Professional Documents

Culture Documents

Exelene Hdpe 5100M

Uploaded by

Andres Quiroga JuarezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exelene Hdpe 5100M

Uploaded by

Andres Quiroga JuarezCopyright:

Available Formats

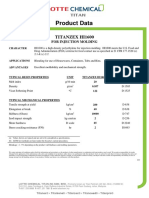

Exelene® HDPE

Product Data Sheet

High Density Polyethylene

HMW-HDPE1 copolymer 1-hexene

5100M

Extrusion-Blow Molding Melt Flow Rate 0,05

Density 0,949

Applications

■ 55 gallon plastic drums, chemical tanks for agriculture, automobile gasoline tanks.

Characteristics

■ The Exelene resin HDPE 5100M meets the requirements of section 177.1520, paragraph C, from chapter 21 denominated “Olefin

Polymers” from the Code of Federal Regulations of the FDA, to be utilized with direct food contact.

Properties ASTM Testing Units Nominal Value

Resin Properties

MFI2 D 1238 (190°C; 2,16 kgf) g/10 min 0.05

Melt Flow Rate

HLMFI D 1238 (190°C; 21,6 kgf) g/10 min 10.00

Density D 792 (23°C) g/cm3 0.949

Melting Point DSC °C 127

Properties in standard test tubes by compression molding

Tensile Strength @ yield D 638 (50 mm/min, IV) psi 3,600

Elongation @ break D 638 (50 mm/min, IV) % 700

Tangential Modulus of Elasticity D 790 I/B (13 mm/min; 3,2 mm) psi 175,000

Notched Izod Impact D 256A (muesca; 3,2 mm) ft x lb / in 10.0

Tensile Impact Strength D 1822 (S) ft x lb / in2 90

Durometer hardness (Shore D) D 2240 D (23°C; 1 s) ---- 68

Brittleness Temperature D 746A (F50; 25 lbfXin) °C < -75

Vicat Softening Point D 1525A (50°C/h; 1,0 kgf) °C 126

Deflection Temperature Under Load D 648 (2°C/min; 66 psi) °C 78

Condition A (2) D 1693A (F50; 3,1 mm) h >600

ESCR

Condition B (3) D 1693B (F50; 1,9 mm) h >600

Properties in standard bottles by extrusion-blow molding

ESCR Condition B (4) D 2561 B (F50) h > 1000

(1) HMW-HDPE : High Density Polyethylene with high molecular mass.

(1) Condition A: Grooved Specimen with thickness of 3,175 mm = 0,125 inch in 100 % Igepal CO-630 at 50°C

(2) Condition B: Grooved Specimen with thickness of 1,905 mm = 0,075 inch in 100 % Igepal CO-630 at 50°C

(4) Condition B: 16 oz cylindrical bottle (approximated mass of 20 g) filled up to 33% of its capacity with a aqueous solution of 10 % Igepal CO-630 a 60°Cla

http://www.montachem.com

Revision 0/15-2-2007

You might also like

- Exelene Hdpe: HDPE Copolymer 1-Hexene High Density PolyethyleneDocument1 pageExelene Hdpe: HDPE Copolymer 1-Hexene High Density PolyethyleneGregorio Gaviria HernandezNo ratings yet

- Exelene Hdpe: High Density Polyethylene HDPE Copolymer With MWD Thin Injection MoldingDocument1 pageExelene Hdpe: High Density Polyethylene HDPE Copolymer With MWD Thin Injection MoldingOctavio DavidNo ratings yet

- Exelene Hdpe 20000 2021Document1 pageExelene Hdpe 20000 2021diana sarmientoNo ratings yet

- Durolon HFR 1910Document2 pagesDurolon HFR 1910elrolo3000No ratings yet

- Becdd 0369 CDocument1 pageBecdd 0369 CHichamSalamaNo ratings yet

- GM5340PRK enUS ASTMDocument2 pagesGM5340PRK enUS ASTMDuongthithuydungNo ratings yet

- LG Chem TDS SP988 EnglishDocument1 pageLG Chem TDS SP988 EnglishSérgio BarbosaNo ratings yet

- H6105JUDocument1 pageH6105JUhunghiepvanNo ratings yet

- M6007LDocument1 pageM6007LempacNo ratings yet

- High Density Polyethylene GF4950: DescriptionDocument1 pageHigh Density Polyethylene GF4950: Descriptioncesar1scribdNo ratings yet

- Opal - Hdpe - 4Document2 pagesOpal - Hdpe - 4Piyush A JoshiNo ratings yet

- PP - Braskem - CP 442 XP PDFDocument1 pagePP - Braskem - CP 442 XP PDFAdemilson Alves Dos SantosNo ratings yet

- Ficha Tecnica Polietileno Chemium Hdpe 2285 (7000f)Document1 pageFicha Tecnica Polietileno Chemium Hdpe 2285 (7000f)Carlos SiuNo ratings yet

- LdpeDocument1 pageLdpeArdy WiyogoNo ratings yet

- InnoplusDocument1 pageInnoplusRizaldi Nur Imani100% (1)

- Innoplus 1100J PDFDocument1 pageInnoplus 1100J PDFindahNo ratings yet

- High Density Polyethylene HS5407: Descrip OnDocument1 pageHigh Density Polyethylene HS5407: Descrip OnJosiola MariledoNo ratings yet

- Low Density Polyethylene: Property Value AstmDocument1 pageLow Density Polyethylene: Property Value AstmAdemilson Alves Dos SantosNo ratings yet

- Sabic Lldpe MG200024: PolymersDocument2 pagesSabic Lldpe MG200024: PolymersYoshie IwaiNo ratings yet

- Halene - H : Technical Data SheetDocument1 pageHalene - H : Technical Data SheetIshah KaziNo ratings yet

- Material Spec For 6600Document1 pageMaterial Spec For 6600Namelezz ShadowwNo ratings yet

- Property Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)MohamadMostafaviNo ratings yet

- High Density Polyethylene HC7260LS-L: DescriptionDocument1 pageHigh Density Polyethylene HC7260LS-L: DescriptionJaime222No ratings yet

- Sabic BM 1052Document2 pagesSabic BM 1052ifahNo ratings yet

- B6401 JarDocument1 pageB6401 JarStella KazanciNo ratings yet

- Technical Data Sheet Polyimide: Benefits ApplicationsDocument3 pagesTechnical Data Sheet Polyimide: Benefits Applicationssanthosha rkNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- Pebd - Marpol - LDM 740Document1 pagePebd - Marpol - LDM 740Daniel FlosinoNo ratings yet

- Property Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)MohamadMostafaviNo ratings yet

- Product Description: Properties Value Unit Test MethodDocument1 pageProduct Description: Properties Value Unit Test MethodRPM28XINo ratings yet

- Exelene Ldpe 0700Document1 pageExelene Ldpe 0700diana sarmientoNo ratings yet

- SCGC LSP L2420J Technical Datasheet ProvisionalDocument3 pagesSCGC LSP L2420J Technical Datasheet Provisionalakankshas06No ratings yet

- LLBF 218aDocument1 pageLLBF 218aYefrain J. ArzolayNo ratings yet

- Technical Data Sheet ADFLEX F 500Document2 pagesTechnical Data Sheet ADFLEX F 500leftpowtaNo ratings yet

- DP03HDocument1 pageDP03HDiadam SharmaNo ratings yet

- Hdpe 3272Document1 pageHdpe 3272Diana SarmientoNo ratings yet

- Petrothene: High Density Polyethylene Blow Molding Grade Melt Index 0.35 Density 0.953Document1 pagePetrothene: High Density Polyethylene Blow Molding Grade Melt Index 0.35 Density 0.953Junior Lazaro AnticonaNo ratings yet

- InnoPlus HD8100MDocument1 pageInnoPlus HD8100MLe Minh TuanNo ratings yet

- PP PP9074MED DatasheetDocument1 pagePP PP9074MED DatasheetDiogo SouzaNo ratings yet

- Polye PDocument2 pagesPolye PFranco Gabriel MercadoNo ratings yet

- Technical Data Sheet Hifax CA 10 ADocument2 pagesTechnical Data Sheet Hifax CA 10 AafidyusufNo ratings yet

- EP 440L-enUS-ASTMDocument1 pageEP 440L-enUS-ASTMAndersonNo ratings yet

- PN2021 enUS ASTMDocument1 pagePN2021 enUS ASTMChu Nguyễn Anh QuânNo ratings yet

- HC7260LS L enUS ASTMDocument1 pageHC7260LS L enUS ASTMCristian Tomas Del Solar EspoueysNo ratings yet

- PolystyreneDocument1 pagePolystyrenejoshkajasmineNo ratings yet

- Lotte Titanpro PM903 Product DataDocument1 pageLotte Titanpro PM903 Product DataJoni Sie MssNo ratings yet

- Halene - L : Technical Data SheetDocument1 pageHalene - L : Technical Data Sheetdharmendrasinh zalaNo ratings yet

- Description and Use: WWW - Muntajat.qaDocument2 pagesDescription and Use: WWW - Muntajat.qaEleannys GarciasNo ratings yet

- Muehlstein Certene HWF-852BDocument1 pageMuehlstein Certene HWF-852BManuel martinezNo ratings yet

- High Density Polyethylene: ASTM D 1505 G/CM 0.963-0.968 ASTM D 1238 G/10min 4.5-5.5Document1 pageHigh Density Polyethylene: ASTM D 1505 G/CM 0.963-0.968 ASTM D 1238 G/10min 4.5-5.5Oswald SolorzanoNo ratings yet

- He150 Enus AstmDocument1 pageHe150 Enus AstmDiegoAlvarezHuguezNo ratings yet

- TDS Pe 202 SP4808Document2 pagesTDS Pe 202 SP4808Desri AkbarNo ratings yet

- RX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourDocument1 pageRX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourEetu SatosalmiNo ratings yet

- HI1600Document1 pageHI1600Nawal SahraniNo ratings yet

- HDPE Pipe Ineos TUB121GNDocument2 pagesHDPE Pipe Ineos TUB121GNluisalbertolvNo ratings yet

- Mdpe 37120-TDSDocument1 pageMdpe 37120-TDSMauricio Alejandro Castillo SorianoNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Gas CalculationsDocument3 pagesGas CalculationsaizatNo ratings yet

- Review of The Main Factors Affecting The Flotation of Phosphate OresDocument23 pagesReview of The Main Factors Affecting The Flotation of Phosphate Oreskhodjetelfehm oussamaNo ratings yet

- Ester Phosphate As Fat-Liquoring AgentDocument10 pagesEster Phosphate As Fat-Liquoring Agentrajdewaan0% (1)

- Accepted Manuscript: Computers & EducationDocument32 pagesAccepted Manuscript: Computers & EducationAlpyh ZahrohNo ratings yet

- Engineering Manual Viscous and High Density: General Industry SegmentDocument52 pagesEngineering Manual Viscous and High Density: General Industry SegmentingrbarrosNo ratings yet

- Chapter-1 Intro & Properties of Particulate SolidsDocument11 pagesChapter-1 Intro & Properties of Particulate SolidsKartik DesaiNo ratings yet

- Bixby Knolls Preparatory Academy - San Antonio, Quezon: Science and Technology 8Document6 pagesBixby Knolls Preparatory Academy - San Antonio, Quezon: Science and Technology 8Teacher OliNo ratings yet

- Transfluthrin WHODocument20 pagesTransfluthrin WHOYudhytha AnggarhaniNo ratings yet

- API en - Atm.co2e.pc Ds2 en Excel v2 2764338Document28 pagesAPI en - Atm.co2e.pc Ds2 en Excel v2 2764338Lion HunterNo ratings yet

- Derakane - Tech SupportDocument32 pagesDerakane - Tech SupportJainam ShahNo ratings yet

- ESTOP TDS - Estofoam PU300 R01Document2 pagesESTOP TDS - Estofoam PU300 R01Fawwaz IlmiNo ratings yet

- Intrinsic Viscosity As Quality Control Parameter of PET: Relevant For: Polymers, Plastics, ISO 1628, PETDocument3 pagesIntrinsic Viscosity As Quality Control Parameter of PET: Relevant For: Polymers, Plastics, ISO 1628, PETParesh Hadkar100% (1)

- Practicum Journal of Chemical Separation Principles Thin Layer Chromatography (TLC)Document5 pagesPracticum Journal of Chemical Separation Principles Thin Layer Chromatography (TLC)Rizki AuNo ratings yet

- Boiler Handbook Guide-Rev 1Document326 pagesBoiler Handbook Guide-Rev 1venus energy100% (1)

- Referentne ElektrodeDocument26 pagesReferentne ElektrodeZlata JašarevićNo ratings yet

- Science of The Total EnvironmentDocument11 pagesScience of The Total EnvironmentfranklinNo ratings yet

- Activity Series LabDocument4 pagesActivity Series LabjeffoisawesomeNo ratings yet

- Fully Automated Determination of TAN/TBN in Industrial Samples According To ASTM Standards D 664 and D 2896Document1 pageFully Automated Determination of TAN/TBN in Industrial Samples According To ASTM Standards D 664 and D 2896Wilber AraujoNo ratings yet

- Aerowhip Foam Stabilizers For Wipped ToppingsDocument4 pagesAerowhip Foam Stabilizers For Wipped ToppingspedrazasNo ratings yet

- M.Tech (Metallurgy & Materials Engineering)Document3 pagesM.Tech (Metallurgy & Materials Engineering)Dharbaranyeswaran MNo ratings yet

- (EDQM) 2020 Technical Guide For The Elaboration of MNG - Medicinal Products Containing Chemically Defined Active SubstancesDocument14 pages(EDQM) 2020 Technical Guide For The Elaboration of MNG - Medicinal Products Containing Chemically Defined Active SubstancesAn TaNo ratings yet

- AA7075Document7 pagesAA7075Trial_TNo ratings yet

- Nonconventional Methods of Gas LiquefactionDocument45 pagesNonconventional Methods of Gas LiquefactionImtisal E NoorNo ratings yet

- SDS Nickel Cadmium PP ContainersDocument6 pagesSDS Nickel Cadmium PP ContainersharmlesdragonNo ratings yet

- Asme Material SpecsDocument4 pagesAsme Material SpecsRajwinder Singh100% (1)

- 6th Grade - Mixture Test ReviewDocument19 pages6th Grade - Mixture Test Reviewleojohn267% (3)

- 115 Rock Drill Oil ApplicationsDocument2 pages115 Rock Drill Oil ApplicationsRandi Riki AdtiaNo ratings yet

- Photosynthesissho 0-MadisonmacdonaldDocument4 pagesPhotosynthesissho 0-Madisonmacdonaldapi-305117392No ratings yet

- Paints and CoatingsDocument28 pagesPaints and CoatingsMaximiliano MackeviciusNo ratings yet

- Power Plant Inspection, Repair, and Testing: Learning ObjectivesDocument30 pagesPower Plant Inspection, Repair, and Testing: Learning ObjectivessamiNo ratings yet