06DHL7-25MB

synthetic support mesh. 0110D020BHHC HP06DHL7-25MB

0140D003BH3HC HP06DHL8-3MB

0140D003BHHC HP06DHL8-3MB

Tested to ISO quality standards 0140D005BH3HC HP06DHL8-6MB

ISO 2941 Collapse and burst resistance 0140D005BHHC HP06DHL8-6MB

ISO 2942 Fabrication and Integrity test 0140D010BH3HC HP06DHL8-12MB

ISO 2943 Material compatibility with fluids 0140D010BHHC HP06DHL8-12MB

0140D020BH3HC HP06DHL8-25MB

ISO 3724 Flow fatigue characteristics

0140D020BHHC HP06DHL8-25MB

ISO 3968 Pressure drop vs. flow rate *If No HC in Hydac/Hycon p/n or number not listed

ISO 16889 Multi-pass performance testing above call or consult interchange guide

*For Viton seals (where A in MP p/n is V) replace

Fluid Compatibility the B in Hy-Pro p/n with a V.

Petroleum based fluids, water glycols, polyol *Water removal and Dynafuzz media also available.

Call or consult the Hy-Pro on line interchange guide

esters, phosphate esters, HWBF at www.filterelement.com

For technical service call 317.849.3535 or fax 317.849.9201 www.filterelement.com

L4 Dualglass Dp vs flow rate L7 Dualglass Dp vs flow rate

flow rate lpm flow rate lpm

0 8 15 23 30 38 45 53 61 0 16 31 47 62 78 93 109 124

30 2.0 30 2

25 1 3 6 25 1 3

6

1.5 1.5

20 20 12

12

Dp bar

Dp bar

Dp psi

Dp psi

15 1.0 15 1

10 10

25 25 0.5

0.5

5 5

0 0.0 0 0

0 2 4 6 8 10 12 14 16 0 4 8 12 16 20 24 28 32

flow rate gpm flow rate gpm

L8 Dualglass Dp vs flow rate

Pressure Drop Calculation

flow rate lpm Pressure drop curves based on oil viscosity of 141

0 19 38 57 76 95 114 132 151 SSU, and specific gravity = 0.86. Dp across ele-

30 2 ment is proportionally related to viscosity and spe-

1 3 6

cific gravity. For new DP use the following con-

25

version formula:

1.5

20 12

Dp bar

Dp psi

DP element = DP curve x Vis/141 x SG/0.86

15 1

10 25

0.5

5

0 0

0 5 10 15 20 25 30 35 40

flow rate gpm

table 1 table 2 table 3 table 4 table 5

HP06DHL __ - __ __ __ __

table 1 table 2 table 3 table 5

code length code filtration rating code Media code seal

4 single 1 B2.5[c] = 1000 (B1 = 200) A G6 Dualglass B Nitrile(buna)

7 double 3 B5[c] = 1000 (B3 = 200) w/water removal V Fluorocarbon

8 7 inch 6 B7[c] = 1000 (B6 = 200) M G6 Dualglass E EPR

10 extended 12 B10[c] = 1000 (B10 = 200) SF Dynafuzz

25 B22[c] = 1000 (B25 = 200) W wire mesh

or 25u nominal wire mesh

74 74u nominal wire mesh table 4

149 149u nominal wire mesh code design option

omit standard design

S reduced capacity design

smaller OD, larger OAL

Hy-Pro filters are tested to the latest industry

standard ISO16889 (replacing ISO4572) resulting in New (ISO16889) vs Old (ISO4572) size comparison

A new scale for defining particle sizes and determining Bx(c)=1000 (ISO16889) 2.5 5 7 12 22

TB06DH-0302 a beta ratio. Bx=200 (ISO4572) <1 3 6 12 25

You might also like

- Alien Bestiary PDFDocument450 pagesAlien Bestiary PDFDũng Lê100% (13)

- HP2727 Filter Element Data SheetDocument3 pagesHP2727 Filter Element Data Sheetjose manuelNo ratings yet

- 13-5m Annular Bop Operation ManualDocument20 pages13-5m Annular Bop Operation ManualJaime Yovany Rodriguez100% (1)

- Structural Analysis of English SyntaxDocument26 pagesStructural Analysis of English SyntaxremovableNo ratings yet

- New Criticism Hills Like White Elephants FinalDocument4 pagesNew Criticism Hills Like White Elephants Finalapi-313631761No ratings yet

- HP75 Series: Hy-Pro G6 DualglassDocument2 pagesHP75 Series: Hy-Pro G6 DualglassOscar NavarroNo ratings yet

- HP5H/5N Series Hy-Pro G8 Dualglass: High Performance Filter ElementsDocument3 pagesHP5H/5N Series Hy-Pro G8 Dualglass: High Performance Filter ElementsRizkyNo ratings yet

- Data Sheet Hp33dnl (0660d010bn3hc)Document2 pagesData Sheet Hp33dnl (0660d010bn3hc)tunradotNo ratings yet

- HP74/76/76V Series: Hy-Pro G6 DualglassDocument2 pagesHP74/76/76V Series: Hy-Pro G6 DualglassOscar NavarroNo ratings yet

- Filtro Hidráulico Pi2300 MahleDocument5 pagesFiltro Hidráulico Pi2300 MahleHIDRAFLUIDNo ratings yet

- Duplex Filters Max. 200 L/min. 40 Bar: Cast Iron Duplex Filter For Marine ApplicationsDocument4 pagesDuplex Filters Max. 200 L/min. 40 Bar: Cast Iron Duplex Filter For Marine ApplicationshidagamersNo ratings yet

- Hichine GLM Pump 2015Document8 pagesHichine GLM Pump 2015Anonymous Tj3ApePIrNo ratings yet

- Hyquest Solutions Pty LTD: Series IiDocument28 pagesHyquest Solutions Pty LTD: Series IiAprilighostNo ratings yet

- Document Title: 512kx8bit CMOS SRAMDocument11 pagesDocument Title: 512kx8bit CMOS SRAMFlorin Bila-NicolaNo ratings yet

- Gree Dehumidifier Service ManualDocument58 pagesGree Dehumidifier Service Manualjdv1234No ratings yet

- Marathon LDocument16 pagesMarathon LmohamedNo ratings yet

- L5235X00000000Document2 pagesL5235X00000000D.CORNEILLENo ratings yet

- Dat004 Eng PDFDocument68 pagesDat004 Eng PDFAslam ShaikhNo ratings yet

- Fluid Dynamic BearingsDocument27 pagesFluid Dynamic BearingsaqibazizkhanNo ratings yet

- AHLSTAR End-Suction Single-Stage Centrifugal PumpsDocument24 pagesAHLSTAR End-Suction Single-Stage Centrifugal PumpsDoanh VoNo ratings yet

- 10 TechX 2019 Clarified HPPDocument13 pages10 TechX 2019 Clarified HPPngocanh492No ratings yet

- 11-5k Annular BOP Operation Manual-Shaffer TypeDocument19 pages11-5k Annular BOP Operation Manual-Shaffer TypeDaniel RinconNo ratings yet

- HY62V8100B (Rev13) PDFDocument12 pagesHY62V8100B (Rev13) PDFsmhzzNo ratings yet

- Rexroth FDDocument116 pagesRexroth FDIvan GudeljNo ratings yet

- BrochureDocument10 pagesBrochureMohamed ImranNo ratings yet

- Interruptores de Nível MobreyDocument28 pagesInterruptores de Nível MobreylavascudoNo ratings yet

- HF 705 Series: in Line High Pressure FiltersDocument16 pagesHF 705 Series: in Line High Pressure FilterssitnikovsNo ratings yet

- 11-5K Annular BOP Operation ManualDocument20 pages11-5K Annular BOP Operation ManualAlfonso Ibarra BenavidesNo ratings yet

- Product - Selection - Guide RexrothDocument76 pagesProduct - Selection - Guide RexrothTokowi AutopartsNo ratings yet

- Filtro Hidráulico Pi4230 MahleDocument6 pagesFiltro Hidráulico Pi4230 MahleHIDRAFLUIDNo ratings yet

- 30HXCDocument2 pages30HXCvbharath21100% (1)

- FLN Series: Inline Filters - To DIN 24550Document4 pagesFLN Series: Inline Filters - To DIN 24550hamdaNo ratings yet

- s-5610q1 5620 5620d1Document4 pagess-5610q1 5620 5620d1Ujwal KhandokarNo ratings yet

- PDS Poweroil Turbo AWDocument2 pagesPDS Poweroil Turbo AWNitant MahindruNo ratings yet

- 186f5aba-18d7 - ZA - Hydraulic Metal Free 22 - EN-ZA PDFDocument2 pages186f5aba-18d7 - ZA - Hydraulic Metal Free 22 - EN-ZA PDFBerry.MotewaNo ratings yet

- h07rn F en 50525 2 21 Flexible Rubber CableDocument5 pagesh07rn F en 50525 2 21 Flexible Rubber CableBradNo ratings yet

- Atlas Bulkhead: Specification SheetDocument2 pagesAtlas Bulkhead: Specification SheetRaghu paryNo ratings yet

- De400001 SM-6Document3 pagesDe400001 SM-6seve1No ratings yet

- Filtro Hidráulico Pi260 MahleDocument6 pagesFiltro Hidráulico Pi260 MahleHIDRAFLUIDNo ratings yet

- 6.B SED Valve 186Document9 pages6.B SED Valve 186MartinNo ratings yet

- Duplex FilterDocument24 pagesDuplex FilterAnirudh JavagalNo ratings yet

- Semikron SKM195GAL123D DatasheetDocument8 pagesSemikron SKM195GAL123D DatasheetPramod DixitNo ratings yet

- Slim Line Ceiling Concealed Ducted Split Systems: 53QDMT 12-18-24-30-36-42-48-60 Heat PumpDocument49 pagesSlim Line Ceiling Concealed Ducted Split Systems: 53QDMT 12-18-24-30-36-42-48-60 Heat PumpOmer IkhlasNo ratings yet

- Filtro Hidráulico Pi410 MahleDocument5 pagesFiltro Hidráulico Pi410 MahleHIDRAFLUIDNo ratings yet

- Mega Himel Price List 2022 Starting AugustDocument41 pagesMega Himel Price List 2022 Starting AugustYvan Jacen ErnacioNo ratings yet

- Bobcat 2500 Hydraulic Concrete Breaker ManualDocument16 pagesBobcat 2500 Hydraulic Concrete Breaker ManualpurnomoNo ratings yet

- Hydraulic Pumps, Motors & Filters: Replaces: DOC 02 R E Edition: 03/05.2010Document32 pagesHydraulic Pumps, Motors & Filters: Replaces: DOC 02 R E Edition: 03/05.2010Juan Carlos Bermudez Cardenas100% (1)

- Pressure Switch and Pressure Sensor CatalogDocument76 pagesPressure Switch and Pressure Sensor CatalogNandoGonçalvesNo ratings yet

- Gulf Oil Marine - Product Data SheetDocument10 pagesGulf Oil Marine - Product Data SheetObydur RahmanNo ratings yet

- Catalog IXYSDocument220 pagesCatalog IXYSdbayeah100% (1)

- ME (Parker DF60 Duplex Filter F160 - 40 I - v1)Document7 pagesME (Parker DF60 Duplex Filter F160 - 40 I - v1)TuyenNo ratings yet

- Denison-Parker Premier SeriesDocument40 pagesDenison-Parker Premier SeriesDamNo ratings yet

- Iplex GuideDocument70 pagesIplex GuidebalotNo ratings yet

- 2050 2060 2070 Series High Pressure Filter Assemblies FLTR Purple EngineeringDocument2 pages2050 2060 2070 Series High Pressure Filter Assemblies FLTR Purple EngineeringFLTR PURPLE E.No ratings yet

- Merlin Gerin Miniature Circuit Breakers C60HB TechnicalDocument5 pagesMerlin Gerin Miniature Circuit Breakers C60HB Technicalamitd_hupar666No ratings yet

- 15P/30P Series: High Pressure FiltersDocument12 pages15P/30P Series: High Pressure FiltersPartsGopher.comNo ratings yet

- Hdpe Alathon H5520 EquistarDocument2 pagesHdpe Alathon H5520 EquistarEric Mahonri PereidaNo ratings yet

- Etatron GB BP Motor Pump Datasheet 2017Document2 pagesEtatron GB BP Motor Pump Datasheet 2017Mohamed amine BenfarhatNo ratings yet

- Hicool CatalogDocument12 pagesHicool CatalogNARENDER NIMMANo ratings yet

- Flat Panel Display ManufacturingFrom EverandFlat Panel Display ManufacturingJun SoukNo ratings yet

- CCTV Surveillance: Video Practices and TechnologyFrom EverandCCTV Surveillance: Video Practices and TechnologyRating: 4 out of 5 stars4/5 (1)

- Sources of InnovationDocument22 pagesSources of Innovationm umair zahirNo ratings yet

- DiseasesDocument11 pagesDiseasesapi-307430346No ratings yet

- S.NO. Students Name Contact Number CAP 10TH: Ideal Institute of Pharamacy, Wada SESSION-2020-21Document12 pagesS.NO. Students Name Contact Number CAP 10TH: Ideal Institute of Pharamacy, Wada SESSION-2020-21DAMBALENo ratings yet

- Orifice Plate Calculator Pressure Drop CalculationsDocument4 pagesOrifice Plate Calculator Pressure Drop CalculationsAnderson Pioner100% (1)

- Air Quality StandardsDocument2 pagesAir Quality StandardsJanmejaya BarikNo ratings yet

- How To Plant Thoughts in Her Mind Ross Jeffries: TranscriptDocument12 pagesHow To Plant Thoughts in Her Mind Ross Jeffries: TranscriptAlcajNo ratings yet

- Tata Steel LTD.: Elements Unit Min Max RemarksDocument2 pagesTata Steel LTD.: Elements Unit Min Max RemarksPavan KumarNo ratings yet

- I J E E: Nternational Ournal of Nergy and NvironmentDocument8 pagesI J E E: Nternational Ournal of Nergy and NvironmentsheilamegumiNo ratings yet

- Supplier Accreditation Application-V1 - RevisedDocument8 pagesSupplier Accreditation Application-V1 - RevisedCandiceCocuaco-ChanNo ratings yet

- SPC Company BrochureDocument22 pagesSPC Company BrochureDaivasigamaniNo ratings yet

- Cognitive Benefits of Language LearningDocument11 pagesCognitive Benefits of Language LearningIlhamdi HafizNo ratings yet

- 18TE72 - Wireless Communication Experiential Learning ReportDocument10 pages18TE72 - Wireless Communication Experiential Learning ReportRitika BakshiNo ratings yet

- Saes TABLEDocument13 pagesSaes TABLERiyaz BasheerNo ratings yet

- Too Early! by Anton Pavlovich ChekhovDocument4 pagesToo Early! by Anton Pavlovich Chekhovapi-19787590No ratings yet

- Trockel Flash Art 1987Document4 pagesTrockel Flash Art 1987cvg_geNo ratings yet

- Hermes - GodDocument19 pagesHermes - GodAvocadoraNo ratings yet

- Securing Your Organization From Modern Ransomware: Ransomware Attacks Are Now A Team EffortDocument11 pagesSecuring Your Organization From Modern Ransomware: Ransomware Attacks Are Now A Team EfforttiagouebemoraisNo ratings yet

- Major06 QP DLP NEET2019 (Pmtcorner - In) PDFDocument40 pagesMajor06 QP DLP NEET2019 (Pmtcorner - In) PDFMegha HazarikaNo ratings yet

- Mat210 LectureNotes 1Document7 pagesMat210 LectureNotes 1Franch Maverick Arellano LorillaNo ratings yet

- Armenotech PCIDSS AOCDocument13 pagesArmenotech PCIDSS AOCHakob ArakelyanNo ratings yet

- Detailed Lesson Plan in English 2Document9 pagesDetailed Lesson Plan in English 2RENELYN PANSIPANSI100% (1)

- Juan LunaDocument2 pagesJuan LunaClint Dave OacanNo ratings yet

- Wireless Cellular and LTE 4g Broadband PDFDocument26 pagesWireless Cellular and LTE 4g Broadband PDFAE videosNo ratings yet

- TelemetryDocument8 pagesTelemetryKristin WiseNo ratings yet

- National Institute of Industrial Engineering: Part - B (10 Marks) : Answer All The QuestionsDocument4 pagesNational Institute of Industrial Engineering: Part - B (10 Marks) : Answer All The QuestionsTulasi PatleNo ratings yet

- Tahmina Ferdousy Jhumu: HND Btec Unit 15 Psychology For Health and Social CareDocument29 pagesTahmina Ferdousy Jhumu: HND Btec Unit 15 Psychology For Health and Social CareNabi BoxNo ratings yet

- Upfc PlacementDocument0 pagesUpfc PlacementVamsi KumarNo ratings yet