Professional Documents

Culture Documents

AMS3617 D

AMS3617 D

Uploaded by

Tinh nguyen0 ratings0% found this document useful (0 votes)

21 views7 pagesAMS3617d

Original Title

AMS3617d

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAMS3617d

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views7 pagesAMS3617 D

AMS3617 D

Uploaded by

Tinh nguyenAMS3617d

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

SAE Aerospace AEROSPACE

—: MATERIAL Tad OL Ta

SPECIFICATION | feve5.5 estes

Superseding AMS 3517C

Nylon Plastic, Moldings and Extrusions

jefication covers one type of nylon thermoplastic resin in the form of moldings and

‘extrusions,

Application:

These products have been used typically for parts requiring high strength and resistance to alreraf

fuols and lubricants up to 120°C (248 °F), but usage is not limited to such applications

Safety - Hazardous Materials:

‘While the materials, methods, applications, and processes described or referenced inthis

specification may involve the use of hazardous materials, this specification does not address the

hazards which may be involved in such use. Its the sole responsibilty of the user to ensure

familiarity with the safe and proper use of any hazardous materials and to take necessary

precautionary measures to ensure the health and safety of all personnel involved.

2. APPLICABLE DOCUMENTS:

The following publications form a part ofthis specification to the extent specified herein. The

applicable issue of referenced publications shall be the issue in effect on the date of the purche:

order.

amet men

AMS 3617D SAE AMS 3617D

2.1 ASTM Publications:

Available from ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2989 or

wwwwastm org

ASTMD 256 Impact Resistance of Plasiles and Electrical Insulating Materials

ASTMD570 Water Absorption of Plastics

ASTMD638 Tensile Properties of Plastics

‘ASTM D 638M Tensile Properties of Plastics (Metric)

ASTMD 648 Deflection Temperature of Plastics Under Flexural Load

ASTMD 790 Flexural Properties of Unreinforced and Reinforced Plastics and Electrical

Insulating Materials

ASTMD790M Flexural Properties of Unreinforced and Reinforced Plastics and Electric

Insulating Matertais (Metric)

ASTMD 792. Specific Gravity (Relative Density) and Density of Plastics by Displacement

ASTMD 3418 Transition Temperatures of Polymers by Thermal Analysis

2.2. U.S. Government Publications:

Avallable from DODSSP, Subscription Services Desk, Bullding 4D, 700 Robbins Avenue,

Philadelphia, PA 19111-5094.

MIL-STD-2073-1 DOD Materiel, Procedures for Development and Application of Packaging

Requirements

3. TECHNICAL REQUIREMENTS:

3.1 Material

‘Shall be a nylon resin with any necessary filers, modifiers, and plasticizers necessary to meet the

requirements of 3.1.1 and 3.2.

3.1.1 Color: Shall be light cream, opaque.

3.2 Properties

‘The product shall conform to requirements shown in Table 1, Table 2, Table 3, 3.2.9 and 3.2.10; tests

shall be performed on the product supplied and in accordance with specified ASTM methods, Insofar

as practicable

3.2.1 Tensile Strength: Shall be as shown in Table 1.

purchaser, determined by a procedure acceptable to purchaser.

AMS 3617D SAE ‘AMS 3617D

TABLE 1 - Minimum Tensile Strength

‘Nominal Thickness Nominal Thickness Tesi

Inches Milim eters Value Method

Up to 0.375, excl Up to 9.52, excl BOKsi G2 MPa) ASTM D 638 oF

0.375 and over 9.52 andover__11.0ksi (76 MPa)__ ASTM D 638M

3.2.2 Elongation: Shall be as shown in Table 2.

‘TABLE 2 - Minimum Elongation

—Wominal Thickness Nominal Thiekness———SSSSSCSCSCST

Inches imeters ve Method

Up to 0.187, exci Up to 4.75, excl 50% ‘ASTM D 638 or

0.187 _and over 4.75 and over 25% ASTM D 638M

TABLE 3 - Properties

Paragraph Property Value Test Method

323 Flexural Modulus of Elastily 370 a ‘ASTM D 790 oF

CFangent), min (2137 MPa) ASTM D 730M

3.24 Impact Resistance perunit of 0.8 foot pounds/inch ASTM D 286,

noteh, min (62.7 sim) Method A

3.25 Deflection Temperature 66°C (151 °F) ASTM 0 648

al 264 psi (1.82) MPa) fber

stress, min

3.26 Waler Absorption 1.5% ASTM D670

(24 hour immersion),

Welght gain, max

3.2.7 Specie Gravity 1.4310 1.15 ASTM D 792,

al 7373°F (23/23 °C) Method A

3.28 Melting point 250 to 285°C ASTM D 3418

® (482 t0 509 DTA or DSC

3.29. Weather Resistance: When specified, the product shall have weather resistance acceptable to

3.2.10 Corrosion: The product shall not have a corrosive effect on other materials when exposed to

conaitions normally encountered in service, determined by a procedure acceptable to purchaser.

(

8.2)

AMS 3617D SAE AMS 3617D

3.3 Quality

The product, as received by purchaser, shall be uniform in quality and condition, smooth, and free

{trom foreign materials and from imperfections detrimental io usage of he product.

4. QUALITY ASSURANCE PROVISIONS:

4.4 Responstbilty for Inspection:

‘The manufacturer of the product shall supply all samples for required tests and shall be responsible

{or performing all required tests. Purchaser reserves the right to sample and to perform any

confirmatory testing deemed necessary to ensure that the produc! conforms te the requirements of

this specification.

4.2. Classification of Tests:

4.2.1 Acceptance Tests: Tests for tensile strength (3.2.1). elongation (3.2.2), specific gravity @.2.7), and

meting point (3.2.8) are acceptance tests and shall be performed on each lot

4.2.2 Preproduction Tests: Tests for all technical requirements are preproduction tests and shall be

performed pifor to or on the inlial shipment of the produc! by a manufacturer, when a change in

Ingredients and/or processing requires reapproval as in 4.6.2, and when purchaser deems

confirmatory testing to be required.

4.2.2.1 Forditect U.S. Miltary procurement, substantiating test data and, when requested, preproduction

test material shall be submitted to the cognizant agency as directed by the procuring activity.

contracting officer, or request for procurement.

4.3, Sampling and Testing:

Shall be as follows:

4.3.1 For Acceptance Tests: Sufficient product shall be taken al random from each lot to perform all

required tests. The number of determinations for each requirement shall be as specified in the

applicable test procedure or, not specified therein, not less than three.

4.3.1.1 When the produet is of such size or shape that suitable specimens cannot be obtained, separate

specimens, injection molded from the same batch of molding powder and under concitions

representative of those used in making the product, shall be supplied upon request

4.3.1.2. Alot shall be all product from the same batch of molding powder processed in one continuous

run and presented for manufacturers inspection at one time.

4.3.1.3. A batch of melding powder shall be all powder produced in one continuous set of operations.

434

432

44

44a

442

45

46

54

Bad

512

5. PREPARATION FOR DELIVERY:

AMS 3617D SAE ‘AMS 3617D

4 When a statistical sampling plan has been agreed upon by purchaser and manufacturer,

sampling shall be in accordance with such plan in lieu of sampling as in 4.3.1 and the report of

4.5 shall state that such plan was used.

For Preproduction Tests: As agreed upon by purchaser and manufacturer.

Approval

‘Sample product shall be approved by purchaser before product for production use is supplled,

lunless such approval be waived by purchaser. Results of tests on production product shall be

‘essentially equlvalent to those on the approved sample.

Manufacturer shall use ingredients, manufacturing procedures, processes, and methods of

Inspection on production product which are essentially the same as those used on the approved

sample. If necessary to make any change in ingredients, in type of equipment for processing, or in

‘manufacturing procedures, manufacturer shall submi for reapproval a statement of the proposed

changes in ingredients and/or processing and, when requested, sample product, Production

produel made by the revised procedure shall not be shipped prior to receipt of reapproval

Reports:

‘The supplier ofthe product shall furnish with each shipment a report showing the results of tests to

determine conformance to the acceptance test requirements and stating that the product conforms to

the other technical requirements. This report shall include the purchase order number, lot number,

AMS 3617D, manufacturer's compound number, form and size or part number, and quaniity.

Resampling and Retesting:

Itany specimen used in the above tests falls to meet the specified requirements, disposition of the

product may be based on the resutts of testing three addtional specimens for each original

nonconforming specimen. Failure of any retest specimen to meet the specified requirements shall be

‘cause for rejection of the product represented, Result of al tests shall be reported,

Product Identification:

Molded Parts: Each molded pai of sultable size shall have the part number molded or permanently

impressed therein. If size precludes integral marking, parts of each diferent part number shall be

packed in separate, suitable containers marked wth the part number.

Extrusions: Shall be marked near one end with AMS 3617D and the manufacturer's designation. it

extrusions are supplied in coils, the marking shall appear at the outside end of the coil

AMS 36170 SAE AMS 3617D

5.2. Packaging and Package Identification

5.2.1 Packaging shall be accomplished to ensure thal the product, during shipment and storage, will not

be permanently distorted and will he protected against damage from exposure to meisture,

Weather, or any other normal hazard

5.22. Each package shall be permanently and legibly marked with nat less than the following

Information:

NYLON MOLDINGS (or EXTRUSIONS)

AMS 36170

SIZE OR PARTNUMBER __

COLOR __

QUANTITY

PURCHASE ORDER NUMBER,

MANUFACTURER'S IDENTIFICATION

5.23. Packages of product shall be prepared for shipment in accordance with commercial practice and in

compliance with applicable rules and regulations pertaining to handling, packaging, and

transportation of the product to ensure carrier acceptance and safe delivery.

5.24 For dlrect U.S. Miltary procurement, packaging shall be In accordance with MIL-STD-2073-1,

‘Commercial Level, unless Level Is specified in the request for procurement.

6. ACKNOWLEDGMENT:

‘Supplier shall mention this specification number and its revision letter in all quotations and when

acknowledging purchase orders.

7. REJECTIONS:

Product not conforming to this specification, or to modifications authorized by purchaser, wil be

subject to rejection,

8. NOTES:

8.1 Revision indicat

‘The (R) symbol Is for the convenience of he user in locating areas where technical revisions, not

editorial changes, have been made to the previous Issue ofthis specification. Ifthe symbol Is next to

the specification ttle, it indicates a complete revision of the specification,

82 ASTMD4066, notes C and D, Table PA, heating rate 10 °C (18 *F) degrees /minute; the resulls of an

Intemational round robin (ISO-USA, Germany. Japan, Poland, and Italy) showed DSC melt point to

bbe the method having the best reproducibilty of results when compared to other available methods

(ef. 1S0 3146)

AMS 3617D AMS 3617D

Dimensions and properties in Inch/pound units and the Celsius temperatures are primary:

dimensions and properties in SI units and the Fahrenheit temperatures are shown as the

approximate equivalents of the primary units and are presented only for Information

For direct U.S. Miltary procurement, purchase documents should specify not less than the following:

Tile, number, and date of this specification

Form and size or part number of product desired

‘Quantity of product desired

Method of test and acceptance standards for weather resistance (3.2.9) and corrosion (3.2.10)

Level A packaging, if required (see 5.2.4)

‘Similar Specifications:

Federal L-P-410 and ASTM D 4066 are listed for information only and shall not be construed as

‘acceptable alternates unless all requirements of this AMS are met,

Products meeting the requirements ofthis specification have been classified under Federal Supply

Classification (FSC) 9330.

PREPARED UNDER THE JURISDICTION OF AMS COMMITTEE "CP"

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Astm 2438Document10 pagesAstm 2438Tinh nguyenNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mil I 8846DDocument12 pagesMil I 8846DTinh nguyenNo ratings yet

- Within The Tides - 184Document223 pagesWithin The Tides - 184Tinh nguyenNo ratings yet

- 27.12.2022 - Curing Condition of Sealant - PPG Aerospace PS 870 B-1.2 - MIL-PRF-81733D - NHThongDocument3 pages27.12.2022 - Curing Condition of Sealant - PPG Aerospace PS 870 B-1.2 - MIL-PRF-81733D - NHThongTinh nguyenNo ratings yet

- Mil PRF 16173e (Document34 pagesMil PRF 16173e (Tinh nguyenNo ratings yet

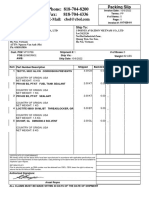

- 817428-01 Packing SlipDocument1 page817428-01 Packing SlipTinh nguyenNo ratings yet