Professional Documents

Culture Documents

Ferrous Metals-MD0486 Article

Ferrous Metals-MD0486 Article

Uploaded by

latshare0 ratings0% found this document useful (0 votes)

4 views27 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views27 pagesFerrous Metals-MD0486 Article

Ferrous Metals-MD0486 Article

Uploaded by

latshareCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 27

| Wnatnapponsto those carpon atoms deter-

Section 7 Ferrous metals

Introduction to

ferrous metallurgy

IRON and the large tami of iron alloys

called stool aro the most common of the

‘commercial metals. ron ts abundant (ron

fore constitutes apoxt 33> ot the earth's

‘rust) and is ea8y to convert from ore to 8

‘setulform

iron mets at 2.777*F anc bois et 4 442°,

Small adations of carbon reduce the molt

ing paint. A commercia forms of wor and

Stool contain carbon. utich is an integral

part ofthe metallurgy of ion and test. Ma

‘ipulationotator-to-atornclationships be

‘ween Fon, carbon, and various alloying ole-

mons estabishas the specie oroperias of

ferrous metals. Az atoms transform from

‘one specie arangoment, or crystal ate

tonnotner, strength, toughness, impacto

sistance, hardness, ductity. and other

Properties are altored. The metallurgy of

ton and steei a study o! how these atomic

arrangements take pleco, how thay canbe

controled, and which properties are at

tected.

‘A motal undergoes # “phase trans.

formation" when it changas irom one ciys

talarrangement to anot'or. in the ironscar-

bon alloy system, an important phase

\wansformation ties place oetween about

41800and 1,600 F. The oxact temperatures

Getermined by the amount of carbon ane

‘thor aioying elamients 9 the metal. ran

tranalorms from a face-centered cubic

(CO) structure—caliod tno gamma phase,

(OF austenite—at high temperature to a

bbody-centered cubic (BGO) structure—al

‘pha phase, of ferrte—at a toner tempera

‘ure. Inpure ron, ths tansformation (he As

transformation is marked by a distinct i.

rense in length as the metal cooks below

the crtea! temperature bacause the Dody-

Canterad latice fe less compact than the

face-conterec lattice

‘The high-temperature austen

strueture, slows anough spac

te aqueezo in Between tha ron atoms. ron

‘lomsmaiain thai place on te latte and

‘earbon atoms become "intersties." Inthe

fow-tomparature torrie, or BOC structure,

howovar, there ig no Yo0%" for carbon atoms

‘mings many of the proparties of iron and

seh

For example, during to siow cooking ofa

tow-carbon stosl such as AIS! 1020 (0.20%

carbon) through the transformation tempor-

lature range, transformation begins as the

metal reaches 1,555°F. The frst motal to

reachthis temperature transforms toferrite,

tna BCC structure, andexpels the interstitial

carbon nto the remaining regions ot ausien-

ite Asthemetalcoo's, nore iron transforms

into terite, leaving less austenite and more

regione richin expeliad carbon

Finally et about 1.350°F, the lower ond of

the transformation temperature range for

1020 steel, the astremaining austenite tres

{0 wansform—in spite of the rich carbon

Concentrations, At this point, two things 0c-

‘cur The carbon bonds with avaiable iron

‘atoms to form FexC, an intermetallic com

‘pound caied cement, orivon carbiée, and

it precipitates out as a discrete structure:

the remaining austenite then transforms to

ferrite,

‘The structure that results from this tinal

transtormation is @ lamination consisting of

hternating layers of ferrite and von carbide,

‘Of course, the portions of metal hat trans-

formed previously remainasiargeisiands o

pure forte. The laminated structure formed

atthe last moment is called pearite. The

Combined structure of ferite and pearite is

soft and ductile. tgenerally represents ise!

Initslowest-strength condition

In contrast, when ferrous alloys are

cooled rapidly, or quenched, expelled car-

bon atoms oo not have tine to move away

from the iron as it transforms to ferie. Te

stool becomes so rigid that, before the ca *

The result Is & body-centered tetra92al

structure In which the carbon atom is an

; sy

toits distorted, stressed lattice structure

‘onsite. Naturally, martensite ina state of

Lunequiibrum, butt owes much o ts high

strength and hardness (and lower ductity)

‘A number of neat-treatment cycles have

been developed to alter tha structure of

steal For example, when martensite tern-

‘paarte,omairs as the swe C5000.

ame ees

acne Gosh Ap

Peres (heated below As temperature) some

Internal stresses ave relieved. and the ro-

‘sulting structure is more ductile than as-

quenehod martensite

ther heat westments change the pro-

Portions of pesrito and martensite; some

‘even entrap austonke at roam temperature

(thers ator or vciure We size of he grains

‘or pattern of these structures, providing im-

proved stangtn or toughness. And when

other alloying elemanis—inciuding boron,

Pick, chremivm, manganese, slfoon, and

vanacium—are ada tothe matal he Be

havior of farrous aloys, as thoy transform

fom one structure to snother, «8 further

Complicated. But because the structure of

stael—-and thus, tno mechanical properties

Of steet—can be alrorad in 20 many way

ferrous alicys can be coveloped to suit an

fextromely wide variety of design needs,

Castiron

[BECAUSE of is ow cost, cast Iron is often

considered 2simpie metaltaproduce and to

specily, Actual, the metalurgy of east ron

Is moco compiox tae that of tool and most

thor moras

Stoals and cast iron are both primary

iron with carbon as the main alloying ole

ment Steels contain lose than two and usu

aly lose than one percent carbon, while al

tat one contain more than two percent

carbon. About two percent tthe maximurh

Carbon content at which won caa soliy a

| single-phase acy with atthe carbon in

‘olution in austenite. Thus the castirone, by

ofintion. solcity as heterogeneous alloys

land sways have more than one constituent

in thelr microstructure. in addition to ear

bbon, cast fons must also eontain siteon,

‘usualy rom one to thre pares thus they

are achuayror-carbon-sticon alloys.

The high carsen content ana the siteon in

‘cast rons make them: oxcallent casting al-

loys, Thaw malting temperawres are appre

clabiy lover than those of steel. Molten ron

igmore iis than moltan sol andless eac-

tive wh molging materia. Formation of

‘ower density raphe i the ren during 90-

lestieabon raduess the change i volume of

the mata as it goes tom quid to sold and,

makes proguction of complex shapes pos

sible. Cost irons, however, de not nave su

folont ductility 19 be rolled or forged.

Because size and shape ots casting con-

twos solidification rata and strength, da-

sign ofthe casting and tho casting process:

to bo used mus! be considered when the

type ofiran is selected. Whereas mostother

rotsls ae specitod by a standardehemical

analysis, a single analysis of cast on ean

rocice several eniteaiy cMforent Bes of

in, éapanding upon foundry practice and

i

i

{

|

i

t

shape and size ofthe casting, a of which

Influence cooing eats. Thus, ron is usually

pected by mechanical properties. For ap-

plications involving high temperatures or ro

uiring spect corrosion resistence, now

fever, some analysis 'aquirements also may

De spectiod.

“The catbon content inironis the key tots

distinctive properties. The precipitation of

‘carbon (88 graphite) curing solidification

Countocacts the norma! ehrinksge of tho

Soliditying metal, producing sound sec

tions, The presence o! graphite in the metal

provides excellent. machinabiity (even at

‘woar-resiating Marcness loves), damp vr

bration, and sis lubvicaton on wearing sur-

feces (oven under Dorderiine lubrication

conditions). When most ofthe carbon re-

‘maine combined witn te iron tas in white

tron), the presence ct hace on carbides

‘provides good abrasion resistance.

Insome cases, mcrostuctureoliron may

be all ferrite--the same constituent that

‘makes low-carbon steo!s sot and oasty ma

‘hined. But the ferrite of iron is cifrent

because t contains suticiont dissolved si

leon to eliminate the charactoretie gummy

nature of low-carbon stee!, Thus, east icone

Containing ferrite do net require sutur or

leadadditonsinordor to 0¢troe-machuning

\Whtin each basic type of cast ron are 8

umber of rages with widely ditfring mo

‘chanioat properties. These variations are

‘eaused by diferences nthe microstructure

‘tthe meta thet surrounds tno graphile (or

tori carbided). Tuo diferent structures can

‘@xist In the same casting. The micro-

‘s¥ucture of cast won can be controllad by

hat trestment but the graphite, once

formed, remains,

‘Soma cast-iron grades consist alterna

‘tg layers of got forrite ar hard iron car

Dida, This laminated structure-—callad

‘eerite—is strong ard yvar resstent, but

Stil qute machinabie, The ficae the tam

rations. the hardor and stronger the iron.

Lamination size can te controlled by heat

‘woatmant ar eoolns ="

Cast irons that are fame hardened, in-

uetion hardened, o° furnace:

cit quenched contain a martansite structure

‘which (when tempered) provides machin.

‘bitty with maximum strength and good

‘wear resistance,

Gray iron

Gray ron is a supersaturated solution of

‘earbonin aniron matrix. The excess carbon

precipitates out in the form of graphite

fakes. Gray ron is specified by a two-cigit

nation; Class 20, for exemple, speci

‘ies a minimum tense strength of 20,000

5

150 178 200 25 250

Mnmum aravess (80)

si. In addition, Nowever, because the

‘trengtn of gray Ion is highly sensitive to

‘ross section (he smaller the cross section,

‘the faster the cooling rate andthe highar the

strength) gray iron is also speciied by the

cross section and minimum strongin of &

‘special test ar. Usually, the test-bar cross

‘section matches or is rolated to 8 particu

lary cra! section ofthe casting.

Impact strength of gray iron is lowsr than

‘that of most other cast ferrous mats. In

‘adaiton, gray iron does not have a distinct

Typical mechanical properties of cast irons

——— ues —— wane

astwasoe77)

0-90-92 a 8

rm

© asmanera7

so se HO

Ye sangre revs Geteinod

‘Sepensentonsachon size $y won ct wuly v0 for mpactreastance. "Special ade Nae te

‘oro ps. Seng veues app tonechestveatad maleabie won Heat eaimentscanicrease slong

The five types of cast iron

Ccastiron structures contain, in adation

{0 $044 ron, olor carbon or graphite (2

‘oft iow strength constituent) or ron

‘carbie (a nard, bitte materia). These

‘wo constituents, depending on thet

‘shape, amount, and distribution, form

‘he basis of the family of fvecastirons.

hevng widely varying properties

‘Searing ecren merephote (250.

Fact anaratCo

10. Macrina Design / Ave 17,1966

PEARLITIC ANO MARTENSITIC.

asinan220 78)

(an or

| yotapointas ctintny cession formulas)

| and should not be used wen parmanont,

| plastic detormation is profersesto fracture,

| Anottior important characteristic of ray

{_iron—-particuiarty tor precision machin-

|) ery-is ite ability to damp winraton. Damp

}_ingeapactyis aaterrnines principally by the

|. amount and type of graphite iekos, AS

| amnountof graphite deeraasas, damping ca-

fh protvaeocecoacos

Gray trons have excellent wear re-

sistance, Evan tho softer grades perfor

wall under certain borderline hibrcation

‘conditions (es fn thie upoercyinder walls of

Internal-combustion angines, fo: exarnpe).

For high harcngss requiremonts of abra-

sive-wear appications, hardooss of Fay

Iron oan be increaced by aading atioyna

‘lament, by using spacial foundry tech

‘ques, or by heat taster. Grey ron cen

Dehardened by teme or induction methods,

forthe foundry can use a cilia the moKs 0

Produce harceied, "~wistewson” surfaces,

“The high compressive strength of gray

lron-—three to five times tenia etength—

can be used to acvantage in certain situ=

‘ions. For example, placing ribs on the

‘compression side of @ plate instead ot he

‘enaion side produces a stronger. 'ghter

‘component Typical epitcations of yay iron

indude automotive engine blocks, gears,

fywheels, brake discs and crums, ana ma

chine bases. Gray Iran serves well in ma~

‘chinary spploations because ots goos fe

tigue resistance.

Ductile iron

Ductile, or nodular iron contains wa‘

amounts of mageesiun: whieh, by aering

“ani eid

ADL anergy sng in

ese Ooh

Ree ass

2 s ”

anger Aa

Specification methods differ

ASTM spoctications for iron castings aro basod on a diferent philosophy than that

thine SAE. The ASTM spocifications dasignats he properties of the metal to be

‘Sbiainedin an sppropriately sized but separately cast tester, whichis poured

ader the same conditions as are the castings. The SAE specifications, on the other

hand, require thatthe microstructure of the casting be appropriate fr the grado of

theta! speciiod and that the hardness of each casting ata designated iccation shall

‘be within tho specified range.

incommercial use, the ASTM specification s more commonly used for general

engineering applications where the strongtn ofthe ion necessary in the parthas

Sean established. The SAE specications are usually uses for large quantities of

Smaller cust components such as are typical in automobiles andin agricultural anc

fategeraton equipment. n these cases, the suitably of @ particular grade otron is

‘etabiisheg not only on design coneideratons buton actual proot in operation: he

purpose tthe specication is to ansure a consistent product comparable to those

found, by experience, tobe satisfactory

the surtace-tension mechanism, precip

itates out carbon in the form of smalt

spheres, This structure is the source of im

proved stitinass, strength, and shock re-

Sstanee of duct iron over gray ion.

Ductile kon is speciied by a three-part

designation syetam: The designation of a

typical alley, 60-40-18, for example, speci-

fies & minimum tensile strength of 60,000

psi, a minimum yield strength ct 40,000 psi,

land 18% elongation nin.

Ductile iron is used in applications such

1s crankshafts because ots good machin-

‘lity, fatigue strength, and high modulus ot

lastly; nneavy-duty gears because cts

highyield strength and wear resistance: and

in automobile door hinges because of Its

‘ucility Because it contains magnesium as

fan adtional alloying element, ductie irons

Songer end more shook resistant than

rayiton, But although ductile ron also has

A higher modulus of elasticity, ts damping

Capacity and thermal conductivity are lower

than tose of gray ron

(On a weight basis, ductile ron castings

‘ere moro expensive than gray iron but, be-

‘cause they off higher strength and provide

pettor impact resistance, overall part costs

‘may be about the same.

‘Although not a new treatment for ductile

iron, austempering has become, only inthe

past the years, increasingly known fo the

Engingering community. Austempering

Soesnotprodues the same typeof structure

fas It doos in steel Because ofthe high car-

bon and siicon content of iron. The matrix

Structure ot astempered ductile ron Sets t

‘part trom other east irons, making truly &

separats clase of engineering materials.

Proposed specification for four ADI grades,

Tienes imac,

ionmn Hardness nnotebed,

os, hy math)

ae oT

Interms of properties, the ADI matrix

most doubles the strength of conventional

‘ductile iron while retaining its excelent

toughness, Like ductile iton, AD! is not &

‘single material; rather, Risa tary of mate-

fials having various combinations of

Sirengtn toughness, and wear resistance

Unfortunately, the absence of a standard

specication for the materials has restricted

Its widespread acoeptance and use. Tonelp

‘liminate this problem, the Ductile Iron Soo:

tty has recently proposed property speci.

tations forfour grades of austempered.ouc-

tie iron

Most current applications for AD| are io

transportation equipment—automobileo,

trucks. and railroad and mitary verictes.

‘The same improved performance and cost

savings are expacted to make these mater

fl attractive n equipment for other indus-

{res such as mining, eathmoving, agricul

ture, construction, and machine tos

White iron

write ion ie produced by “ching” se-

lected areas of a casting in the mold, which

prevents graphiticearbon trom creciptating

but Both gray and ductile iron can be hited

to produce a surface of white ion. In cast

ings that are white iron throughout, hove

ver, the composition ot irons selecied ac

cording to part size to ensure that the

olume of metal involved can chil rapihy

fencugh to produce the whiten structure

“The principal disadvantage of white iron is

that ts vory Bite. Britteness can be £0

duced somewhat by reducing carton con-

tant oF by thoroughly sWess relieving to

Spheroidizethe carbides in the matrix. How

ver, these measures increade cost and

duce harcness.

‘The use of chile produees castings with

white-iton working surfaces and cores that

bre a tougher and easily machinable gay OF

Guetie on. During ching, that portion of

the casting hats to resist wear is cooted by

12 metal of graphite beat sink (chil) the

‘nok, When the molten iron contacts the

Chil it solidies 0 rapioly that the ror and

ate fterece'ssie 11

canyon carnat become associated and £0

‘become wnte ton. This process 5 used for

raking to's o¢ wneels, for example, th

white ston working surfaces.

ching snouts notbe contusea wan heat

‘reat hardening. which involves an entirely

‘atferent metallurgical mechanism. White

Ton 90 cad because ofits vary white tracy

ture, can be formed only during sol

‘heation it wlnot sften except by extencioc

tznnealing, and it cetans its hardness even

‘above 1.900"

‘Because oftheir extreme hardness, white

irons ae sed primanty for applications 2

{uiring wear and abrasion resistance such

fs mi liners and shotblasting nozzles,

‘ther uses include rairosd brake shoes,

‘ells. slmy-mixing and brick

"yer, ard crushers and DuNve-

fizers Serre, pin (unalioyed) white iron

Corts cos Par ser east irons.

mange

Compactea graphite iron

Une! reoanay, cumprcteds graphite tron

{0G also known ae vormicular ron, has

been primanty a laboratory conosity. Lo

now a: an intermediate Between gray ec

‘ucts ron, possasses many of te favor

thie properties oF each. Bacsues of 070

fess controidmeutias and re nscesity oF

Neesine aly adeitions within very tight ry

wre Deaan / Ape 17,1966

Typical physical properties

of cast irons

Denatyion

Merang temperate °F)

6

e s588

Decale T4007) 68

Matleabie 70212")

59

18

Eezouateabe,

etait?) 1820(0vct)

iecticalresistaty 16 16(Maesb0)

£8 s0(Gray duce)

ae

its, however, CGI has been extremely di-

ult to produce successfully on a commer:

‘Gal scale. For example, if the magnesivrn

‘ition varied by as itl 25.0 005%, results

‘woul be unsatistectory

{ine problem has beon solved by the int

development affore of the Foote Mineral

‘Co. and the British Cast iron Research

‘Assocation with an aly adltion package

that proves the essential alloying ingreci-

tnts_-magnesiom, titanium, and rare

farts in exacty the right proportions

Strength of CGI parts approaches that of

uel east iron. CGI also offers high thor-

fe ron Machinabiy te

and casting

wkageandtoed-

(oko ray kon.

Superior to tat of

reign becau"

Ing charactersties aro

‘The combination of high strength and

‘conductivity suggests the ase

engine Docks, Brana drums, and

micins, OG! gear

plates have replaced eh

pressure gaer pumps bacatse ofthe ron's

Eby (0 inaintain dimensional stabity at

pressures above 1,500 ps.

Maileabie iron

atsable one whuta ton that has bean

converted by & teo-stage heat treatment

Resulting propertios are opposite from

hose ofthe white con rom which fs de

red Rather nen boing herd and brit is

fraileable and easly machined

Malieabtc iron typically contains 2:20 to

2.65% 6, 0.90 0 1.10% Mn, 1.00 0 2.109%

51,0.07100.1295, and0.05t00.12%6P. The

fatoy i usualy cast rom an seidmaltofsteo!

Serap. 0 on, anid rotrns from previous

Makesbie von afters trom other cast

irons inthe shape othe contained graphite,

tenich exisis as tener carbon nodules

(compared with grepivte fakes in gray ron

fr true carbon spheroids in ductile ren.

Malicabie kon. -omponents that

require ts impact and fatigue resistance,

twour resistanco, end good machinebility.

Malleable-tron sastings generally &

Sighty lass than aucne-ron castings.

“Tho three bas

rete, pe

(Graces are more machinablo and ductile,

tinerens the pearsic grades are stronger

tnd harder. Gonoraly, the martensitic

‘graces are grouped! with the peafitic male

fats: they might be thoughtof as extensions

{atthe fegher-stvangih end ofthe ange) of

pearitomalacdis cr

pes of malioable iron

nsherp contrast frre malienble on,

mone merostveture is free from com>

bined carbon, pearine malleable iten con

tains from 0-40 0.9% carbon in the com

bined form, Since this constituent ean be

transformed rewly into te hardest form of

‘ombined carbon by a simple heating and

Quenching testment, pearlitic malleable

iton castings can be seloctvely hardened.

‘Dopih of hardening = controied by the rate

‘f heat input, time at tomporature, and

quonching rat eat-treating can produce

Shirtaee hardloess io about Rockwell C60,

c ‘on sestingsareoftenusesfor

heavy duty veering surfaces in auto~

nodes, ticks, ralraad roling stock, and

farm and constrsction machinery. Pesviic

‘grades are highly woar resistant, with har

nesses ranging row 152 to over 300 Bho,

Applleations are its, nowever, 0 rela

tively thin-sectioned castings because of

{

|

}

|

|

the high shrirkage raio and the need for

rapid cooling to produce white ron

The carbon in ail mallesbie irons helps

retain and sore lubricants and, in extenne-

woar service, the peariti: maleate ron

Surface wears avay in harmioss, micron

‘sizeparicies, which aro lass damaging tian

‘other tyes of fon paricios. The porous

‘malleable-icon surface tra abracive de

bri that accumulates batwoen boaring Sur

faces, Gall streaks can form on maeable

iron but galing does not usunty progress

High-alloy irons

4, High-alioy rons are cust, gray, o° white

‘rons that contain 2 to

‘Contant. Propertio: of wes irons, which are

usualy produced by specslized touncrios

aro signiticantyaitierant trom those of the

Lunalloyed irons. These irons are ususty

Speci by chemical composition as well

{a8 by mechanical proparnes,

|Whito igh-lloy irons costaining nickel

{and chromium dovsio 2 microstructure

with @ martensite matrix around primary

chromium cartices. This sivucture provioes

‘ayeryhigh harcngss with extrome wear and

abrasion resistance. Kigh chromium icons

Atyplally, containing about 18%), combine

‘wear and oxidation resistance with tough=

oss. fons contisring trom 1410249)

‘79 austenitic; they provide excelient cor

rosion resistance for nonmagnetic appt

cations. The 25% nical rons hava en ex

ttemelylow costicientot thermal expansion

‘and aro also normEgnetis and corrosion

resistant

Carbon steel

‘tay wit sma arsounts ct other olemonis

tatiare insarenty present. Stosls con ba

tether cast to shape oF wr ious

aiforms rom nich tnished pans 270

128d, or ath:

Wrought stae! is fst sitner pourad into

Ingots oF is stranc-east Arter soltication

thomotalisrenestes end hot road into the

fished, wrought form. Hut~olled steal is

jac surface and a

characterized by 2

ecarourized ekin. Ho

subsequently 1

shot basting to remove se

Cold-drawing through a die and re

Straightening foimeros vurluce oropertes

landsvengtn 2” forelaser 9.28 cent! Also,

hot-rolled steet may be cold finished by

flements influences hardness, machin.

meta-removal processes such asturningot ability, corrosion resistance, tensile

grinding. Wrought steel can be sub- strangtn, deoxidation of the soliitying

‘Sequontly heat treated to improve machin- metal, and microstructure of the solid

ablityorto adjust mechanical properties. meta

Cast steels are pouredtonear tinal shape

In sand molds. The castings are then neat

lweated to specified properties and mi

chined to required dimensions,

Carton stesle may be specified to any of

the following: chemical composition,

nical properties, method of de

‘oxidation, and thermal treatment (and re-

ng microstructure)

Composition: Wrought steals are most

chon specified by composition. Although no

Single element controls the characteristics

of a stool, the combined effect of several

Predicting fatigue behavior

Carbon is the principal harganing anc

strengthening element in steel. As carbon

content increases, hardness and strength

increase and weldabilty and ductity de-

crease. For plain carbon steels, abou 0.20

00.25% C provides the best machinabity,

Above and below this level, machinabily's

‘generally lower for hot roied steels,

AA series of standard wrough steel com:

positions (for both carbon and acy stoeis)

ts designated by an AISI or SAE four-dgt

code the last wo digits of whichincicate the

nominal carbon content. The carbor-stee

grades ar

peal

Miser e

A ndicate tha the endurance

40% 10

BOM at he tna

poked at 1eyoies consspening io a tavcue strength 60.31

{tna aed thet preximarey pret ot

‘specttun-basod soley on the static variable 6,

“Torelate ths curva fo reste design concitions,

‘ature recoctin eet te acoowrt f

ad mean Sires4, corrosion

sven ‘he

eatin

‘quasi os

thareabtte

peal cine

on 8, béconion, 5.~ 0.5). The foutng ia Both he

raat etd apo voted yp ik-ete thown

Hotmeas vena nee

MateraaReterrcelenwe 13

Design refresher on smell

ing, Superior'sincluded. is

‘sold through distnbutors. Its an efficient

‘way 10 operate for everyone concerned.

However, tubing stocks can quickly be-

‘come complex. Wall thickness options alone

make “complete stocks” virtually imy

ble, This is why 80% of tubing sold is nor

from warehouse stock,

So ifthe tubing you need is unavailable

locally, remember that the mill i as close as

your phone. And we don't mean just for

{xotic materials or long runs. We mean as

Inte as 100 feet if need be.

Ways to boost tubing strength

Tensile, yield, hardness, ductility are major

design considerations with small wubing

They are elso potential routes to over-design

Tike going to a heavier wall or different

analysis fo get higher tensile.

“The tensile strength of most tubing can

be raised by cold working, and the strength

‘ofsome metals can also be increased by heat

treatment. With Nicke! 200, for example,

it jumps from 80,000 psi for soft annealed

10 100-1 30,000 pai for full hard drasin,

=

ey area] wes

oe afe[

oF [|e

ame ope] o

ke ewe

oF sf 7 |

at hele

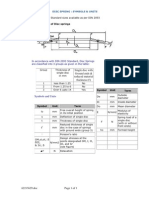

Fig tc of heat erm on verdes

(rodeo er Soper Tobe Typ propercy ot

‘om temoererre

Fig. 1 examines the effects of heat treat,

specifically, on several alloys available from

Superior. Effects of subsequent cold draw-

ing.can be stated more generally: the greater

the reduction to finished size, the higher

the tensile yield and hardness but the less

duct

Obviously then, wehave two significant

ways to boos tubing strength — heat teat

and cold working, Another, more sophisti=

ated way — one that can increase faigue

life as much as five times — isto induce

compressive stessson the OD by peening

Tn each instance, the design implications

include savings in weight bulk and utimate

Coping with extreme

temperature environments

“Tubing that is eminendy satisfactory at

room temperature (Wo 25°F) may prove &

esign ditster al elevated of cryogenic

temperatures Soler review the state o the

a

For high-temperature service o 1200°F,

the material of choices probably one ofthe

austenitic stainless stels, They offer excel-

lent oxidation and corrosion esisiance,

alongwith adequate strength, Also app

‘able are several titanium alloys.

crn

ere Steere

Saeaae

— | =

ee el

= srs

= = |

Sees

z) & | &

: e | &

: e | s

s s | &

ie 3s |

flees

ine|

ws =

ee

om” | 09

Fig. Note lowar ratings for imtermivent ser.

"Ws in becouse thous onder tbr do form oot

{otro the same manner othe snorted mel

AAs you move to higher temperatures

1200? to 1650°F — the stainless stecls go

along for awhile especially in terms of oxi

dation resistance (Fig. 2). But they begin to

falter when it comes to such increasingly

pertinent strength considerations as stress

rupture. Here the high-nickel, nickel-base

and cobalt-base super alloys begin to tke

‘over (Fig. 3), Request our Super Alloy

Bulletin No. 72

Above 1650°R, you begin to get into

‘more exotic materials — nickel or cobalt

‘based alloys; columbium, tantalum, moly,

vanadium, And in certain instances, these

and other materials may requite a protec-

tive atmosphere or coating. Consult Sui

‘ior who has the technology needed here

lots woud rk overs endetion evan,

St dove pectonmance toma of tee pre

Atlow temperatures, wateh for bitte

ress As you drop down into the cry-

‘ogenic range, the properties of metal change

once again Teese, yield and hardness

tity and love

tures appronch the critical ductile-to-britde

fracture range. Those phenomena —- for

304 stainless specifically -- are depicted in

Fig. 4. They are shown in tabular form, for

some of the other 300 grades, in Fig. 5.

erin etn

acai

peace saae

fg Note mani ann nia dang

(70 forearm oreES

‘e| | wo] & 1

wf} ie] | S| om

™ 2 mt

8

Ey *

® *

Fa. § tramp of

‘which eer druvobie cre thorn

lubing metallurgy

{FI selocting small tubing for cryogenic ser-

1 vice itis essential, thereloce than its ductle-

' to-brite transition point be well below

| proposed operating temperature. For ex-

| ample, 400 series and precipisation harden-

> ing stzinless steels would be risky below

LS,

t

Generally the tubing materials indicated

for cryogenic environments are the 300

© setes stainless stcels, nickel allows and eer-

© tain carbon and alloy steels, Applications

typically involve a fiquefidl gis — say

liquid nitrogen (-320°F),

Additionally, in certain aeros ace app

(ations the material must also remain non

© magnetic and exhibit bigh etoctrival cos

‘ity at low temperatures ible still

“retaining strength. Certain of se high-nickel

loys (Monel, fnconel*) possess this un

{sual combination of propertis,

‘esa alloy such a 316 oe 317 sans,

Intergranular corrosion. Ocursin 304 and 316

sinni above 800°F hen elevated temperate

‘ue eartonto dil ts gran toundaroe Mn

Sized by ation of tan and columbiom

alloying constivens ot ty ing ow carbon

eae

Forming and machining

considerations

Moxt small tubing is subject to “secondary

operations” Here are three of the most

common, along with comments:

ing. Do nt aterp o fare har materials

‘eanncaed or onceighih tard bing Also cut

‘wiv on a lathe spose, 1o.e agare cg

re ef elmuate all OD aa TD buts

‘nde stempuing hr operations

ending. Minima bending radia bows in

Fig fo g0 tghich, we filer to avoid wall

lagu or wrating

é 1 7-ano exo nns

“The corrosion protien _____ Bromine on

‘FAtmostevery meteors ioscmeentent, “Wome ry

= Bltthereare many tubing wraiysesthatcan “Fax oo

i iminate potential mechanic! Fate from cae i

a :

fe ear 3 i -

Bios arom and aliey steels: Stamless sec are pect

= iy more demanding Const eur i cesing

= ing Sl ea std wed Tous ras

ete actuary

oo Sen 12 yd 108)

id \ ‘ad Ai Soa

Bee | sae ae

‘mine | 3 | k

timo i re sm | oS

ages About availability and

i ay Solerances

The most common way to 1

‘tubing corrosion problems isto substtote a

‘hore highly alloyed maiciial Evertvall. of

outed to 2 trade on ial ve

feplacement cost Howser. ure are teee

Specie eeerosion probes an! thes

Fer corrosion, Occas hia otros ack

‘Guncdes wat stew a the pon ales

Sow icine modi eee and

St eving 9 erp

oop 8 pe

Superior offers over 100 analyses — in

carbon and alloy steel, stainless, nickel and

fickel alloys, copper-base, glass sealing,

rwactives, refractones. Most are available

from 012-in. through 1.125.in. OD. Cer-

tain stainless aod nickel alloys are available

fo 2.50040, OD with resriged wall thick-

Standard commercial tolerances are

shown in Fig. 9. When required, Superior

‘can hold to far tighter tolerances — half

‘commercial one-third up to the very lierits

of the art, We can ako provide microinch

surface nish levels to ASA 16 through 250.

hoxein

pm rt

Sas

Wee nant

atc m0

‘oo oe

aoa =

ots pe

mes ae |

Fig 9 Commerc tolerance for ened bing Pound

Surface finishes

Various surface finishes on OD and ID are

available depending upon size, reductions,

and in some cases, materials. Special pro

cessing techniques frequently allow {6 max-

imum RMS ID finishes t0 be obiained.

Consult the mill with your requirements

New materials on the scene

Materials being evaluated by Superior as

‘candidates for small tubing markets are

‘Titanium 18.3 — shea damm alloy

sernfce awit appistions

Tiasivm GAL — space foc! ns

Alloy 20-4C — bigh panty frit ui

Comlenertbing

Alloy 2206 —- a duplex sles Oil and as

Fated applications

‘Alloy MA9S6-— wow ion based mechorivaly

Alloyed powder meaorgy: product icra

cre.

Custom 485 — WELDRAWN grade of arg

ing sel Comesionresan, hghsteag

‘orl appatons

Alloy 16:6 PHL marine prpiaton han

hing ames scl High settee

Ssan apptcanom,

Alley 690 — so shane strengthen

thy. Scam genrton

ironic $0 nitrogen sabe ait 0

[es Stengh and coon rea

‘Alloy MP3SN — the ultimate in svcr and

orion resiane. For madcal $n Sra)

Tubing in Coll Form — sandard suites yao.

and Allo §28 and “Alloy C276 ae ssi

ing ca fro wel astrametaton ene

Free information and

Selection Guide available

‘Our free Bulletin 46 covers

materials, characteristics, ize

ranges, and applications for

‘overa hundred different anal-

yses. Write or call

©) Superior Tube

94,21) @9 5200

Tube: Lowangees A004

esuiturized

‘Yaxx: Resullurized and rephosphotized

‘51x: Nonresulluized, Mn ovOr 1.0%

‘Theletter"L” betwoen the second and tra

digits ndicates aleadec steel, "B"incicates

boron stew.

‘The cast carbon stools are usualy speci

fied by grade, such a8 A, B, or C. The A

{rade (also LGA, WCA, AN, AQ. ete} con-

tains 0.25% @ and 0.70% Mn maximum

B-grade steels contain 0.30% C and 1.00%

8

Macnnaity Range 5

5

Mn, and the C-grade steois contain 0.25% 6

‘and 1.20% Mn. These carbon and mai

‘Ganese contents are designed to provide

Good strength, toughness, and weidabiity

Gast carton stools are specified in ASTM

AZT, A216, A352, oF A487.

Mechanical properties: Cast and

wrought products Intended for strucoral

‘ppications where forming and machining

isnot extensive are sometimes specified 0

‘meet specific mechanical requirements

When steels are specified by mechanical

properties only, the producer's free to 2¢-

steel (within its) 10

ee

‘Typical mechanical properties of free-machinining carbon steels

Typical physical properties

of carbon stee!s

eee

‘Meriva temper

102007 ares

‘Thermal conduct ty

eae?) a

enaty 0" om

locricaresiaite

on

Y anebe 77627502775

eoea

a

028s

1518)

‘Typical mechanical properties

of cast steuctural-grade

“nate enh oe 6

‘els poet 1 Be 2

Boapatenn2n is) | 0

Hardness, 9 wr

Impact etenat

‘norpyeh ey

AI7OFF ns

ae a,

Endurence i108)

Uneatnas » 2

Need

Machinabilty ratings of

cold-drawn carbon steels

vara

289 1997, 1198, 1199-

Hot cold Hot Cold Mot Cold and

rated Grown rolled crawn rolled drawn tempore

cor SET a oe a eae ee we

‘Tena strong 10 9) 57 705) 5515 G76 OO7B 89.13

engation nai pri) a ieilgew sem oe

Macnnabiny(1703fpmn = 100%) 136205114168 82106

oredontato vein bare Single values are minimum properties. ‘Quenched and tempe'er a 60°F

~ Oi quenenedt and tempered at 400°F, average prorarties

16 Machina Design / Apr 17, Y086,

Typical mechanical properties of rolled and drawn carbon steels

1018, 100,102 ——_ ——— 1006, 1049-——— 1085, 1050 ——— 3088.

‘Quenched ‘Quonehed ‘Cold drewn, Quencheg

ot ole Anneaied Wot Cold and Hal Cold and. Hot annaeied” and

rolled dew

yy ol niiomboying hse

Wa Hovrcatogoryolteraing

p3atisnad oon goatanain

pe bedives a caccon ents

minuto quanto of

ements -~ uses than

courage

obtain the requsred properties. Properties

‘may vary with cross section and part siz

Mechanical tests aie usuelly epeciieg

under one of two conditions: mechanical

{estrequicemoats and no cherie its on

any element, oF mechanical tact raquire-

‘ments and chemical mis on one or more

ements, provided tha! such requirements

a tochnolagically compete.

Method of daoxidation: Moen steolcon-

tains dissolved oxygen—an important ela-

‘ment the stool-making raacion. Haw tis

‘oxygen is removed oF atone to escape as

the metal soles determines some of the

‘ropertis ofthe steo!, So in many case,

"method of ceoxission” is specinad in

ition to AISI and SAE chamical compo-

‘tons,

For “kod steals, stoments such as al

mnnumand sligon my be ddd to combine

hamicaiy with tho oxygen, removing most

St from the iquid sige: Killed stents are

hten spectied for hot forging, car>uaizing,

and other processes or applications where

maximum uniformity \s required. in shoet

Steel, aging is controled by Kili ty

Wh aluminum, Steels ictended for use in

the us-castcondiion ar aivays Kies

On the other nana, tr rimmed stls

‘ygen (nthe form ef car8on moncxie)

‘rhea ish ought he seston

Brocess, The outer sho rimmed stools i

Bact res rom c3'b20 4nd very

19, Pinas seats ao ion species tor

btorming apptesions is! banal trom

fe duckie, lower-carbon surtace tay

Renimad stools are vsusily svaincia in

0 wih igs ti 0255 ¢ and D0

Ma. Sagragaten—e roruntorm variation

(1800"F)

coneemonstcatvon

ened

Beat

In intornal characteristics and composition

{hat results whan various alloying elements

recistibute themselves curing sokhlica-

tion —may be pronouncedin rimmed steels,

soTmece stools are usualy not specified for

ht forging or for applications requiring uni-

form

"Capped" and“som:-kiled” steals tal be-

‘ween tha rimmed and killed stoois in behav

\ot, properties, and degree of oxidation and

segregation. Capped steels, for exempo,

| skin, For other cole-forming appii-

tions, such as cold extrusion. kiled steals

Microstructure: The microstructure of

carbon and ally steels In the as-roled oF

as-cast condition ganerally consis offer

rte and pearite. This basie structure can be.

‘ahered significantly by various hoat treat.

‘ments oF by roling techniques. A spher-

‘idized annealed structure would consist of

spheroids of iron and alloy carbides dis-

‘persed ina ferite matrix for low harcooss

‘and maximum ductilty, ag mightbe required

{or cols-orming operations. Quenching and

tempering provide the aptimum com=

bination of mechanical properties and

toughness obtainable from steel. Grain size

‘can also be an important aspect ofthe mi-

crostructure. Toughness of fine-grained

stools is generally graster than that of

coarse-grained teste

Free-machining steele: Sovora roe-ma-

chining carbon steals ae avaiabie as cast-

ings and as hot-olled or cole-ravin Bar

stock and plate. Machinabitty n steels is

Improvedin soveral ways, including: 1. Adi

lion of elamants to the stost such as tad

(the “ieacea” stools such as 12113 and

12114), phosphorus and suifur (the “7e-

DPhosphorized resufurized” stools such as

1211, 1212, oF 1219), sulfur (ihe "ree

sulfrized only” stools Such as 1117, 1131

0F 1918), and, telurum, selenium, and be

‘muth (the super" fre-machining sieois:2

(oid tmishing: 3. Reducing the level of ra-

sidual stress (usually by a stress-releving

heat treatment), and 4. Adjusting moro”

structure to optimize machinabity,

ie sess narcomain a races amount righ snes Cas stots ao goneray

Lepore lesion bees gl eaten ed reg

pegs mea piie

Alloy steel rchafie properice War rope tal

i lech anaes: Camara apa a wake

ip oan bry raped Ki gap

Sane eer MECaMECouice. =, Alep jenna Goma nopea Seortceee ae a menue

Gaga cecwtons nvaaianoece nine (hs michcas bn cwciginatiecse! San iano temsat ln mera

Pe ieeiinr a bs chuegtc. Coreanneer wom emomin tee nn eee

He er errors try Trrcorcnctonmng pranks: ch ay ngage See

Va GM mc emiaec, mamaenremoarturcess: | coeabinn cnn cme

eCitee econ BOLL Me cml wen Neo EO erp ema

eee aie taeet recoe mt ok eas el ee

oe cov mnaroutio shear, bancrtcree

Beast tee cme aang oak aor och cots a

dite baa boisaitot oun soos-non ws otiretg px atten te, 250 come

peso kag tenprea pele pet hadnt fed tg ke mpetbrw gp lee

Pap scies ae raphe tal Node pete prpeetge diego oo

ouenci, — SOMINY TEST BARS

OTE Te 2 ae 20 ae

stance tom quenenadena

‘ony bar Bin)

caine

Typical mechanical properties of alloy stee!s —through-hardening grades

—— 0" —auos7e0: ase:

Normalized

jected Qvenched uanches ‘venched

Annealed Atemperect Annealed Stomperedt Annealed kiemperedt Annewiod & tamperedt

aT a Tas pe aa Tae

Tamale svengQh (0p) M2 MIT os asp OO DIS ag ETS

LA ELE SNARE BS DT ‘ao: lea

‘These ay lets oe etter Seed or Mah ampertareapplcatons, so sreep Sata are mi ah: we,

20 Machine Design / Ap. 1988

‘Typical mechanical properties of alloy steels—carburizing grades”

270 rae eae nee ey

Annasiod Ceroureeot Annoaled Carbuizedt Anneaied

20

Te ——

2620 — avo

Corpurest _ Aanesied — Curourized?

mt a al deme a :

Tate evenginF=0 owes Cena Ar a)

‘esi atrengin, Carty (40) a TEM RE RET

Exeemnnen 0 Sen renal ° eat ie

‘Fepcie nets ts Sn ons Cap sion ce te laoreet eh en

Fearne stoprentvamant tne oa ompemnann Onn app oc meas

Minimum mechanical properties of cast low-alloy steels

asTwOLASBIEATION —

fae are Awe Me es RR

Z ad Se Sees pee

ia wor moat weno nee ieee tenon toes

rontcined Notctced Nommatzed Nomattad QuenchedA Oveacudt Quinchedh Oienced

Ninpecs_ticarees_Shopees_Simpret euoune enone ewe tno

ieee et

Seitooran co) ra oh ae agri ee ae oe =

Seceestenei Se) @ Fc

tion Rembeth. Garey At) a STEM LATTE

Retpeendwance ti

eaahasaeca (%E=) 2 =

pti es ai. mw a“ aa ae oe seamegemanngs 3)

i - my ‘are now available that are reported to dou- crease toughness: low service tempera:

AISI designation systein ble or triple toot life and to provide improved ture, high loading rates, and stress concen:

for alloy stee!s ‘surface finish. trations or residual stress. The general

— - titers of nese tee condtions ae dus

‘oy Aroma There are few exact res for selcog ately iar, s0low-tamperatur inact

fe ee Seat) ‘hrough-hardening or surtace-hardening tests (to ~ 50°F) ae useful for many ap0h-

array Giedecctaioy sos. Inmostoases-eiial catorsesinacators cf tougest unde” &

fox hast Sure oe fod tested to ealste the petox- vara of serves concttons an tempos

FBR Seacsencomos fmanosfvrous sy tel fre

Be Miewzonccowom

wean Pans wih large secions—heavy for9- cee Se

§ oor 0025-045 ings for exampie-—are often made from ale FUlY neat ee

460% NIO.7O200: MoO 15.020 oy steels that have been vacuum degassed. baal Bible yor lack Samcieyl este

4X O91 2. Cr 0 35.0.56, aa . good combination of strength and tough-

neo ion a taten sti, tose sl are Ress, orn a oom and ov Taree

wx noma womon cla aparece 0; Gare must be ten in heat treament of

oe eonen Rees Me neap eee. See certain alloy-steel grades, however, be-

SKK CrO.70-1.15 pr cause toughness may be decreased sub-

esi Conese is

Stanly by tempor trenwss-—a 0:7 ot

E00 Ci0b.ori 0) a Aioy steels are often specifiod when high 2h i

eine nia.¥ 21018 strangtn is neoded in moderate-o-large ombrinvement developed BY sew costa

BBX 940070; 079 0K 5 1s. Whether tensile or yield strengtn ew Se rinae © —

uae 15 i isthe basis of design, thermally treated alloy "OldNGOr lempering inthis range.

Pk“ Raaamcr04098 steais generally offer nigh strength-to-

Be aehetes on ae er a edurng _Whenkaud aenenrais impacts

as caer oeeoealty ahorewrniow sofurlen, ©4U860fN@ danger of racking or isorion

em tae a i rary pre: 0% bacaune Ol oat, varous tv-

ee 4

22 Macrina Design | Ap 7.1908

|

I

t

Hardness ve approximate

strength of alloy steo!2

—Hardnasa

te mo

Tora

810108

ato 94

ratte 18

Ya to

BSegeeeeeER

“Theva ates to secs hy narsovac blece beng

Aeepereh most acca 3 sts wih O20

eaten hgher

Typical physical properties

of alloy steels

“Decienes win rsoanng chia conan

spscity minimum properties for ential

‘Structural, praseure-vesse), and nvelear2p-

lations,

Cast aloy steels ar clossiied by ASTM

‘pecifictions that reli the steel to the

‘mechanical proports aitained and the in-

tended ervice condition. Chemical analys's

's secondary, There are ASTM spect

cations for goneral ice such #5 AZ7 or A149

\whenmachanical proper are erica! For

low-temperature serace, A252 of A757

lel, and for presse

‘Service, A217 oF A3E9 's rocommonced

‘shen anumber of properties are important

‘St¥other ASTM alloy siseisaroavalable for

Special applications. Other specifications

suchas SAE J435 aroused forcast steels in

stomotive appications

Tool stee!

[ALTHOUGH too! steels are con thought of

‘8 belng used exclusively for tooting, the

‘tame propaties that quaity thom for tools

nd dios also apply to other parts tnatre-

ure resitance 10 wear, stabity curing

beat westrent, strongth 21 high tempera

Lures. oF toughness. Too! sieels are ine

iaasingly Being spoctied for mechanical

parts to reduc9 sizo or weight, oF to resist

‘wear or high-temperature shock

‘Tool steals aro metalurgicaly clean,’

highraloy steels that are meltodin eiatively

‘smal naats in electric furnaces and pro-

‘duced with careful attention to homo-

‘geneity, Thay ean be further refined by ar-

‘gon/oxygen decarburization (AOD),

vacuum methods, or electrosiag refining

(ESR), AB a rosult, tool steels are often

specified for ential high-strength or wear

resistant applications where uniform prop-

erties are required from part to pert. Be

{eauso of thor high alloy content, to! stesis

‘must be rolled oF forged with care to pro-

duce satistactory Dar products,

‘Tool stools are sbvays heat-treated to de-

woiop their Dest properties. Because the

arts may distort during heat treatment,

precision parts should be semitinished,

heat-treated, then finished. Severe dis

tortion is most thay to occur during tquic

{Gueniching, £0 an alloy should be selectec

‘hat provides the needed mechanical prop

erties with the least severe quench.

‘oo! steels are classified into several

‘broad groups. soma of which are further

Givided Into subgroups according to aioy

Composition, hardenabilty, or mechanicat

simiaries.

Water-nardening, or carbon, tot steels

osignated Type W by AISI, rely solely on

‘cerbon content for their usetul properties.

‘Those steels are available as shallow, me-

‘ium, or deep hardening, s0 the specific

‘oy selected dapends on part cross sec

‘ion and required surtace and core hard-

‘Shock-esiating toot steels Type 8) are

strong and tough, out they are not as wear

fosistant as many other tool steals. These

20s are formulated to resist sudden and

jopaated Woadings. Applications include

‘breumatic tooling parts, cisels, punches.

hear blades, bolls, and springs subjected

tomoderste

Cold-work too} stoets, which include ci

‘and air-hardaning Types O, A. and D.

‘often mora eostly but can be quenched lass

Grastically than water-nardening types

‘ype O steels are llhardening: Type A and

D stoets are air hardening (he least severe

‘quonch), and are best suited for appl

Cations auch as machine ways, brick mck

liners, and fuelinjector nozzies. The air

hardening types are spacifed for thin parts

‘oF parts with severe changes in cross sec:

tion—parts that are prone to crack or distor.

during hardening. Hardened parts trom

these stools have a high surface hardness

but should not be specified for service at

‘levated tomporatures.

Hotwork steels (Type H) serve wel at

slevated tomperatures. The tungsten

‘molybdenum high-aloy Hotwork steals are

hes

are subjected to service at 600 10 1.000°F

[But although these alloys do not soon at

these high temperatures, they should be

nested Before and cooled siowiy ater

Service to avord eracking. The chromium

[grades of hot-work steels are less ex

General characteristics of tool steels

erdering

“dapth Toughness

‘Woer

‘These data apply only to those toot

steels vet ytd consistent and reliable

\valuos: the data representa consensus

ithe members of AISI Committee of

“Too! Stee! Producers. Because many

1001 steels have bean developed tor

‘highly specialized appications, certain

their mechanical properties exten

Conaion®

Seyonitecminangeoreapacty a Ampoatgteme"

conventional test equipment and thus, ns €

Sonnaersnjeciopesntin for yews

Cre secclootsoatainan — ate

Seencelpestornghiarcrane or ag

era 58)

Roa. ee

Thon ne selec omental i es

eer roen

hardness test, Similarly, some tool

‘steals are so unpact-esistant that they

speci mosninglese Charpy tastresults

{hat cannot be reproduced. Atthis time,

vaio mechanical ast data cannot be

report for many tool steels

pensive an the tungsten and molybdenum

fprades. One ofthe chromium grades, 411,

isused extensively for areratt parts such as

primary ait frame structures, cargo-support

[ge, catapulthooks, and alevon hinges.

High-epeed tool stools —Types T (tung

sten alloy and M (melyboenum alloy)—

make good euting-tools because they re-

Sist softening and maintain a sharp cutting

f9dge at Pigh service temperatures. This

Characteristic 's sometimes called "red

hardness.” These deep-herdening toys

are used for steady, rightoad conditions:

Father than shock loads. Typical apo

cations are pump vanes and parts for

heavy-duty strapping machinery.

Other grades, called special-purpose!

001 90s, include low-cost, Type L. lw-al-

loy steals, often speci for machine parts

when wear-resistance combined with

toughness is important. Carbon-tungsten

aiioys (ype F) are shallow-hardening and

‘weer resistant, Dut not suited for high ter

peratures or for shock service.

Type P mold sigels are designed specif

caly for plasticnmolding and zine die-cast

ing dies. Those steels are seldom used for

‘antooling components

Many steel mits have formulated their

‘own special-purpose tool-stea alloys. Such

‘shoys may not match a specific AIS! desig

rahon and mustbe specified by rade name.

Speciarpurpose too! stgels may be sup

rior to the standard gredes when used as

Intended, but they should be specified oniy

aitor careful evaluation of mechanical prop:

rues, neat-treatbehavier andavalablityin

‘comparigon with the standare grades,

20 sthliontelal) tase oF tae

"chaz Wich (ib)

SSngnronpar ob auren wes erwin

‘Sogn spacers etamal ros sacorabe sac 1

atenerea rate rt ppc aryl tas so SSE

Stainless siee!

STAINLESS stools are iron-chromium al

loys hat contain, by definition. aminimum ot

10.5% etwomium. Four major eategories of

‘wrought stainless steel, based on meta

lurgieal structure, are austenitic, ferric,

martensitic, and preciptation-nardening

Cast stainless stoel grades are ganeraly

‘dosignated as ether heat-resistant or cor

rosion-rosistant.

‘Austenitic wrought stainiess stoe! are

classified in three groups: 1. The AIS! 200

ries essentially, alloys of ron-chromium:

‘ickal-manganese), 2. The AIS! $00 series

{alloys of ron-chromium-nickal, and 8. Nr

trogen-strengthened alloys. Carbon con~

ntfs usually fow (0.15% of less), and the

‘loys contain a minimum of 16% chromium

‘with sufficient nickel and manganese to pro-

‘ide an austonitc structure at al tamer

{ures from the cryogenic region to tne mel

Ing pointot the alloy.

Nirogen-strengthened austenitic stain.

tess steels are alloys of chromium-man

anese-nitrogen: some grades also contain

Fickel. Yield strengths of these alloys (an

‘healed are typically 50% higher than those

Of the non-niirogen-bearing grades. They

fre nonmagnetic and remain $0, even aftor

severe cold working,

Nitroger

strength ot

ike carbon, increases the

too! But unine carbon, ito

‘combine sigraficantiy with

‘This com-

bination, whion forms chromium carbide,

Typical mechanical properties of tac! steels

ort can

secede cme

or ee

oi ac

ee ae

Pare is, |

ee eae

i °

reduces the strength and corrosion re-

‘otanceol analy.

ntl eocanny, otaturgisis had dificulty

‘acing controled amounts ef nitrogen to an

‘iloy. The dovelopmant ofthe argon-oxygen

Secarvurizaion (AOD) method nas made

sible strength levels formerly un:

less ays,

‘Tho austenitic stanioss steals are gener

aly used where corrosion resistance and,

toughness are primary requirements. Typ,

‘cal applicaione include sats, pumps. fos:

terers, and piping in sea water and equip.

‘ment for processing chemicals, 100d, and

dairy prods

Fenritlc wrought alloye (the AIS! 400 80,

as) contain hom 10.5 19 27% chromium. I

‘2ddtion, th uso of argon oxygen decars

burization and vacuum induction melting

has produced several now ferrite grader

Including 18 Cr-2Mo, 18SA, 26Cr-1Mo,

29Cr-4Mo, and 28Cr-dMo-2NL Low in car!

ben content, but ganeraly higher in chro,

mourn than the eartensiic grades, these

Steels cennot be harconed by heat tat,

‘ant ancl are oniy moderately hardened Oy

‘oid working, Fernie stainless stools an,

magnetic snd retain their basic micro

structure up to the reeting point if suticien,

Gr ang Mo aro prasent. fp the annealed

onaition, strength ofthese grades te ap,

proximately 508% highor than thet cf carbo

steels i

‘Te tortie sainioss stals are typical

used whe maderete earrosion rsistanat

Toquired and where toughness is not

major need. They se also used where che

‘Typical properties of cast stainless steels

ConnOsION RESISTANT GRADES (ci DESIGNATION) ————_—

case coe Cea" Ora cHao! | CO F

“- NEAT-RESISTANT GRADES (ACI DESIGNATION ————————

royce beret aa aaa

TE gQUIVALENT AISIGRADES?

Groep song 0001 110

Pires, 1400°F

‘coils wroughtgeades are gen ft comoaritan oy tha ACI designations, gary

Treuduain ATLA? ond AOS around aspect ne eat stresses

Motes Retrence aeue

rs

CARPENTER TECHNOLOGY

CARPENTER STEEL DIVISION + READING. PA 19509

(Check tis listing for atlays that may be most pertinent to your needs.

Then use the reader response nurivers to snd for additional information

‘and technical details. Or, ask us about our othar specialty metals,

tool steal. Olfes superior wear resistance to

@axecH}

anny

eee

Extrusion of brass, eopper, steel and stainless

‘ vl otk ens Inrowed wear restonce | ste pats

Thermowear” | ions long exr runs efor too dressing is 61

Alloy | Seeded: Can hip ore beter contol of pat dimen

| eer temmaent

Pyrowear” | is soniy did catwing soy sed | Gee pein in emp aris

Alloy 53 4 properties in high temperature applications. It provides: ments, such 2s gear boxes for aircraft turbo 62

Noy high inpactsiength end fracture toughness. charged engines,

icating esa Snot coving | De cxig

vu | Wis Eanbls esteme toughness and god re

883 PLUS™ | farness Clee impcoved slope properties fr 63

Moy frente: vntrmiy and better strctral neg

fi be Leried fo ADH Speciation 01 83.020

f dnd to Ciyser Corporation NP2OD.

pecscmmmamnncns nnn

© ‘Anicket:molybdenum-iron alloy. Capable of being heat Toroids in the manufacture of core components.

on fated chow very hil permesbes, mas 64

rs arte cv ae ew Pa

3 ti fx deste,

=|

Z hcp aoe cae

SS Hiperco” ttn miatanond tie

Say spy Hipucn S08" far tanlomer laminations

pee oe a tape toraidsHipereo "0B" Tor hat | ©

4 508" loys Speed pier machines

oi ian sty, Has been used for solenoid | Solenoid cares that are machined to shape

8 fc eae component incor on

CS wor ‘camer Goats coroson om atosphete sh 66

a ae, aes, como Oevetagt, ay pods

‘Ss

1 sonmagnetc, ickel-enbalt-chromium-molybdenum

y. Has unique bend of properties: strength to 300

Fastener stock and components in medical

marine oil and gas wel, chemical, foo pro

2 sapagnet | teres duchy, toughoes, exelent caroson | —esng and nonmagnetic electical produ

a. gine as esa ed temperatures up 1 7507

a (Aon the mov ordened plus aged cain. staged Inde ot 3 eng

a - sudatonandcorsin etal precpitatin hard Sou gas andl wel application and otter

ce sa eet hacker an unset combeaton ot | demanding tuations, induding hardware is

c corrogon resistance and strength to temperature 2s ‘coal gasification units. 68

i high as 1500°F (616°C). Has shown good resistance to

= Stu eno such stove encountered in d2ep

5 Sout psandol wel

A high suena, precitationhardenate superatoy | _Applicabons such as gs turbine engine compo

: 1 ey fotaen ol thermal exganson win | nei, ol work de appear, orsnace

tes ee amperes to OOF (0°) Hos | hardare seam tre Dade ene BOCs. | GQ

b high tint hardness and good thermal fatigue resistance. ings, rocket thrust chambers and die-casting

a Cla ores 0 Ppt CTCL, Bt has 2 ae

= cts eanigtieingior bat sty | Gas tne vols, mie aphaen vies,

Ae yest temperatures Pres | sping. one dl bs, and eat aves 70

food resistance to oxidation and eorosion

faragetic in the work hardened condition

ais

og high temperature Bearing st

iWeat resistant. Has high

nts high Rarcness levels at

variety of bearing applications anc

seaming

n

ep

SPECIALTY METALS. They're only

HERE ARE 22 CARPENTER GRADES DESIGNED TO

‘The crasssection of Carpenter grades described below are typical exam- theyre just part of our selection. You ean choose from over 450 grades of?

ples of aur special application products. They were developed in response Carpenter specialty steels, e2ch one offering distinct performance advan |

{o specific customer requirements..perhaps very similar to yours. And tages fora particular application, i

Dae Lau SUL}

2, cables, chains, boat

superior to conventional chromium-manganese stain

Tess for many cil and gas wll diling applications.

Stainless This nitrogen-strengthened, austenitic atte ay Pumps, valves and fi

C-I3Ni- | rovies Deter consi restance than Type 316, shafing a pte eget

tough, corsion esistant alo. texts good lon ‘ave pat, iting, cold headed and rachined

PH 13.8Moe | fia and rarsrese popes in ae Scions, Fasteners, staf, lending gear pars, arrtt

lus good toughness. Has good fabrication characteris ana clear reactor componenis, and pete | SY

Stainless tics Can be agefardened by a low temperature Chemical appicetions requing resistance to |

treatment tegstee Tademaholten stresscorgson cracking i

‘A macerstic precipitation hardening stainless stel Purp impels, shafts, vale bodies, fitings,

sp | Hasa coasionresstancecomparble to that of Type ‘oe and eer process equipment components

Custom 450® | 304. Can have a yield strength of 100,000 psi in the 52

Stainless ¥mesiesconiton. roger Heat reatment develops ©

ie strength of 175.000 pin one stp, Can be ma

hind, Pot worked cold formed and welded

af |Our ighest strength, highest harness martensite Valve stems, sas components cetaring rings

ainless anca Wesdly machin ged Ga word |

il ecactunmasmicmtcins | mech erases

3 200-3° | lotartearodens ncuing at sun soa Vie | pling equpner, pons sats tots we | gal

Tl Stainless ally immune to stiess-corosion cracking. Weldabe, Stems, fitings and fastene's. |

e sachin ancl orale |

ae |

2 An austenitic staness see designed for harsh acid Heat exchangers. piping, mining tars, pcg

2 ervironments with 2 moderate level ot cries that bhasphoric

te Moe Gan lend fe iting 9n6 crevice eoranon. Viral 55

st Stainless ‘immune to chlotide stress-cortosion cracking, Available

= in tubing, pipe, sheet and plat.

else

= a A hardenale martensitic stainiess seek. Provides a Sel ling fatness, fod processing eauip-

“ TrimRite” ‘moderately high level of corrosion resistance, with po: ‘ment, valve parts, gauges, guides, shaftin, |

Stainless tential for hardness upto Re 51, good cold fomabiity conser chin instruments a6 ooting mails.

and ease of heat eatrent

: combining sess corrosion caching resistance, high

SCF-19® Serpe tal lod eae par oeiy ass any 57,

Alloy tests and intial onto tess indicate ths ally to be i

j

‘

|

A ule sais ante ay wth suet et | Hea xoryer ptm rn, pete

5 | acetointeranlr conor, ptingeMonde sess | chum chemi, pup and paper, a ae

7-Mo PLUS? | Soros ekg and mines afk on welded | pos 58,

Stainless Seams. Has moe than twice the annealed yield |

Sten of pia este stainless sels |

ue Conbnes Meh sven ond tugmes ovr a wide | Yes and pus rate ites ad fst '

ickel temperature rang. with exalt resstance to many |e. chameal pressing equipment, eaalie | gal

SPP Nickel.Coppery core conden partly m marine and cher ium sits, | SS

ES oy 400 | lone nnn ey ee : festwater |

sa Strengthened 18 woking Equal to "Monel 400 feats, ee i

Sa (registered trademark of Huntington Alloy) i

Nickel-Copper| tree mchicing grade wth characteristics denial to

Miloy 405, ‘alloy 400. 6t

‘ide stress-corrosion cracking may bo a

problem because thoy have nigh resistance

to this type of corrosion failure. in heavy

sections, achieving sufficient toughness I=

dificult with the nigher-alloyed territic

‘graces. Typical appications include auto-

‘motive trim and exhaust systoms anc hea

transter equipment for the chemical and

petrochemical industries

‘Martensitc stools are alsointhe iS! 400

series, These wrought, higher-carbon

‘steels contain from 1145 to 189% chromium

and may havo sma quantives of addtional

toying elements. They are magnetic, ean

be hardoned by heat treatment, and have

high strengin ang mocecate toughness in

the hardenod-and-tempered concition,

Typical properties of wrought stainless steels

Yield Terao Elon Impact strength Crocpsty Thermaleond Coat

suengm strength gation 0000 Se2i2F thermalexp

——pesianarion—— “Torr ore tee Torr Tor anor Gu eat

Aisierce. uns (pay 10%) * ew) (ps) MEF) nF)

TusTENTC GARDES

32

s PSR

92

SOARS ad

NITROGEN STRENGTHENED GRades

‘SARIN ICR

SEO 10 2 Sc

21C-e avn ico

oe

7

Z2ce Rasa

Nore

i306)

8

ce

SSSR SMe ae 2

ro RN SO at ss

ts aera «

“ue, seas00 40 °

‘sci aur Sia 7540,

RMR 1 :

Sen Cue coe) 7s S

RaRESRORNRE MR TS

“6 ‘41600 .

4160 i caer ale,

NE ARBRE TIATORS =.

woe ‘se004 IS ee coe

‘Shupy Voth or 1? cyoos,consion 0 FT AGAIN? Fer WPycos aged

“For 15% 0c, condition OED. Sabired lw oleratal eee, stp) Preemectining bse

‘Note: Unies hari cca, ata are for annealed ought bar Properties of eran my ary cmt

28 Mactine Design / Ap. 1988

] Feiming shoe be done inthe srnssied The marten staiees sto reused srucu'al pens, and wronecomponents

| Sootn Martens sores sols we wore ang andor arches are

ieee ressanttocovoocn thn the assur. aryooncemand where bt ereonmertis eciptalin-terdening states srs

| Wear tonic grades Tus iypes--416 snd rtay mad rom a corosion slandpait develop very Ngh srengihivough «ow

| ‘S20e nme beendovsioosaspectinly tor These loys retypcalyusedtorbeerngs, tamperaure heat Westra fut dors nt

| gonlmachnabay. Imes, cuerymedealieuments,arratsigicanly ston pres prt Conca.

sitions of most precipitation-hardening

stainless steels are balanced to produce

hardening By an aging treatment

tages pons 10 palo cd cipitates hard, intermetalic eompounds and

Mar caer Lewd Nawonic simultaneously tempers the martensi

Galling resistance of stainless-steel pairs (unlubricated)

autem ~ — asi yp0———_— ese ThebeginnngmerostructureotPHai0;= 6

yee ___ "Banat _aser_sr ence aos" awh _ateh Team" ooh__ austenite or martensite, The ase

Te a EE SEE Taw lys muse thermally tested wo tenstorm

38 og @ 28 sp_tustontetomarenstebelore precptaion

fie dete teaethactemntonelbcamses heroening canbe accompaned

ets ar

scares GOTREHETATIA? Those alloys are used where high

Bo Poa 22 5 strength, maderale corrosion resistance,

eR RENT BE and good favicabiy are required. Typical

eae Sppicatons include shaféng. hgh-eres

eee tae sure pumps, aireraft components, high

temper springs, and fasteners.

eee ee

joavenaiumertlenian

SSavoetione tna poveran, owes

peinnsunieeenae

Ss Sere

aS eae

ee Same escapee erates

remewroreeee TT} | omnia Casig res ty

os ‘the designation of simitar wrought alloys.

3211532100) a sit

Frnib o e109] [Aciatnction, based on service empera-

eae ‘ures made between heat-resistant ad

|

|

|

inh en %

corrosion resin cast rae, The € oe

Jets bonged nase ian ais ‘eect ACigradesdelgnatestne corrosion.

eaiimatjontra con ease (seae [| ‘esitant stele eras designtos te

TL sieesree0 heat-resistant steels, which cane used for

en ae = | srt apptcatons a service tonper:

ectes {ures peteeen 1200 and 2200°7 Cweon

| Bes] anc nici conn ofthe trans stoys

eon | Ese conser tiger en tose tne C

mee $ series. H-series steels are not immune to

Sek comrolon, bt By corrode sony ores

So } | sen exposed to tel combuston procs

eee Gr armonpneree prepared f° areneng

= ad aiveing, Ceres grades ace sed

moe 5) ‘eves.pumpa ond ing Vtemras grades

sea reused tor timace pert and tubing sore

"302 Se (S90323) pore

~ i 36s i er

ee Se

area |) stosis because these meters sor in

soos ar wae |] manynarshonviconments. They oer opsr-

aor eee aio, for example, at high temperatures. in

129 (80 fooa-contact applications, ano were ac

22054200) [| cassis ited Suchrestictons pewntihe

rene [ -] uso ot icant, leading to motate~netal

Shae t ontact—a eanditon tat promotes gating

ones anconananee:

249 g4ea00)

In asting wear situation, a galling faliure

mode occur fst, fofowed by dimensional

1095 due to woar, which is, in turn, usually

followed by corrosion. Gali is a severe

form otachesive wear that shows up as tor

‘areas ofthe metal surface. Gating can be

rninimized by decreasing contact stresses

MaterasFaterenceissie 29

(oF by the use of protective surface layers

‘such as ubcicants (where acceptable) wold

overlays, platings, and nitided oF carbu-

‘ize6 surtace treatments,

Results of tests on stainless-stoo! cou-

les (table) indicate the relatively poor gal-

fing resistance of austenitic grades and

‘ven alloy 17-4 PH, despite its high hard

ess. Among the standard grades, only AISI

418 and 440C performed wel. Good to ex-

nents,

The 9% Ni, 4% Co-alleys were designed to

Provide high strength and toughness at

oom temperature as wall a at moderately

loveted tomporatures — to about B00°F

Wolgabiity and fracture toughness aro

900d, but the alloys are susceptibie to hy.

‘drogen embritioment. These steels are

Used in airrames, goars, and large acral

pans.

res

HSLA steel

THE FAMILY of steel alloys known a6 high-

‘strength fow-alloy (HSLA) steel was devel:

(ped to improve strength-to-weight ratios

‘over thea of conventional low-carbon,

stools. Gocause HSLA alloys are stronger,

thay can be used in thinner sections, thus

reducing weight of transportation equip.

‘ant. Genoraly, tho stronger a mater

more it costs. and HSLA etaels are 10 ox.

‘option. Butthey provide considerably more

strength than iow-carton stools with ony 8

‘modest price pramium. They ere genaraly

avaiable in all standara wrought forms

al shapes, bar

1apes, and special shapos.

HSLA stoels are typically low-carbon

steels with up 1.8% manganese that are

Typical mechanical properties of HSLA steeis

ae Bnae Tian ——

Semitecor contrat

itec—improved Improved

‘corrosion Semvkiled ——_tommebany,

reslotance —orklag ales

‘a0 020% onimun) Guts HSLA soon rors

fesstnce dcarbon ste “Reduce by 50

“asiceow

4 Seeatarrot

a

(eapratay)

cn zs

SLA stems have mach higher trenath

fontod as way Eo oon:

‘shapes such

, Bulracertyoare eve re aeee

ha ff somns of the Deut eet

ghana sheetie au 0 reco ad

arene Taaiocs winger ee

oo tart with

FF] concentionst

roming

P Vevaiy soot

Deoiener

‘Seat Corp.

rand Steet.

LTY Steet Cor.

3. Steel Cor.

Carlene aregeiedincure US Seal

ontena

Pa

fai ha,

es

Tsim Aso pagsa

ght ert tht

— ASTw gPeciFICATION

(rennet eng)

xu AST sao

sOKs) 270K) TOSS)

Harovengh® —MgnSvenghG Hen sheng

este

Manganase Viele

“ara

Thiet racstele

en xen

Mayo 50

cocten

pune 60

“slr sca cmpanis ae teaneodoprodion The

Serves

orblee

ivan

ssananre

Bae

Semaog

‘rhe

Chander pee

raveeaiha 2+

een

icin Fartanawesaserang.cssvlues Wea

Subtract Dor tckness O09 otows.

strengthened by smal adations of alloying

‘elements, such as columbium, copper. va

duo ttanium and somatimes by ¢90=81

rolling and cooling techniques. Improves:

formabiity HSLA stasis contain additions

Such @8 zirconium, calcium, oF rare-earth

laments for sulide inclusion shape coo:

trol,

Because parts made trom HSLA stoeis

cannnave thinner eros sections than equiv

alent parts made from low-carbon sie

corrosion ito the surface of an HSLA stee!

can significantly reduce strength by de:

creasing the toad-bearing cfoss section

While adatone of elements suchas coppe'.

silicon, nickel, chromium, and phosphorus

can improve atmospheric corrosion re-

sistance of these alloys, hey also increaso

‘cost. Galvanizing, zincrich coatings, and

‘other rust-preventve finishes can help o-

tect HSLA-stee! parts from corrosion,

‘The grades known as “improve:-form-

ablity” HSLA steols (sheet-stee! graces

esignates ASTM A715, and plates 2es-

nated ASTM A656) have yield strengths up

10 80,000 ps, yet cost only about 24% more

‘than atypia! 36,000-ps! piain-carbon stce!

Because these alloys must compete with

‘other structural metals such as AIS! 1010

steel and aluminum. they must be a8 ne