Professional Documents

Culture Documents

SKF LGMT 3

SKF LGMT 3

Uploaded by

ANILOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SKF LGMT 3

SKF LGMT 3

Uploaded by

ANILCopyright:

Available Formats

SKF General purpose industrial

and automotive bearing grease

LGMT 3

SKF LGMT 3 is mineral oil based, lithium soap thickened grease. This premium

quality, general purpose grease is suitable for a wide range of industrial and

automotive applications requiring stiff grease.

• Excellent rust inhibiting properties

• High oxidation stability within its recommended temperature range

Typical applications

• Bearings >100 mm (3.9 in.) shaft size

• Outer bearing ring rotation

• Vertical shaft applications

• Continuous high ambient temperatures >35 °C (95 °F)

• Propeller shafts

• Agricultural equipment

• Car, truck and trailer wheel bearings

• Large electric motors

Available pack sizes

Packsize Designation

420 ml cartridge LGMT 3.0,4

0,5 kg can LGMT 3/0.5

1 kg can LGMT 3/1

5 kg can LGMT 3/5

18 kg pail LGMT 3/18

50 kg drum LGMT 3/50

180 kg drum LGMT 3/180

Electro-mechanical lubricant dispensers

TLMR 101 series 380 ml refill (incl. battery) LGMT 3/MR380B

TLMR 201 series 380 ml refill LGMT 3/MR380

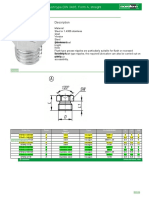

Technical data

Designation LGMT 3/(pack size)

DIN 51825 code K3K-30 Corrosion protection

Emcor: – standard ISO 11007 0–0

NLGI consistency class 3

– water washout test 0–0

Thickener Lithium

Water resistance

Colour Amber DIN 51 807/1,

Base oil type Mineral 3 hrs at 90 °C 1 max.1)

Operating temperature range –30 to +120 °C Oil separation

(–20 to +250 °F) DIN 51 817,

7 days at 40 °C, static, % 1–3

Dropping point DIN ISO 2176 >180 °C (>355 °F)

Lubrication ability

Base oil viscosity R2F,

40 °C, mm2/s 125 running test B at 120 °C Pass

100 °C, mm2/s 12

Copper corrosion

Penetration DIN ISO 2137 DIN 51 811 2 max. at 130 °C (265 °F)

60 strokes, 10–1 mm 220–250

100 000 strokes, 10–1 mm 280 max. Rolling bearing grease life

R0F test 1 000 min. at 130 °C

Mechanical stability L50 life at 10 000 r/min., hrs (265 °F)

Roll stability, 50 hrs at 80 °C, 10–1 mm 295 max.

V2F test 'M'

1) Typical value

Lubrication management

Just as asset management takes maintenance to a higher level, a lubrication management

approach allows lubrication to be seen from a wider point of view. This approach helps to

effectively increase machine reliability at a lower overall cost.

SKF Client Needs

SKF

Analysis Improvement Design and

Lubrication Optimisation

Lubrication proposal implementation

Audit

Management

Step 1 Step 2 Step 3 Step 4 Step 5

Normally implies one Detailed assessment. Formulation of Execution of the Reassessment and

day of assessment and Normally implies five specific activities proposed activities implementation of

provides an overview days and provides a additional improvement

on the lubrication thorough analysis of the proposals

programme maturity lubrication programme

skf.com | mapro.skf.com | skf.com/lubrication

® SKF is a registered trademark of the SKF Group.

© SKF Group 2017

The contents of this publication are the copyright of the publisher and may not be reproduced (even

extracts) unless prior written permission is granted. Every care has been taken to ensure the accuracy

of the information contained in this publication but no liability can be accepted for any loss or damage

whether direct, indirect or consequential arising out of the use of the information contained herein.

PUB MP/P8 12053/2 EN · June 2017

Certain image(s) used under license from Shutterstock.com.

You might also like

- MWM Catálogo de Peças Motor X10Document338 pagesMWM Catálogo de Peças Motor X10LEODECIO BELO DE OLIVEIRA93% (42)

- Modeling, Control, and Optimization of Natural Gas Processing PlantsFrom EverandModeling, Control, and Optimization of Natural Gas Processing PlantsRating: 5 out of 5 stars5/5 (1)

- Mounting, Maintenance & Repair of Cardanshafts - GEWESDocument5 pagesMounting, Maintenance & Repair of Cardanshafts - GEWESHesham MahdyNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Working Guide to Drilling Equipment and OperationsFrom EverandWorking Guide to Drilling Equipment and OperationsRating: 5 out of 5 stars5/5 (9)

- Tiempo de VaciadoDocument12 pagesTiempo de VaciadoRichard Yangali RamosNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- Elastomers and Rubber Compounding MaterialsFrom EverandElastomers and Rubber Compounding MaterialsI FrantaRating: 4.5 out of 5 stars4.5/5 (3)

- Introduction to Microsystem Technology: A Guide for StudentsFrom EverandIntroduction to Microsystem Technology: A Guide for StudentsRating: 5 out of 5 stars5/5 (1)

- Environmental Analysis and Technology for the Refining IndustryFrom EverandEnvironmental Analysis and Technology for the Refining IndustryNo ratings yet

- Deactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingFrom EverandDeactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingNo ratings yet

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Working Guide to Petroleum and Natural Gas Production EngineeringFrom EverandWorking Guide to Petroleum and Natural Gas Production EngineeringRating: 5 out of 5 stars5/5 (2)

- H.264 and MPEG-4 Video Compression: Video Coding for Next-generation MultimediaFrom EverandH.264 and MPEG-4 Video Compression: Video Coding for Next-generation MultimediaNo ratings yet

- Manufacturing Surface Technology: Surface Integrity and Functional PerformanceFrom EverandManufacturing Surface Technology: Surface Integrity and Functional PerformanceRating: 5 out of 5 stars5/5 (1)

- Lubrication Tactics for Industries Made Simple, 8th Discipline of World Class Maintenance Management: 1, #6From EverandLubrication Tactics for Industries Made Simple, 8th Discipline of World Class Maintenance Management: 1, #6Rating: 5 out of 5 stars5/5 (1)

- Handbook of Quality Integrated Circuit ManufacturingFrom EverandHandbook of Quality Integrated Circuit ManufacturingRating: 5 out of 5 stars5/5 (1)

- Microturbines: Applications for Distributed Energy SystemsFrom EverandMicroturbines: Applications for Distributed Energy SystemsRating: 5 out of 5 stars5/5 (1)

- Principles and Applications of Thermal AnalysisFrom EverandPrinciples and Applications of Thermal AnalysisPaul GabbottRating: 4 out of 5 stars4/5 (1)

- Iso 45001 enDocument1 pageIso 45001 enHesham MahdyNo ratings yet

- 0452 Antillean ShippingDocument2 pages0452 Antillean ShippingHesham MahdyNo ratings yet

- For Industrial & Energy Solutions LLC: Company PresentationDocument17 pagesFor Industrial & Energy Solutions LLC: Company PresentationHesham MahdyNo ratings yet

- Greases and Grease Thickener Systems: Dr. George S. Dodos, Chemical Engineer, ELDON'S S.ADocument2 pagesGreases and Grease Thickener Systems: Dr. George S. Dodos, Chemical Engineer, ELDON'S S.AHesham MahdyNo ratings yet

- Applying Open Gear LubricantsDocument13 pagesApplying Open Gear LubricantsHesham MahdyNo ratings yet

- Fluke Reliability Why Use CMMSDocument1 pageFluke Reliability Why Use CMMSHesham MahdyNo ratings yet

- Quotation: Growth Promoters World ةراجتلل تازفحملا ملاع ةسسؤمDocument1 pageQuotation: Growth Promoters World ةراجتلل تازفحملا ملاع ةسسؤمHesham MahdyNo ratings yet

- Reservoir Vent FiltersDocument8 pagesReservoir Vent FiltersHesham MahdyNo ratings yet

- Parthan Ep: Industrial Gearbox OilsDocument1 pageParthan Ep: Industrial Gearbox OilsHesham MahdyNo ratings yet

- Bearing Grease Cleaning Solution by MOSIL LubricantsDocument5 pagesBearing Grease Cleaning Solution by MOSIL LubricantsHesham MahdyNo ratings yet

- Hesham Elmahdy: Reliability, Account ManagerDocument5 pagesHesham Elmahdy: Reliability, Account ManagerHesham MahdyNo ratings yet

- LP - 46 - 23 - 17977 - 1636466674 - Mobius Institute LP 04Document1 pageLP - 46 - 23 - 17977 - 1636466674 - Mobius Institute LP 04Hesham MahdyNo ratings yet

- Best Practice 40varnish and Oxidation ControlDocument5 pagesBest Practice 40varnish and Oxidation ControlHesham MahdyNo ratings yet

- Lubricant Varnish: What It Is, How It Forms and How To Mitigate ItDocument3 pagesLubricant Varnish: What It Is, How It Forms and How To Mitigate ItHesham MahdyNo ratings yet

- For Industrial & Energy Solutions LLC: Company PresentationDocument17 pagesFor Industrial & Energy Solutions LLC: Company PresentationHesham MahdyNo ratings yet

- IDEA UnicalDocument72 pagesIDEA UnicalAnastasia KazaNo ratings yet

- Catalogue ElektrogasDocument24 pagesCatalogue ElektrogasLucas IwaniszynNo ratings yet

- Perkins 2306a PDFDocument2 pagesPerkins 2306a PDFAbdulRehmanNo ratings yet

- BHS Solid-Liquid Filtration and Final Drying OptimizationDocument28 pagesBHS Solid-Liquid Filtration and Final Drying OptimizationBarry PerlmutterNo ratings yet

- AMEF Bomba PistonesDocument9 pagesAMEF Bomba PistonesRicky Hurtado M0% (1)

- Use of Lba-Mna Methodology For Determination of Bearing Capacity of Compressed Shells Lyubomir ZdravkovDocument6 pagesUse of Lba-Mna Methodology For Determination of Bearing Capacity of Compressed Shells Lyubomir ZdravkovnithinjcNo ratings yet

- Problem As Cinematic ADocument4 pagesProblem As Cinematic Aeduard jhon vasquez quintosNo ratings yet

- 6698 en Hub UnitsDocument13 pages6698 en Hub UnitsAlvaro MunozNo ratings yet

- ENGI Handbook 2006Document155 pagesENGI Handbook 2006swazsurv100% (1)

- IDRA 2 Analisi DimensionaleDocument14 pagesIDRA 2 Analisi DimensionaleNello D'AuriaNo ratings yet

- 10.1 Memoria de Cálculo de EstructurasDocument7 pages10.1 Memoria de Cálculo de EstructurasHerbert FloresNo ratings yet

- Hose & Electrick SakaiDocument6 pagesHose & Electrick SakaiUJANGNo ratings yet

- TME1 Uso e ManutenzioneDocument20 pagesTME1 Uso e Manutenzionecorsini999No ratings yet

- Conventional Pumping Unit Specification BUKAKADocument2 pagesConventional Pumping Unit Specification BUKAKAachmad mahmudyNo ratings yet

- Mechanical Seal-Part One PDFDocument193 pagesMechanical Seal-Part One PDFusmaniqbal15No ratings yet

- Review On Bore Well Pipe Lifting and Transportation Machine Ijariie8295Document4 pagesReview On Bore Well Pipe Lifting and Transportation Machine Ijariie8295KADIRIPURAM ARJUNNo ratings yet

- LHM 200SCDocument92 pagesLHM 200SCInnova TranspaletNo ratings yet

- Propiedades de Los Fluidos - Adrian CalderinDocument13 pagesPropiedades de Los Fluidos - Adrian CalderinAna SantanaNo ratings yet

- Hydraulic System Troubleshooting, Testing and AdjustmentDocument33 pagesHydraulic System Troubleshooting, Testing and AdjustmentBoris Zhilkin100% (1)

- Construction Plan For WorkshopDocument118 pagesConstruction Plan For WorkshopMohammed KhalidNo ratings yet

- Dinamica Dei Fluidi - FisicaDocument14 pagesDinamica Dei Fluidi - FisicaAxelDustNo ratings yet

- Champion HM Series Hammermill BrochureDocument4 pagesChampion HM Series Hammermill Brochurejohn patrick camoNo ratings yet

- 3828A20454J SpanishDocument28 pages3828A20454J SpanishRoberto SuarezNo ratings yet

- Structural Reliability of Ultra High-Performance Fibre Reinforced Concrete Beams in FlexureDocument12 pagesStructural Reliability of Ultra High-Performance Fibre Reinforced Concrete Beams in FlexureGemiezNo ratings yet

- Norsok D-10 Well Barrier Element Acceptance Table 2Document1 pageNorsok D-10 Well Barrier Element Acceptance Table 2Carlos OlmosNo ratings yet

- 9794 2 - A Grease Nipples Flush Type DIN 3405, Form A, Straight 97942 - A Grease Nipples Flush Type DIN 3405, Form A, StraightDocument2 pages9794 2 - A Grease Nipples Flush Type DIN 3405, Form A, Straight 97942 - A Grease Nipples Flush Type DIN 3405, Form A, StraightMauricio SánchezNo ratings yet

- Common Rail System Handling Instructions PDFDocument35 pagesCommon Rail System Handling Instructions PDFTung NguyenNo ratings yet

- T404Document5 pagesT404yavkoyNo ratings yet