Professional Documents

Culture Documents

Training Plan

Training Plan

Uploaded by

Wilmer0 ratings0% found this document useful (0 votes)

3 views3 pagestraining

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenttraining

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views3 pagesTraining Plan

Training Plan

Uploaded by

Wilmertraining

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

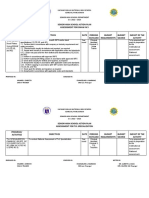

TRAINING PLAN

Qualification: SMAW NC1

Trainees

Training Activity Mode

’ Facilities/

of Assessment Date and

Training /Task Staff Venue

Trainin Tools and Equipment Method Time

Require

g

ments

LO1. Perform Root pass in Supervi Arc Welding machine AC/DC School Year

Weld accordance with WPS and/or client se Trainer and accessories Observation & round

Carbon specifications. Trainin Chipping Hammer oral questioning

Steel 1.1. Perform task in accordance g

Steel brush Written test

Plates with company or industry

Using requirement and safety Ballpeen Hammer Interview

SMAW procedure. Plier/tong Institutional

1.2. Checked weld visually for assessment.

Portable disc grinder

defects and repaired, as required

Head shield/helmet National

1.3. Accept weld visually in assessment.

accordance with applicable codes Leather apron/jacket

and standards Power hacksaw

LO.2. Clean root pass and free from Leather glove,

defects and discontinuities

Safety goggle, wide vision,

2.1 Perform in accordance with clear

approved WPS

Work bench w/ bench vice on

2.2 Perform subsequent/ filling 4 corners

passes in accordance with

approved WPS

2.3 Check weld visually for defects

and repaired, as required

2.4 Accept weld visually in

accordance with applicable codes

and standards

LO3. Perform capping in

accordance with WPS and/or

client specifications

3.1 Check weld for defects and

repaired, as required

3.2 Accept weld in accordance with

applicable codes and standards

Prepared by: Approved by:

WILMER J. DIRECTO JONITO TORDICILLAS

SIT Facilitator

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pre Immersion12 Q3 SLM6Document11 pagesPre Immersion12 Q3 SLM6WilmerNo ratings yet

- Milton Intro FINalsDocument2 pagesMilton Intro FINalsWilmerNo ratings yet

- Action Plan DRRMDocument2 pagesAction Plan DRRMWilmerNo ratings yet

- Second Quarterly ExamDocument4 pagesSecond Quarterly ExamWilmerNo ratings yet

- Action Plan 2022 2023Document2 pagesAction Plan 2022 2023WilmerNo ratings yet

- Letter of Basketball ClubDocument2 pagesLetter of Basketball ClubWilmerNo ratings yet

- Luciano Millan 300322 DepedxmastreesDocument1 pageLuciano Millan 300322 DepedxmastreesWilmerNo ratings yet

- Q I Module 1 GR 11 Week1Document7 pagesQ I Module 1 GR 11 Week1WilmerNo ratings yet

- Letter of Intent AnnalynDocument2 pagesLetter of Intent AnnalynWilmerNo ratings yet

- Scrap DesignDocument1 pageScrap DesignWilmerNo ratings yet

- Report On Bagyong EgayDocument1 pageReport On Bagyong EgayWilmerNo ratings yet

- Cot 1STDocument4 pagesCot 1STWilmerNo ratings yet

- Long QuizDocument2 pagesLong QuizWilmerNo ratings yet

- Module 2 GR 12Document37 pagesModule 2 GR 12WilmerNo ratings yet

- Assessor'S Script: Conducting Competency AssessmentDocument14 pagesAssessor'S Script: Conducting Competency AssessmentWilmer100% (1)

- Power Point Essentials of WeldingDocument53 pagesPower Point Essentials of WeldingWilmerNo ratings yet

- Work CertificationDocument1 pageWork CertificationWilmerNo ratings yet

- Ia - Gas Metal Arc Welding (Gmaw) NC IIDocument17 pagesIa - Gas Metal Arc Welding (Gmaw) NC IIWilmerNo ratings yet

- Ia - Masonry NC II 20151119Document25 pagesIa - Masonry NC II 20151119WilmerNo ratings yet

- SMAW Demo Teaching 2019Document44 pagesSMAW Demo Teaching 2019WilmerNo ratings yet