Professional Documents

Culture Documents

Planta de Tratamiento Aguas G y N DRL (MANUAL)

Uploaded by

joroma580 ratings0% found this document useful (0 votes)

20 views26 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views26 pagesPlanta de Tratamiento Aguas G y N DRL (MANUAL)

Uploaded by

joroma58Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 26

SWEM Type multilevel marine sewage teatment plant ___Instuetion Book 321DF-1M-00SM

SWCM Type

Marine Sewage Treatment Plant

Manual

Implement of IMO MEPC.159 (55) Resolution

Dongtai City Dongfang Marine Fitting Co., Ltd

Dongil City Dongiang Marine Fiting Co Lid, Page T0126

SWCM ‘ype multilevel marine sewage treatment plant____Instruetion Book 321DF-1M.00SM

Marks.

1 The sewage treatment plant as a Type ll marine sanitation device, MSD can be

used on un-inspected vessels.

2 The device is designed to operate in salt or fresh water.

3 The test pressure of the tank is 0.021MPa,

4 The effluent quality of the device is in compliance with the standards of

IMO MEPC159 (55, and 33CFR159 for type II device.

WARNING

1 The plant cannot be installed in explosive atmosphere.

2 Paint tar epoxy as that coat on inside surface of the tank, welding should not

be worked on the surface of the tank.

3. It needs clear space at front of device 600 mm and right side of device 300

mm to allow for operation and maintenance of the device.

4 Any anti-virus agent can’t be used in the progress of device using.

Type description

swe M — x

Rated number of persons allowed

Membrane Biological Reactor (MBR)

SWCM series

Dongiai City Dongiang Marine Fiting Co, Tid, Page 20126

‘SWCM ‘Type multilevel marine sewage treatment plant Instruction Book 321DF-1M-00SM

Contents

1 Preface

2 Specifications and Main Technical Performance

3 Working Principles

4 Installation Requirements

5 Operation Instructions

6 Trouble Shootings

7 Maintenance

Bonga Ciy Dangling Marine Fiting Co, LA Page 3 25

SWCM ‘Type multilevel marine sewage treatment plant Instruction Book: 321DF-1M008M

1 Preface

This plant is applicable to treat the sewage, which means human body wastes and the wastes from

the toilets on vessels and which is also called “black water”. It is also applicable to treat galley &

shower drainage which is called “grey water” on condition that the “grey water” should be

pretreated or should select a bigger capacity model to match witl

Marine Sewage Treatment Plant belongs to the key devices for prevention of pollution form ships

in seas and oceans according to the revised Annex IV of the Intemational Convention of the

Prevention of Pollution (MARPOL 73/78), This device is according to the MEPC.159(55)

resolution enacted on 13 October 2006, which is called “new standards”. The convention

(MARPOL 73/78) provides that all STPs installed on board on or after 1 January 2010 should meet

the MEPC. 159(55) resolution

‘Summary all the rules and effluent standards as followings

IMO IMO

__| old Standard | New Standard | USCC | Alaska

Tss_____(mg) 50 Beas) 130__| 30

BODS (mg/l) 50 25____| NR 30

COD (mg/l) NR 125 NR NR _|

coliform (per 100ml) 250, 100 _200 20

PH é 6-9 6-85 NR 6-9

Residual chlorine (mg/l) NR <05 NR 10

Duration of type approval test (days) 10 16 10 30

The SWCM type marine sewage treaiment plant uses activated sludge, contact oxidizing and

principle of biologic membrane to digest the organic pollutant, which can treat sewage effectively

and reach at the IMO new effluent standard or other stricter requirements.

The device is patent product, provided with independent innovation intellectual property.

Warnin;

Mechanical Hazards

Before maintenance is performed on motor driven equipment, the main circuit switch

should be off and labeled “OUT OF SERVICE”. Only authorized maintenance

personnel can make repairs to equipment

Electrical Hazards

‘The equipment is supplied with high voltage that is dangerous and could prove fatal

if contacted by personnel. Under no circumstances should any door or cover be

removed or tapered in any way. To avoid electrical shock, remove the electrical

power by placing the main circuit switch on “off” position, do this before performing

‘Dongia Ciy Dongling Marine Fiting Co, ba, Page 40826

SWCD Type mlidvel ain evagetximentplant___Tastuston Bok S2IDE-IMans4

any maintenance on electrical equipment or motors. Personnel should exercise

extreme caution when opening the door of the electric control cabinet.

Disease Hazards

Sewage is a common mode of transmission for parasite organisms such as bacteria,

fungi, protozoa, viruses and worms; some of these may be pathogenic, meaning they

have the capacity of causing serious communicable diseases. Most diseases

associated with sewage result from hand to mouth transfer of the pathogenic

organisms. Good personnel habits by those servicing or in any way coming in contact

with the equipment are imperative.

After coming in contact with sewage on any contaminated equipment items,

personnel should thoroughly clean themselves with a disinfectant soap solution. This

precaution is an absolute requirement before eating, drinking, smoking or performing

any hand to mouth functions. Skin abrasions, punctures, or any other wounds require

immediate and proper medical attention,

Dongtd Ciy Dongiing Marine Fiting Co, Lid. Page 30126

Instruction Book S21DF-1M-00SM

SWM Type mule

2 Main technical performance

marine sewage treatment pl

Iz SWCM-

] : ae

~~ wo | is | 20 | 2s | 30 | 40 | so | 60 | 80 | 100 | 120] 150 | 200 | 250 | 300 | 400

arias 840 | 1190 | 1540} 1890 | 2310 | 3080 | 3780 | 4480 | 6020 | 7700 | 9100 | 11200 | 14700 | 18200 | 23100 | 30800

voap| Peles’ 7 tos | 14a | 193 | 237 | 289 | 385 | 473 | soo | 753 | 963 | 1138| 1400 | 1838 | 2275 | 2888 | 3850

Organic load 5

(ebony) | 242 | 0595 | 0.77 | as4s | 1155 | 1.54 | 189 | 224 | 301 | 385] 455] 5.6 | 735 | sto | ss | 154 ||

Gara 10 | 1s | 20 | 25 | 30 | 40 | so | 60 | 80 | 100] 120] 150 | 200 | 250 | 300 | 400

‘Max capacity (men) 12 17 2 27 33, 44 54 64 86 M0 | 130 160, 210 | 260 330 440

Electricity ‘AC 380V, S0HZ. 39/AC4ISV, SOHZ. 3Q/AC 440, 60Hz, 39

Power (kW) 25 [23 [25] 25 | 25 [30[30]35]40[40[ 40] 60 | 60 | 70 | 90 |

1510 | 1870 | 1743 | 1935 | 1985 | 2400 | 2410 | 2670 | 2780 | 2795 | 3000 | 3050 | 3600 | 3880 | 4750 | 5950

Outline dimension | x | x | x | x x |« |x| «|e | we | we] x x x x x

(mm) 1200 | 1200 | 1400] 1400 | 1500 | 1600 | 1700 | 1700 | 1900 | 2000 | 2000 | 2200 | 2200 | 2400 | 2400 | 2400 |

Lew x x x x x x x x x x x x x % x x

a. 1300 | 1400 | 1525 | 1560 | 1650 | 1700 | 1850 | 1850 | 20s0 | 2200 | 2200 | 2300 | 2350_| 2570 | 2570 | 2570

Ez pameee 900 | 1000 | 1000} 1100 | 1200 | 1300 | 1450 | 1600 | 1850 | 2200 | 2300 | 2800 | 3000 | 3300 | 3700 | 4200

weight et weit 2

(kg) 1775 | 2283 | 2640} 2740 3500 | 4400 | 5073 | 5270 | 6517 | 8268 | 9166 | 11340 | 13267 | 16538 | 20357 | 25417

Effluent standard BODS+25mgiL. COD-F12SmgiL ,TSS+3Smg/L . coliform>100/100ml, PH6~85, ClatOSmg/L

Remarks: Our company keeps the right of modifying the outline, the outline is only for your reference, please take the material object as standard,

Dongtai City Donglang Marine Fitting Co.,Ltd Page 6826

SSWCM Type multeve min evagetestment lant __Tnsouson Book S21DE-IM00SM

3 System principle

3.1 Process pri

ple; please refer to 321DF-IM-00XT

The device adopts activated sludge, contact oxidizi

2 and principle of biologic membrane to

digest the organic pollutant, which can treat sewage effectively and meet the IMO new effluent

standard or other stricter requirements.

The treatment procedures of the plants are shown as following:

Sewage inlet—> aeration—> contact oxidation —> setting —* membrane* sterilize

discharge

oxidizing

sludge return

|__ sludge ret

In the Ist stage aeration tank, the activated sludge mainly consisting of aerobic bacteria form

sticky flock is used to absorb and digest the organic substance to carbon dioxide and water under

the condition of aeration, and produce new activated sludge in the meantime. The bacteria will

die owing to the decreasing of organic pollution substance. The death bacteria are digested by

the protozoa and the metazoan, which attached in the active sludge, The 95% of the sewage is

easy-digested organic substance, they are oxidized entirely

‘The soft bio-film stuffing is hung in the 2™ stage contact oxidizing compartment. The bio-film,

which can digest organic substance, is floated in water. Most of the protozoa and the metazoan

live in the fiber film. The organic substance is further digested by the protozoa on film. If

restarting plant after stopped for some while, the restarting time is much quicker than that of

conventional aeration starting time, because of the bacteria existing in the spore on the

membrane. Meanwhile, the soft stuffing, similar as “cotton boll”, is able to expand as over

nutrition and absorb superfluous activated sludge, or digest themselves as lack of nutrition,

which is also called “endogenous respiration”. The “cotton boll” will be shrunk and wait for the

future nutrition

Then the sewage enters into setting tank and the sludge will settle as no aeration and with help of

solid filter material, The activated sludge sediment accumulated in the setting tank is to be

returned to the 1* stage aeration tank by the method of air lifting for reproducing of aerobe

medium,

The clear supernatant liquid then flows into membrane tank, and creates good operational

conditions for membrane module. The membrane module placed in membrane tank is an

immerged type and can create biochemical reaction, which is also called membrane bio-reactor

‘Dongtai Ciy Dongiing Marine Fiting Go. Lid Page T0126

SWCM Type multilevel marine sewage teatment plant Instruction Book 321DF-IM-00SM

(MBR). The membrane is made of hollow fiber ultra filtration material, through which the

permeated clean water is sucked by vacuum pump, then disinfected by ultraviolet ray (or ozone),

it can meet effluent standard, and discharge overboard or to clean holding tank on ships.

Itis designed automatic lifting procedure for the sludge sediment in membrane tank. When the

vacuum pump is working, the solenoid valve opens once every 30min to lift the sludge in

membrane tank to the I* stage coalscer, SV2 is closed after it is opened for Smin. Then the

solenoid valve SV3 in settling tank opens for Smin to lift the sludge in settling tank to the I*

stage coalescer, And that cycle repeats. Note: only when the vacuum pump is working, the

device can lift the sludge in membrane tank

During the working process of vacuum pump, it runs for 9min and stops for Imin

automatically in regular, during the time of stopping, the scale on the membrane threads drops

by no suction force, and aeration at same time, it is good for scrubbing the membrane threads to

prolong the cleaning period. The membrane can be cleaned “on-line” due the membrane tank is,

single closed structure, easily without taking out. The scale on the membrane threads can be

cleaned quickly by feeding chemical into membrane tank, and aeration at same time, working as

washing machine. Then the membrane flow flux can be recovered to original status. If only

soaking but no aeration, the effect may be poor

The sludge discharge cycle depends on the sewage quality and load,

is appropriate to discharge

the residual sludge once 6 to 9 months. In normal operation, take out the liquid including

suspended matters with the measuring cylinder of 100m! from sampling outlet. Still for half an

hour, Ifthe sediment interface is over 60%, please discharge sludge overboard or to the overflow

tank provided by shipyard

3.2 Main spare parts

(1) Air pump

Air pump is used for transporting air to the plant. The plant is equipped with two kinds of air

pump, they are main air pump and lifting air pump. They have the same structure but different

functions, The main air pump is used to aerate to aeration tank and contact oxidation tank. The

lifting air pump is used to lift the sludge in membrane tank and settling tank to aeration tank and

to aerate to membrane tank.

(2) Cutting and discharge pump

Cutting and discharge pump is the open impeller centrifugal pump, the sewage is cut and

macerated by cutting pump to recycle or discharge it to overboard at the emergency time, The

sewage in all tanks can be discharged empty, so long as open the corresponding bottom valves

(3) Vacuum pump

‘Vacuum pump is a centrifugal pump with stronger ability of self-suction, but it is better to keep

some water in the pipes to avoid the problem for restarting. It can create a certain difference

pressure and make the water permeate the membrane, If the membrane is blocked for pollution

Dongiai City Dongiang Marine Fiting Co, Dig Pages of 26

SWCM Type mulilevel marine sewage teatment plant ___Tnstrvtion Book 321DF-1N.008M

and not suction smoothly, the discharge capacity will come down, and cause the equipment to

alarm at high level

(4) Ultraviolet ray sterilizer

The disinfection principle of ultraviolet ray sterilization is to adopt appropriate length of UV

wave to damage the molecular structure of the DNA (desoxyribonucleic acid) or RNA

(ribonucleic acid) of organism cell. It causes the deaths of growing cell and (or) regenerative

cells and makes content of coli form in effluent meet the requirement of discharge standard

Its main element is lamp pipe to take care. Please see the “manual book” of “JX-UV type UV

Disinfection Device”, if maintenance:

(5) Electric control box

The electric box is provided with the function of electric operation, protection and procedure

control for the equipment.

4 Installation requirements

4.1 Pipes

(A) Sewage inlet pipe

‘The sewage from toilet is divided into two roads, one road is leaded to overboard, the

other road is leaded into the device. They are separated by check valves (DN150). The two

valves should be placed as near as possible.

(2) Discharging water pipe

The inlet of the cutting pump and part-time for discharge pump is connected with the aeration,

the contact oxidizing, the settling and the membrane tank and to be separated by ball valve

Generally, the ball valve V1, V7 of aeration tank is normal opened, when the condition is in

emergency, open the emergency discharge valve V6, close V7, the smashed water is discharged

overboard or to international shore connector directly through discharge pump. Close V1 and

open valves V6, V7 and V8 to discharge the supernatant from settling tank, the normal effluent

is discharged from membrane tank by vacuum pump.

Note: When installing the water discharging pipe, the water discharging pipe should be

leaded from water outlet to overboard. A check valve should be provided. In normal

condition, the height of discharge outlet should not exceed the level of working liquid in unit.

I the di

connection is above the draft water line, an inverted drain anti-siphon should be

provided to prevent the effluent self-flow from the device to overboard.

(3)Ventilation Pipe

‘There is an air-collecting dome on the top of the aeration tank. The dome can be used to collect

the air escaped from water, in the other function; it can be used to restrain the swaying of the

Dongtai City Dongtang Marine Fiting Co.,11d, Page 9 of 25

SCM Type multilevel marine sewage treatment plant___Insiction Book 321 DF-1M-00SM

liquid in the tank. The vent pipe is connected with air-collecting, domes. When installing, the air

vent pipe should be led from vent of plant to the upper deck; the flue should be 3 meters higher

than the deck, At the top a gooseneck shall be installed on the pipe end (shipyards supply)

Although the waste gas produced by aerobic bacteria does not contain odors and methane like a

common storage tank, it should be kept far away from residential areas or windows of living

house. The model of anti-fire sparking net can be selected according the dimension of vent inlet

(Please see the details in “marine pipe accessories” or consult our company),

Note: Transport pockets should not exist in pipe lines to prevent transport pockets

blocking up pipe lines, In addition vent pipe should be smooth, can’t be added any

addendum.,

(4)Air pipe

‘The compressed air from the main air pump Al enters into the aeration tank and contact

oxidizing tank through V11. The compressed air from the lifting air pump A2 is divided into

three ways through V10, one way is to solenoid valve SVI for aeration in membrane tank. The

other 2ways are to membrane tank and settling tank for air lifting the sludge automatically in

regular through the solenoid valves SV2, SV3 on the two pipes.

In case that either air pump is fixing, open V9, and then close either V10 or V1, to maintain the

air supply. Itis dangerous that the plant is working without air supply.

(5) Emergency overflow pipe

‘Water will overflow from the emergency outlet on the top of the settling tank when automatic

control and high level warming are out of order and the troubles have not been resolved. The

emergency outlet on the top of settling tank is connected to the bilge of the ship by overflow

pipe. The emergency overflow pipe should be provided by ship.

Note: Keep the overflow outlet unblocked. There couldn’t be any accessories.

(6)Flushing water pipe

One pipe of the fire fighting system on board should be connected to the flushing water

of the device for using when cleaning tank. The shipyard should install a check valve. The

flushing water pressure can’t be more than 0.3Mpa (usually is 0.1 Mpa). Try to use fresh water as,

flushing water.

(7) Emergency discharging pipe

‘The emergency discharging pipe is connected to overboard through the outlet of cutting pump.

Donguat City Dongiang Marine Fiting Co. Lid Page 10 of 26

SWCM Type multilevel marine sewage treatment plant ___Instwetion Book 321DF-1M-00SM

4.2 External flange connections

Model | Sewage | Gray water | Air vent | Emergent Overflow Flushing | Auto back | Dischargin

inlet | infet(reserved) discharging | outlet water | flushing | gwater |

outlot inlot_| water inlet | outlet

SWCM-10_ | DNIS0 DNOS DNIOG | _DN32 DNOS__[_DN32 [Das

SWCM-13_| DNIS0_|~—_DN@s__ | DNT00_[_DN32 DNOS__ | DN32 [N25

SWCM-20 | “DNIS0 DN6s | -DN100_|_DN32 DN6s | _DN32 [nos

SWCM-25_ | DNISO NOS DNIO0_| __DN32 DN6S__|_DN32 N25 |

SWCM-30 | DNISO NOS DN100_| N32 DN6s__ | DN32 DN2S,

SWCM.40_|-DNISO DNGS DNISO_| __DN32 DN6s_|_DN32 DN25

SWCM-50_|_DNISO NOs DNiSo_|__DN32 DN6s__|_DN40 DN2S

SWCM-60_[ DNI50 NGS DNISO_| __DN32 DN6s__| _DN4O DN2S

SWCM-80_|-DNISO DNGS DNIS0_| _DN4O DNés__| DN4O_|_DN2S__| _DN3Z

[/SWCM-100 [DNISO DN6S DNISO_| __DN4O DN6s__| DN40_| _DN25_| _DN32

['SWCM-120 | DNI50 DNGS DNIS0 DN4O DN6S) DN40_ [| _DN25 DN32

[SWEMETS0_|DNISO DNGS DNISO_| __DNaO DN8O__|DNaO_|_DN25__ | DN32

SWCM-200_|_DNISO DN6S DNIS0_| _DN4O DN80_| _DN40_| _DN25__| _DN32

‘SWCM-250_|-DNISO DN6S DN200_| __DN4O DN100__| DN4o_| _DN25__| _DN32

[sweM-300 | DNIS0 DNGS DN200_|__DNaO DNi00 | DNsO_|_DN25__ | DN32

SwCM-400 | DNIS0_[_DN6s_|-DN200_ | DNsO DNio0 | _DN40_|_DN25_ | _DN32

Note: the extemal connection flange of this plant is designed as per the National Standard

GB2506-2005, but also can be modified as per the results of negotiation between the customer

and company, technology department.

433 Standard shore connection

In order to connect the shore connection to match discharge pipe in ships, the discharge outlet

and emergency discharge outlet should be equipped with standard shore connector complying

with the requirements as followings:

Standard dimension of discharge connection flange

Trems Size

Outside Diameter 210mm

| Inside Diameter ‘Ace, to the outside diameter of pipes :

Diameter of Bolt 170mm

Ring

Channel of The 4 holes with 18mm diameter is distributing on the

Flange above-mentioned bolt ring, open the channel to the outside edge of

flange. The _width of channel slot is 18mm

Thickness of 16mm

Flange

Bolt and nut (Quantity -4 pieces; diameter: 16mm (with suitable length )

number, diameter

The flange should be designed as the one which can be connected with the pipe whose

maximal inner diameter is less than 100mm. And it should be made of steel or other equivalent

materials and its surface should be smooth. Together with a suitable gasket, its working

pressure should reach 0.6kg/om.

Dongiat Ciy Donglang Marine Fag Co, Lid Page 11 of 26

‘SWCM Type multilevel marine sewage treatment plant___Instruction Book 21D F-1M-00SM

For the ships whose molded depth is no more than Sm, the inside diameter of the discharge

connector should be 38mm. For merchant fleets i.e. passenger ferries, the discharge connector

can be equipped, which is approved by appropriate authority, such as quick-connect coupling

4.4. Installations

(1) The plant base is welded by channel steel 5#, 84 or10#, the connection between the ship base

which is supplied by shipyard and the plant base should be welded or bolted. The weld length

should be all around the ship base continuously with ship plate form. The bolt number has to

meet the base drawing of each model of device.

[2] A barrier should be provided on the location of the plant, which is 80mm height and is used to

collect the sewage in case constructed around of leakage from pump axle or overflow,

collected sewage is lead to a bilge tank, where has a submerged pump inside,

(8) Device should have electrical grounding connection after finishing connection of extemal

wires of the electric control box;

(4) A running water tap and a washbasin for cleaning and a space for chlorine storage room

should be provided. The space should be kept dry and far away from the place where

explosion may occur.

4.5 Electricity

() An electric wire power supply of 3 phase, 380V, S0Hz should be connected into the electric

control panel. The waterproof seal of wiring and connectors to the control box should be

ensured. If the water pump rotates in the wrong direction, the two incoming wiring terminals

should be exchanged with each other.

2)A place for installation with a minimum of 600mm free clearance in front of the control box to

allow for maintenance should be provided

5. Operation Instructions

5.1 The functions of electric control box control panel

(1) Procedure control switch St

‘The procedure control switch has three positions: auto, manual and high seas. The three working

conditions work independently. So circuits can’t affect each others.

when the device is in normal working, turn the procedure control switch $1 to “auto” position,

then the device will work continuously for 24h without guard.

® When cultivating bacteria, turn the switch to “manual” to cultivate bacteria and

commissioning

@When discharging to high seas, turn the switch to “high seas” position to discharge to high

Dongiai Cy Dongfing Marine Fiting Co. Lid Page 12 0f 26

SWCM Type multilevel marine sewage treatment plant Instruction Book 321DF-1M-00SM

seas or irregular sea area. If condition permission, discharge the sewage overboard without

‘treatment,

(2) The change-over switch $2 of cutting pump PI

‘The change-over switch $2 of cutting pump P1 has three positions: auto, manual and stop.

@®When S2 is turned to “manual” position, the cutting pump P1 will work continuously.

@When the procedure control switch S1 is turned to “high seas” position and the $2 is turned

to “auto” position, the cutting pump P1 controlled by PLC, if the liquid in device reaches the

middle level M2 in settling tank, the cutting pump P1 will start pump automatically. If the liquid

level falls to low level L2, the cutting pump P1 will stop, the device will implement high sea

discharging procedure to discharging the sewage without membrane treatment

@When the procedure control switch $1 is turned to “auto” or “manual” position and the $2

is turned to “auto” position, the cutting pump will work for 20min and stop for 20min, work

fitfally

@When $2 is tumed to * stop” position, the cutting pump will stop working,

(3) The change-over switeh S3 of vacuum pump P2

The change-over switch $3 of vacuum pump P2 has three positions: auto, manual and stop.

When the procedure switch $1 is turned to “manual” or “high seas” , the vacuum pump P2

can’t work automatically and manually.

@When the procedure control switch is turn to “auto”, The vacuum pump can implement the

following procedure:

1) When $3 is turned to “manual”, the vacuum pump P2 will work continuously, the vacuum

pump work indicator lamp will be bright, the UV light of UV sterilizer won’t be bright.

This function is just appropriate for testing machine.

2) When $3 is tured to “auto”, the liquid level rises to M2 , the solenoid valve SVI and

lifting air pump are working for aeration, the vacuum pump will start to work

automatically until the liquid level is lower than L2.

3) When the $3 is turned to “stop” position, the vacuum pump will stop working

(4) The change-over switch S4 of main air pump Al

@When $4 is turned to “manual”, the main air pump A1 will work conti

jously.

@When $4 is tuned to “auto”, The main air pump will work automatically controlled by device

internal procedure. It is usually used in “bacteria breeding”

@When $4 is turned to “stop”, the main air pump Al will stop working,

(5) The

1ange-over switch S5 of lifting air pump A2

Dongiat City Dangling Marine Fiting Co, Lid, Page 13 of 36

SWCM Type mullevel marine sewage testment plant ___Tstruetion Book 321DF-1N-008M

@When $5 is turned to “manual”, the lifting air pump will work continuously.

@When $5 is tured to “auto”, the lifting air pump A2 will work automatically controlled by

device internal procedure.

@When $5 is tured to “stop”, the lifting air pump A2 will stop working,

Note: When the change-over switch SS of lifting air pump A2 is turned to “manual”, the lifting

air pump will work continuously. This is just appropriated for transitory testing machine. The air

pump will idle run unless opening the membrane tank manually to aerate the solenoid valve

svi

(6)The change-over switches $6, S7, $8 and S9 of solenoid valves

The four solenoid valves SV1, SV2, SV3 and SV4 are separately controlled by change-over

switches $6, $7, $8 and $9. They all have auto and manual function. Normally they are in

auto” status. When one or several of the solenoid valve is out of order or needed to use

‘manual, please turn to “manual” separately.

(7)The change-over switch S10 of UV light

The change-over switch has three positions. They are manual, auto and stop. If it needs manual,

please turn the change-over switch to “manual”.

(8)Indicator light

Control power and comprehensive alarm indicator light: When the device is plugged in and

the device is alarming for the fault, the indicator will be bright.

®ndicator light of solenoid valve: When the four solenoid valves SV1, SV2, SV3 and SV4 are

all in normal working status, the indicator light of solenoid valve will be bright.

@The indicator lights of pumps and UV light: When the main air pump A1, lifting air pump A2,

cutting pump PI, vacuum pump P2 and UV light are all in normal working status, the indicator

light will be bright.

@The indicator light of liquid level control: When the liquid level in device reaches the low

level L1, middle level M1, high level H11 in aeration tank and the low level L2, middle level M2,

igh level H2 in membrane tank separately, the indicator light will be bright.

(9) Noise elimination button TAL:

comprehensive alarm sound will disappear.

Press the noise elimination button TAL, the

5.2 The preparation before normal work

(1) Check the power of electric box to see whether it complies with the design requirements;

Check the rotation direction of all pumps, which should be adjusted as incorrect. Engage or turn

on the power switch and all sub-switches.

Dongiat City Donating Marine Fiting Co, Tid Page 14 of 26

SWCM Type multilevel marine sewage teatment plant Instruction Book S21DF-1M-00SM_

(2) Check the tightness of tank body, valves and pipe accessories, open the flushing water ball

valve at the place of flushing water outlet and feed water into plant until the water level is up to

MI position. Check whether the tank body, valves and piping have leakages

5.3 Breeding bacteria

The new plant should have the “breeding bacteria” procedure before raw sewage treatment.

‘Tum the procedure control switch $1 to “manual” position, it’s also called “breeding bacteria”

mode, The change-over switch $2 of cutting pump P1, change-over switch $3 of vacuum pump

P2 are turned to “stop” position, the change-over switch $4 of main air pump Al, change-over

switch $5 of lifting pump A2 are turned to the “stop” position, Close the valves V1, V2, V3, V4,

V5, V6, V7, V8 and VOmanually. Open (manually) valves V10, VII. At this point the plant is

completely controlled by personnel and should be monitored closely.

Open sewage inlet valve, the sewage will enter into the plant slowly until the level reaches the

M2 position, then close it, Manually open V1, V7. Tum the change-over switch S2 of cutting

pump PI to “Auto”, the pump PI will macerate the sewage in aeration tank, and carry out

“stagnate aeration” where sewage or sludge is not exchanges so that the bacteria can breed

One day later turn the change-over switch $4 of main air pump Al to “Stop” for 1h, and

manually turn the lifting air pump A2, change-over switch $5 and the change-over switch $8 of

solenoid valve SV3 to “Manual”. More nutrients, such as chemical fertilizers can be fed into

tank according the density of sewage. Open V6, V8, close V1, V7 manually, turn the

change-over switch $2 of cutting pump P1 to “manual” to discharge some water in the setting

tank until down to L2 water level. Then close V6, V8, open V1, V7, and let raw sewage enter

again, repeat the above operation. It requires about 3~4 weeks to breed enough activated sludge.

Note: If the activated sludge seed material can be feed into plant directly, it will speed up the

process of breeding bacteria

Take a sample of sewage in a 100ml glass cylinder and observe the breeding state of the

activated sludge. When it reaches one-third sediment, after 30min, it indicates that the sludge

volume is equal to 30% and the” breeding bacteria” process has been completed.

5.4 Normal operations

(1) Manually open V1, V5, V7,V8, V10, V11, V12, V13, and close V2,V3,V4, V6, V9, V14, turn

the change-over switch S2 of cutting pump P1 to “auto” position, The cutting pump will smash

sewage intermittently and circularly, start 20min and stop 20min,

(2) Tur the procedure control switch $1 to “auto” position,

(3)Turm the change-over switch $4 of main air pump Al to “manual” position, Al will run

continuously. The air enters into the aeration and contact oxidizing tanks.

‘Dongiat Ciiy Dangling Marine Fiting Co id, Page 13 0f 26

SWCM Type mulilevel marine sewage treatment plant Instruction Book, 321DF-1M-00SM.

(4)Tum UV switch, all solenoid valves SV1—SV4 to “auto” position.

(5) Turn the change-over switch S5 of lifting air pump A2 to “auto” position, A2 will be operated

according the procedure.

(6) Turn the change-over switch $3 of vacuum pump P2 to “auto” position, P2 will be operated

by the level of the membrane tank, P 2 will start at mid level of the tank and stop at the low

position

(7) Open the inlet valve of raw sewage and let the sewage enter into the plant.

(8) Meanwhile the valve V12 of the vacuum pump should be adjusted so that the flow is

controlled at the rated value in instruction manual, If the flow rate is too high it will cause high a

trans-membrane pressure differential; if the flow rate is too slow it will cause a high level alarm.

Note: When the vacuum pump P2 is in operation, air should be supplied to membrane tank.

‘The vacuum pump P2 will be started up as the level reaches the M2 position and stopped

automatically when the tank level is below the L2 position, P2 should not be started up if

the level is lower than L2 position.

(9) When the tank level is up to the M2 position, the vacuum pump will start and operate a 10

‘minute cycle, on Smin and off Imin. The air pump is run continuously during the Imin stop time

of vacuum pump to enable to a self-cleaning for the membrane threads. Please refer to Figure |

Smin

‘min

beAT AR A2 | pea eee

Figure 1, In normal water-level, Vacuum pump run 9min and stop Imin

Thus, the plant enters into normal operation status.

(10) the auto-return of sludge

1) The sludge in settling tank will be lifted and retumed to aeration tank according the designed

procedure in figure 2: where the solenoid valve SV2 is opened for Smin every 30min,

cya 3tnin ape SiN

[ :

A2

Figure2, the sludge lifting valve SV2 of membrane tank close 30min, open Smin

2) Sludge lifting in settling tank: After the valve SV2 is opened for Smin, solenoid valve SV3 is

opened for Smin immediately, lift the sludge in settling tank and return it to the 1" stage. (see

Figure 3),

‘Dongiai City Donatang Marine Fiting Co,, Ud Page 16 0826

SWCM Type multilevel marine sewage treatment plant Instruction Book 321DF-1M-00SM

Geeeeneeaneeees| at Smin. es

evo C\/ 2m

SV 2 SV34

Fighure3

4) After the sludge in settling tank is lifted for Smin, valve SV4 is opened for Imin

immediately to blow down the scum on surface of water in settling tank, please refer to

Figure 4.

Smin Amin

Fighuret

5.5 Comprehensive alarm

When the liquid level in device is up to high position, the system will send out an audible and

visual alarm signal and the “stop to use” lamp sign in toilet will light, reminding the crews to not

flush for a while, If the level is staying in high position for a long time, the operator should

check the plant for problems

5.6 High sea discharge

According to the international convention, it is permitted to discharge sewage without any

treatment in high sea and unregulated sea. So crews can cease the use of membrane modules and

use according to this regulation, There are two operation methods as follows

(1) Close sewage inlet to the device and to discharge sewage overboard directly, meanwhile turn

the procedure switch SI to “Breeding bacteria” position, so as to conserve seeds in aeration tank

and restart the plant quickly in next time.

(2) Do not close sewage inlet and let sewage flow into the device. At that time, $1 should be

turned to “High Seas Discharge” then open valves V6, V8, and close valves V1, V2, V3,V4, VS,

‘V7. Turn the change-over switch S2 of cutting pump P1 to “auto” (“High Seas Discharge”). Turn

the change-over switch $3 of vacuum pump to “stop”, then membrane modules and vacuum

pump will not operate. Turn the change-over switch $4 of main air pump to “manual”, then main

air pump will run co:

inuously. Then turn the change-over switch S6 of solenoid valve SVI to

“auto” to prolong the life of membrane modules.

5.7 The sludge discharge

(1) Take @ mixed sludge water from the aeration tank with a 100ml graduated cylinder, under the

‘Dongat City Donglang Marine Fiting Go. Page 17 of 26

SWCM Type multilevel marine sewage treatment plant ___Instction Book 321DE-IM-00SM

normal operation conditions. After the sludge rests for half an hour, if the level of sediment

exceeds 60% the sludge in the aeration tank should be discharged to overboard or to the

emergency overflow tank provided by the shipyard

(2) When discharging the sludge in the aeration tank, close V7, open V6, V2, and start the

cutting pump manually. When the liquid level drops down to L1 position, stop the cutting pump

manually,

(3) The discharge frequency of the sludge is generally 3~6 months. And the sludge must be

discharged in high seas. Whenever the ship is navigating on the open sea, the sludge can be

discharged at anytime even if it is <6 months. Do not discharge all of the sludge in order to keep

a certain amount of seed material for device restart.

(4) The MARPOL73/78 allows to discharge the macerated and disinfected sewage outside 3

nautical miles from land and the raw sewage outside 12 nautical miles from land. When in a

harbor, or where has recycle vessel, the sludge can be discharged by shore connection.

5.8“Zero Load”

“Zero load” means stopping sewage inflow for a long period time (>1 days). To avoid starvation

of seed material, it is advisable to put some material into a dormancy state by turning the

change-over switch $4 of pump Al to “Auto” to let the air pump sequence stop and start to

reduce the supply of oxygen. The Zero Load” should be performed when the level is at the L1

position

5.9 Stop

If you intend to stop the plant for a long time (3 months), close the sewage inlet valve;

discharge thoroughly all water in the device; open the flushing water valve V15 of the device,

‘wash the tank with flushing water for twice, and discharge thoroughly through opening valve V1,

V2, V3,V4, V6 by pump or empty the tanks through drain screw.

In the end, cut off the power supply.

6. Troubleshooting

No. ‘Trouble Possible cause — Suggestion

‘The pipeline between contact

1 | Hl iswaming, H2 not | oxidation tank and settling tank is Clean the pipe

blocked.

Read the How meter, iPabove rated

flow capacity, may caused by peak | Stop using the toilet for a while

load.

Hand H2 are | Read the flow meter, below rated

2 pny flow capacity, may caused by block | Open V13, check outlet pipes

of discharge pipe

Read the flow meter, if below rated

flow capacity, may caused by ‘Clean the membrane

membrane pollution

Bongiai Ciy Dongiing Marine Fiting Co, Tid Page 18 of 26

SWCM Type multilevel marine sewage treatment plant

Insirvtion Book

321DF-1M-00SM

The outlet valve is not opened ‘Open the outlet valve]

Replace the slide vane or replace

3 | Voice of air pump is Slide vane is damaged the air pump

‘abnormal ‘The lifting air pump is not opened

synchronously for the problem of Cheek the control circuit

solenoid valve

go) Neeser 7 Suction is not a Check the suction pipes

‘pump is abnormal 'o water inside, maybe the Clean the membrane

membrane is polluted

‘SV3 isnot opened | The sludge in settling tank can not :

5 ee a tits regularly ‘Check the control circuit

| 8V2docs not it and. |_95 opened, cannot stop aration CloseV9

return the sludge | Lifting air pump is not synchronous ‘Chock the control circuit

| 7] ae Pat UV-lamp is broken Replace the lamp

i The procedure switch position is not

8 | Wioneoreratim ot | Quy wih he eoniion af aie, | RE%@tH63 proeiurescaefilly in

vice ee ‘manual book

- ‘Activated sludge is not enough or

9 | Water quality is not qualified Breeding bacteria

| ualified The membrane is out of order Replace membrane

7. Maintenance

7.1 Cutting pump

(1) Purpose:

The cutting pump installed in front of the plant, is used to macerate and recycle the sewage in

the aeration tank, and also can be used to discharge the sludge in all tanks of main body. When

carrying out the “high sea discharge” or “emergency discharge”, it also can be the discharge

pump.

(2) Operation and maintenance

@If the pump is found leaked, it is needed to stop and check, close valves in order to avoid

causing electrical burn. Replace a new seal ring when necessary. When the pump is working

normally, the leakage of sealing ring should be less than 10ml/h

@t is need to put calcium-sodium base grease into the place between shaft seals of pump

through the oil cup on the pump so as to lubricate oil seal and bushing,

@®When the long period of time without using, it is needed to remove it to clean, When

removing, please don’t damage the two sealing faces of mechanical seal ring, Please coat a right

amount of lube oil when reassembling and keep it somewhere safe.

@The pump can’t idle run in order to avoid burning out the seal ring

7.2 Air pump

Dongtai City Dongiang Marine Fitiag Co. Page 19 of 26

SSWCM Type mulilevel marine sewage restment plant ___Tnstrtion Book 321DF-1M.008M.

(1) Structure

The air pump body and its motor are fixed on a common base, a coupling connects them. The

rotor of the air pump has a supporting connection at both ends. The fan of the motor cools the

device.

(2) Operation and maintenance

® The air pump should be installed in a stable location in a clear well ventilated and room

temperature environment,

® The sliding vane is made of self-lubricating material and no oil

is required for the pump.

® The air pump inlet is open to air with a particulate filter in place.

® The air pump filter and the filter element should be kept clean, clean them once every two

months,

© Clean and reassemble the air pump once every 6 months. Inject No.2 or No.3 calcium grease

or bentonite grease into the rolling bearing after cleaning. If the rotor operates ineffectively,

replace it or clear it, Replace the sliding, vane if it is damaged. Pay attention to the following

notes when replacing the sliding vane.

1) Take care not to break the sliding vane. The edge of new sliding vane needs to be chamfered.

The bevel edge of the sliding vane needs to be arranged outside the rotor groove an

direction need to be same as the circular of outside diameter of the rotor.

2) Do not touch the machined surface and do not allow dirt or debris to enter into the air pump.

3) Clear inside surface of the air pump with a clean dry cloth

4) When the plant is stored, the pump shall be kept from rust and moisture.

7.3 Electric control box

Warning: Make sure the external power supply switches are off and that the current

breakers in electric control box are also off when performing maintenance.

(Removal

Replacement of control box components does not require removal of entire panel

When checking the components and removing wires, pay attention to the mark and code of wire

for reassembly.

(2) Reassembly

When it is necessary to replace damaged parts or reassemble components, refer to the electrical

principle diagram, Ensure that the wiring is correct before turning the circuit breaker to ON.

7.4 Membrane module

(1)The storage of membrane

Dongiat Ciy Dangling Marine Fiting Co, 1d Page 20 of 26

SWCM Type multilevel marine sewage treatment plant Instruction Book 321DF-1M-00SM

If the vessel should stay on a cold area for a long time and the device is in a place where is lower

than 0°C, please do the following anti-freezing measures: Mix ethylene glycol of 20-60% as

antifreeze solution whose freezing point is -49°C. Pour it into membrane tank. The antifreeze

solution has no damages for membrane and plastic. The higher the concentration is, the lower

the freezing point becomes.

Warning: The membrane modules can’t function in subzero water. And they also can’t be

placed in environment of subzero temperature except being stored separately when

transiting or storing the plant.

(2)The structure and installation of membrane module

@Membrane module (hereinafter called MBR-module) structure:

There is KH-MBR-8.18 type piece in SWCM type STP. It’s diagram of structure size as follows.

KH-MBR of MBR-pieces

@KH-MBR type MBR-module connection manner

In normal use, KH-MBR type MBR-module can be combined one group with single piece, two

pieces or three pieces as required, and fixed on membrane shelves in the biochemical treatment

tank. This system is designed to use a single or a two piece connection for a group. Please see

the attached diagram for the connections and dimensions. In the process of usage, membrane

threads should be paralleled with the level of biochemical treatment tank.

Dongat Ciy Dongling Marine Filing Co, Lid Pagel of 26

SWCM Type multilevel marine sewage weatment plant____Instruction Book. 321 DF-IM-00SM

750

@Water collection pipe of MBR-module

All outlets of MBR groups are connected in parallel to an outflow pipe, which is called “water

collection pipe”, The number of joints on water collection pipe is decided by the number of

MBR groups. Connect the water collection pipe to the vacuum pump; the effluent from

MBR-module is discharged through the pump.

The seal connector joints of membrane module and water collection pipe are connected by PU

flexible tube.

~

}

a

eects

connect to connector ants of NER- piece by PC Hele Lute.

@lnstallation steps of MBR-module and related items

1) Fix the bracket of MBR-module in membrane tank first, when replacing the membrane, to

prevent vibration and shaking

2) At the same time, you may feed the raw sewage into the aeration tank, and breed the sludge

seed material in accordance with the activated sludge biochemical treatment method

3) Note: Only open the membrane tank inlet valve VS when the sludge activity is good and the

‘Dongil Gay Dongiing Marine Fiting Go.,Lid Page22 of 26

SWCM Type multilevel marine sewage teatment plant Instruction Book 321DF-1M00SM

settlement ratio is more 20-30%.

4) Connect the loose joints between MBR-plates after the installation of MBR-plates according

to the assembly methods as above-mentioned. Please pay attention to place sealing gaskets

and seal up the loose joints.

5) After the MBR module groups are connected well and slid into the channels of membrane

module bracket, connect the effluent outlet of MBR module groups to the connector joint of

the water collection pipe

6) In order to prevent the MBR-module from floating at the time of aeration in biochemical

treatment tank, a fixed rod is needed after the MBR-modules are slotted into the channels

7) As a debugging for the MBR-module, inject water into the collection pipe through a prepared

hole until the suction pump is full of water, then the pump can be started up.

8) The membrane threads should be submerged in the water, to prevent the MBR-module from

losing water.

9) Please check the packing container of the modules before installation, to see whether the

airproof bag is broken. If seal is broken or the protective solution is missing, the MBR-module

will require re-treatment or consult the relevant technician,

(3)Matters needed attention when using membrane

OThe products provided to our clients have been pretreated, and can be used directly after being

installed in the MBR reactor.

If the clients have purchased the non pretreated MBR-modules or the module has lost the

protective saline solution during transport, the MBR-module should be pretreated before using,

The pre-treatment method is to immerge membrane in the 95% of industrial alcohol for about 10

minutes, then rinse it with water. If the treated MBR-module will not be used immediately, it

should be sealed in air tight packaging in order to maintain membrane thread moist.

® In order to save the life of membrane, proper operation is very important, For example, use

the membrane process all the time, so the membrane is working for long periods of time without

stops. Especially when the vessel is navigating in high sea or unregulated sea areas, the sewage

is allowed to discharge overboard directly, due to the fact that sewage is a kind of nutrition for

sea life-forms and the sea also has the ability of self-cleaning. The life of membrane can be

prolonged by always performing the “high sea procedure” for the plant.

® In normal operation, the sewage in membrane tank is transferred from settling tank, and does

not contain large solids so it has little damage to membrane, The flushing water should not

contain dirt. Do not throw cloth into the toilet, which may wind the membrane. A hair filter

should be used, if the water from showers enters into the plant

Dongiat Ciy Dangling Marine Fiting Co. Lid, Page 33 of 26

SWCM Type mullevel marine sewage weatment plant ___Insietion Book 321DF-1N-00SM

@ The sludge in membrane tank can be concentrated; the high density can cause scale buildup,

which may cause the membrane not to recover after cleaning. For this reason the auto-lifting

sludge mode is built in the auto-control procedure. If it is found that the vacuum pump cannot

operate for a long time due to overload, you should open SV2 and A2, to lift and return sludge

manually,

(4) Membrane cleaning

Air washing

In order to slow down the pollution to membrane, it is needed to flush the surface of MBR

regularly during operation, When flushing, close the vacuum pump, stop effluent, turn up the

aeration quantity, then flush the surface of MBR for 2h. The flushing cycle is 7days each time

® Chemical cleaning

1) on-line cleaning

‘When the plant is sending out a high level alarm caused by a slow or no effluent, this means

the membrane should be cleaned. When cleaning the membrane, the toilets should not be

used so as to not allow the sewage enter into the plant. If you don’t want to stop using toilet,

you can use the high sea discharging procedure to discharge the clean water after

chemical treatment. Then clean the membrane according to the following steps:

1, Open V6, V3 and close V1, V5, V7 manually, and then start up the discharge pump PI to

empty the sewage in the membrane tank. Then open the flush water valve V15 to wash the

membrane tank with tap water. Close V3 and keep the tank level up to middle position then

close the flush water valve V15.

2. Pour into dissolved NaClO supernatant from dosing vent(the concentration of NaClO

solution be 0.5%,.e dosage is 10kg),

3. Soak for 2 hours. Empty the membrane tank, flush it again by clean water.

4. Fill into clean water to the level L2 by the same method, then pour NaOH supematant

(dosage is 23kg)

5, Start pump A2 manually, open solenoid valve SV1, scrub membrane threads with air.

6. Soak the membrane with NaOH solution for 2hours, empty the membrane tank, flush it

several times with clean water. Here to chemical cleaning is finished, normal operation can

be down,

Please use chemicals according to instruction book.

Dongisi Ci Dongiang Marine Fiting Co, Did Page 24 of 26

‘SWCM Type multilevel marine sewage treatment plant ___Instrtion Book 321DF-1M-00SM

Volume of =

Items | membrane tank | °°” Pea ro Remark

Type ()

SWCM-10 170 15 3.4

-_ SWCM-15 200 18

SWCM-20 260 2.35

SWCM-25 280 25

‘SWCM-30 300 2.65

SWCM-40, 420 3.7

SWCM-50 510 45 10.2

SWCM-60 510 45 10.2

SWCM-80, 980 BS 19.6

SWCM-100 1150 10 23

SWCM-120 1350 12 aT

SWCM-150 1350 12 27

SWCM-200 1550 135 31

SWCM-250 2230 19.5 4.6 7

SWCM-300 3000 25 60

SWCM-400 3850 34 7

2) Take out to clean

Generally, the membrane doesn’t have to be taken out to clean. If the membrane hasn’t been

cleaned in time regularly and is very dirty, please take it out to clean

The cleaning method is to remove the MBR-module from bracket, wash the membrane surface

with clean water, in order to remove the activated sludge and scale attached on the membrane

surface; immerge it in the 0.5% NaCIO solution for 2h, in order to kill the bacteria attached on

the surface; rinse the membrane with clean water and then immerge it in 2-3% NaOH solution

for 2 hours, in order to remove the organic matter and colloidal material attached on the surface.

Then a final flush of the MBR-module with clean water. On this manner the membrane flux

can be recovered. If the hardness of local water is high, an acid method can be combined to clean

the membrane. The membrane should be submerged in prepared 1%-2% HCI for hours, and

then take it out, flush it with clean water.

Caution: The operators should very be careful in the cle

1& process, to prevent the membrane

thread from being broken.

After several kinds of cleaning above mentioned, if the water discharging quantity isn’t enough,

please replace the membrane.

Dongiai Cig Dongling Marine Fiting Co,,id, Paged3 of 26

SWCM Type multilevel marine sewage teatment plant Instruction Book 321DF-1M00SM

Warning:

1. Do not mix up bleaching powder near other substances such as grease, oil, lubricating oil,

solvent, acid, alkali, soap, paint, home products, garbage, beverage, pine oil, dirty rags ete.

If the powder is mixed up with these materials, it may cause fire that might be severe.

2. Prevent any hot or burning substance such as lit cigarette from falling into the vessel of

the bleaching powder.

3. If the powder catches, pour the water into it and spray the surrounding area with water.

4. Do not touch eyes, skin, mucus membranes or clothes with bleaching powder otherwise it

could cause severe chemical burns. If bleaching powder is swallowed, it may have deadly

consequences.

5. Be careful to place the vessel containing bleaching powder. Don’t drop it, roll it or spill it.

Keep it vertical.

6. Use the bleaching powder only with clean dry rubber gloves or metal ware. Any

contamination can cause a fire.

7. Use large quantity of water to deal with the spilling bleaching powder. If the leftover

bleaching powder in the vessel needs scouring, large quantity of water is needed to wash

them into appropriate treatment system.

Antidote:

External: If exposed use large quantitative of clean water to rinse skin or eyes for 15 min.

If pain persists, consult a doctor. If you get the chemical in your eyes, consult an

ophthalmologist immediately.

Internal: drink large quantities of water or milk, milk of magnesia, vegetable oil or egg and

go to the internal medical department for emergency.

8, Keep chemicals far from children.

9. Keep bleaching powder in cool and dry place and original vessel. Do not change the label

and don’t store the bleaching powder in other containers.

10, Do not reuse the empty container. ¢ the empty vessel thoroughly with water and

place the cleaned vessel in safe place.

11. Post notices of “fire protection” around the place where the bleaching powder is stored

and dispensation area, Provide fire prevention equipment such as fire extinguishers,

foundry flasks ete.

‘When there is sewage in the device, the device will generate harmful gases such as HS and

methane ete. that could harm people around the area. The air pump should be operated at

all times to prevent build up or escape of harmful into working area.

Dongtar Ciy Dongiing Marine Fiting Co 1d Page 26 of 26

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Recetario Atma HP4060EDocument16 pagesRecetario Atma HP4060Ejoroma58No ratings yet

- Espec Tecnica MAN 440HP@1800 RPMDocument3 pagesEspec Tecnica MAN 440HP@1800 RPMjoroma58No ratings yet

- Norma ISO 484-2Document8 pagesNorma ISO 484-2joroma58No ratings yet

- Guidelines For The Performance, Location, Use and Care of Emergency Escape Breathing Devices (Eebds)Document4 pagesGuidelines For The Performance, Location, Use and Care of Emergency Escape Breathing Devices (Eebds)joroma58No ratings yet

- Weick F.E. - NACA TN 238. Propeller Design. A Simple Method For Determining The Stretch of PropelDocument17 pagesWeick F.E. - NACA TN 238. Propeller Design. A Simple Method For Determining The Stretch of Propeljoroma58No ratings yet

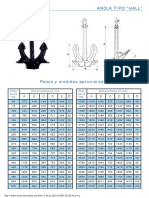

- Dimensiones Anclas HallDocument2 pagesDimensiones Anclas Halljoroma58No ratings yet

- Boat - The Fishing Vessel PropellerDocument2 pagesBoat - The Fishing Vessel Propellerjoroma58No ratings yet

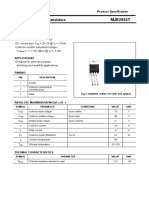

- K1086 MR FujiElectricDocument4 pagesK1086 MR FujiElectricjoroma58No ratings yet

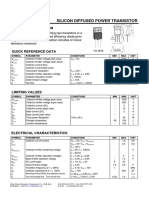

- Silicon PNP Power Transistors: MJE2955TDocument3 pagesSilicon PNP Power Transistors: MJE2955Tjoroma58No ratings yet

- Becker Mewis DuctDocument4 pagesBecker Mewis Ductjoroma58No ratings yet

- Shindengen: Super Fast Recovery RectifiersDocument7 pagesShindengen: Super Fast Recovery Rectifiersjoroma58No ratings yet

- D2499 Transistor de PotenciaDocument1 pageD2499 Transistor de Potenciajoroma58No ratings yet

- RS-540SH-7520|MABUCHI MOTOR CO., LTD. Product SearchDocument2 pagesRS-540SH-7520|MABUCHI MOTOR CO., LTD. Product Searchjoroma58No ratings yet

- Specifications: Customer Item Model Name Part No DateDocument11 pagesSpecifications: Customer Item Model Name Part No Datejoroma58No ratings yet

- Amplificador Tda 1904Document10 pagesAmplificador Tda 1904joroma58No ratings yet