Professional Documents

Culture Documents

Effect of Addition of 50 WT

Effect of Addition of 50 WT

Uploaded by

Mahesh MudaliarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of Addition of 50 WT

Effect of Addition of 50 WT

Uploaded by

Mahesh MudaliarCopyright:

Available Formats

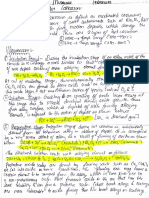

Effect of addition of 50 wt% Al2O3 on dehydrogenation of MgH2 was investigated.

Al2O3 and MgH2 were co-milled using High Energy Ball milling.

Dehydrogenation

P = 0.003 MPa

T= 250 ℃

Timedes = 30 min.

Hydrogen retrived = 3wt%

Activation energy(desorption) = 80kJ/mol

MgH2 powder (98% pure)- from Alfa Aesas particle size ~ 100μm

Al2O3 – 99.99% pure – 2-3μm

Al2O3 and MgH2 are mixed in 50:50 ratio weight using gear driven planetary ball

mill at 673 rpm. Rotation to revolution speed ratio – 1.092:1

Mixtures are stored in purified Argon gas to prevent Oxidation

Presence of oxide aided in reduction of grain size of hydrides.

Smaller the particular size faster the desorption i.e., kinetics can be improved by

reducing MH grain size.

Oxide contributed in increase in surface area area, active surface reaction sites.

25% reduction in activation energy when Al2O3 is added.

Final conclusion

Desorption rate is increased.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mg-2 Mol% NbF5Document5 pagesMg-2 Mol% NbF5Mahesh MudaliarNo ratings yet

- Mg+5 wt%LaMg2NiDocument5 pagesMg+5 wt%LaMg2NiMahesh MudaliarNo ratings yet

- Siverts ApparatusDocument5 pagesSiverts ApparatusMahesh MudaliarNo ratings yet

- MG + WO3 MG+ H0.23WO3Document6 pagesMG + WO3 MG+ H0.23WO3Mahesh MudaliarNo ratings yet

- 19bme0295 VL2021220102708 DaDocument15 pages19bme0295 VL2021220102708 DaMahesh MudaliarNo ratings yet

- Faculty-Dr. Bibhuti Bhusan Sahoo SLOT-C2/TC2/V5: Mahesh Leninkumar MudaliarDocument13 pagesFaculty-Dr. Bibhuti Bhusan Sahoo SLOT-C2/TC2/V5: Mahesh Leninkumar MudaliarMahesh MudaliarNo ratings yet

- Poc1adeyicton: LanagntDocument11 pagesPoc1adeyicton: LanagntMahesh MudaliarNo ratings yet

- 19bme0295 VL2021220103133 DaDocument7 pages19bme0295 VL2021220103133 DaMahesh MudaliarNo ratings yet

- Cultural Diversity in IndiaDocument17 pagesCultural Diversity in IndiaMahesh MudaliarNo ratings yet